Monodisperse micron level spherical vaterite-type calcium carbonate and its prepn process

A technology of calcium carbonate and vaterite, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of high price and complicated steps, and achieve the effects of simple method, uniform particle size distribution, and simple synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

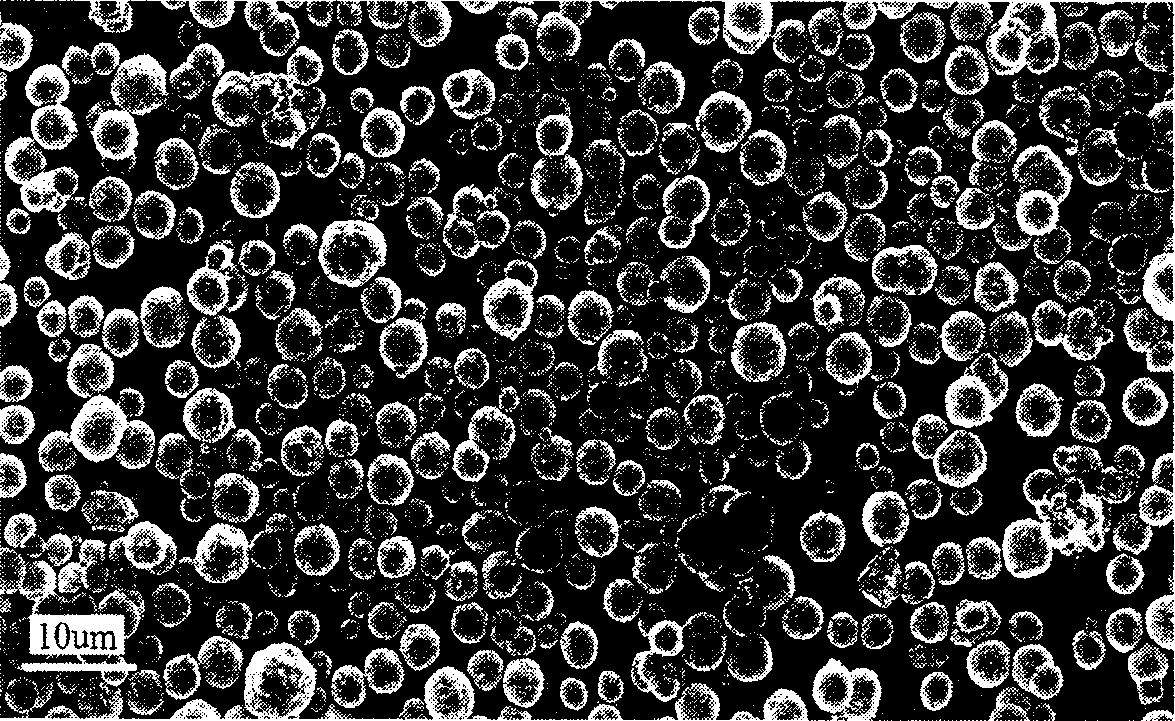

Embodiment 1

[0044] (1) Preparation of calcium salt aqueous solution: This step is for the configuration of an aqueous solution containing calcium ions. 2.775g of anhydrous calcium chloride solid is added to 1L of deionized water, and stirred until completely dissolved, and the pH of the solution is adjusted to 10. Obtaining concentration is 25mmol / L calcium chloride solution, standby;

[0045] (2) Preparation of an aqueous solution containing carbonate or bicarbonate: This step is for the preparation of an aqueous solution containing carbonate ions. Add 2.10 g of sodium bicarbonate solid to 1 L of deionized water, stir until completely dissolved, and adjust the solution The pH value is 10, obtains concentration and is 25mmol / L sodium bicarbonate solution, for subsequent use;

