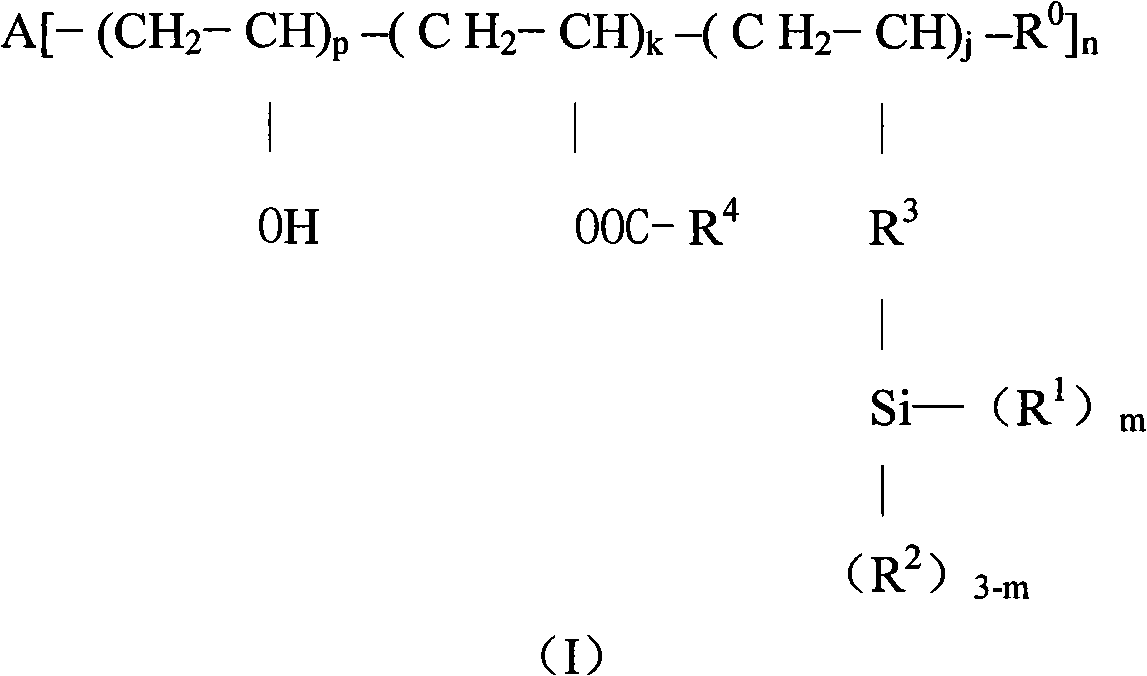

Vinyl alcohol series polymer

A vinyl alcohol-based polymer technology, applied in the direction of unsaturated alcohol copolymer adhesives, adhesive types, water repellent addition, etc., can solve problems such as difficult active polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] This example is for the preparation of vinyl alcohol polymers by traditional free radical polymerization

[0098] A. Polymerization

[0099] In a 250ml four-neck flask equipped with a stirrer, constant pressure dropping funnel, nitrogen gas and reflux condensing device, add 1.8mmol of divinylbenzene, 300mmol of vinyl acetate, and 0.45mmol of azobisisobutyronitrile (AIBN) , Methanol 100ml. Place the four-necked bottle in a temperature-controlled water bath, blow nitrogen and oxygen for 30 minutes, raise the temperature to 60°C while stirring, and stir and react at 60°C for 60 minutes, then slowly add dodecyl mercaptan (DDT) to the system dropwise 0.135mmol, dropped within 30min, and ended after a total of 1.5h of reaction.

[0100] B. Saponification

[0101] After 1.5 h of reaction time, the above reaction solution was cooled to 40° C., then 3 g of 8% NaOH in methanol was added, and the saponification reaction was continued to stir at 40° C. for 2 h.

[0102] C. refi...

