Patents

Literature

108results about How to "Low viscosity properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing submicron grade superfine calcium carbonate dispersion particle

ActiveCN1724378AHigh glossLow viscosity propertiesCalcium/strontium/barium carbonatesCrystalCalcium carbonate

A process for preparing the dispersed submicron-class calcium carbonate particles used for paper, paint, plastics, etc features that the merits of bubbling-carbonizing method and the basic principle of crystallography are used and the particular crystal form regulator and disperser are used to control the performance of crystals and the dispersion of particles.

Owner:建德华明科技有限公司

Holothurian peptide functional food and preparation method thereof

InactiveCN101341978AAvoid residueSave the hassleProtein composition from fishAnimal proteins working-upDiseaseAdditive ingredient

The invention discloses a sea cucumber polypeptide functional food and a preparation method thereof which not only remarkably improves the content of polypeptide, but also has no chemical residues; the contents of salt and arsenic are low; the food is healthier and safer to eat; simultaneously the food is simply operated, easily controlled, is effective and saves energies. The key technical scheme includes: selecting a compound protease of Protamex and needing not to adjust the pH value of materials; carrying out processes of desalting and arsenic removing on an enzymolysis liquid; more than 80 percent of the molecular weight of the product is between 100 to 6000Dalt; wherein, the small polypeptide of 100 to 2100Dalt is more than 70 percent; the product components and the content weight percentages are as follows: 50 to 60 percent of polypeptide, 5 to 10 percent of free amino acids, 2.5 to 7.5 percent of mucoitin as well as containing the inherent nutrition components of a plurality of minerals and vitamins of the sea cucumber. The product has the effects of resisting knub, reducing blood pressure, preventing cardio-cerebrovascular diseases, resisting fatigue, delaying senescence, improving the immunity. The food can be used as a healthy food to eat and can also be used as a food and a medicine additive.

Owner:DALIAN FEIDE BIOIND

Lithium cell electrolyte

InactiveCN101071863AImprove securityImprove flame retardant performanceOrganic electrolyte cellsSecondary cellsOxygenSolvent

A lithium battery electrolyte comprises lithium salt, organic solvent and the chemical additive. The lithium salt is one of lithium per chlorate, trifluoromethyl lithium sulfonate, six lithium flu phosphate, six fluorine arsenic acids lithium, the tetrachloride aluminum lithium, in the tetrachloride boron lithium one kind or its combination thing, the density is 0.5-2.0mol / L; The organic solvent is alkyl phosphate RPO3R ' R ';The chemical additive is the (volume compares) two oxygen link fifth heavenly stem Alkane DOL whose density is density is 0-5% . This invention has good anti- burn performance, the electrolyte conductivity maximum value can reach 4.0mS-1 also but not to affect the reaction nature of plurity of insertion electrode, may be used in -50 degree C-120 degree C temperature ranges, also causes the cathode surface to form a high flexible SEI membrane, thus enhance the safety of lithium battery in the production, storage and transportation and reduce the production cost.

Owner:EVE ENERGY CO LTD

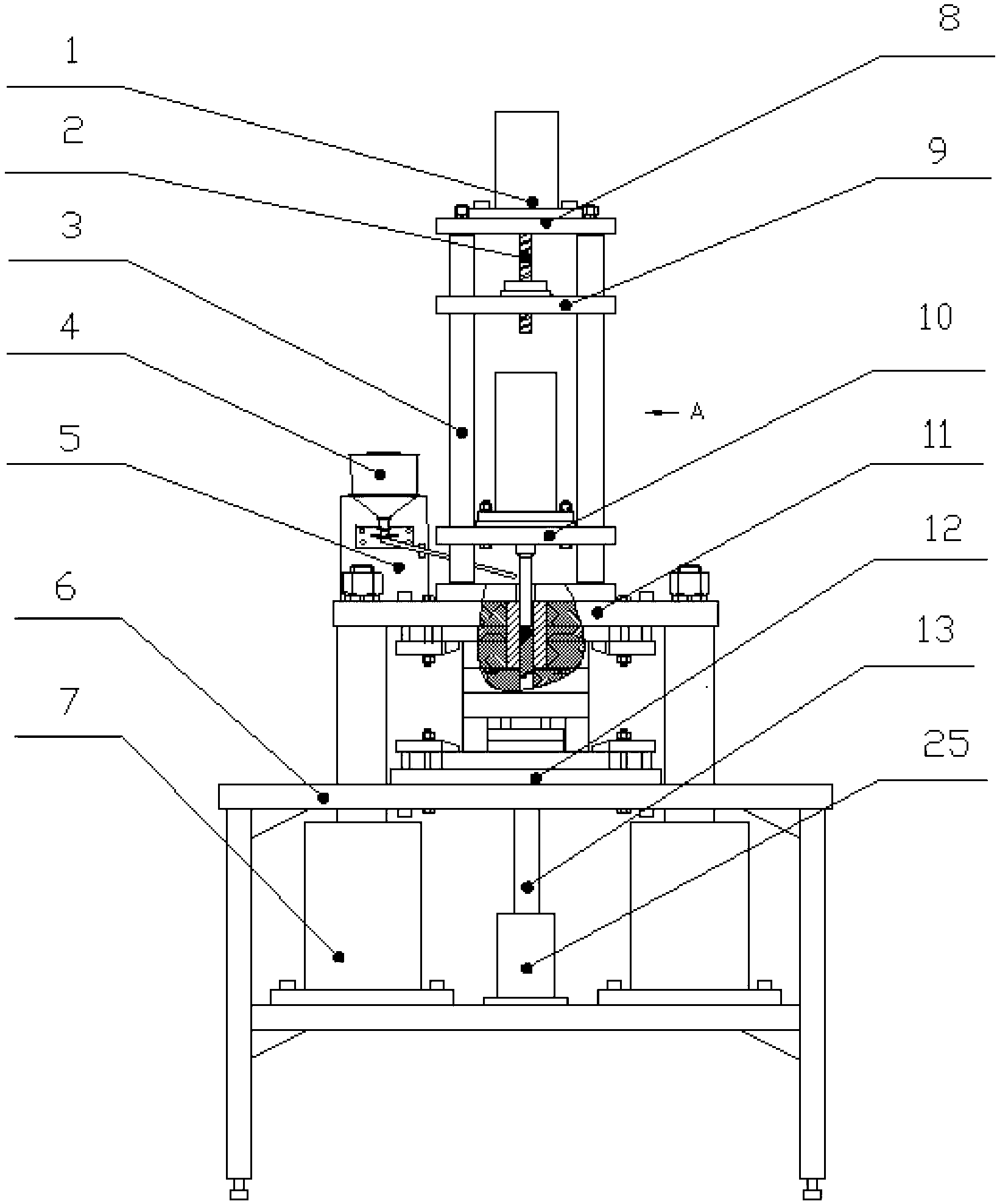

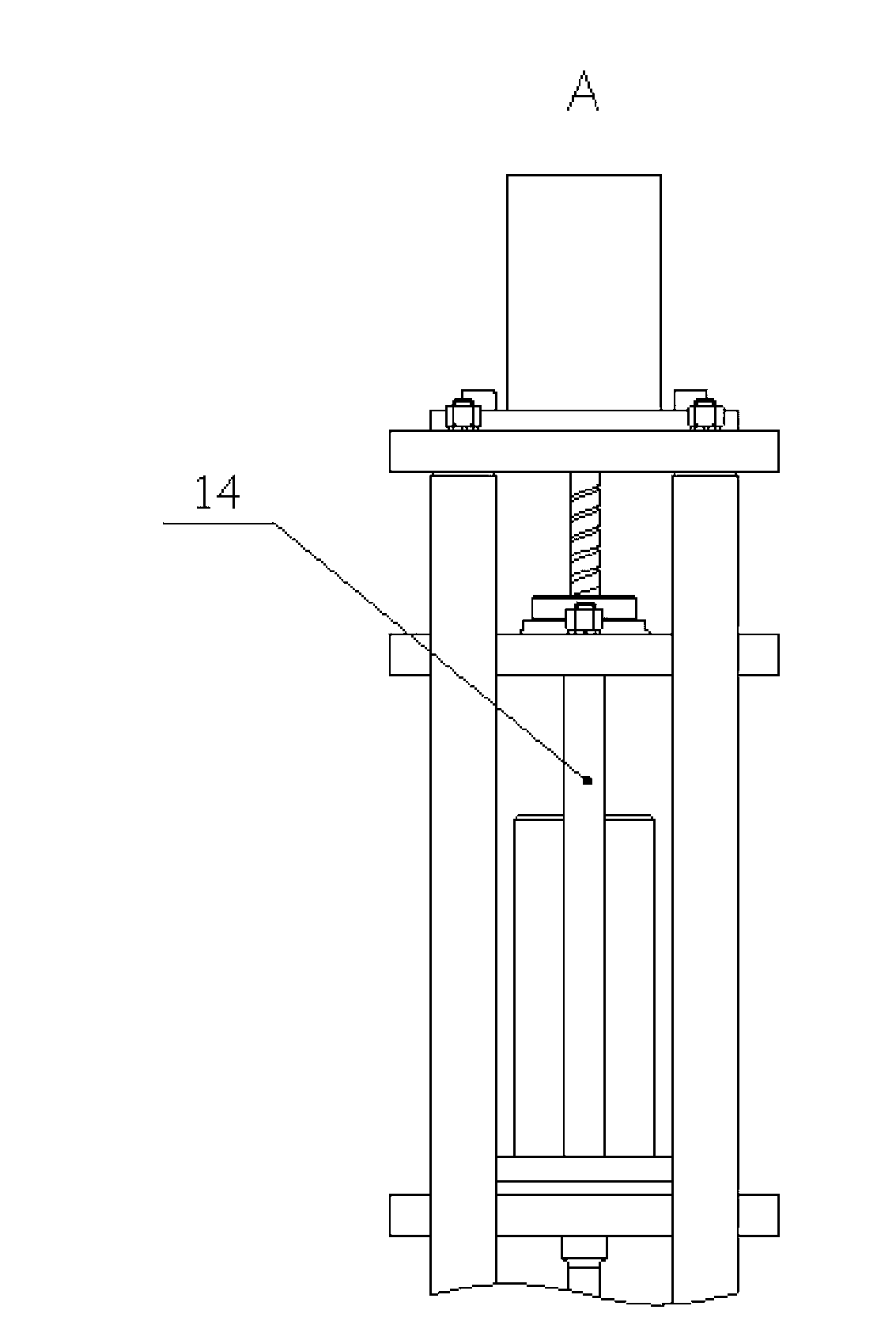

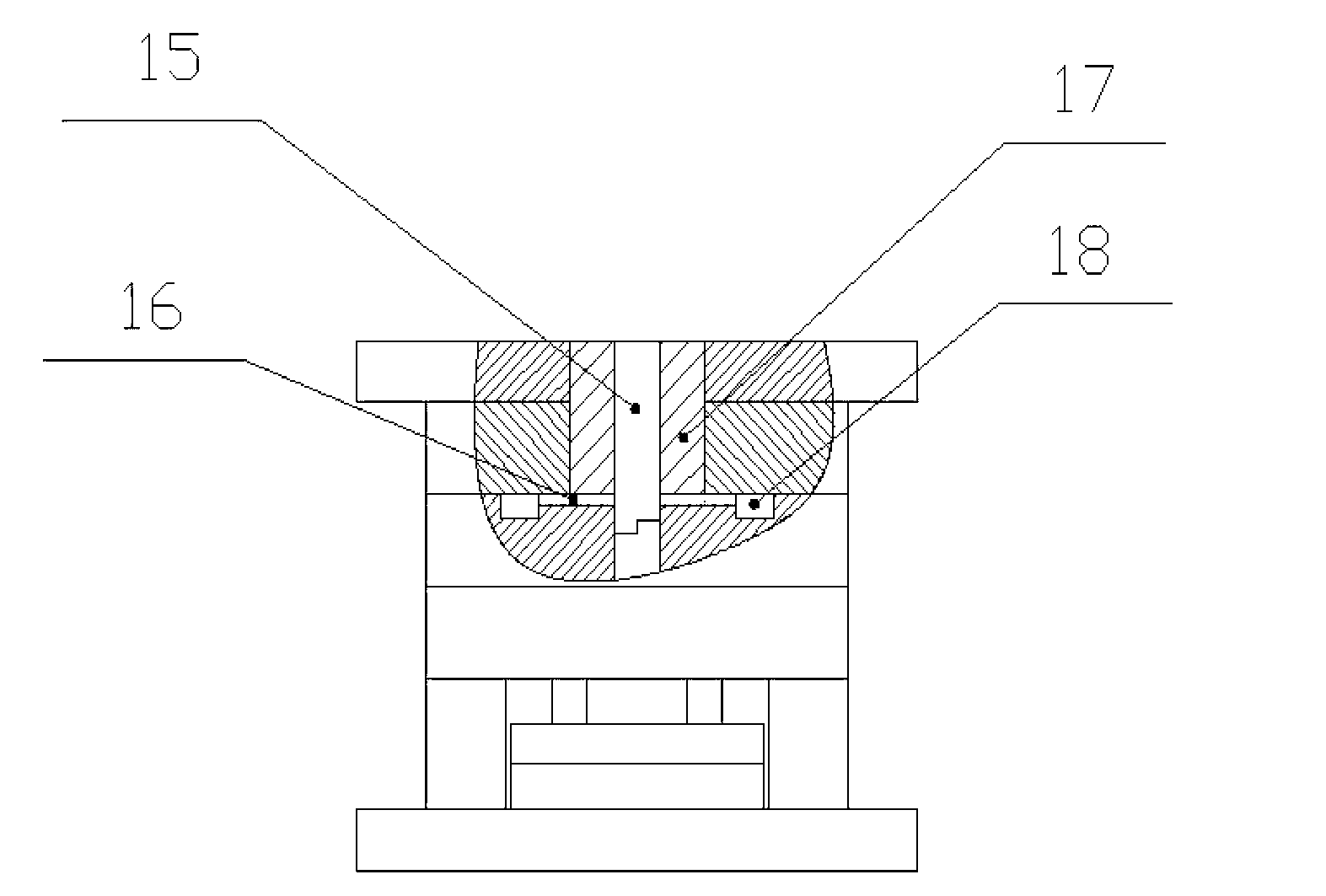

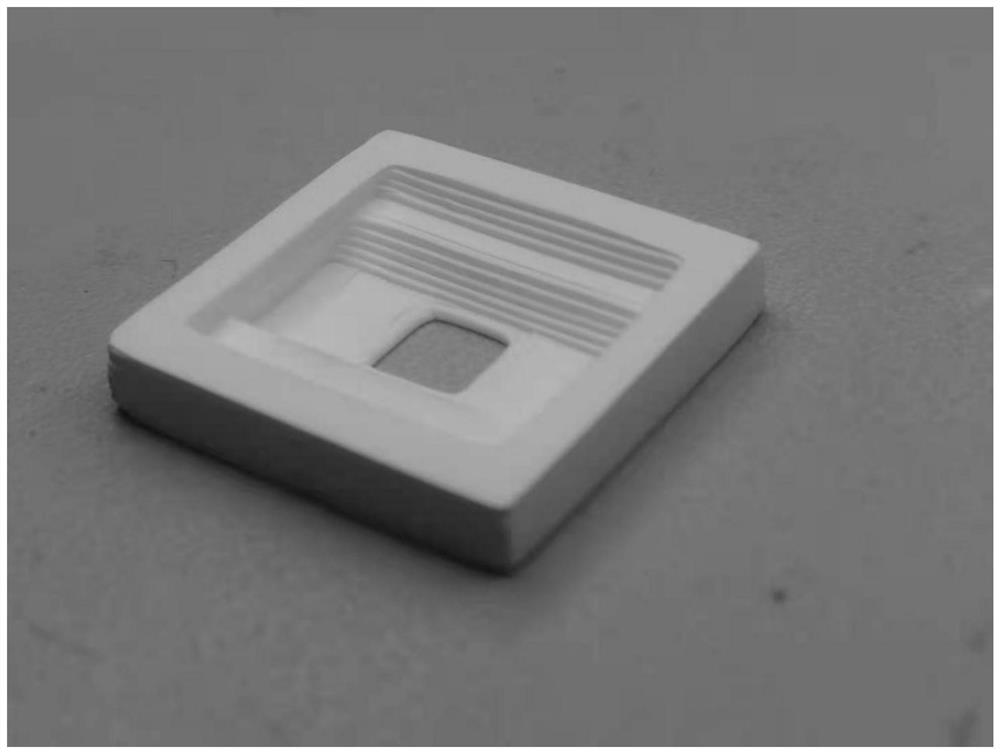

Screw-free ultrasonic microinjection molding device for molten and plasticized polymer and molding method

The invention discloses a screw-free ultrasonic microinjection molding device for a molten and plasticized polymer and a molding method. An injection part comprises an injection motor, a lead screw, an injection push plate and a connecting rod; an ultrasonic vibration system comprises an ultrasonic generator, an energy converter, an amplitude-change pole and a tool head; an injection module is provided with a plasticizing hole, a sub-runner and a mould cavity; a feeding system comprises a hopper and a support; and a mould closing and ejecting system comprises a mould closing hydraulic cylinder, an ejecting hydraulic cylinder, an upper mould fixing plate, a lower mould fixing plate and an ejector rod. A solid polymer is molten into a liquid under the action of frication thermogenesis and viscoelasticity thermogenesis applied into the polymer particle process through ultrasonic vibration, and meanwhile, ultrasonic waves play a cavitation role in the polymer liquid, so that the apparent viscosity is reduced, the phenomenon of short shot or insufficient filling in the machining process is overcome, the injection molding of a small plastic device can be well realized, the energy consumption is reduced, the difficulty in controlling the process is lowered, the economic efficiency of the device is increased, and the production cost is reduced.