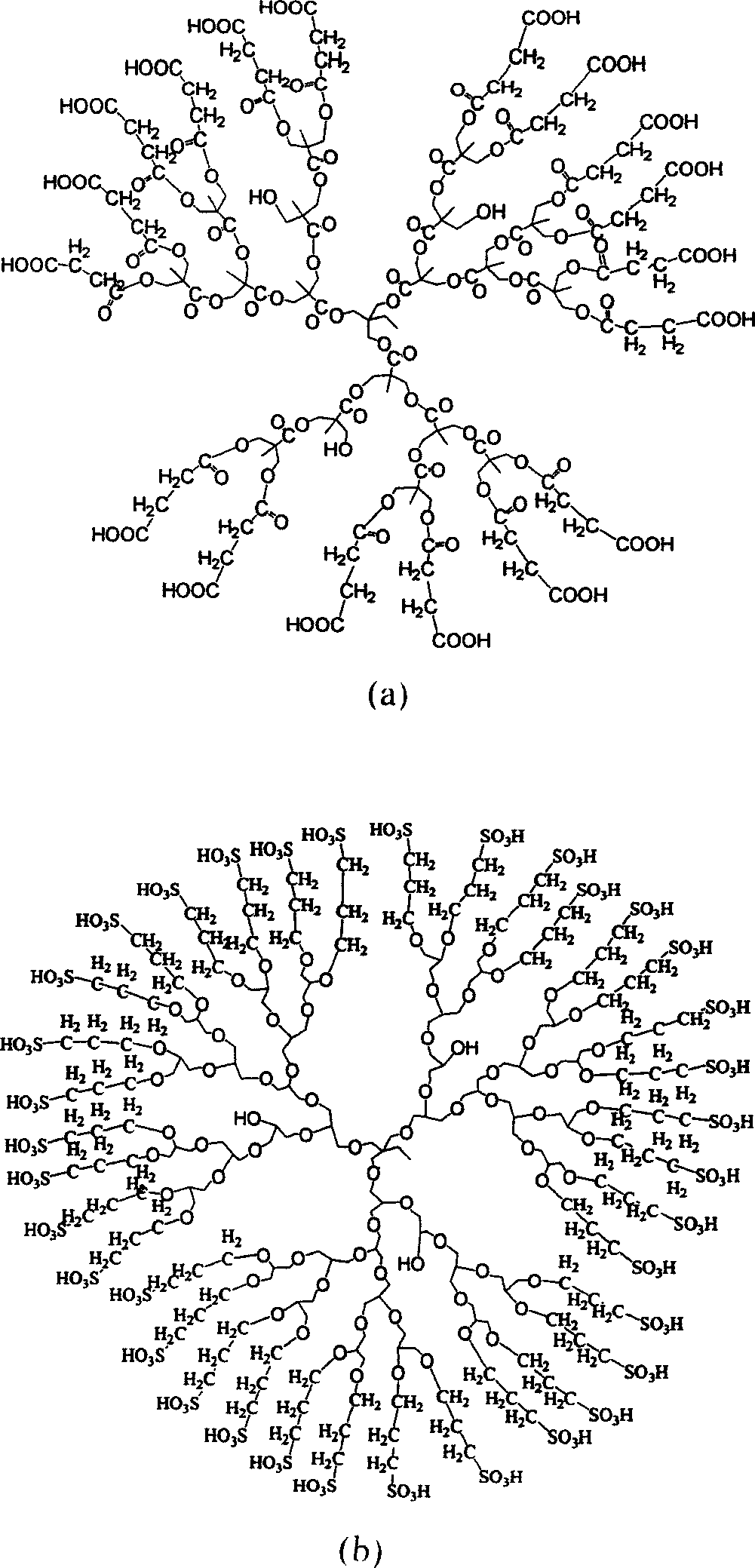

[0046] (3) Preparation of functionalized hyperbranched polymer aqueous solution: This step is for the aqueous solution configuration of carboxyl-functionalized hyperbranched polyester 3rd generation, and 1.0 g of ca...

Embodiment 2

[0051] (1) Preparation of calcium salt aqueous solution: This step is to prepare an aqueous solution containing calcium ions. Add 4.10 g of calcium nitrate solid to 1 L of deionized water, and stir until completely dissolved. Regulate the pH value of solution to be 10, obtain concentration and be 25mmol / L calcium nitrate solution, standby;

[0052] (2) Preparation of an aqueous solution containing carbonate or bicarbonate: This step is for the preparation of an aqueous solution containing carbonate ions. Add 2.50 g of potassium bicarbonate solid into 1 L of deionized water, and stir until completely dissolved. Regulate the pH value of solution to be 10, obtain concentration and be 25mmol / L potassium bicarbonate solution, for subsequent use;

[0053] (3) Preparation of functionalized hyperbranched polymer aqueous solution: This step is for the aqueous solution configuration of carboxyl-functionalized hyperbranched polyester 4th generation, and 3.0 g of carboxyl-functionalized h...

