OLED terminal protection adhesive capable of being quickly cured by UV LED

A fast-curing and protective adhesive technology, applied in adhesives, non-polymer organic compound adhesives, etc., can solve problems such as high energy consumption, high cost, and environmental pollution, and achieve cost reduction, low water absorption, and simple and efficient synthesis methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the terminal protection glue is the prior art, and the preparation method of the terminal protection glue will not be described in detail here.

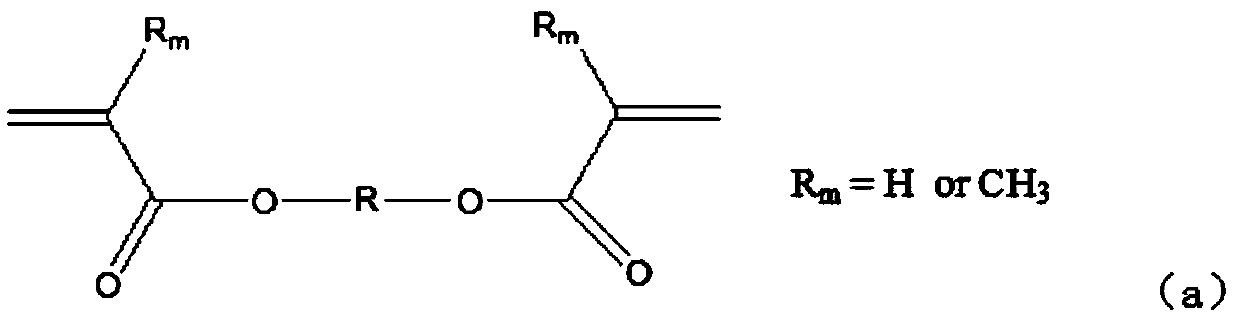

[0033] The "A2" is a difunctional acrylate, as represented by general formula (a):

[0034]

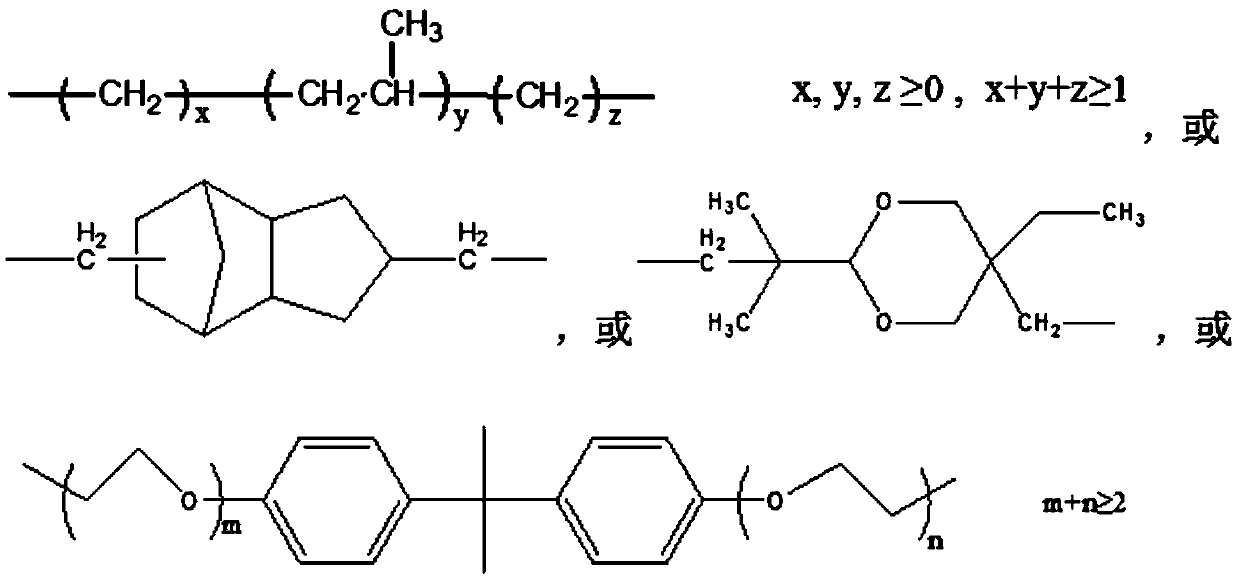

[0035] In the formula, R represents a divalent straight-chain or branched alkylene group, or a molecular segment containing a heterocyclic ring, a benzene ring, or a spiro ring structure, selected from the following structures:

[0036]

[0037]

[0038] "B X In "X=3~6, it is the compound that contains three or more than three polythiol functional groups.

