Naphthol resin, epoxy resin, epoxy resin composition, and solidified products thereof

A technology of naphthol resin and epoxy resin, which is applied in the field of epoxy resin composition and its cured product, can solve the problem of not meeting the influence of epoxy resin or curing agent, curability and physical properties, and the limitation of high filling rate and other problems, to achieve the effects of excellent curability, excellent symmetry, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

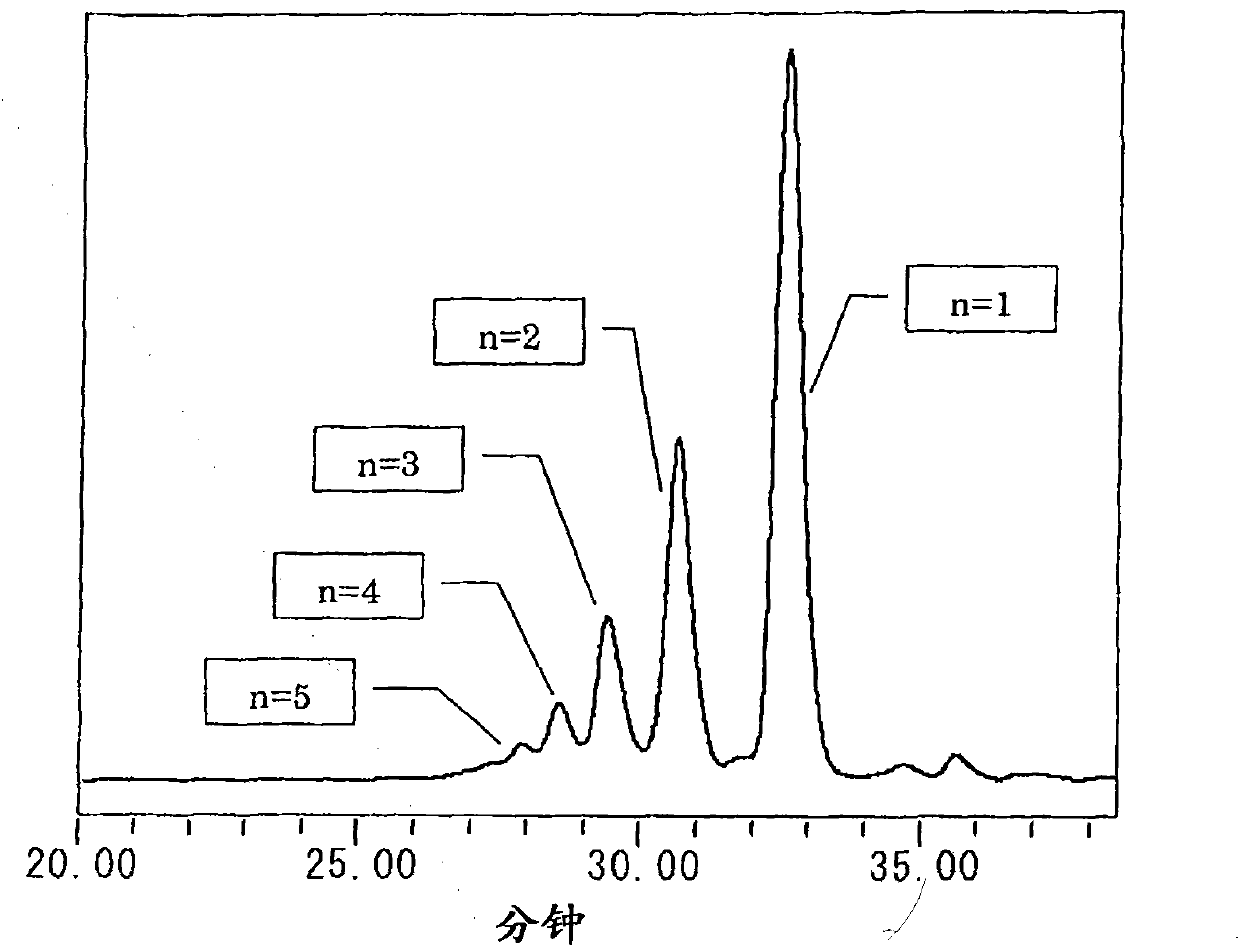

[0065]400 g of 1-naphthol and 200 g of chlorobenzene were added to a 1 L four-neck detachable flask equipped with a stirrer, a cooling tube, and a nitrogen gas introduction tube, and heated to 60° C. while introducing nitrogen gas to dissolve them. Thereafter, a mixed solution of 152 g of 1,4-dichloromethylbenzene and 152 g of chlorobenzene was added dropwise, stirring, and reacted at 60° C. for 6 hours. During this period, hydrogen chloride produced by the reaction was discharged outside the system. Thereafter, after removing ionic components by washing with water, chlorobenzene and unreacted 1-naphthol were removed by distillation under reduced pressure to obtain 275 g of a naphthol resin (naphthol resin A). The softening point of the obtained resin was 93° C., the melt viscosity at 150° C. was 0.21 Pa·s, and the hydroxyl equivalent was 215. According to the GPC measurement results, the proportions of n=1 body, n=2 body, n=3 body, n=4 body, and n≥5 bodies are 52wt%, 24wt%, ...