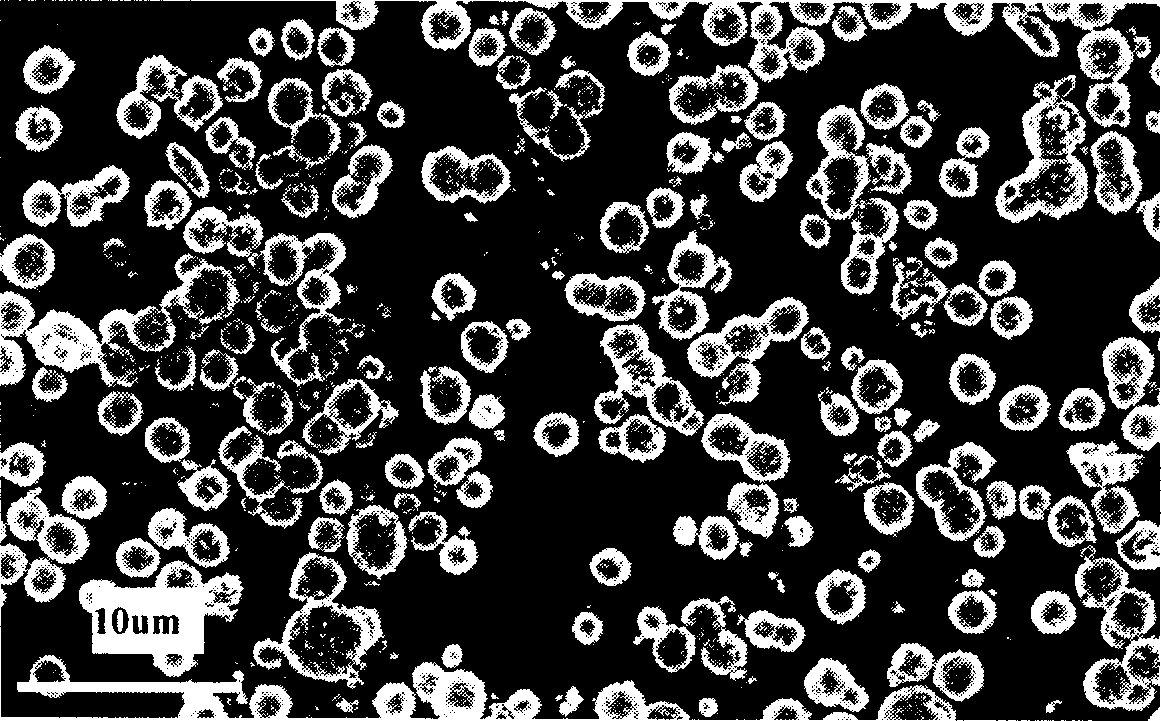

Embodiment 3

[0058] (1) Preparation of calcium salt aqueous solution: This step is to prepare an aqueous solution containing calcium ions. Add 4.10 g of calcium nitrate solid to 1 L of deionized water, and stir until completely dissolved. Regulate the pH value of solution to be 10, obtain concentration and be 25mmol / L calcium nitrate solution, standby;

[0059] (2) Preparation of an aqueous solution containing carbonate or bicarbonate: This step is for the preparation of an aqueous solution containing carbonate ions. Add 1.975 g of ammonium bicarbonate solid to 1 L of deionized water, and stir until completely dissolved. Regulate the pH value of solution to be 10, obtain concentration and be 25mmol / L ammonium bicarbonate solution, standby;

[0060] (3) Preparation of an aqueous solution of functionalized hyperbranched polymer: this step is for the configuration of an aqueous solution of the 3rd generation hyperbranched polyester containing sulfonic acid group functionalization, and 0.3 g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com