Water-borne polyurethane not containing organic tin and preparation method thereof

A technology of water-based polyurethane and organotin, which is applied in the field of synthesis of new polymer materials, can solve the problems of less crosslinking, unsatisfactory, low thermal decomposition temperature, etc., and achieve good hydrolysis resistance, increased heat resistance, and good main structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

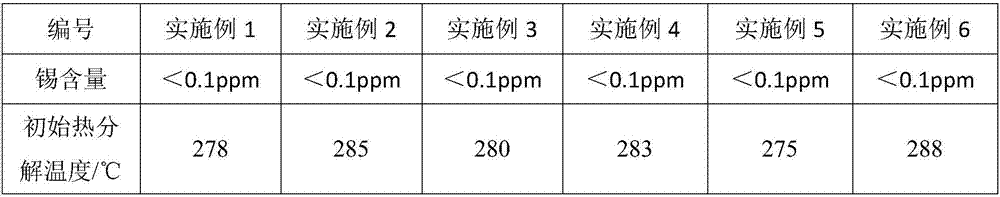

Examples

Embodiment 1

[0036] An organotin-free waterborne polyurethane, made of the following components in parts by weight: 25 parts of phthalic anhydride polyester polyol with a molecular weight of 1000, 10 parts of toluene diisocyanate, and 5 parts of hydroxypropyl silicone oil with a molecular weight of 1000 Blocked methyl phenylsiloxane, 0.015 parts organozinc catalyst, 2 parts 2,2-dimethylolpropionic acid, 2 parts ethylenediamine, 5 parts acetone, and 2 parts triethylamine.

[0037] The preparation method of the water-based polyurethane includes the following steps:

[0038] 1) Add 25 parts of phthalic anhydride polyester polyol with a molecular weight of 1000 and 5 parts of hydroxypropyl silicone oil-terminated methyl phenylsiloxane with a molecular weight of 1000 into the reaction flask, distill under reduced pressure at 100°C for 30 minutes, and cool to 50 ℃, add 10 parts of toluene diisocyanate and 0.015 parts of organic zinc, heat up to 70℃ and react for 4 hours;

[0039] 2) Cool down to 50°C,...

Embodiment 2

[0042] An organic tin-free waterborne polyurethane, which is made of the following components in parts by weight: 80 parts of p-phenylene polyester polyol with a molecular weight of 3000, 20 parts of diphenylmethane diisocyanate, and 20 parts of a molecular weight of 3000 Hydroxybutyl silicone oil-terminated methylphenylsiloxane, 0.06 parts of organic bismuth catalyst, 10 parts of 2,2-dimethylolbutanoic acid, 10 parts of isophorone diamine, 10 parts of methyl ethyl ketone, and 10 parts of three Ethanolamine.

[0043] The preparation method of the water-based polyurethane includes the following steps:

[0044] 1) Add 80 parts of p-phenylene polyester polyol with a molecular weight of 3000 and 20 parts of hydroxybutyl silicone oil-terminated methyl phenylsiloxane with a molecular weight of 3000 into the reaction flask, and distill under reduced pressure at 100°C for 60 minutes, and cool to At 60°C, add 20 parts of diphenylmethane diisocyanate and 0.06 parts of organic bismuth, and r...

Embodiment 3

[0048] An organic tin-free waterborne polyurethane, which is made of the following components in parts by weight: 40 parts of phthalic anhydride polyester polyol with a molecular weight of 5000, 20 parts of hexamethylene diisocyanate, and 10 parts of hydroxyl with a molecular weight of 5000 Propyl silicone oil-terminated methylphenylsiloxane, 0.03 parts of organic bismuth catalyst, 5 parts of 2,2-dimethylolpropionic acid, 5 parts of diethylenetriamine, 8 parts of tetrahydrofuran and 10 parts of ammonia.

[0049] The preparation method of the water-based polyurethane includes the following steps:

[0050] (1) Add 40 parts of phthalic anhydride polyester polyol with a molecular weight of 5000 and 10 parts of hydroxypropyl silicone oil-terminated methyl phenylsiloxane with a molecular weight of 5000 into the reaction flask, and distill under reduced pressure at 100°C for 60 minutes, and cool to At 60°C, add 20 parts of hexamethylene diisocyanate and 0.03 parts of organic bismuth, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com