Process for preparing submicron grade superfine calcium carbonate dispersion particle

An ultra-fine calcium carbonate, submicron-level technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of complex process control, low yield per unit volume, complex process control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

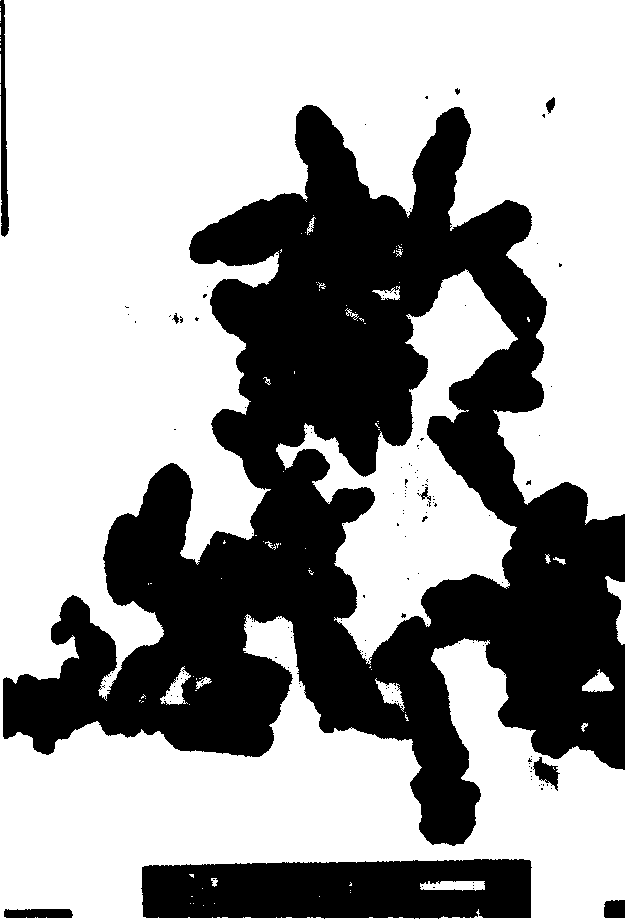

Embodiment 1

[0024] First prepare 15L of calcium hydroxide lime milk with a weight concentration of 10% and a temperature of 30°C, then add 9.6g of ammonium chloride, stir evenly, and then place the slurry in a height-diameter ratio of 8:1 and an inner diameter of 140mm In the bubble carbonization tower, to 25m 3 / h.m 3 The speed of lime milk is carbon dioxide gas with a volume content of 20% for carbonization. When the carbonization rate reaches 90%, 4.8 g of sodium polypropylene is added. When the carbonization reaches the pH value of 7, the ventilation is continued for 20 minutes, and the ventilation carbonization is stopped. Then the product obtained is filtered, baked, pulverized, observed under a transmission electron microscope, and the electron microscope photo is as follows figure 1 , the morphology of the obtained calcium carbonate is cubic or prismatic, the average particle size is 0.2 μm, the particle size distribution is narrow, and the specific surface area is 16 m 2 / g (us...

Embodiment 2

[0026] First prepare 15 L of calcium hydroxide lime milk with a concentration of 10% and a temperature of 55 ° C, add 38.8 g of sodium sulfate, stir evenly, and then place the slurry in a drum with a height-diameter ratio of 8:1 and an inner diameter of 140 mm. bubble carbonation tower, with 2m 3 / h.m 3 The speed of lime milk is to pass carbon dioxide gas with a volume content of 40% for carbonization. When the carbonization rate reaches 95%, add 38.4g sodium polypropylene. When the carbonization reaches the pH value of 6.5, continue to ventilate for 30 minutes, stop ventilating carbonization, and then The obtained product is filtered, dried, pulverized, and observed under a transmission electron microscope. The obtained calcium carbonate has a cubic or prismatic shape, an average particle size of 0.4 μm, a narrow particle size distribution, and a specific surface area of 13 m. 2 / g, the oil absorption value is 50DOPg / 100g.

Embodiment 3

[0028] First prepare 15 L of calcium hydroxide lime milk with a weight concentration of 12% and a temperature of 40 ° C, then add 15 g of sodium bicarbonate, stir evenly, and then place the slurry in a liquid with a height-diameter ratio of 8:1 and an inner diameter of 140 mm. In the bubble carbonization tower, with 15m 3 / h.m 3 The speed of the milk of lime is to pass carbon dioxide gas with a volume content of 30% for carbonization. When the carbonization rate reaches 90%, add 57.6g of sodium dodecyl sulfonate, and when the carbonization reaches the pH value of 6.5, continue to ventilate for 20 minutes and stop. Aerated carbonization, then the obtained product was filtered, dried, pulverized, and observed under a transmission electron microscope. The obtained calcium carbonate was cubic or prismatic in shape, with an average particle size of 0.5 μm, a narrow particle size distribution, and a specific surface area of 10.3 m. 2 / g, the oil absorption value is 48DOPg / 100g. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com