Owner:CENT SOUTH UNIV

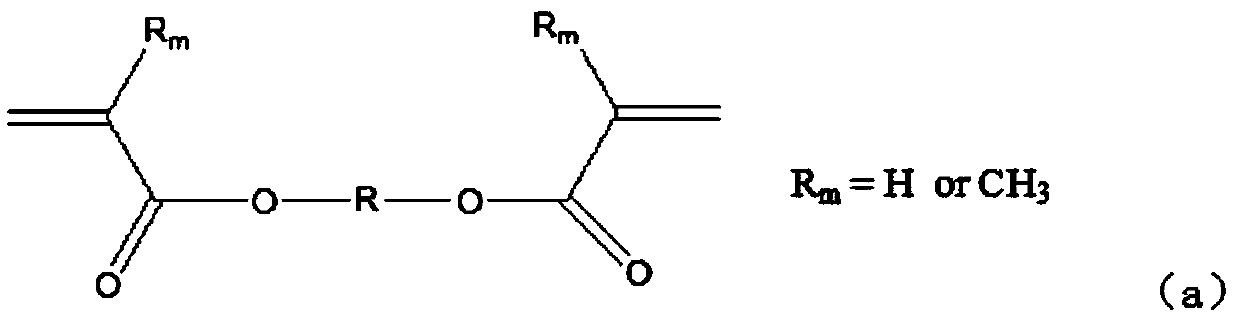

Active energy ray-curable composition for optical material, cured product, and production methods for active energy ray-curable composition and cured product

InactiveCN103237827AExcellent curability with active energy raysLow viscosity propertiesCoatingsOptical elementsCrack resistanceLow temperature curing

Provided are an active energy ray-curable composition for an optical material that has excellent low viscosity, shelf life, low foamability, low-temperature curability, low-warping performance, deep curability, heat-resistant and light-resistant transparency, rubber properties, cracking resistance, moisture permeation resistance and designability; a cured product; and production methods for obtaining the active energy ray-curable composition and the cured product. The active energy ray-curable composition for the optical material comprises (A) a vinyl polymer which has, per molecule, at least one methacryloyl group represented by the general formula (1) -OC(O)C(Ra)=CH2(1) (where Ra is a hydrogen atom or C1-C20 organic group) is produced by living radical polymerization, and has a color difference delta E* of 10 or less; (B) a light-induced radical polymerization initiator; and (C) at least one antioxidant selected from the group consisting of hindered phenol antioxidants, hindered amine antioxidants, and phosphorus antioxidants.

Owner:KANEKA CORP

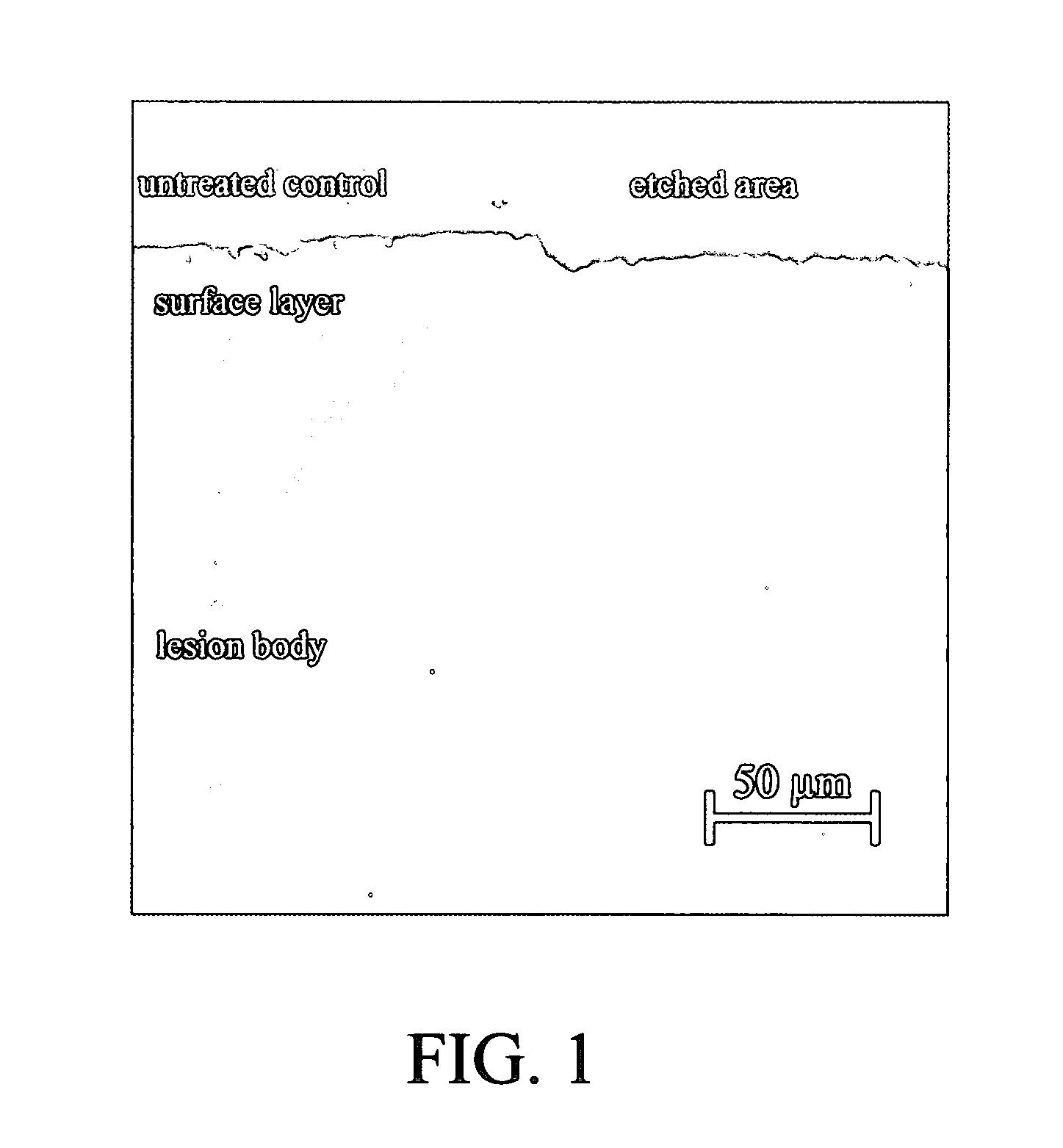

Method of infiltrating enamel lesions

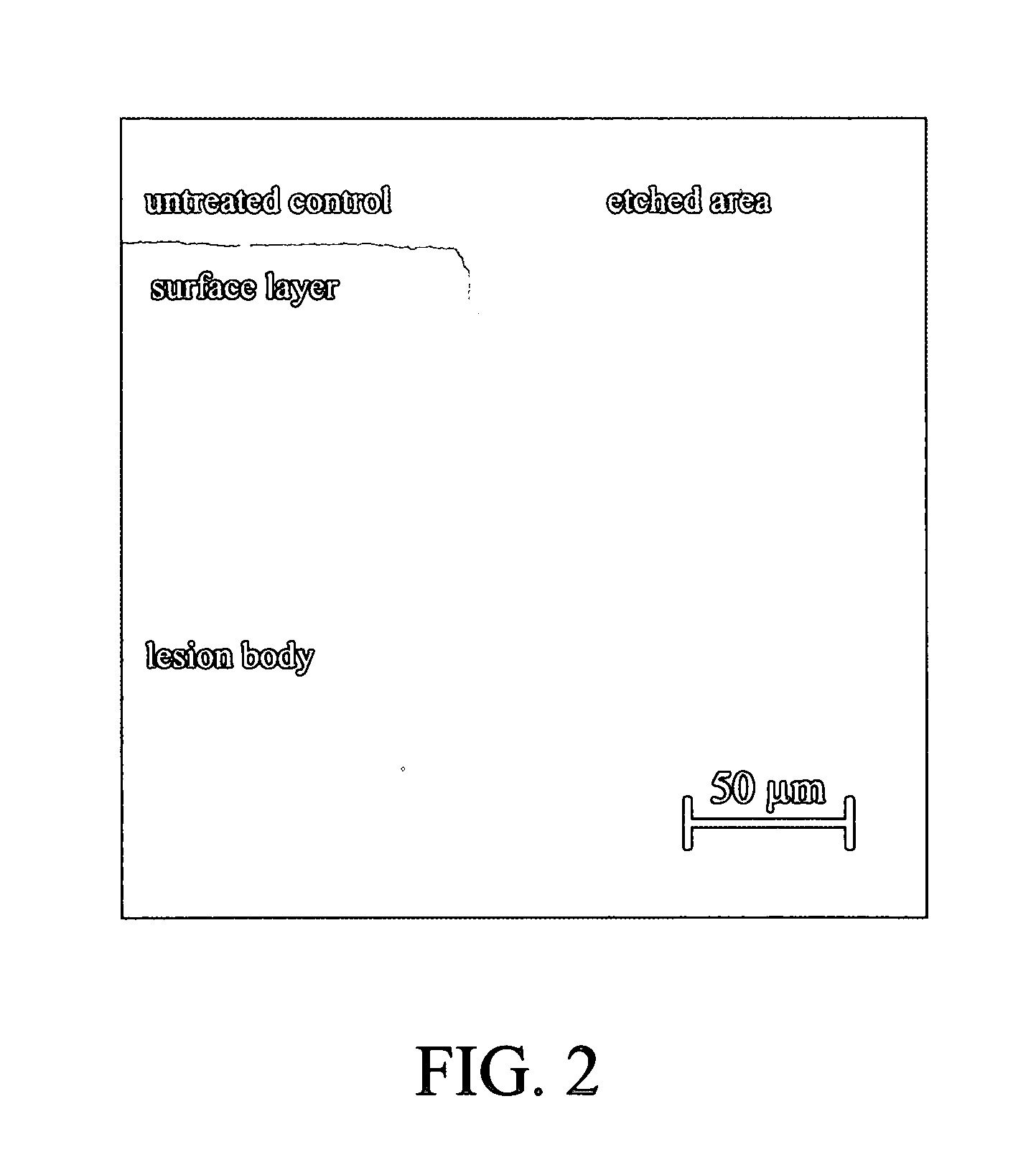

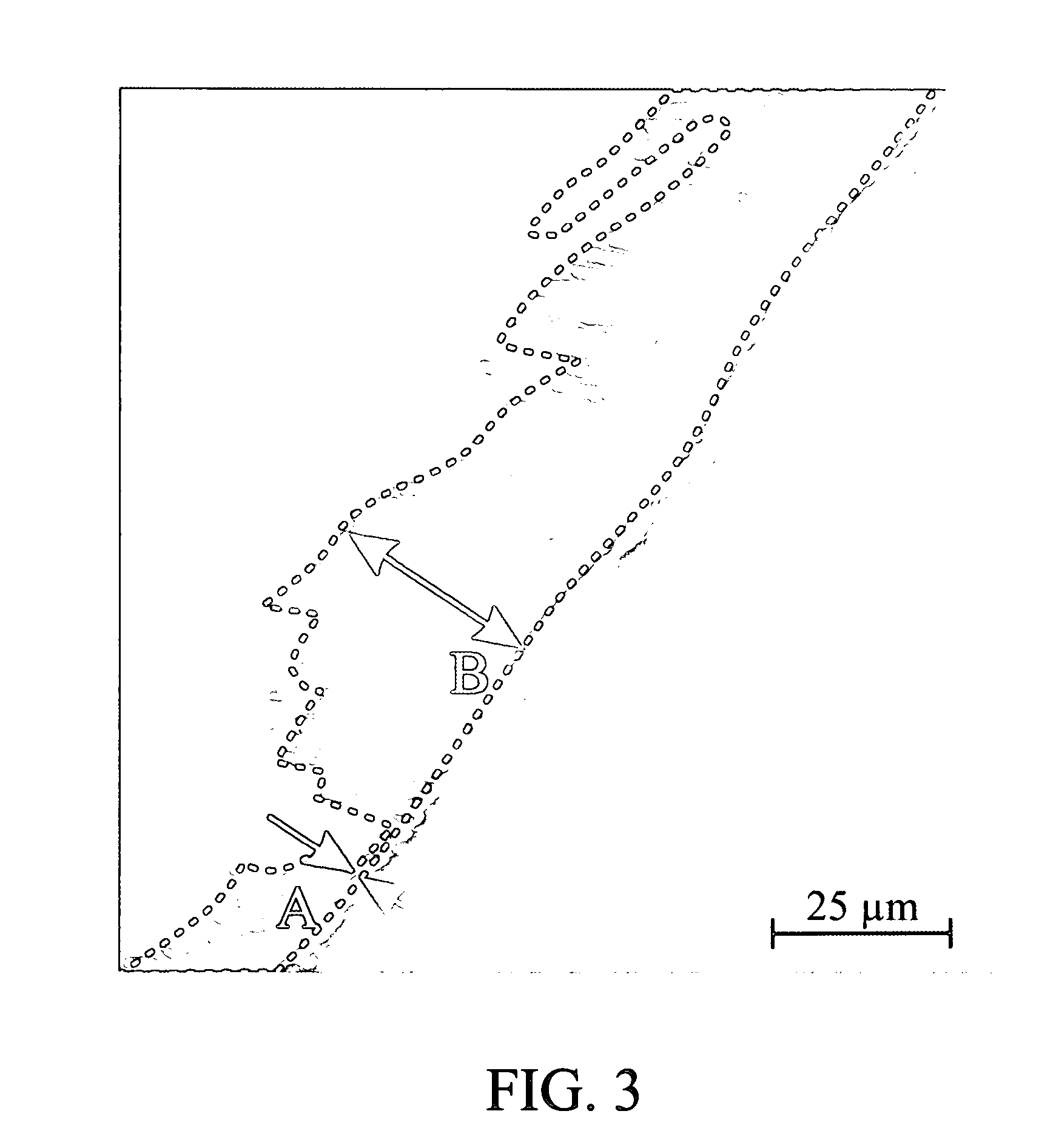

ActiveUS20060167129A1Improve permeabilityLow viscosity propertiesImpression capsMedical preparationsTooth enamelCarious lesion

The present invention refers to a method of infiltrating enamel, in particular for the prevention and / or treatment of carious lesions. Said method of infiltrating enamel comprises the steps of (a) exposing an enamel area to be infiltrated to a conditioner comprising hydrochloric acid; (b) exposing the enamel area conditioned in step (a) to an infiltrant comprising at least one low viscous dental resin; and (c) curing the infiltrant. The present invention further refers to a kit for carrying out said method.

Owner:CHARITE UNIVS MEDIZIN BERLIN

Modified epoxy resin, epoxy resin compositions and cured articles

ActiveCN102083881AEasy to operateImprove heat resistanceSemiconductor/solid-state device detailsSolid-state devicesEpoxyHeat resistance

The present invention discloses a modified epoxy resin which exhibits excellent handleability in a solid state at ordinary temperatures and exerts an excellently low viscosity at a molding temperature; epoxy resin compositions which each comprise the modified epoxy resin and an inorganic filler and which can give cured articles exhibiting high thermal conductivity, low thermal expansion, and excellent heat resistance and moisture resistance; and cured epoxy resin articles made by using the compositions. The modified epoxy resin can be prepared by reacting a mixture of hydroquinone and 4, 4'-dihydroxybiphenyl at a weight ratio of 0.1 to 10.0 with epichlorohydrin, and is in a crystalline state at ordinary temperatures. The epoxy resin compositions each comprises (A) an epoxy resin component, (B) a curing agent, and (C) an inorganic filler as the main components, with the epoxy resin component (A) containing the modified epoxy resin in an amount of 50wt% or above.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

