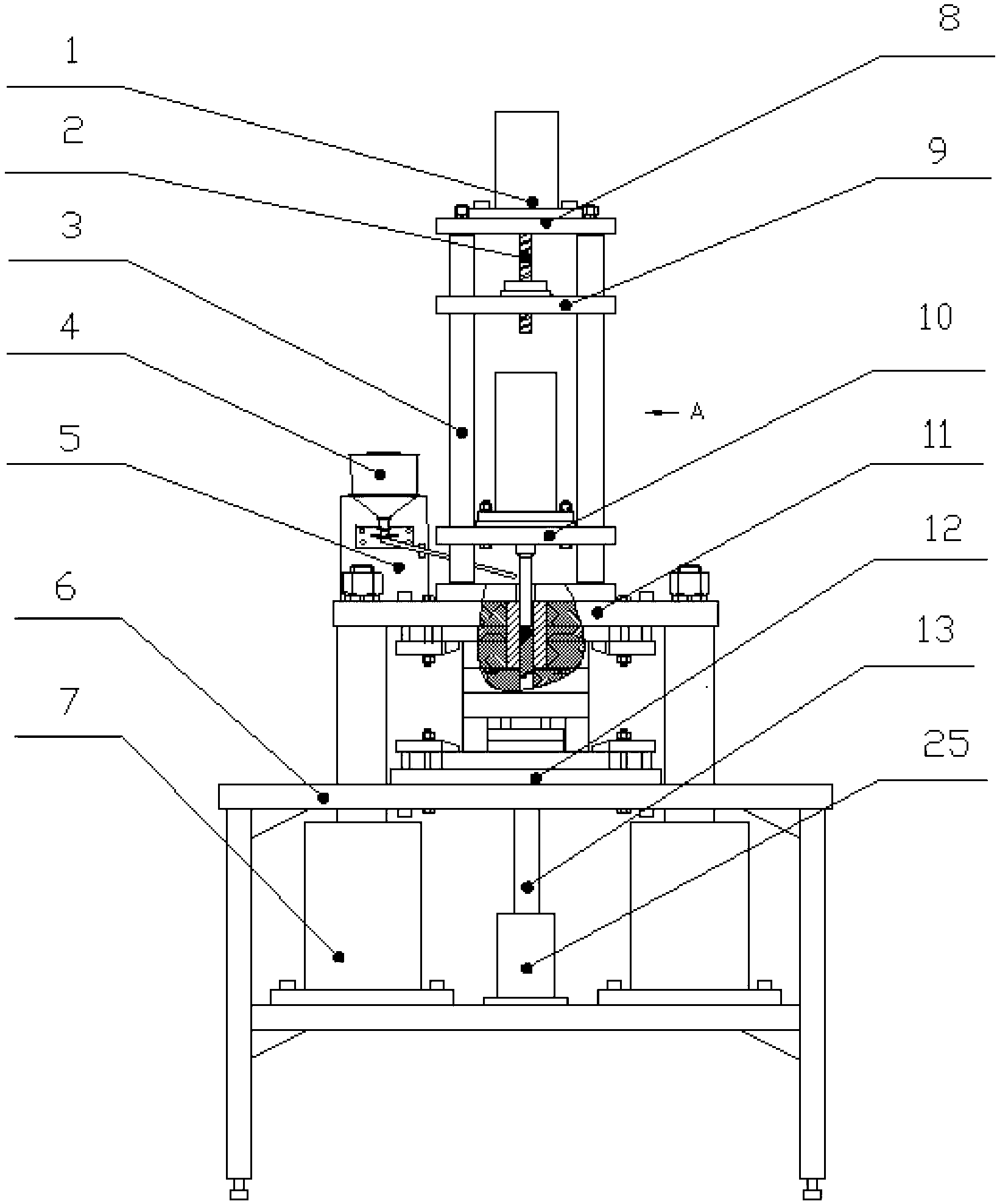

Screw-free ultrasonic microinjection molding device for molten and plasticized polymer and molding method

A technology of micro-injection and molding device, which is applied in the field of micro-injection molding device for ultrasonic melt-plasticizing polymer without screw, can solve the problems of difficult filling, unsuitable melting and plasticizing of micro-polymer, and lengthening of molding cycle, so as to reduce energy consumption and reduce energy consumption. The control difficulty of the process, the improvement of short shot or insufficient filling, and the effect of improving the economy of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

