Cement-based grouting material applicable to narrow-space and long-distance grouting operation

A grouting material, cement-based technology, applied in the field of preparation of the cement-based grouting material, can solve problems such as viscous resistance, ignoring the viscosity requirements of the slurry, unfavorable grouting operations, etc., to achieve low viscosity performance and continuously expand the flow capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

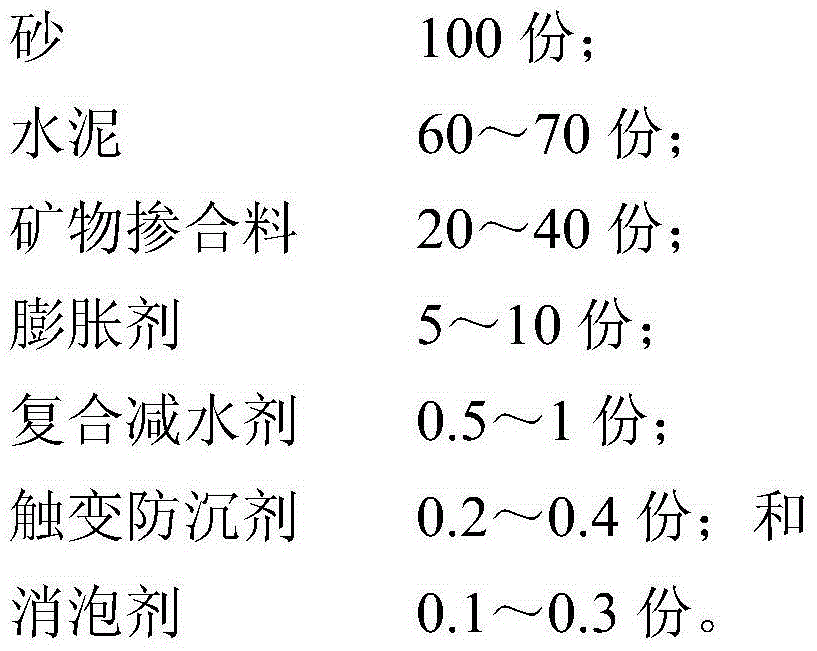

[0022] The ratio of raw materials for cement-based grouting materials suitable for narrow spaces and long-distance grouting operations is as follows:

[0023]

[0024] Among them, based on the total weight of the composite water reducer, the polycarboxylate ether water reducer accounts for 20%, and the melamine water reducer accounts for 80%;

[0025] The thixotropic anti-settling agent is based on the total weight of the thixotropic anti-settling agent, attapulgite (325 mesh fineness) accounts for 90%, and hydroxypropyl methylcellulose ether (viscosity 15000mPa·s) accounts for 10%.

[0026] Preparation: Put the above-mentioned components into the mixer according to their respective parts by mass, and mix uniformly to obtain a dry mix; when in use, add water with 17% of the total mass of the dry mix to the obtained dry mix, and mix evenly. That is, a cement-based grouting material suitable for narrow spaces and long-distance grouting operations can be obtained.

[0027] Me...