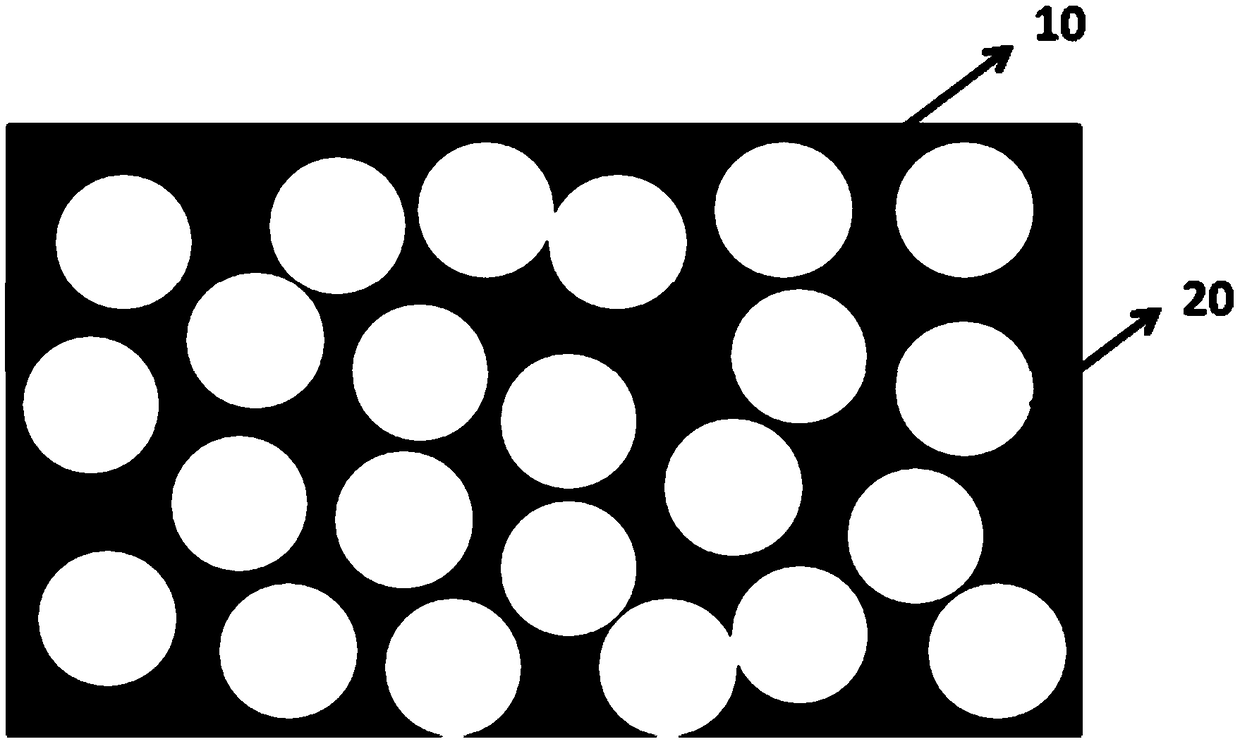

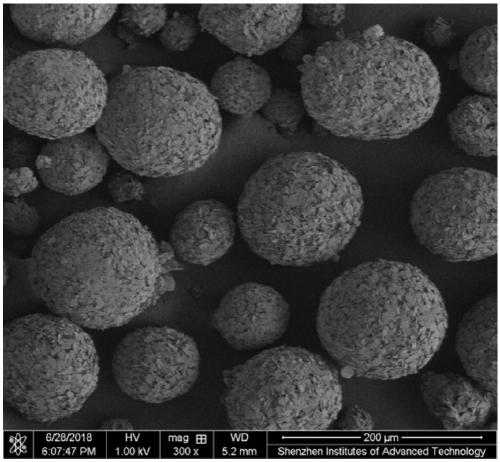

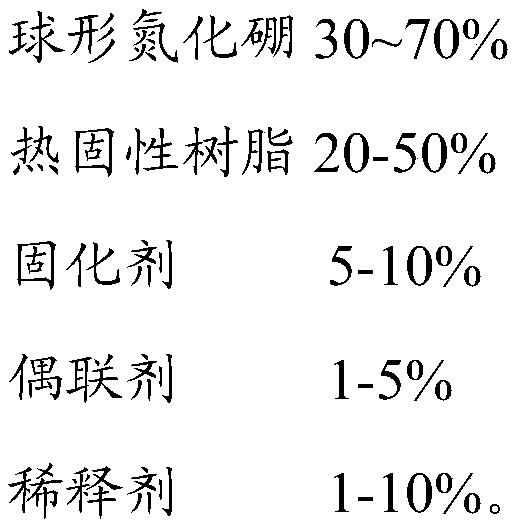

Thermal interface material and preparation method thereof

InactiveCN109054302ALow viscosityHigh thermal conductivityHeat-exchange elementsPolymer scienceHigh density

The invention relates to a thermal interface material and a preparation method thereof. The thermal interface material is prepared from 30 to 70 percent by weight of spherical boron nitride, 20 to 50percent by weight of thermosetting resin, 5 to 10 percent of a curing agent, 1 to 5 percent of a coupling agent, and 1 to 10 percent of a diluting agent. The preparation method comprises the followingstep of uniformly stirring and mixing the spherical boron nitride, thermosetting resin, the curing agent, defoaming agent, coupling agent and diluting agent. The thermal interface material is obtained by virtue of curing of a baking oven. The spherical boron nitride is adopted to substitute flaky boron nitride, so that the filling amount of boron nitride in the thermosetting resin can be improved, and the heat conduction coefficient of the thermal interface material can be improved; and meanwhile, spherical boron nitride can reduce the viscosity of the composite material, and the operabilityof the thermal interface material can be improved. The method is simple, easy, and low in price of raw materials, and the prepared thermal interface material is relatively high in heat conductivity coefficient and can be widely applied to the field of heat dissipation of high-density electron devices.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

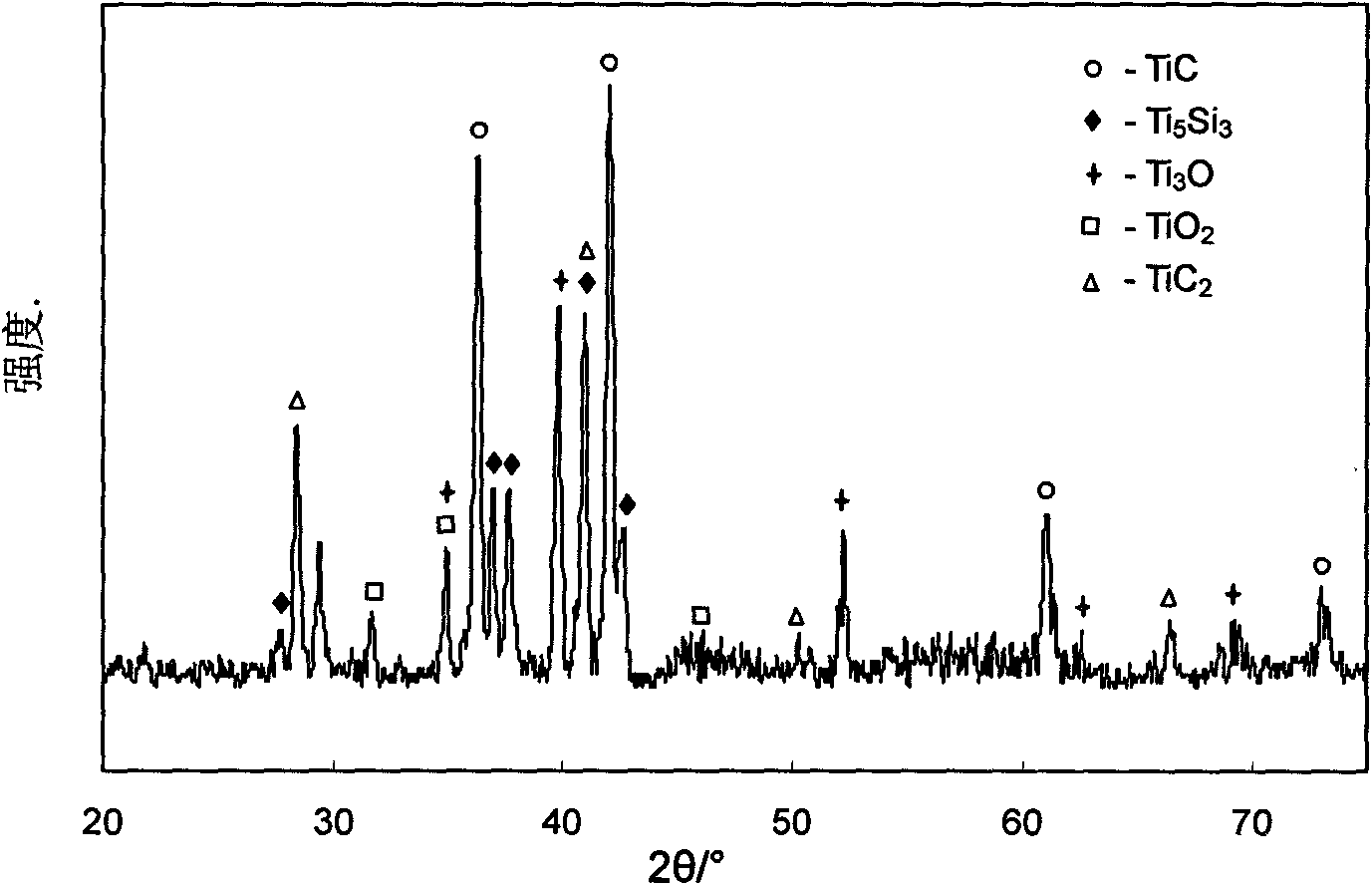

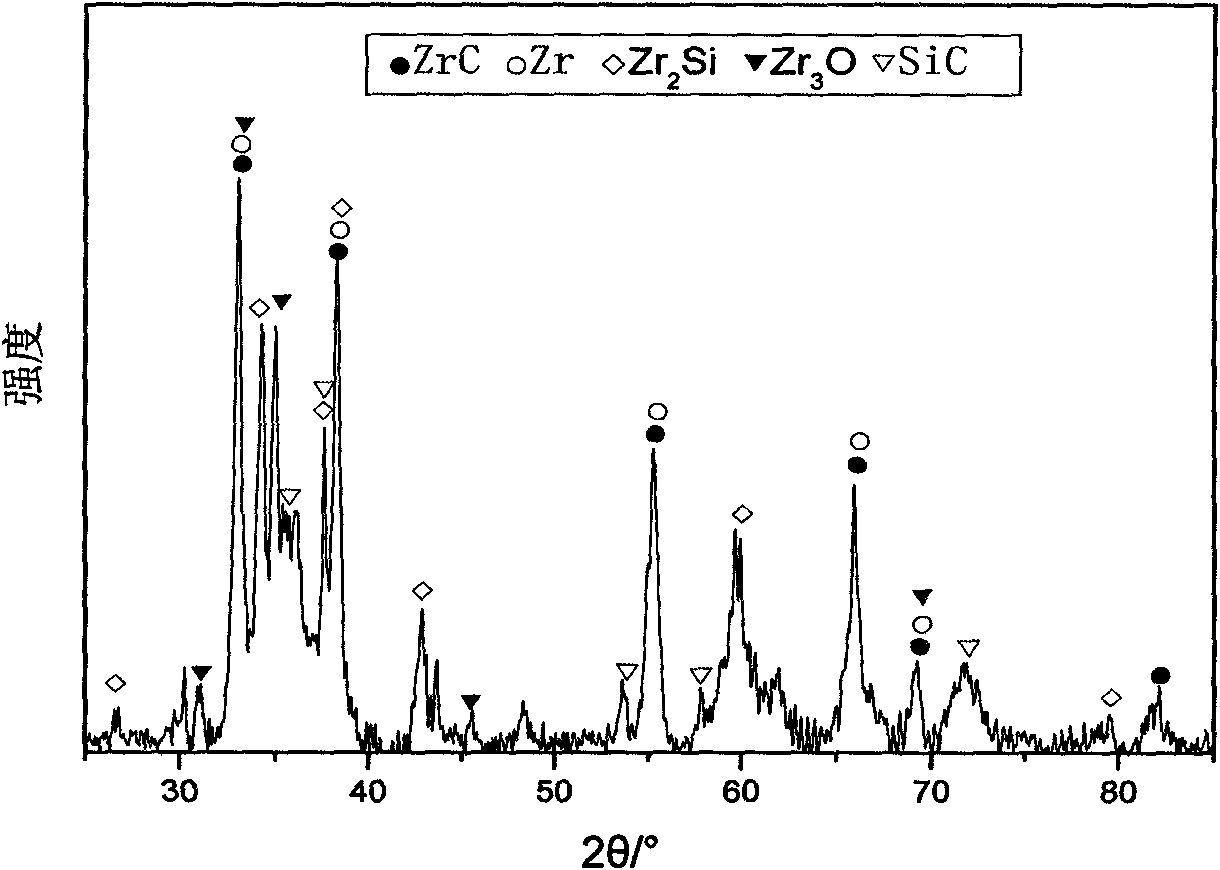

Process based on molten-salt growth method for metallizing surface of ceramic base composite material member

The invention discloses a process based on the molten-salt growth method for metallizing the surface of a ceramic base composite material member, including the following steps: firstly, a molten salt mixed raw material is arranged in a fixed container; secondly, the ceramic base composite material member of which the surface is cleaned is embedded in the molten salt mixed raw material, temperature is raised to 800 to 1200 DEG C under inert atmosphere, and after the temperature is preserved for 1 to 5 hours the ceramic base composite material member is cooled to room temperature along with the furnace; and finally, the ceramic base composite material member is taken out, and the surface thereof is repeatedly cleaned and dried, thereby obtaining the ceramic base composite material member with the metallized surface. The technological process of the invention has the advantages of high preparation speed and efficiency, simple and easily executed operation and high bonding strength between an obtained metallized layer and the ceramic base composite material, thereby meeting the requirement on metallizing the ceramic base composite material member.

Owner:NAT UNIV OF DEFENSE TECH

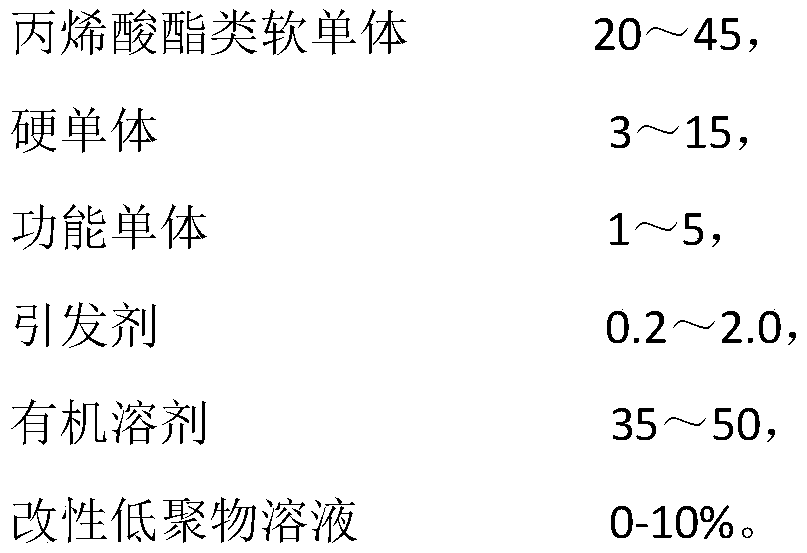

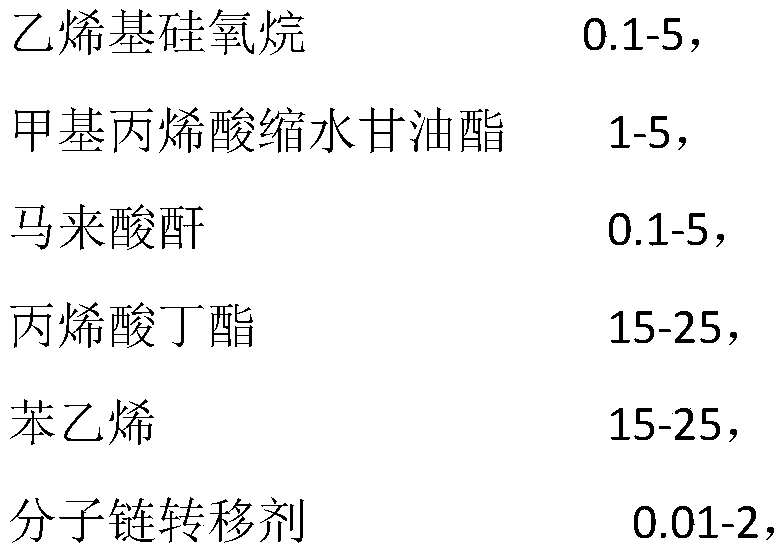

Preparation method and application of high solid content low viscosity acrylic resin adhesive

ActiveCN110684490AHigh solid contentLow viscosity propertiesEster polymer adhesivesHydrocarbon polymer adhesivesAdhesive cementPolymer science

The invention relates to the technical field of adhesives, solves the problem of using low solid content solvent-based composite adhesive in traditional reflective cloth, provides a preparation methodof a high solid content low viscosity acrylic resin adhesive and its application on a reflective cloth. The preparation method comprises the following steps: adding acrylate soft monomer, hard monomer, functional monomer, part by weight of organic solvent and part by weight of initiator into the bottom of a reaction kettle, heating to 78-85 DEG C, reacting for 1-2 hours, making the remaining initiator into initiator solution by using the part of the remaining organic solvent, and continuously dropping into the reaction kettle for a dropping time of 3-5 hours, controlling the temperature to 76-83 DEG C, keeping the temperature for 2-3 hours, adding the remaining organic solvent into the reaction system, adding the modified acrylate oligomer, and cooling to 50-60 DEG C and obtaining the acrylate adhesive with high solid content and low viscosity and the solid content of the obtained adhesive can reach more than 50%, and the adhesive has low viscosity characteristics at the same time.