Embodiment 2

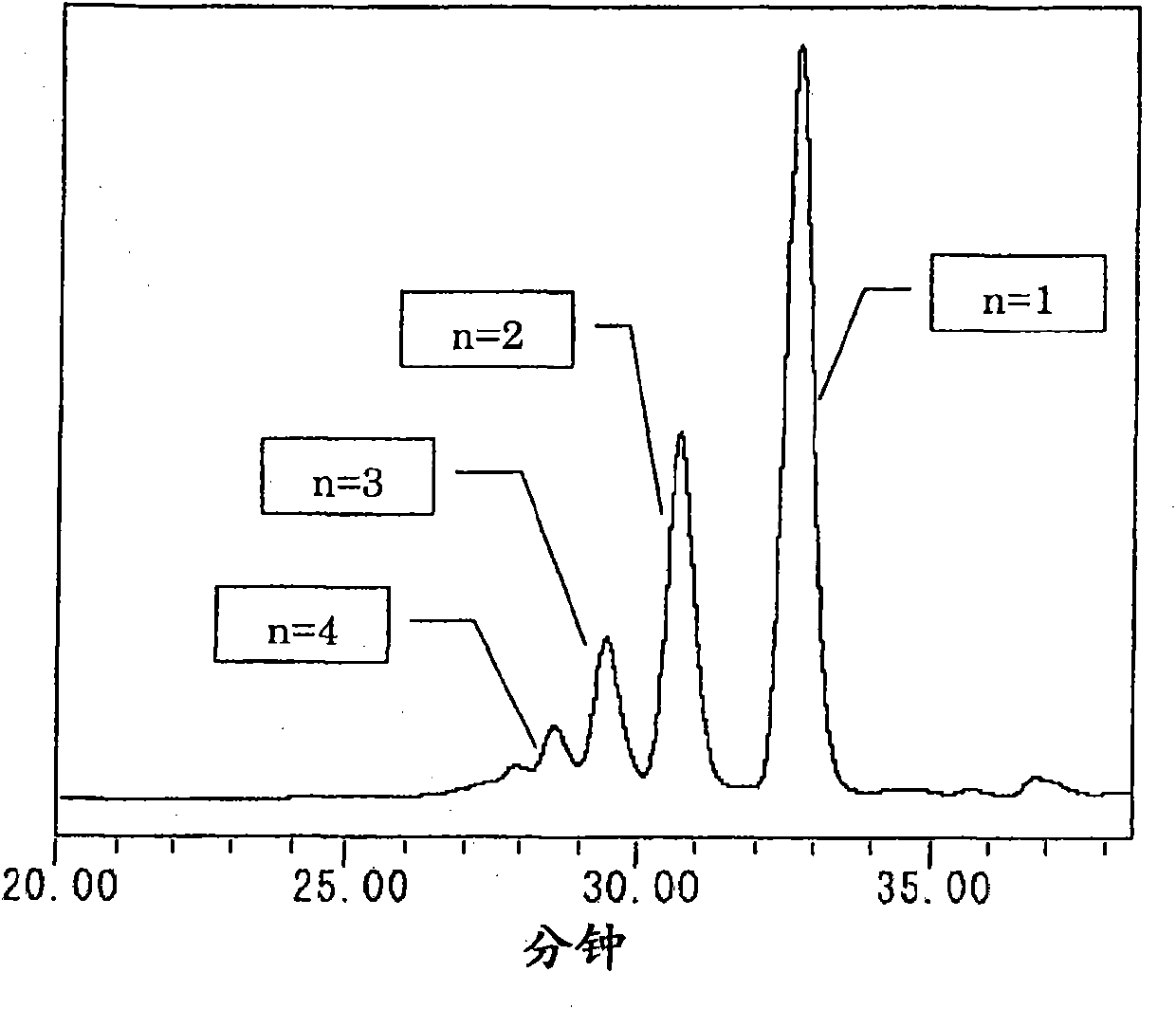

[0068] 400 g of 1-naphthol and 200 g of toluene were put into a 1 L four-necked separable flask equipped with a stirrer, a cooling pipe, and a nitrogen gas introduction pipe, and heated to 40° C. while nitrogen gas was introduced to dissolve them. Thereafter, a mixed solution of 68 g of 1,4-dichloromethylbenzene and 68 g of toluene was added dropwise, stirring, and reacted at 40° C. for 12 hours. During this period, hydrogen chloride produced by the reaction was discharged outside the system. Then, after removing ionic components by water washing, toluene and unreacted 1-naphthol were removed by vacuum distillation, and 134 g of naphthol resins were obtained (naphthol resin B). The softening point of the obtained resin was 85° C., the melt viscosity at 150° C. was 0.09 Pa·s, and the hydroxyl equivalent was 218. According to the GPC measurement results, the proportions of n=1 body, n=2 body, n=3 body, n=4 body are 72wt%, 19wt%, 5wt%, 1wt%, respectively, weight average molecula...

Embodiment 3