Embodiment 2

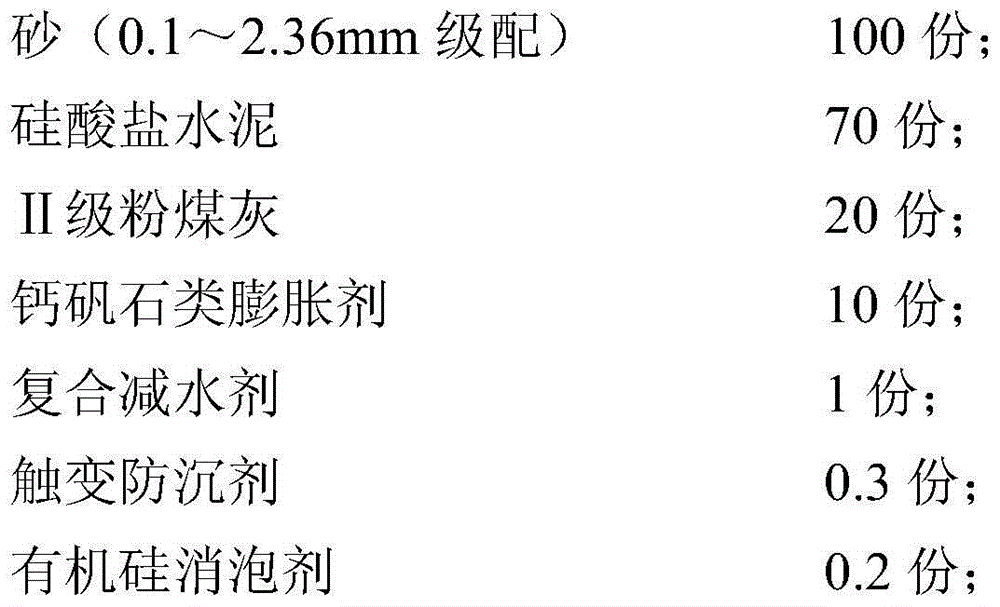

[0029] The ratio of raw materials for cement-based grouting materials suitable for narrow spaces and long-distance grouting operations is as follows:

[0030]

[0031] Among them, based on the total weight of the composite water reducer, the polycarboxylate ether water reducer accounts for 30%, and the melamine water reducer accounts for 70%;

[0032] The thixotropic anti-settling agent is based on the total weight of the thixotropic anti-settling agent, attapulgite (325 mesh fineness) accounts for 95%, and hydroxypropyl methylcellulose ether (viscosity 15000mPa·s) accounts for 5%.

[0033] Preparation: put the above-mentioned components into the mixer according to their respective parts by mass, and mix uniformly to obtain a dry mix; when in use, add water with 16% of the total mass of the dry mix to the obtained dry mix, and mix evenly. That is, a cement-based grouting material suitable for narrow spaces and long-distance grouting operations can be obtained.

[0034] Mea...

Embodiment 3

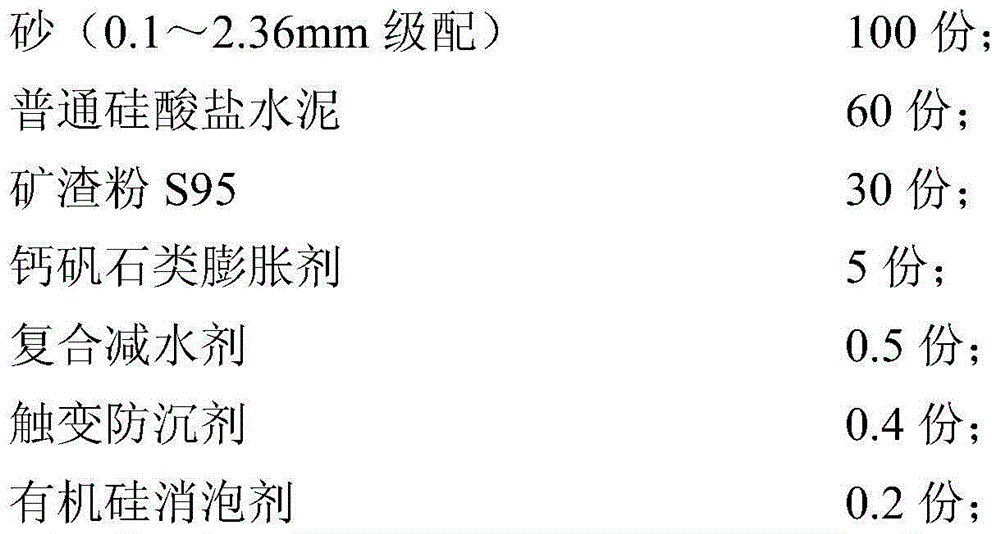

[0036] The ratio of raw materials for cement-based grouting materials suitable for narrow spaces and long-distance grouting operations is as follows:

[0037]

[0038] Among them, based on the total weight of the composite water reducer, the polycarboxylate ether water reducer accounts for 30%, and the melamine water reducer accounts for 70%;

[0039] The thixotropic anti-settling agent is based on the total weight of the thixotropic anti-settling agent, attapulgite (325 mesh fineness) accounts for 90%, and hydroxypropyl methylcellulose ether (viscosity 15000mPa·s) accounts for 10%.

[0040] Preparation: Put the above-mentioned components into the mixer according to their respective mass parts, and mix uniformly to obtain a dry mix; when in use, add water with 15% of the total mass of the dry mix to the obtained dry mix, and mix evenly. That is, a cement-based grouting material suitable for narrow spaces and long-distance grouting operations can be obtained.

[0041] Measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com