Owner:HANGZHOU CHINASTARS REFLECTIVE MATERIAL

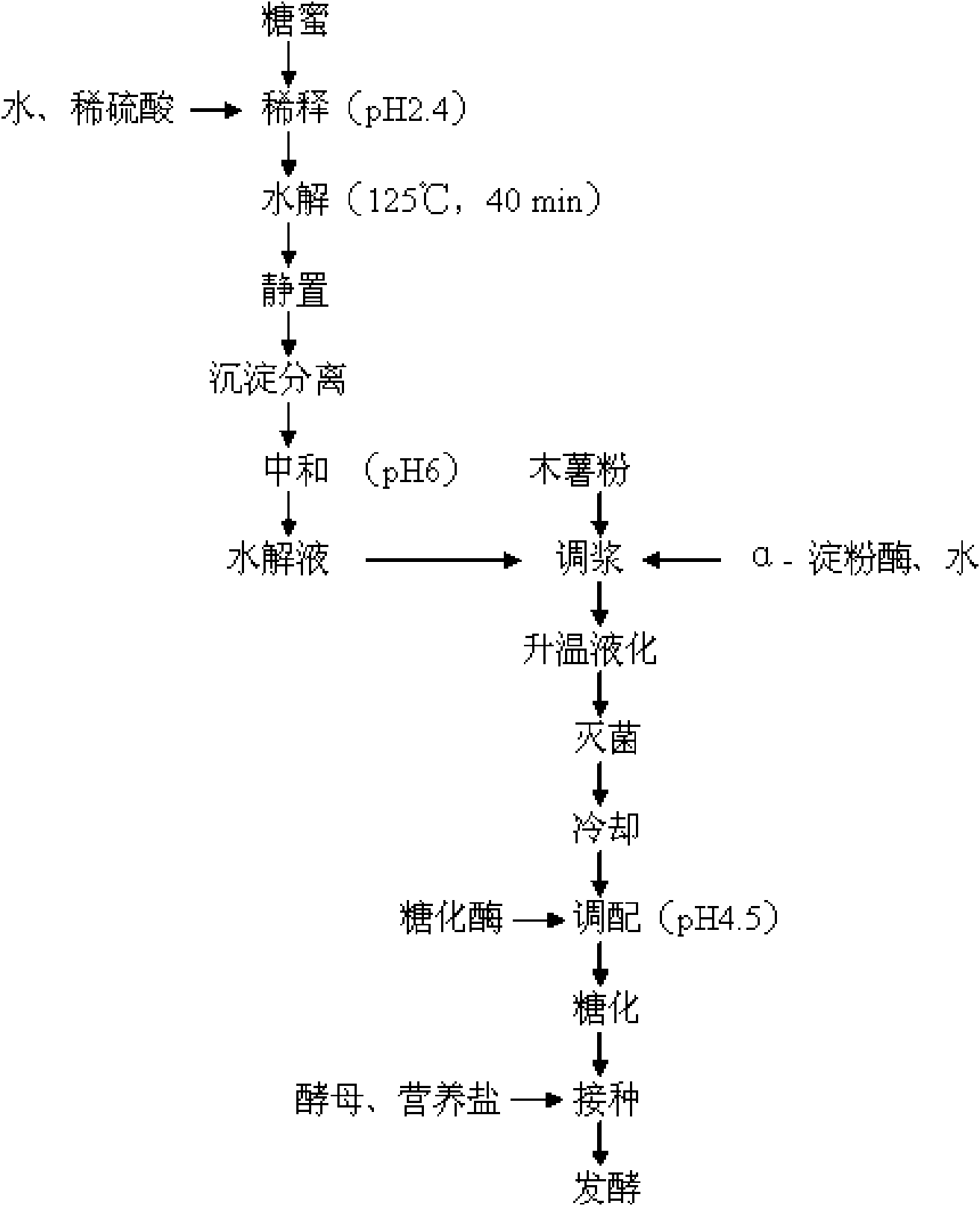

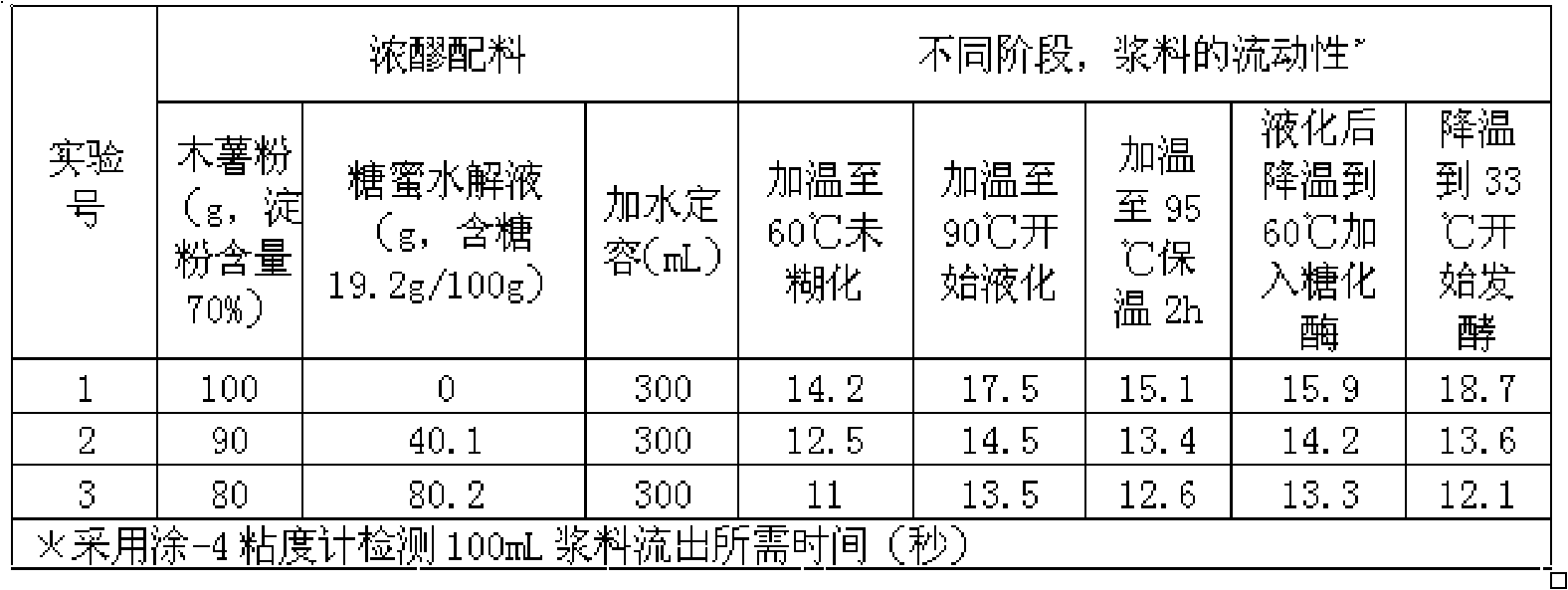

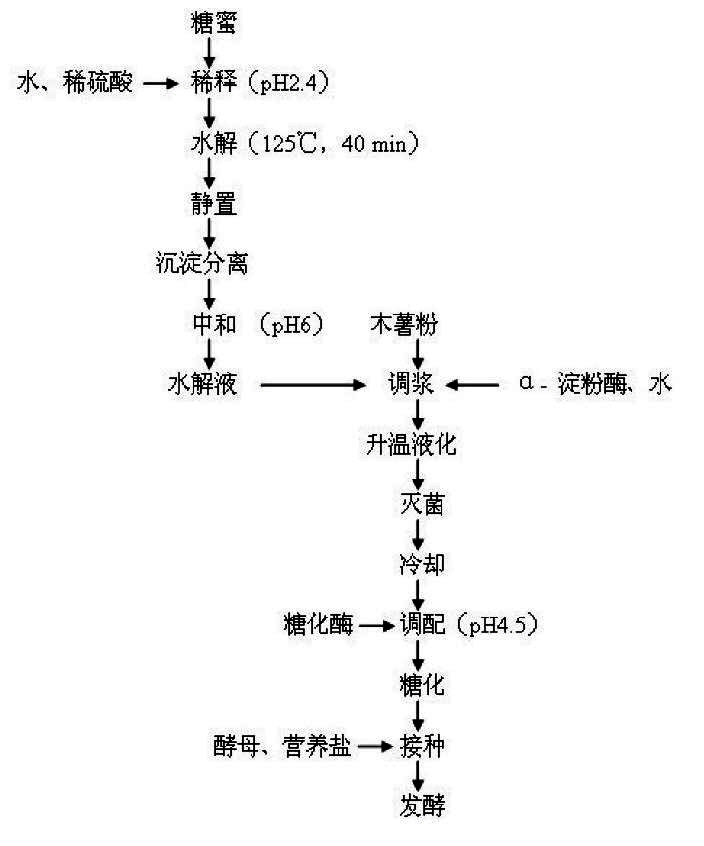

Thick mash alcohol fermentation process for mixing tapioca by using molasses hydrolyzate

InactiveCN102010881ASolve the problem that fermentation is difficult to achieve continuous productionSolve problems that are difficult to achieve continuous productionBiofuelsMicroorganism based processesAlcoholSugar

The invention relates to a thick mash alcohol fermentation process, in particular to a thick mash alcoholic fermentation process for mixing tapioca by using molasses hydrolyzate, which comprises the following steps of hydrolyzing the molasses; then mixing the tapioca with the molasses hydrolyzate and certain amount of water to ensure that the total amount of the tapioca pulp reaches 27.5 to 28.5(g / 100mL), wherein the total sugar content of the molasses hydrolyzate is 10 to 20% of the total sugar of the tapioca; the concentration of the obtained fermented mash alcohol is higher than 15.0(v / v) after the procedures of liquefaction, sterilization, saccharification, fermentation and the like. In the invention, the molasses hydrolyzate with lower viscosity is mixed with the tapioca for pulping, which increases the initial sugar concentration to meet the requirement of thick mash fermentation, and keeps good fluidity in the gelatinization and fermentation processes of the pulp material; the invention can be used for continuous production of thick mash alcohol fermentation; the molasses hydrolyzate can be utilized by alcohol yeast at high efficiency; and the invention has the advantages of good fermentation effect and low production cost.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Micro-carbon casting powder for high-carbon steel in square and rectangular billets and preparation method thereof

ActiveCN110976797ASolve the problem of carbon increaseImprove insulation effectProcess efficiency improvementSteelmakingLithium carbonate

The invention discloses micro-carbon casting powder for high-carbon steel in square and rectangular billets and a preparation method of the micro-carbon casting powder, and belongs to the technical field of steelmaking metallurgical auxiliary materials. The invention discloses micro-carbon casting powder for the high-carbon steel in the square and rectangular billets is prepared from following rawmaterials in cluding, 40-65 parts of a special pre-melting material, 0-30 parts of wollastonite, 3-8 parts of quartz, 1-5 parts of bentonite, 0-3 parts of magnesia, 2-7 parts of albite, 2-6 parts offluorite, 1-4 parts of sodium carbonate, 1-4 parts of sodium fluoride, 1-3 parts of lithium carbonate, 2-6 parts of sodium nitrate, 0-1.5 parts of medium-carbon graphite, 0-1.5 parts of high-carbon amorphous graphite, 1-2.5 parts of superfine color black and 1.8-3.8 parts of a binding agent. The casting powder is low in carbon content, high in pre-melting ratio, not prone to generating a slag ring, capable of generating heat automatically and capable of being applied to the high carbon steel in special steel in the square and rectangular billets, capable of avoiding local recarburization of the high carbon steel in the special steel, meanwhile, low in fluorine content and capable of avoiding erosion to nozzle slag lines.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Preparation method of polystyrene-acrylate core-shell composite emulsion

The invention discloses a preparation method of a polystyrene-acrylate core-shell composite emulsion, belongs to the emulsion preparation field, and solves the problems of adhesion resistance, poor heat resistance and the like of a thermoplastic polystyrene-acrylate random copolymer in the prior art. The preparation method is as follows: 1, weighing raw materials; 2, adding distilled water into a reactor, heating up, adding a compound emulsifier, a pH buffer and then part of a mixed vinyl monomer for emulsifying, adding part of an initiator, heating up to react until no reflux exists to obtain a seed emulsion; 3, continuing heating up, dripping off the rest of the mixed vinyl monomer, synchronously adding part of the initiator, after the dripping of the part of the initiator, keeping warm to obtain a core structure emulsion; 4, dripping a mixed acrylate monomer to the core structure emulsion, in the mixed monomer dripping process, adding part of the initiator, after dripping of the part of the initiator, adding the rest of the initiator, keeping warm, then cooling, adding ammonia water, stirring, further cooling, and filtering. The preparation method is applied in the fields of wood veneering, interior decoration, textiles and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

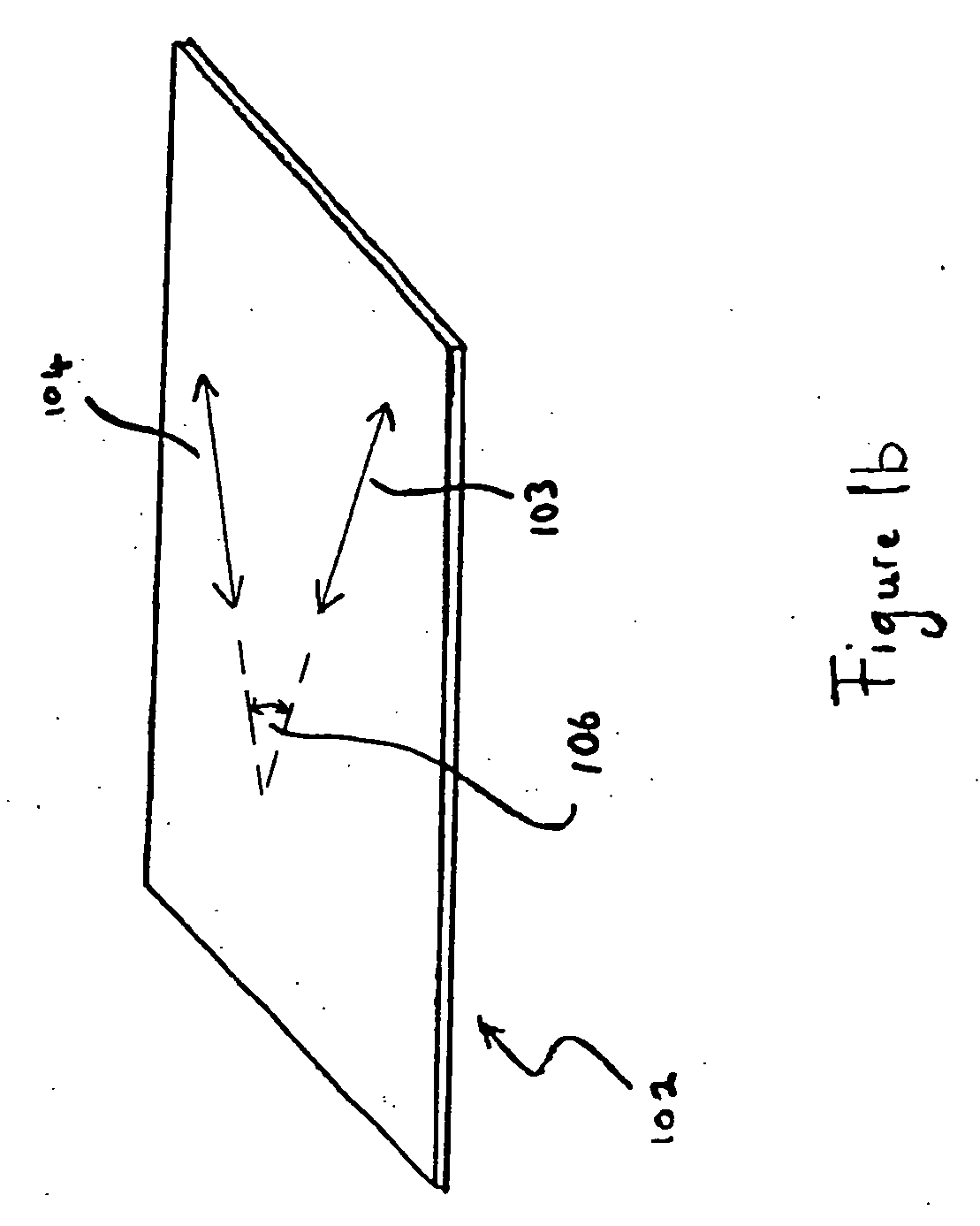

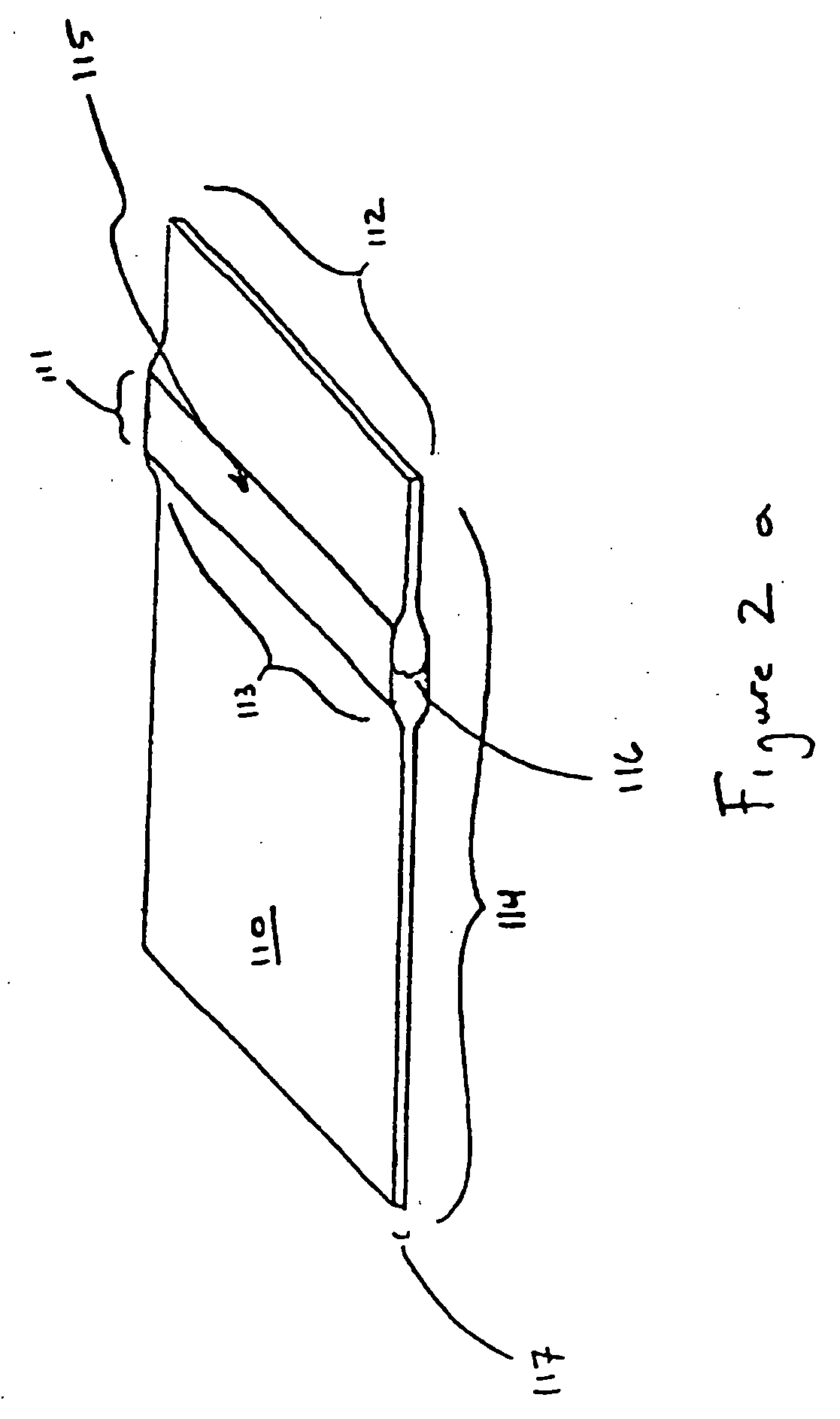

Resorbable thin membranes

InactiveUS20070116739A1Simple chemical reaction and formulationReduce scarsOrganic active ingredientsSurgeryResorbable polymersSide effect

Resorbable lactide polymer thin membranes are disclosed. The thin membranes are constructed of polylactide resorbable polymers, which are engineered to be absorbed into the body relatively slowly over time in order to reduce potential negative side effects. The membranes are formed to have very thin thicknesses, for example, thicknesses between about 0.010 mm and about 0.300 mm. The membranes can be extruded from polylactide polymers having a relatively high viscosity property, can be preshaped with relatively thick portions, and can be stored in sterile packages.