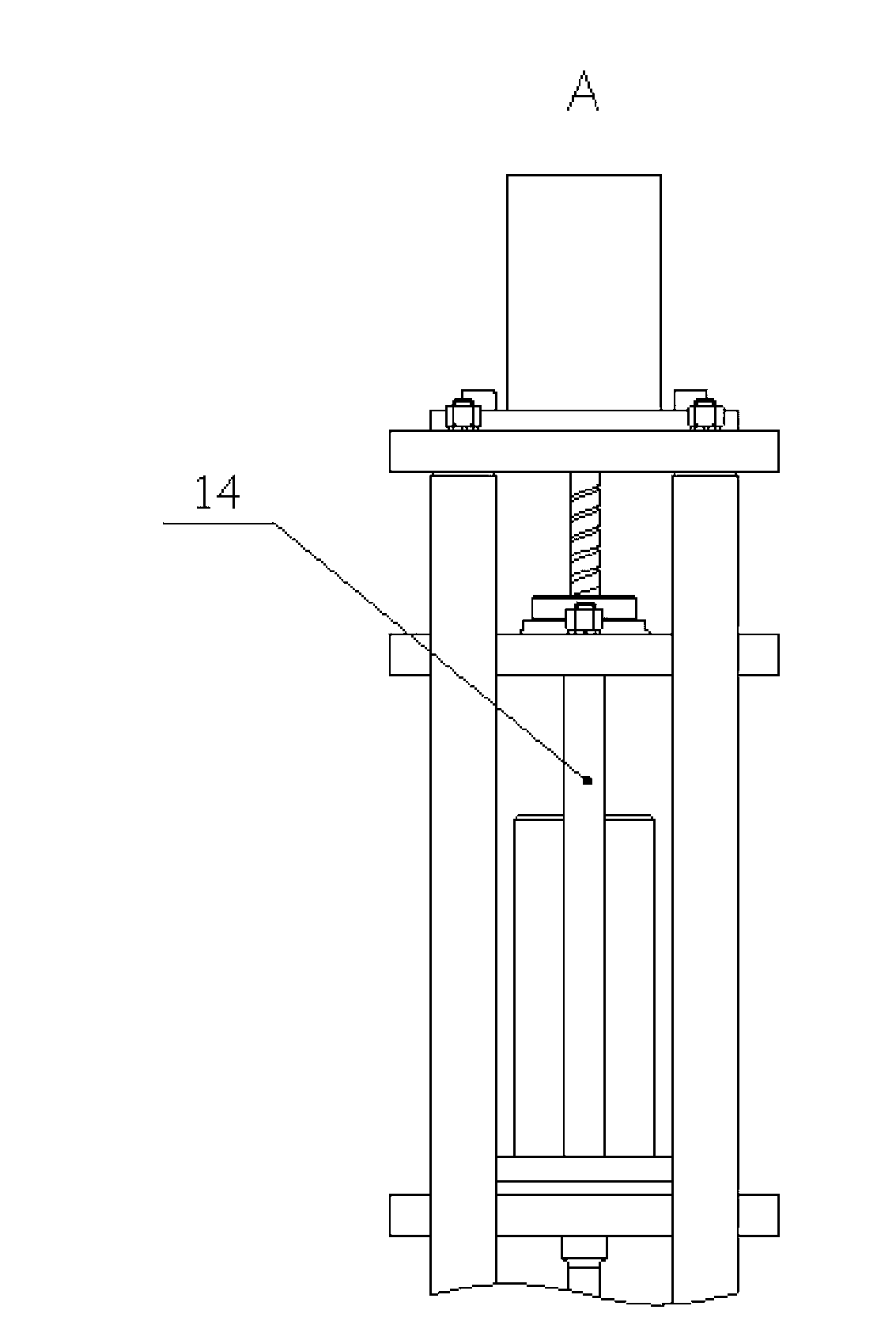

Method used

Image

Examples

Embodiment 1

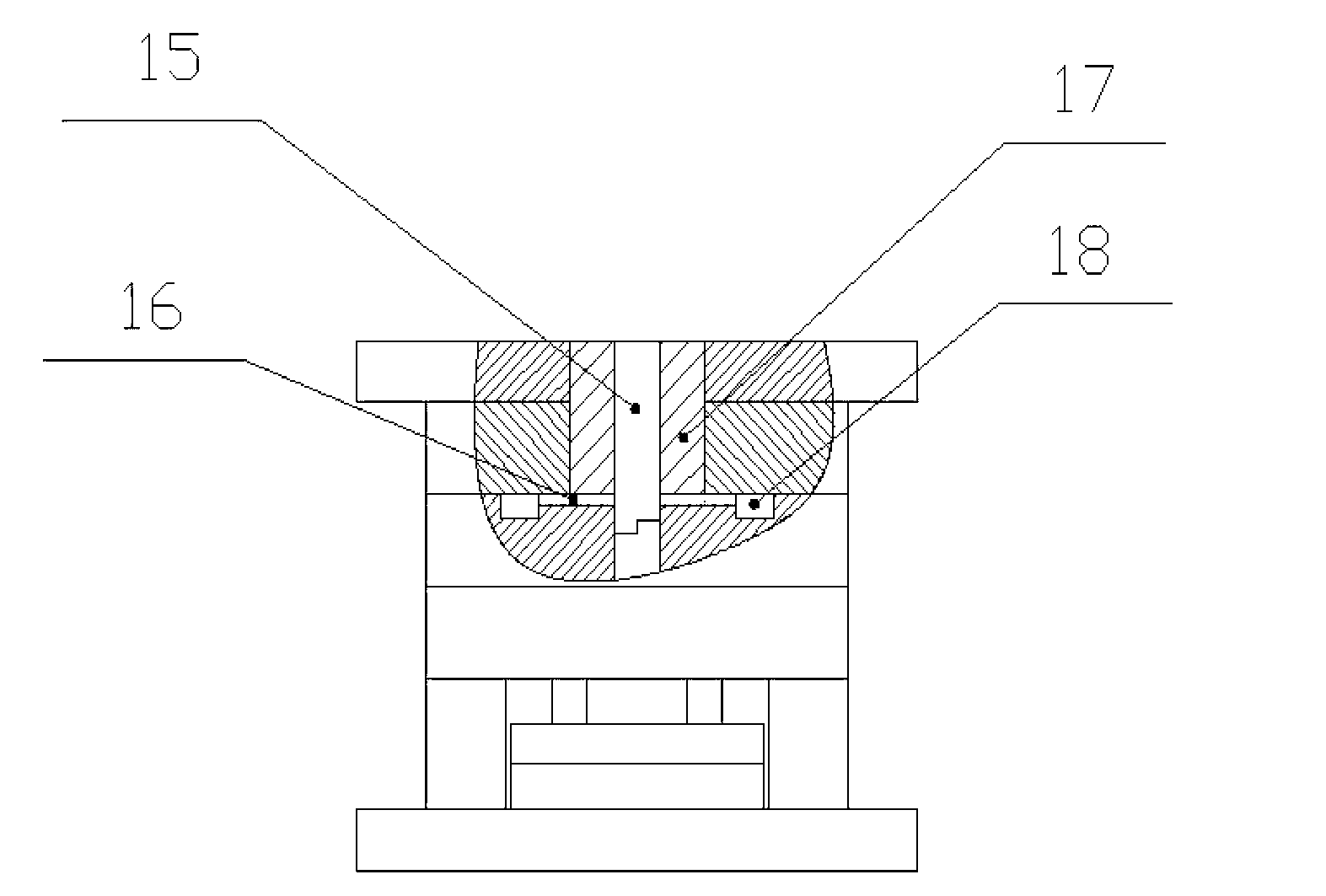

[0054] Turn on the clamping hydraulic cylinder to close the injection mold, add Abs to the feed hole, turn on the injection motor to move the ultrasonic tool head down, the frequency of the ultrasonic vibration system is 20Khz, the working power of the ultrasonic generator is 500W, and the amplitude of the tool head is 20μm. After the object is plasticized and formed, the ejection hydraulic cylinder is opened to complete the ejection of the part.

Embodiment 2

[0056] Turn on the clamping hydraulic cylinder to close the injection mold, add PC to the feed hole, turn on the injection motor to move the ultrasonic tool head down, the frequency of the ultrasonic vibration system is 20Khz, the working power of the ultrasonic generator is 750W, and the amplitude of the tool head is 50μm. After the object is plasticized and formed, the ejection hydraulic cylinder is opened to complete the ejection of the part.

Embodiment 3

[0058] Turn on the clamping hydraulic cylinder to close the injection mold, add PMMA to the feed hole, turn on the injection motor to move the ultrasonic tool head down, the frequency of the ultrasonic vibration system is 30Khz, the working power of the ultrasonic generator is 750W, and the amplitude of the tool head is 50μm. After the object is plasticized and formed, the ejection hydraulic cylinder is opened to complete the ejection of the part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com