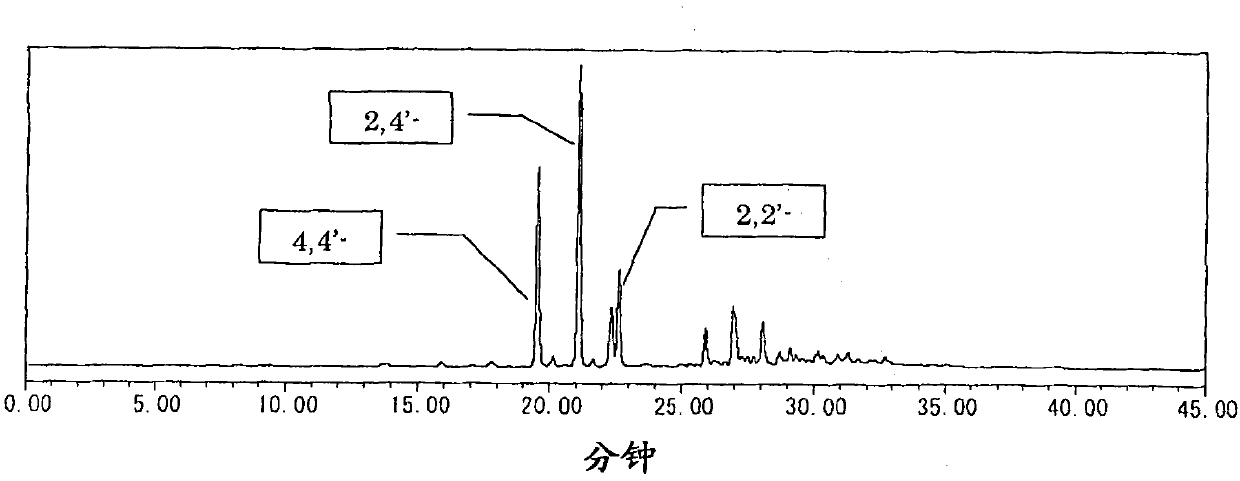

[0070] Dissolve 100 g of naphthol resin A obtained in Example 1 in 260 g of epichlorohydrin and 36 g of diglyme, and add 48% aqueous sodium hydroxide solution 37.5 g under reduced pressure (about 100 mmHg) at 60° C. for 4 hours. g. During this period, the generated water is discharged out of the system through azeotropy with epichlorohydrin, and the distilled epichlorohydrin is returned to the system. After the dropwise addition, the reaction was continued for 1 hour. Thereafter, epichlorohydrin and diglyme were distilled off under reduced pressure, dissolved in 420 g of methyl isobutyl ketone, and the generated salt was removed by filtration. Then, 10 g of 48% sodium hydroxide aqueous solution was added, and it was made to react at 80 degreeC for 2 hours. After the reaction, filtration and water washing were performed, and methyl isobutyl ketone as a solvent was distilled off under reduced pressure to obtain 113 g of a brown epoxy resin (epoxy resin A). The obtained resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com