Owner:MAST BIOSURGERY

Oil well deep composite blocking profile control agent and application thereof

ActiveCN103421475ANot easy to flowPlay a sealing roleDrilling compositionSealing/packingSulfonateSodium Thiosulfate Pentahydrate

The invention relates to an oil well deep composite blocking profile control agent and the application thereof. The composite blocking profile control agent comprises the following components: gel blocking agent solution, particle blocking agent, authigene air source and surface active agent, wherein in the gel blocking agent solution, the weight ratio of the partially hydrolyzed polyacrylamide, the sodium bichromate and the sodium thiosulfate pentahydrate is 1:0.025:0.35, a water solution with the total weight concentration of 0.5-1% is prepared from the partially hydrolyzed polyacrylamide, sodium bichromate and sodium thiosulfate pentahydrate, and hydrochloric acid capable of adjusting the pH of the gel blocking agent solution to 3.5-4.5 is contained; the particle blocking agent comprises phenolic resin and phenolic resin, wherein the weight ratio of the phenolic resin and the phenolic resin is 1:0.06; the authigene air source is CO(NH2) 2; the surface active agent is alkylaryl sulfonate; the weight ratio of the gel blocking agent solution, the particle blocking agent, the authigene air source and the surface active agent is 60:6:2:1. According to the composite blocking profile control agent disclosed by the invention, deep blocking and profile control at the oil layer of an oil well is realized through the Jamin Effect of foam generated in the deep part of stratum and the physical blocking function of a solid phase blocking agent.

Owner:PETROCHINA CO LTD

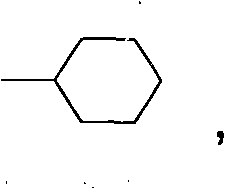

Benzoxazine-derived phosphorus bisphenol, epoxy resin semi-cured substance and epoxy resin cured substance thereof, and manufacturing method their manufacturing method

InactiveCN102558233AImprove solubilityLow viscosity propertiesGroup 5/15 element organic compoundsOxidePhosphorus

The invention relates to a benzoxazine-derived phosphorus bisphenol, an epoxy resin semi-cured substance and an epoxy resin cured substance thereof, and a manufacturing method thereof. The method comprises the following steps: reacting 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and benzoxazine derivatives to generate the phosphorus bisphenol compound; and further reacting the phosphorus bisphenol compound and epoxy resin to obtain the flame-resisting phosphorus epoxy resin semi-cured substance and epoxy resin cured substance.

Owner:萧介夫

Pharmaceutical composition for control of diabetes and complications thereof

InactiveCN107184966APromote secretionIncrease kinase activityOrganic active ingredientsHydrolysed protein ingredientsTherapeutic effectOligosaccharide

The invention discloses a pharmaceutical composition for control of diabetes and complications thereof. The pharmaceutical composition comprises: sea cucumber polypeptide, alginate oligosaccharide, a kudzu vine root extract, a common duckweed extract, a radix trichosanthis extract, an extract of peach kernel and safflower, a ginkgo leaf extract, hirudin and nattokinase. The pharmaceutical composition provided by the invention can treat insulin resistant diabetes, the effective components are compounded to achieve better prevention and treatment effect on diabetes than single component, and the pharmaceutical composition also can prevent and treat some chronic complications associated with blood glucose rise. The pharmaceutical composition provided by the invention has the advantages of simple production process, low cost, high benefit, and obvious economic and social benefits.

Owner:青岛金海宝生物科技发展有限公司

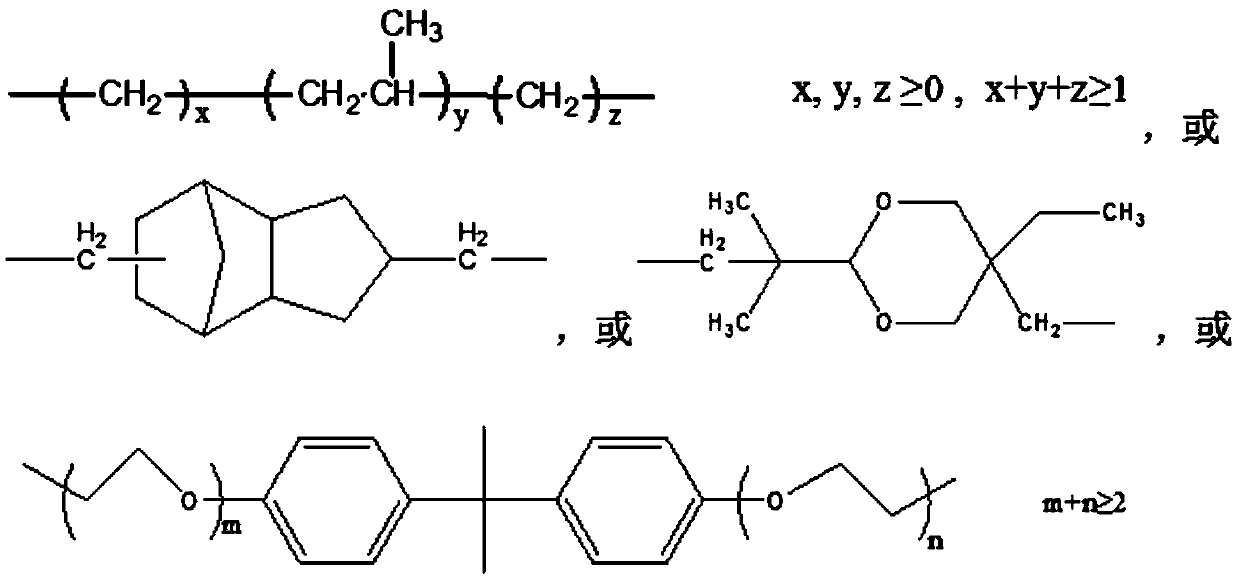

Vinyl alcohol series polymer

InactiveCN101955561ALow viscosity propertiesImprove water resistanceWater-repelling agents additionPaper coatingAdhesiveAqueous solution

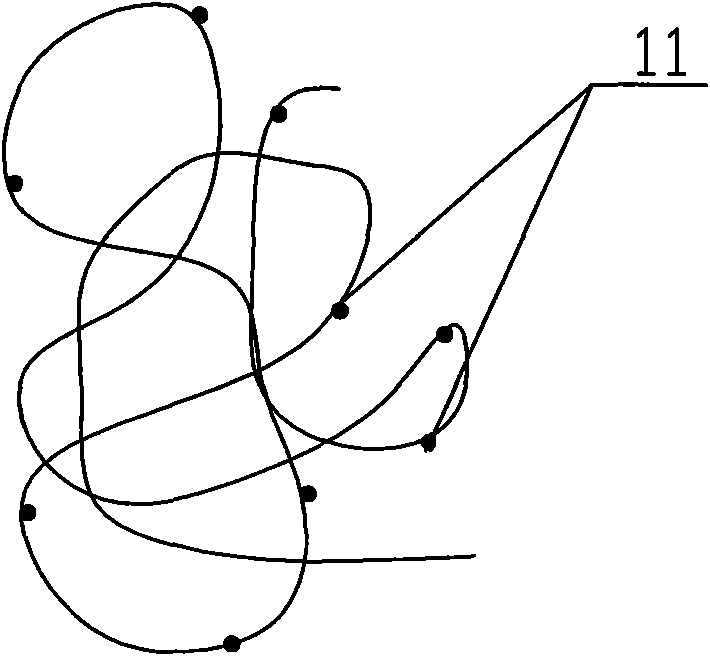

The invention discloses vinyl alcohol series polymer. The vinyl alcohol series polymer consists of a core and vinyl alcohol series polymer arms which are connected to the core and has a core-arm star-shaped molecular structure, wherein the core comprises a polymeric polyfunctional crosslinking agent monomer or polyfunctional chain transfer agent; and the polyfunctional crosslinking agent monomer is a polymerizable monomer with two or more vinyl groups, and the polyfunctional chain transfer agent is a polythiol compound with three or more mercapto groups. The aqueous solution of the polymer has low viscosity characteristic, and the polymer has water resistance and has high cohesiveness to inorganic substances. The invention also provides a preparation method of the vinyl alcohol series polymer at the same time. The polymer of the invention can be applied to a coating for coating paper, and can be used as a sizing agent in the paper or on the surface of the paper, interior and exterior wall coatings for buildings or an adhesive in packaging or textile industries.

Owner:李汝基

Epoxy waterproof paint

ActiveCN104327677AReduce internal stressImprove toughnessConjugated diene hydrocarbon coatingsEpoxy resin coatingsGlass fiberEmulsion

The invention discloses epoxy waterproof paint. The epoxy waterproof paint is prepared from the following raw materials in percentage by weight: 30%-40% of bisphenol A epoxy resin, 8%-15% of fluorocarbon emulsion, 5%-10% of organic silicon, 5%-10% of nano hollow glass fibers, 10%-18% of nitrile rubber, 10%-17% of sheet-shaped highly wear-resistant pigment filler, 0.5%-0.9% of a dispersant, 0.4%-0.8% of a defoaming agent, 0.4%-0.8% of a preservative, 0.2%-0.5% of a leveling agent and 15%-23% of deionized water. The epoxy waterproof paint disclosed by the invention is good in impact resistance and good in water resistance.

Owner:GUANGDONG TAISHI IND CO LTD

Preparation method of epoxy anticorrosive coating

InactiveCN104356882AReduce internal stressImprove toughnessConjugated diene hydrocarbon coatingsAnti-corrosive paintsWear resistantPreservative

The invention discloses a preparation method of an epoxy anticorrosive coating. The preparation method comprises the following steps: (1) weighing the following components respectively in percentage by weight: 15-23% of deionized water, 30-40% of bisphenol A epoxy resin, 8-15% of phenolic amine, 5-10% of organic silicon, 5-10% of polyurethane, 10-18% of nitrile-butadiene rubber, 0.5-0.9% of a dispersant, 0.4-0.8% of a defoaming agent and 0.4-0.8% of a preservative, and dispersing and stirring to obtain a mixture; (2) weighing 10-17% of flaky highly-wear-resistant color filler and 0.2-0.5% of a leveling agent to be added into the mixture, and dispersing for 10-15 minutes in a dispersion tank at a rotation speed of 1000-1500r / min. By adopting the preparation method disclosed by the invention, the epoxy anticorrosive coating with good anticorrosive performance, good impact resistance, good toughness and good high-temperature resistance can be prepared, and the process is simple.

Owner:徐妍玲

Ultraviolet curing coating

InactiveCN101942261ALow viscosityLow viscosity propertiesPolyurea/polyurethane coatingsEpoxy resin coatingsHigh resistanceDiluent

The invention relates to the technical field of building coatings, in particular to an ultraviolet curing coating which is widely used for building decorative boards such as coating boards, wall-surface decorative boards, cement fiberboards and the like. The ultraviolet curing coating comprises the following components in part by weight: 20 to 90 parts of ultraviolet curing resin, 3 to 40 parts of active diluent, 5 to 20 parts of active amine and 3 to 10 parts of photoinitiator. Due to the adoption of the technical scheme, after the coating is subjected to film forming and cured, film layers do not contain acrylate monomers with poor wear-resisting property, and therefore have high wear resistance, rigidity and adhesion; simultaneously, the varieties and using amount of the active diluent are adjusted reasonably so as to avoid the phenomena that the surfaces of cured paint films are rough, bubbles, needle eyes, shrinkage cavities, poor levelling exist on the surfaces and the like in the prior art.

Owner:上海雅达特种涂料有限公司 +1

Process for preparing submicron grade superfine calcium carbonate dispersion particle

ActiveCN100545092CHigh glossLow viscosity propertiesCalcium/strontium/barium carbonatesPolymer scienceNucleation

Owner:建德华明科技有限公司

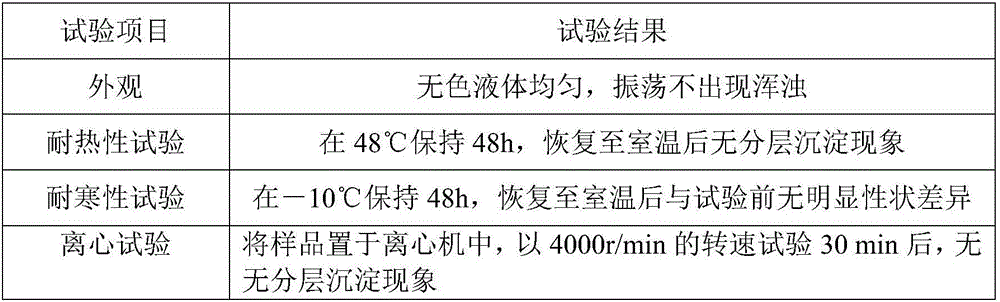

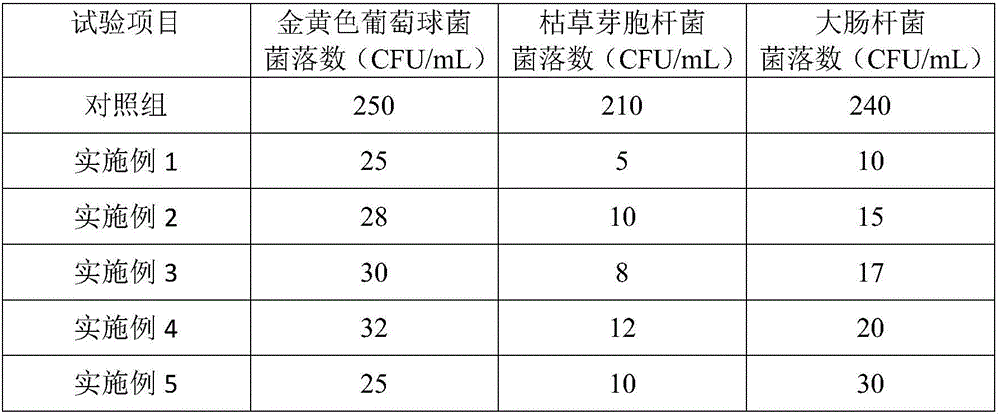

Rose moisturizing antibacterial emollient water and preparation method thereof

InactiveCN106726963AAct as an emulsifierLow viscosity propertiesCosmetic preparationsToilet preparationsSide effectRose water

The invention relates to rose moisturizing antibacterial emollient water and a preparation method thereof. The preparation method comprises the following steps: mixing bactericidal and antibacterial essential oil with an emulsifier, adding the mixture to prepared rose konjac sol, and performing uniform stirring to obtain a product. According to the rose moisturizing antibacterial emollient water provided by the invention, the main raw materials, namely, essential oil, rose water and konjac glucomannan, are prepared into uniform and stable emollient water, the bactericidal and antibacterial effect of the essential oil and the moisturizing effect of the konjac glucomannan are fully used, and the rose water has anti-allergy, anti-inflammatory, bactericidal and antibacterial effects; and the rose moisturizing antibacterial emollient water has cleaning, tightening and lubricating functions on the skin. When in use, the rose moisturizing antibacterial emollient water can quickly penetrate through the skin to supplement the energy of the skin, so that the rose moisturizing antibacterial emollient water is good in beauty and health care effects, free of toxic or side effect, good in moisturizing and antibacterial effects and is pure natural.