Embodiment 2

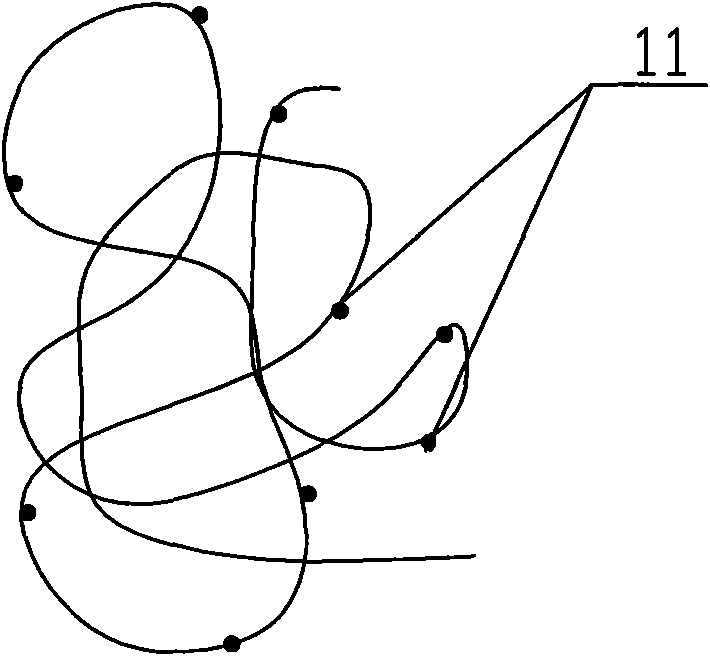

[0106] In this example, a traditional free radical polymerization method is used to prepare vinyl alcohol polymers modified with silane groups.

[0107] Except that in the polymerization step A, when slowly adding 0.135mmol of dodecyl mercaptan (DDT) to the system, and adding 1.5mmol of vinyltrimethoxysilane, the rest are carried out in the same way as in Example 1. Carry out polymerization, saponification and refining to obtain a core and arm star composed of divinylbenzene cross-linked product as the gel core and vinyl alcohol polymer arms modified by silane groups connected to the core. A vinyl alcohol-based polymer with a molecular structure.

Embodiment 3

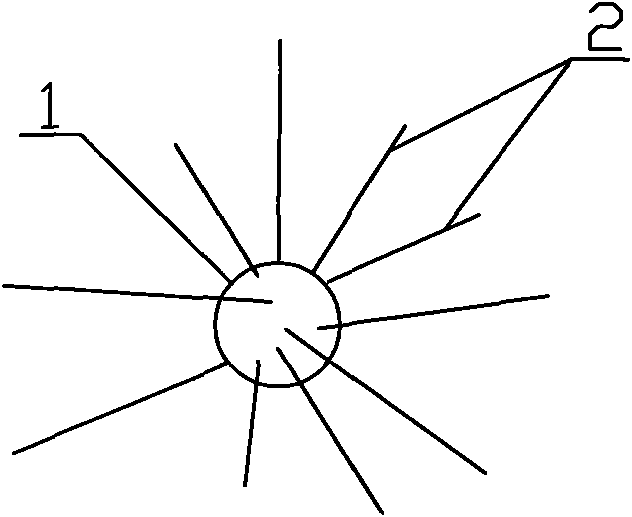

[0109] This example uses atom transfer radical polymerization (ATRP) to synthesize the core of the gel core, and then uses the traditional free radical polymerization method to prepare vinyl alcohol polymers

[0110] A. The core of the synthetic gel core

[0111] a. Calibrate the standard time of the synthesis reaction: In a 25ml polymerization tube equipped with magnetic stirring, vacuuming and argon gas device, add 0.0625mmol of 2-bromo(2-methyl)propionate methyl ester, divinyl Benzene 6.25mmol, cuprous chloride 0.0625mmol, 2,2′-bipyridine 0.125mmol, xylene 10ml, after sealing, stir evenly at 0°C, and the reaction solution was frozen-vacuum-thawed-argon gas for 5 times After deoxygenation, close the reactor under the protection of nitrogen, put it into a water bath temperature control device, raise the temperature while stirring, and stir the reaction at 50 ° C. After the reaction time of 3 minutes, the system is cooled down, and the catalyst is deactivated by passing oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com