[0039] The acrylated liquid rubber refers to viscous liquid rubber based on isoprene or butadiene modification, which has been acrylated, and the acrylated liquid rubber is preferably UC-102, UC -203 or NISSO-PB TE-2000 of Nippon Soda Co., Ltd.

[0040]The reactive diluent contains an acrylate monomer with a long-chain alkyl or heterocyclic str...

Embodiment 1

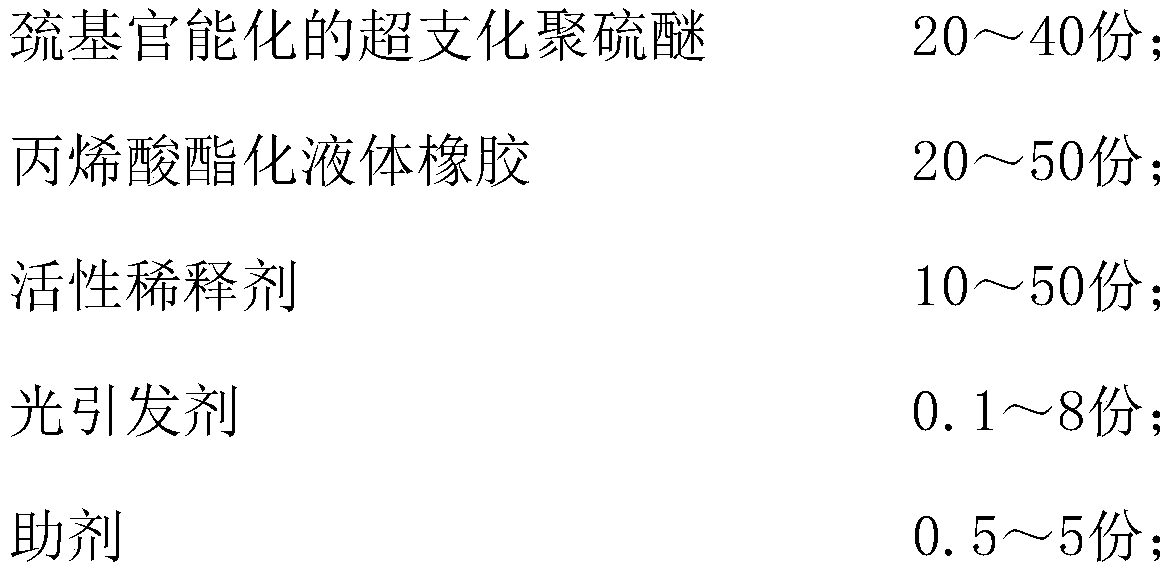

[0045] This embodiment provides OLED terminal protective glue that can be quickly cured by UV LED. By weight, the weight parts of each component are as follows:

[0046]

[0047]

[0048] The hyperbranched polysulfide of described mercapto functionalization is self-made, and by weight, the required material of resin synthesis reaction is:

[0049] Dioxanediol diacrylate: 65.2g

[0050] TMMP: 95.7g

[0051] Catalyst: 0.5g

[0052] The catalyst is Et 3 N.

[0053] The preparation method of the hyperbranched polysulfide of described thiol functionalization, comprises following specific steps:

[0054] Step A: Prepare the various component materials required for the above resin synthesis reaction by weight.

[0055] Step B: Add the TMMP and catalyst weighed in step A in a four-necked flask equipped with a stirrer, a thermometer, a condenser tube, a nitrogen pipe and a constant pressure funnel; Slowly add dioxanediol diacrylate dropwise in the pressure funnel. After the...

Embodiment 2

[0057] A kind of OLED terminal protective glue that can be quickly cured by UV LED, by weight, the weight parts content of each component is as follows:

[0058]

[0059] The hyperbranched polysulfide of described mercapto functionalization is self-made, and by weight, the required material of resin synthesis reaction is:

[0060] 1,6-hexanediol diacrylate: 22.6g

[0061] PEMP: 73.3g

[0062] Catalyst: 0.3g

[0063] The catalyst is pyridine.

[0064] The preparation method of the hyperbranched polysulfide of described thiol functionalization, comprises following specific steps:

[0065] Step A: Prepare the various component materials required for the above resin synthesis reaction by weight.

[0066] Step B: Add the PEMP weighed in step A and the catalyst in a four-necked flask equipped with a stirrer, a thermometer, a condenser tube, a nitrogen pipe and a constant pressure funnel; Slowly add 1,6-hexanediol diacrylate dropwise into the funnel. After the dropwise additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com