Owner:云南健牛环境监测有限公司

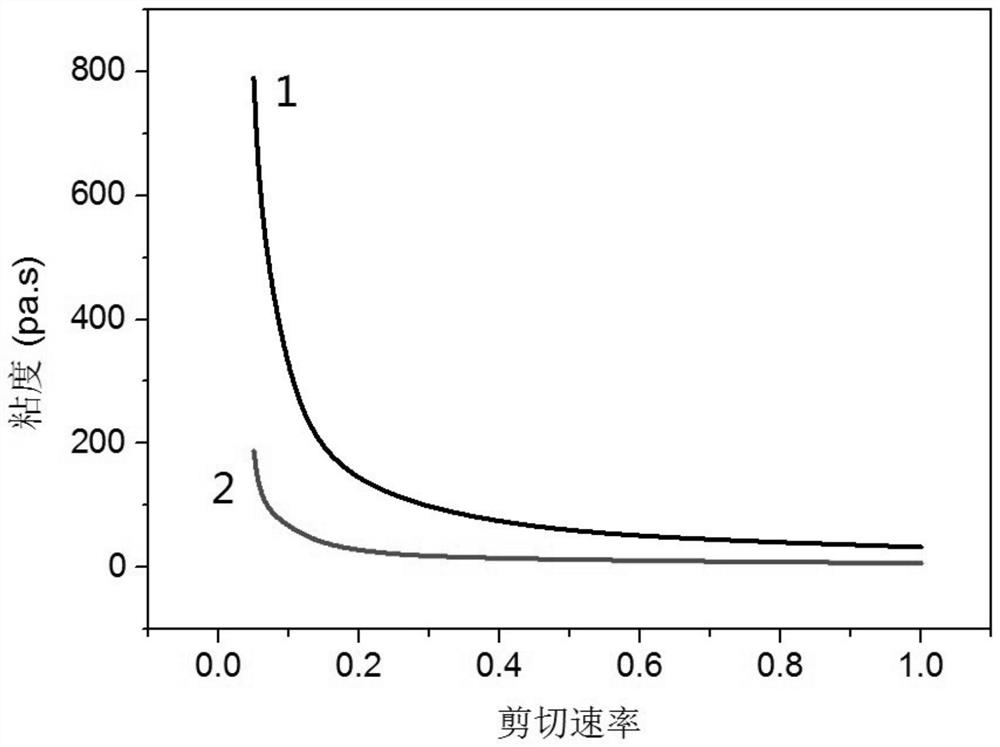

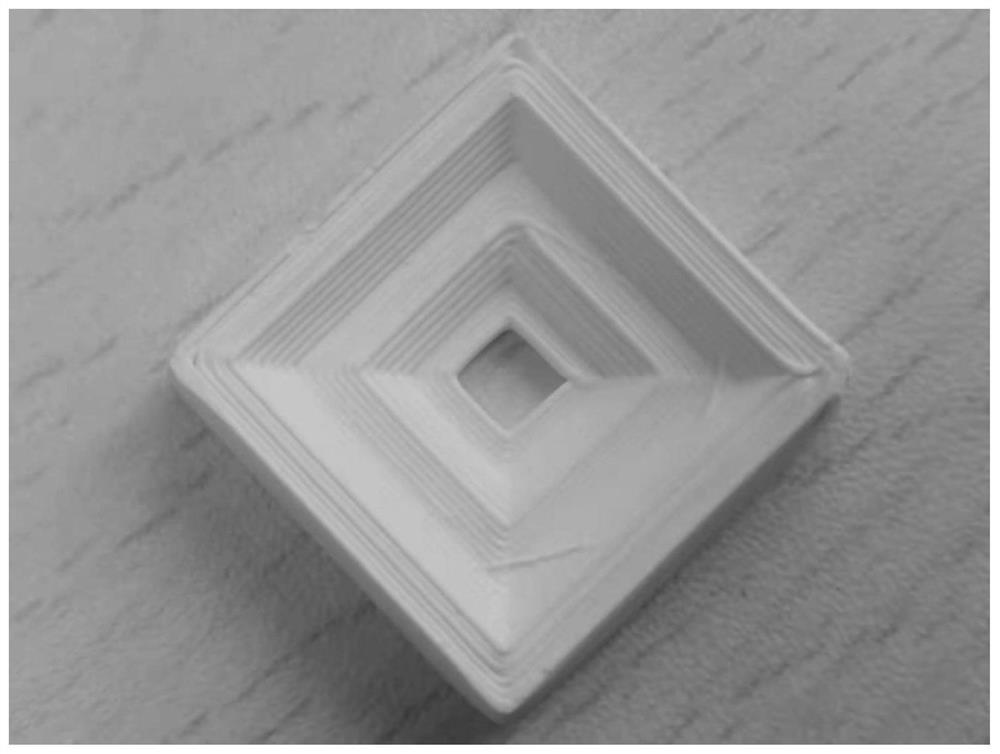

Method for 3D printing of high-solid-content low-temperature co-fired alumina ceramic complex structure

ActiveCN112759372AHigh solid contentReduce sintering shrinkageAdditive manufacturing apparatusOxide ceramicAlumina ceramic

The invention relates to a method for 3D printing of an aluminum oxide ceramic complex structure and discloses a method for 3D printing of a high-solid-content low-temperature co-fired aluminum oxide ceramic complex structure. The invention aims to solve the problems that the pH value of existing high-solid-phase-content aluminum oxide ceramic slurry needs to be adjusted, the prepared slurry is poor in stability and difficult to store for a long time, and high-speed and high-precision direct-writing type 3D printing is difficult to achieve. The method comprises the following steps: 1, weighing; 2, preparation of an organic colloid; 3, mixing of alumina powder and ceramic glass powder; 4, preparation of slurry; 5, heating for 3D printing; and 6, drying, glue discharging and sintering. The method is used for 3D printing of the high-solid-content low-temperature co-fired aluminum oxide ceramic complex structure.

Owner:HARBIN INST OF TECH

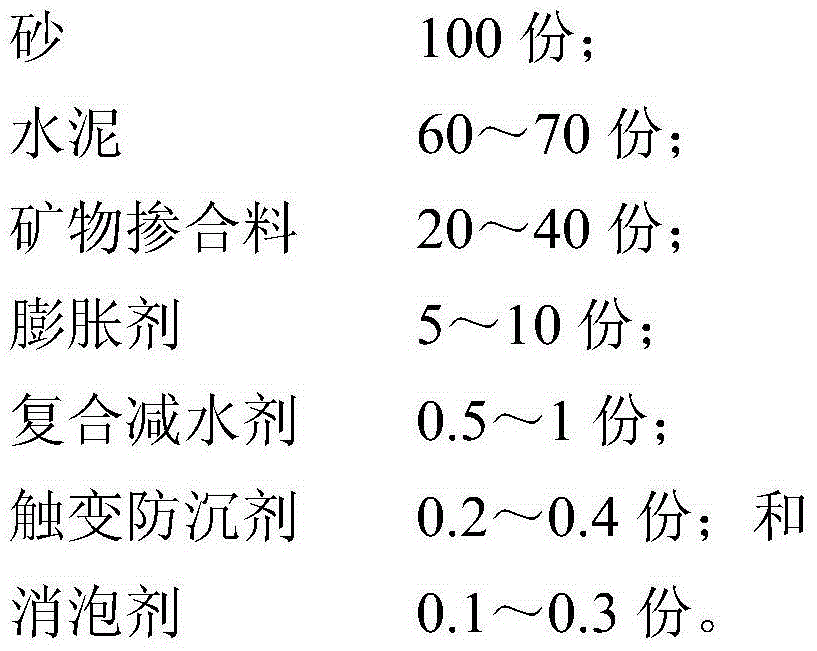

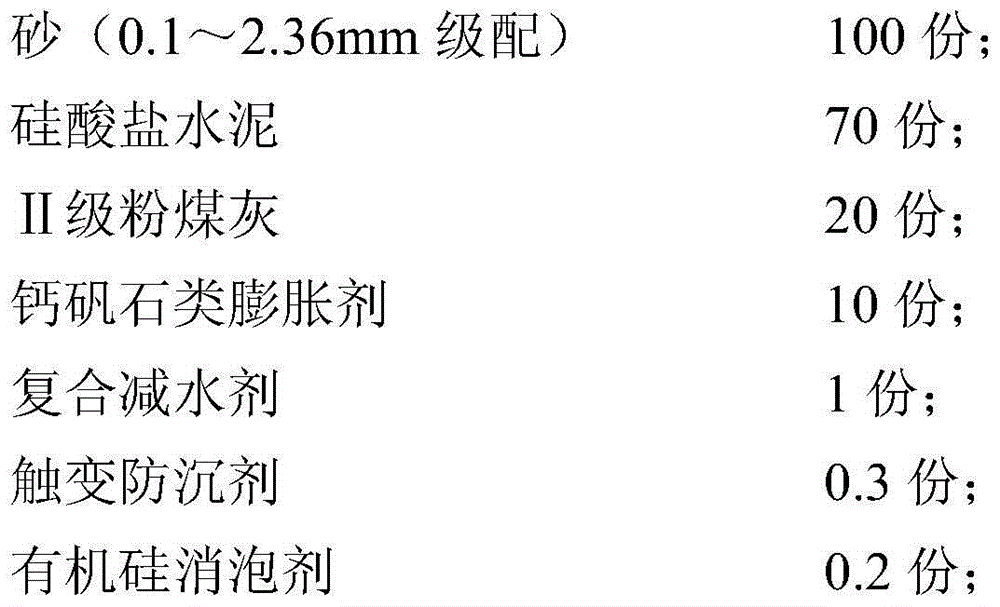

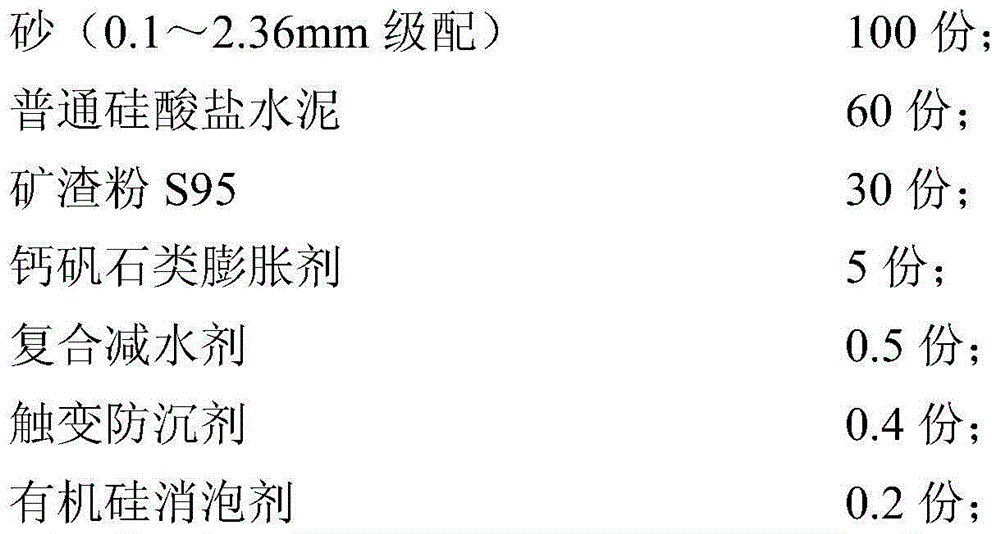

Cement-based grouting material applicable to narrow-space and long-distance grouting operation

The invention relates to a cement-based grouting material applicable to narrow-space and long-distance grouting operation and a preparation method thereof. The cement-based grouting material applicable to narrow-space and long-distance grouting operation comprises the following materials in parts by weight: 100 parts of sand, 60-70 parts of cement, 20-40 parts of mineral admixture, 5-10 parts of expanding agent, 0.5-1 part of compound water reducer, 0.2-0.4 part of thixotropic anti-settling agent, and 0.1-0.3 part of defoaming agent. The cement-based grouting material disclosed by the invention has continuously expanded fluid ability and low viscosity, and flowing property simultaneously satisfies fluidity not less than 380mm of fluidity requirements of grouting materials I in GB / T50448-2008 and flow time not more than 35 seconds of ASTM-C939 flow time requirements, therefore, a more effective solution can be provided for narrow-space and long-distance grouting operation.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

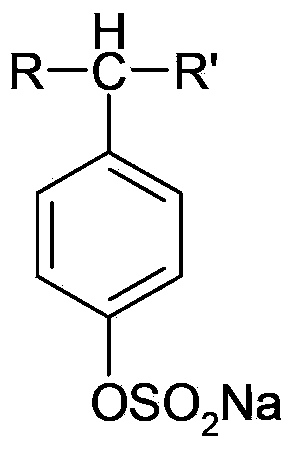

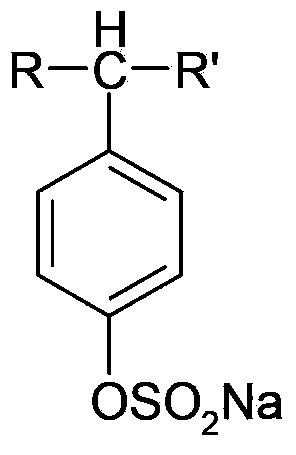

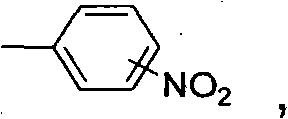

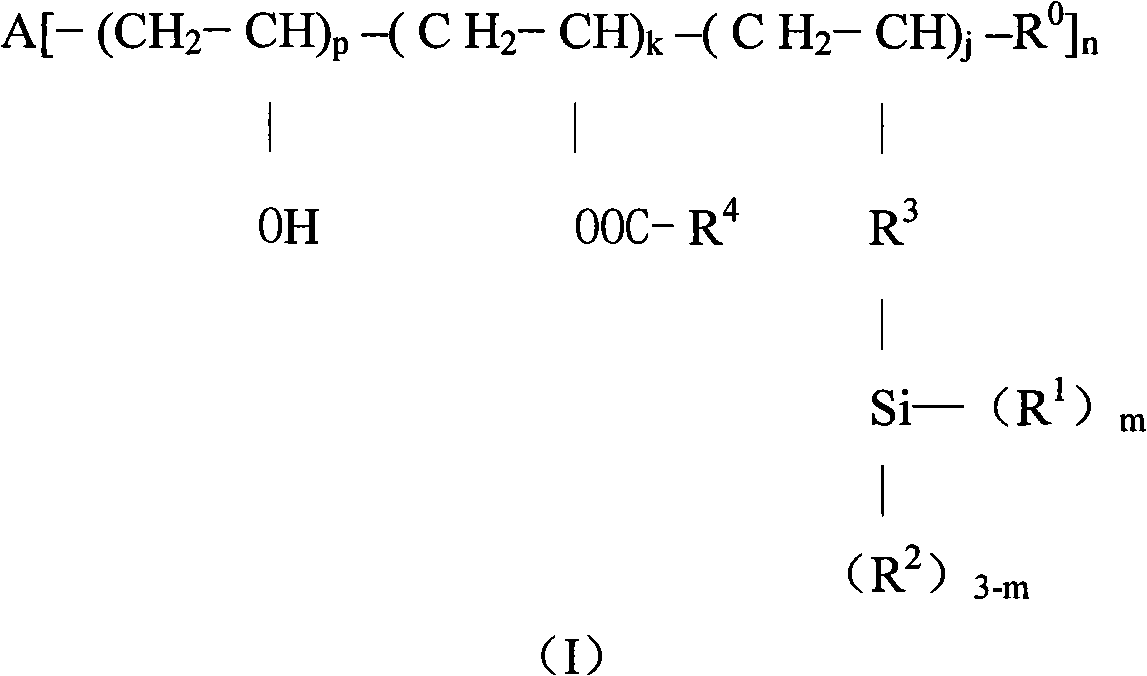

Naphthol resin, epoxy resin, epoxy resin composition, and solidified products thereof

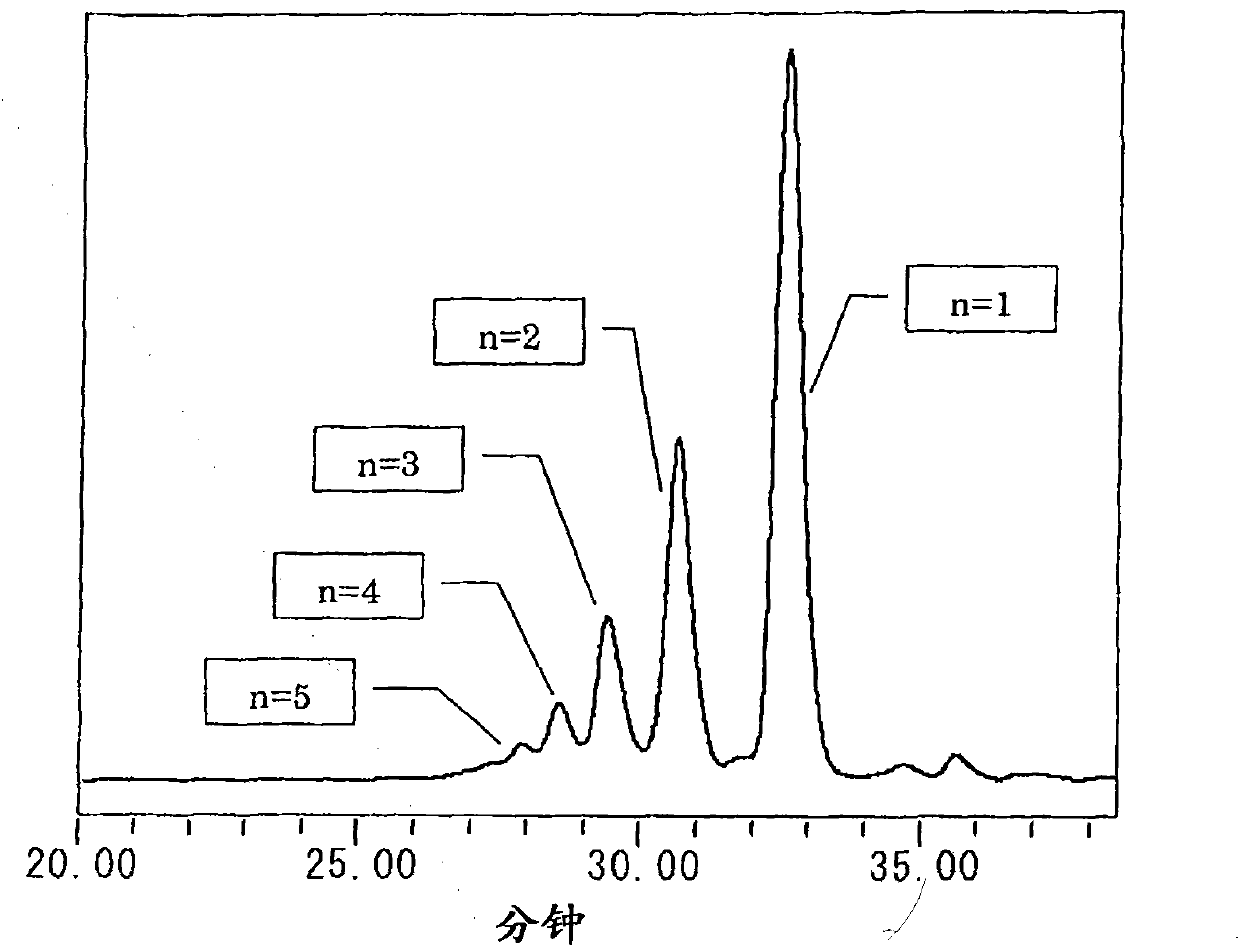

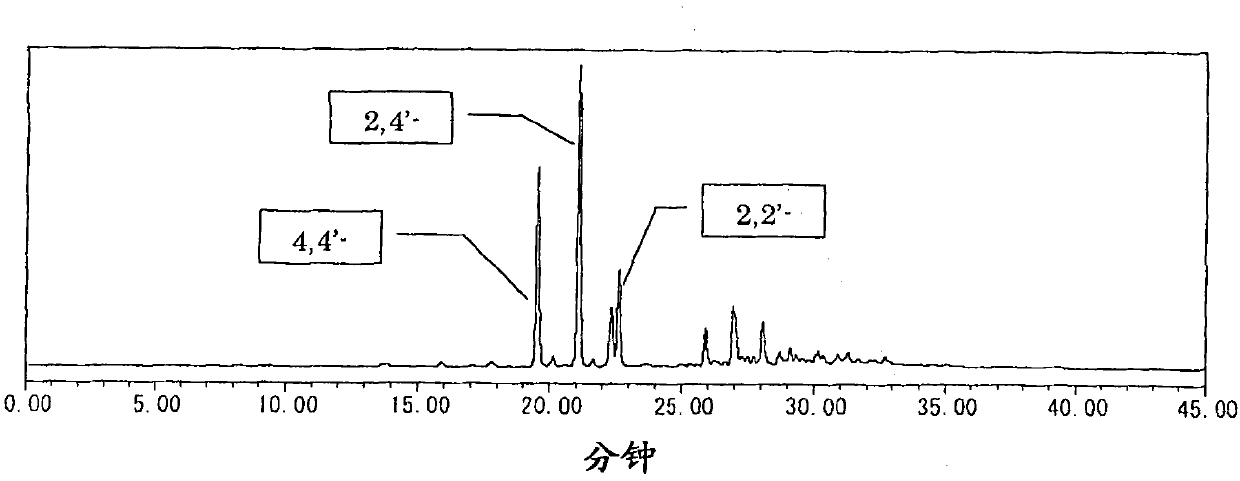

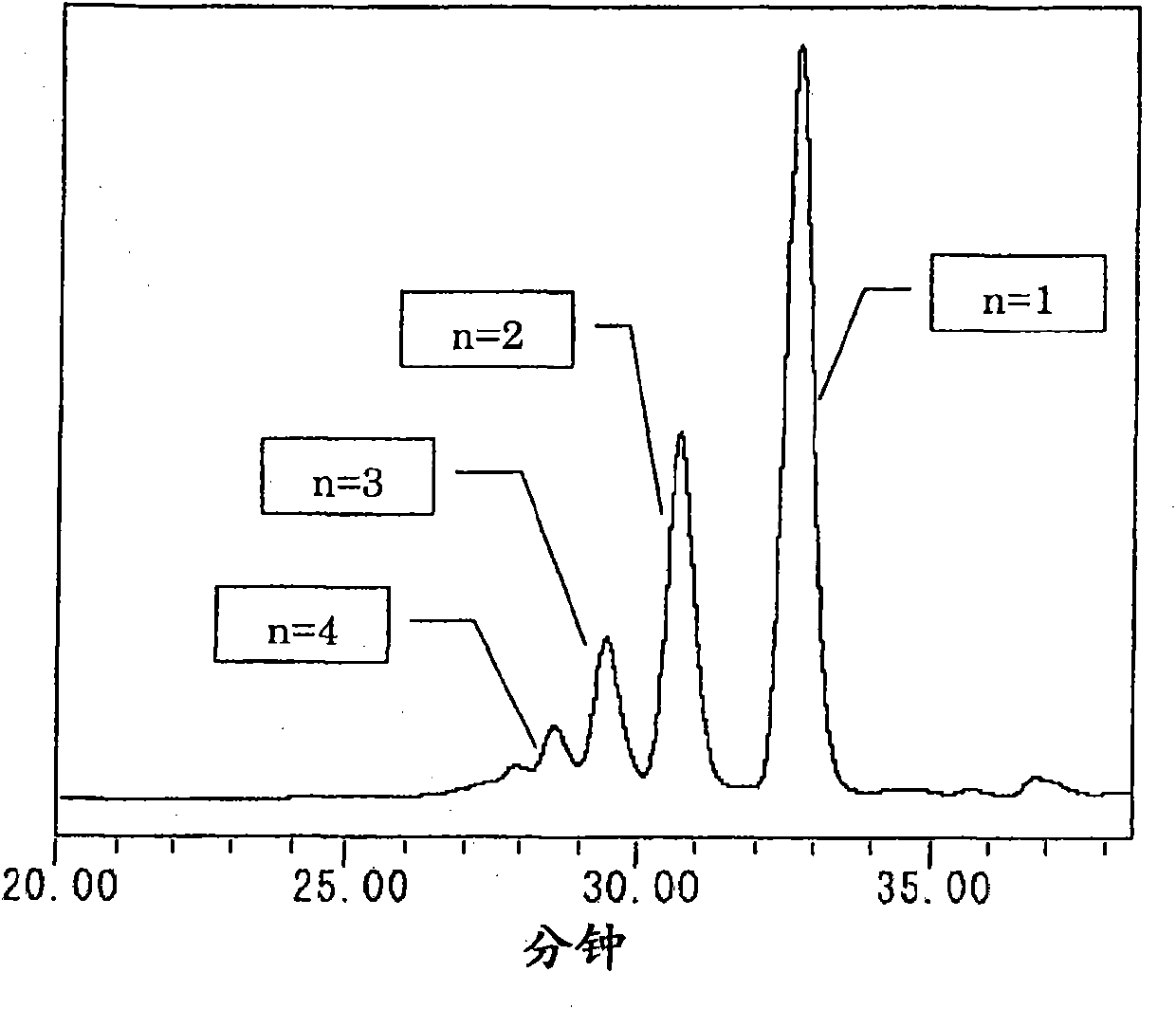

The present invention provides a novel naphthol resin and a naphthol type epoxy resin. These resins are capable of keeping an excellent forming property and a high filling property because of low viscosity and good solidifying reactivity. Solidified products of the resins are obtained by solidifying an epoxy resin composition, has characteristics of excellent fire resistance, high adhesive bonding property, good moisture-proof property and excellent heat resisting property, and has functions of lamination, forming, cast molding, adhesive bonding and the like. The naphthol resin is representedby the following general formula (1) and the epoxy resin is obtained by performing a process of epoxidation of the naphthol resin, and the present invention is characterized in that in the general formula (1), the n=1 part is 50 wt% of the whole part, displacement position of the crosslinked radical of a 1-naphthol framework in the n=1 part is 4 which is of the position of 4', the content of the isomer of 4' is between 20wt% and 60wt%, and the total content of the isomer of 4', 2 and 2' is between 40wt% and 80wt%.[the chemical formula 1].

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

Epoxy anticorrosive antibacterial paint

ActiveCN104356873AReduced compatibilityGood compatibilityAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylonitrilePhenol

The invention discloses an epoxy anticorrosive antibacterial paint which is composed of 30-40% of bisphenol A epoxy resin, 8-15% of phenol formaldehyde amine, 5-10% of antimicrobial modified resin and nano silicon solution in a weight ratio of 30:1, 5-10% of polyurethane, 10-18% of butadiene-acrylonitrile rubber, 10-17% of flaky high-wear-resistance pigment and filler, 0.5-0.9% of dispersing agent, 0.4-0.8% of defoaming agent, 0.4-0.8% of preservative, 0.2-0.5% of leveling agent and 15-23% of deionized water. The epoxy anticorrosive antibacterial paint has the advantages of favorable corrosion resistance, favorable impact resistance, favorable toughness and favorable mold resistance.

Owner:GUANGDONG TAISHI IND CO LTD

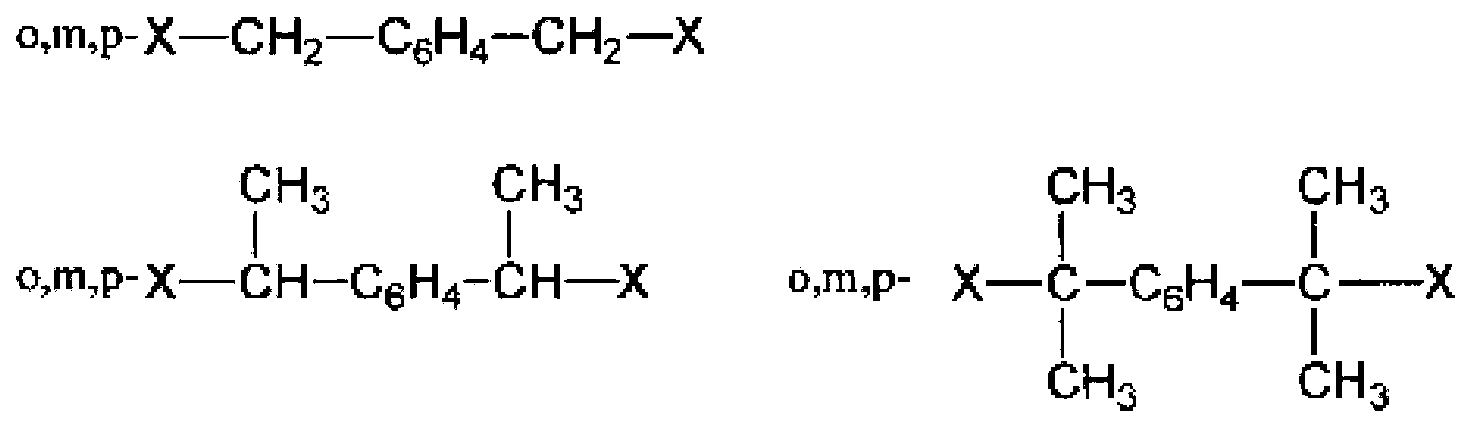

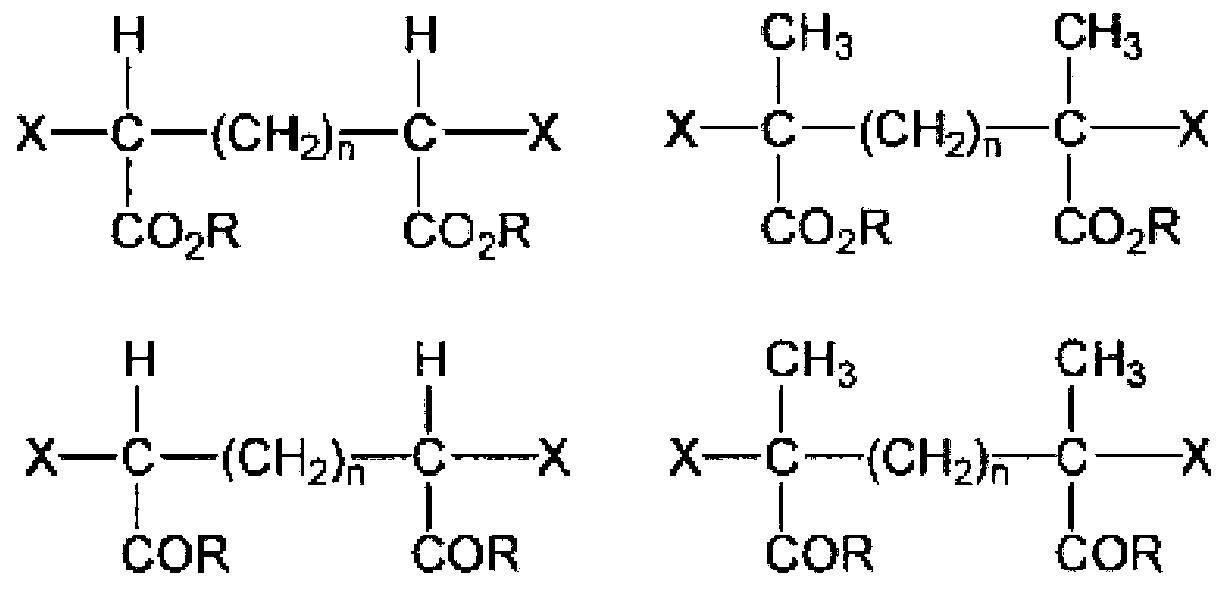

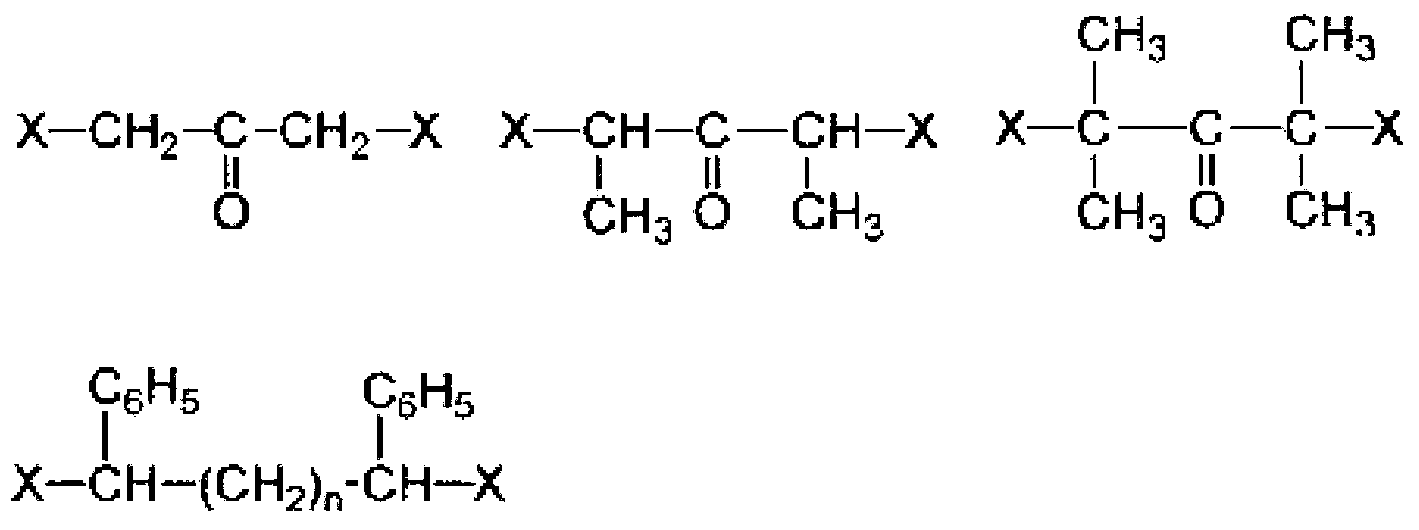

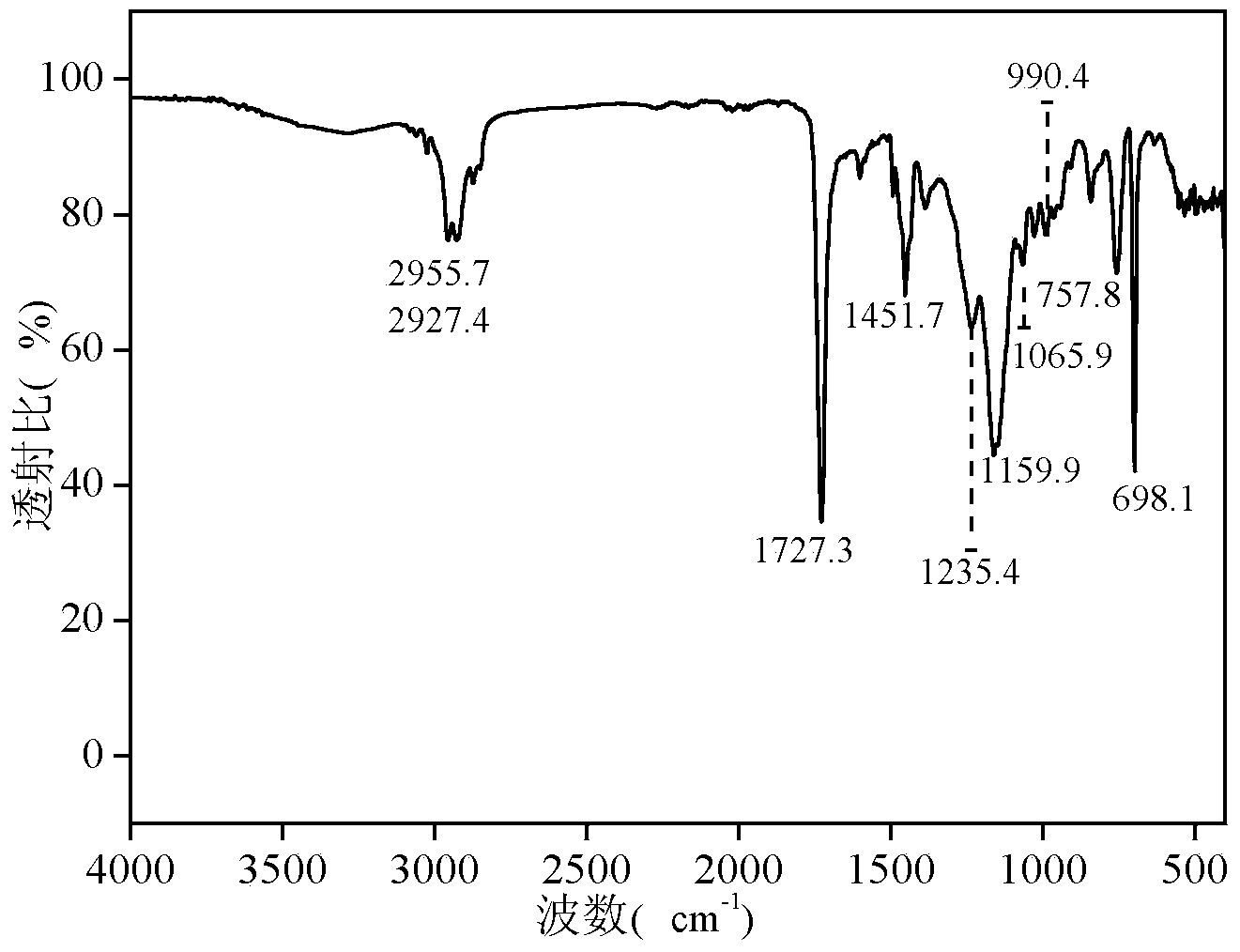

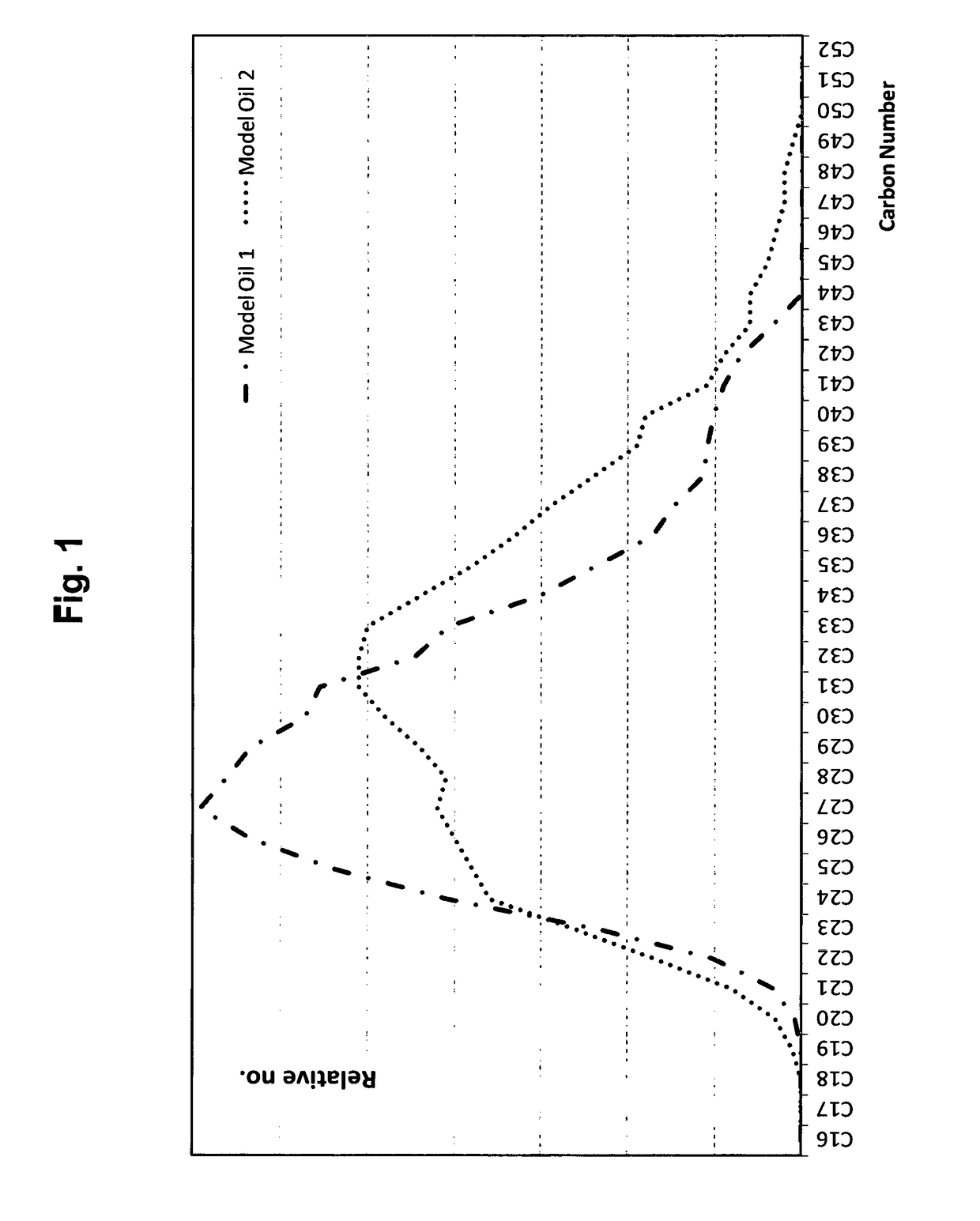

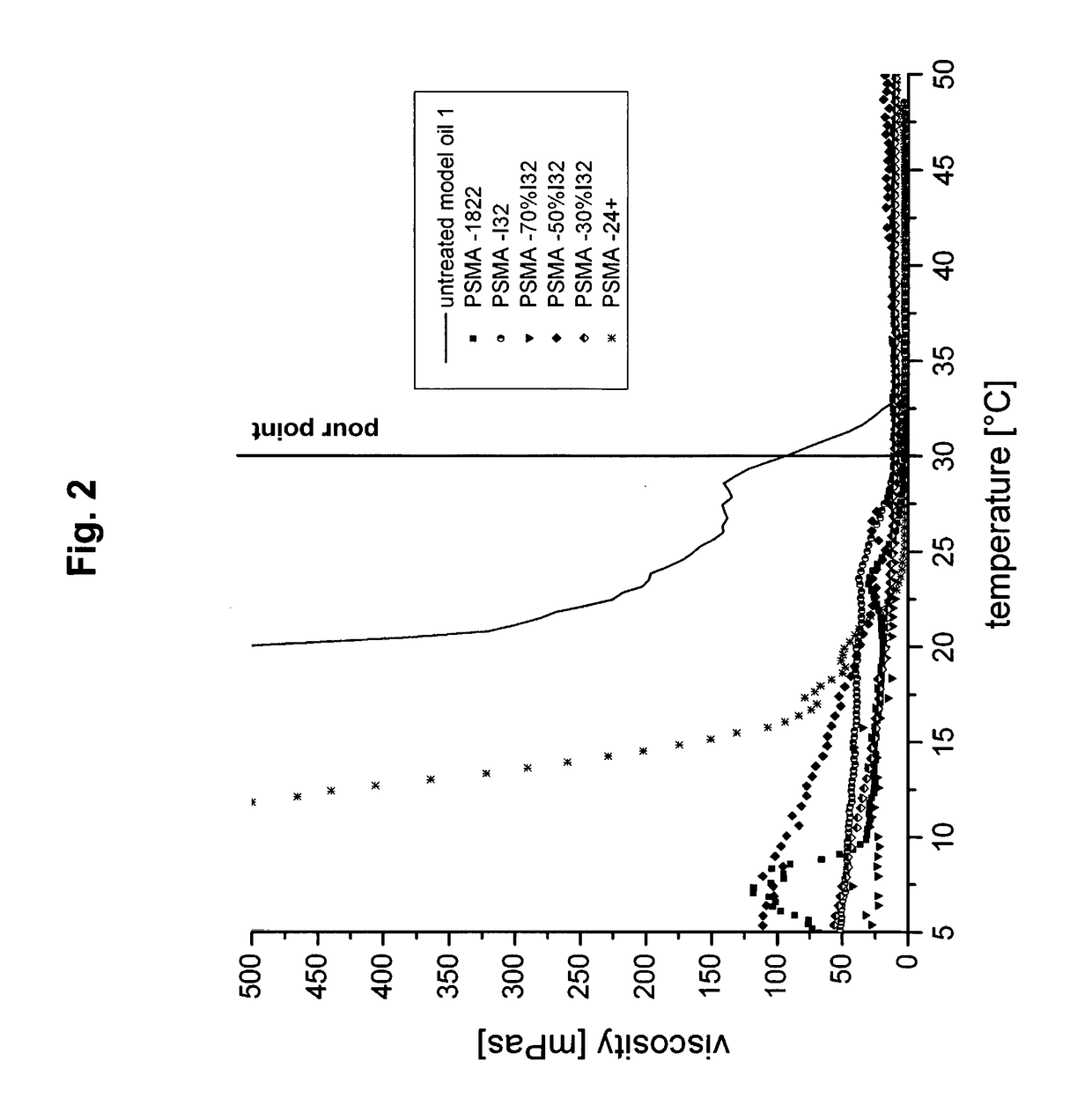

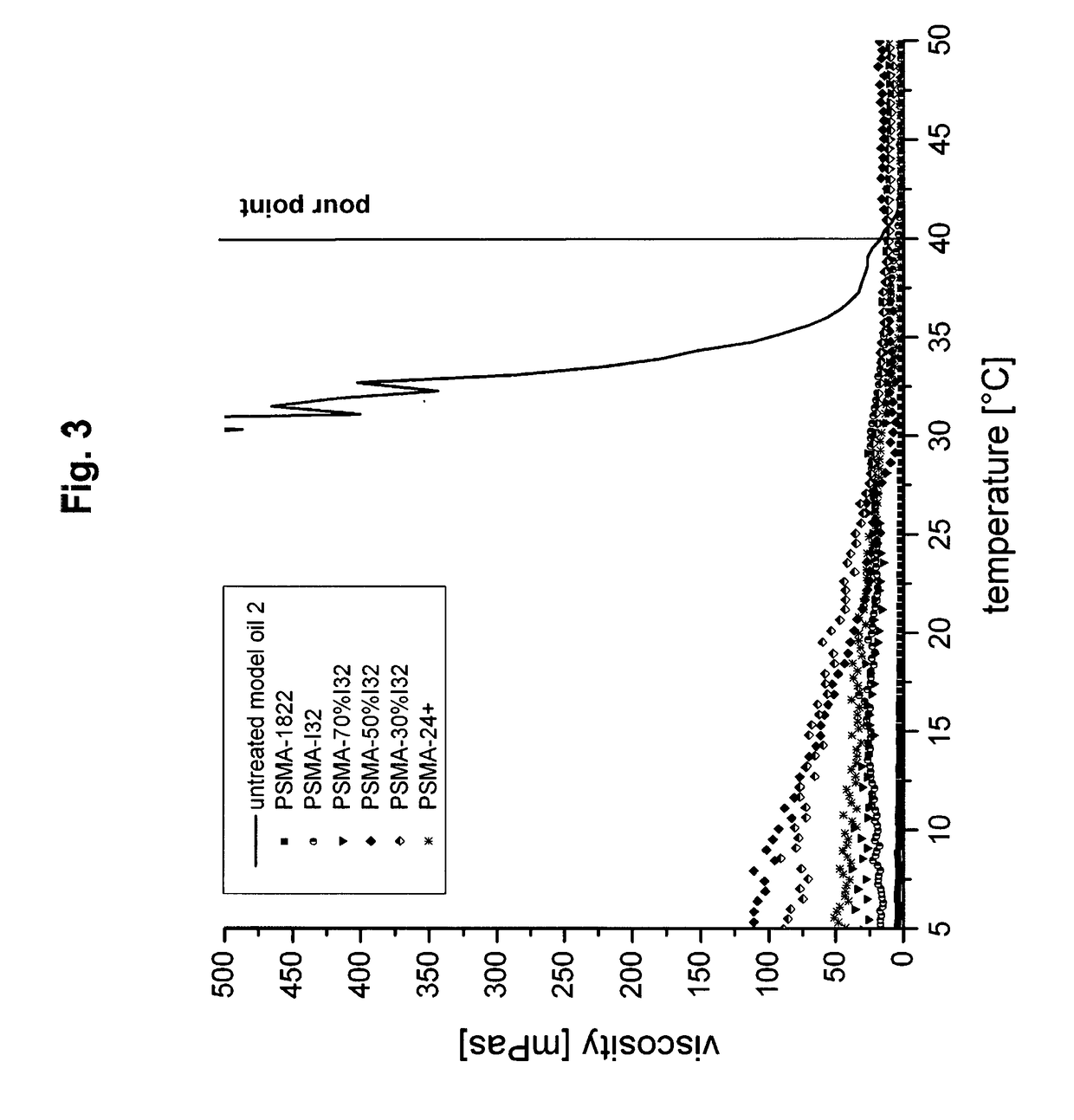

Use of Polymeric Additives for Paraffin-Containing Fluids

ActiveUS20180371353A1Low viscosity propertiesImprove performanceLubricant compositionParaffin waxChemistry

The present invention is concerned with the use of polymeric additives for paraffin-containing fluids as pour point depressants and low temperature flow improvers, wherein the polymers comprise styrene and maleic acid dialkyl ester building blocks.

Owner:SASOL CHEMICALS GMBH

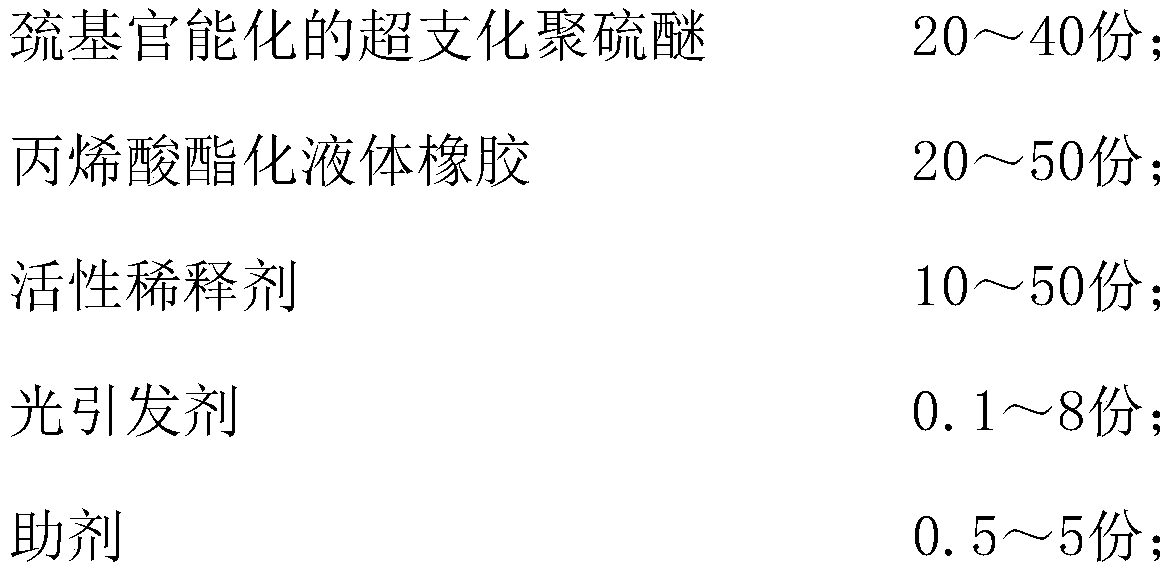

OLED terminal protection adhesive capable of being quickly cured by UV LED

ActiveCN111171729AThe synthesis method is simpleLow costOrganic non-macromolecular adhesiveAcrylate esterReactive diluent

The invention discloses an OLED terminal protective adhesive capable of being quickly cured by an UV LED. The OLED terminal protective adhesive is prepared by mixing the following components in partsby weight: 20-40 parts of sulfydryl-functionalized hyperbranched polythioether, 20 to 50 parts of acrylic acid esterification liquid rubber, 10 to 50 parts of a reactive diluent, 0.1 to 8 parts of a photoinitiator and 0.5 to 5 parts of an auxiliary agent. The sulfydryl-functionalized hyperbranched polythioether is synthesized by a method of A2+BX. According to a formula in the invention, the sulfydryl-functionalized hyperbranched polythioether is used as a protective adhesive of key resin, and the OLED terminal protective adhesive has excellent curing speed, storage stability, colloid strength, water absorption, adhesive force, reliability and the like and is an OLED terminal protective adhesive material which has excellent properties and can be rapidly cured by the UV LED.

Owner:东莞市联灏新材料技术开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com