Thermal interface material and preparation method thereof

A thermal interface material and thermosetting technology, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve problems such as insufficient thermal conductivity, and achieve the effects of cheap raw materials, stable performance and low viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

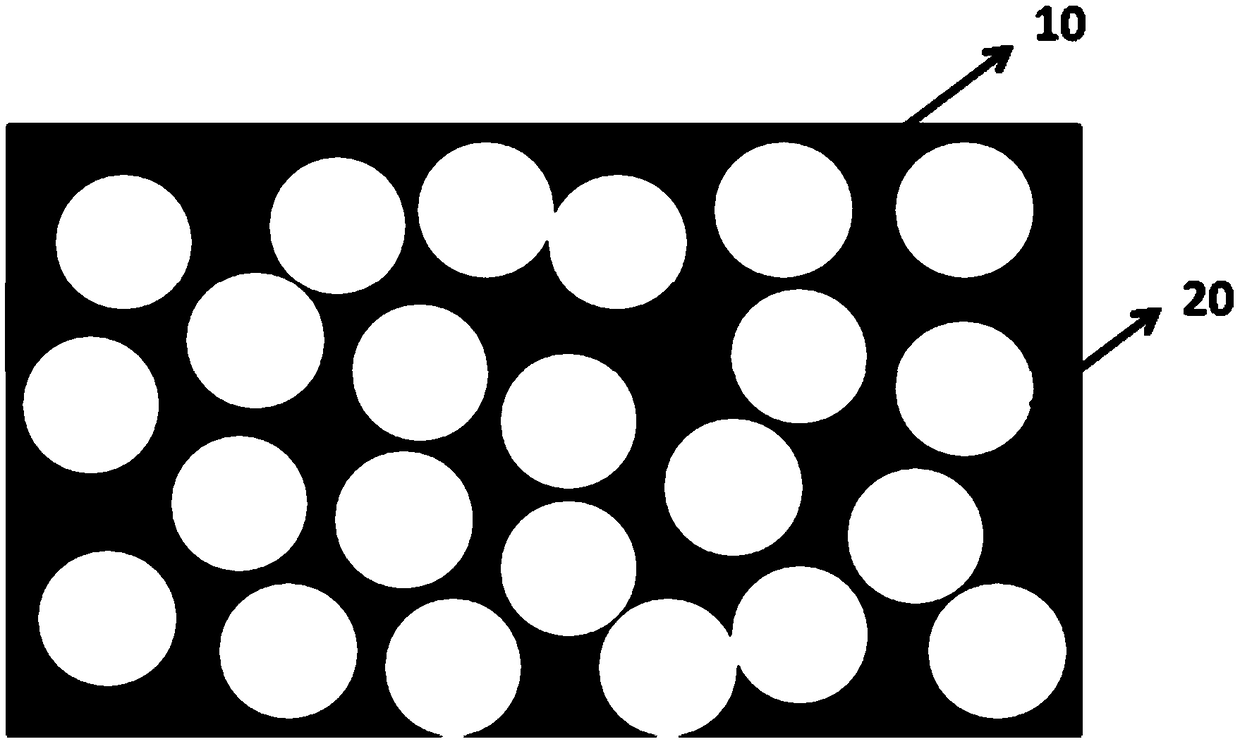

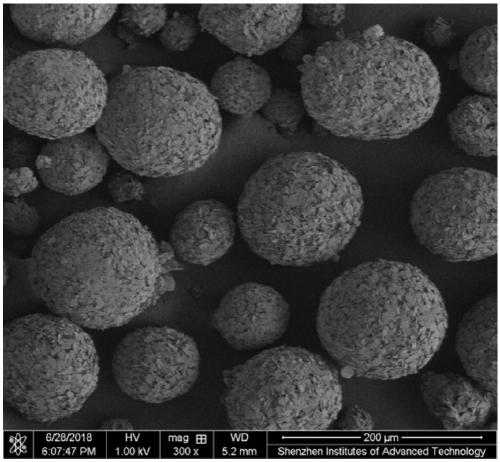

Image

Examples

preparation example Construction

[0037] Based on the above thermal interface material, an embodiment of the present invention also provides a preparation method of a thermal interface material, the preparation method includes the following steps:

[0038] S01: mixing the spherical boron nitride, thermosetting resin, curing agent, defoamer, coupling agent and diluent;

[0039] S02: heating and curing to obtain a thermal interface material.

[0040] The specific mixing process described in step S01 is to make the components mix uniformly, for example, a conventional mixing method can be used to mix the components. As in the specific embodiment, ball milling is used to mix the components thoroughly and evenly. When using ball milling for mixing treatment, the process parameters of the ball milling treatment are: ball milling speed 200-500 rpm; ball milling time 0.5-2 hours.

[0041] In addition, the components in step S01 are the same as those described in the thermal interface material above, and will not be ...

Embodiment 1

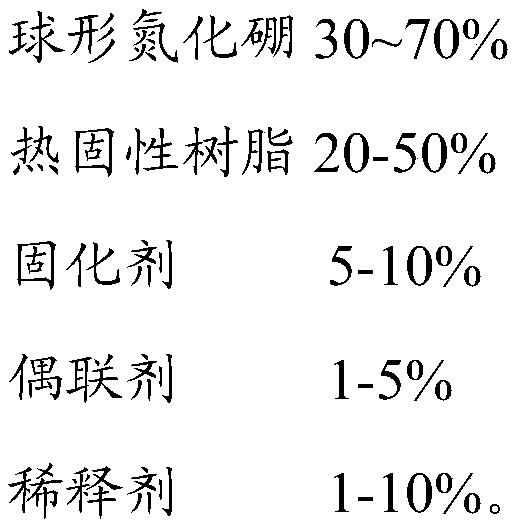

[0046] This embodiment provides a thermal interface material and a preparation method thereof. The thermal interface material is formed by components including the following mass percentages:

[0047] Spherical boron nitride: 30%, 5μm in diameter;

[0048] Thermosetting resin: 50% bisphenol A liquid epoxy resin;

[0049] Curing agent: 4% methyl hexahydrophthalic anhydride and 1% tris-(dimethylaminomethyl)phenol;

[0050] Coupling agent: 10% KH560 silane coupling agent;

[0051] Diluent: 5% n-butyl glycidyl ether.

[0052] The preparation method of the thermal interface material comprises the following steps:

[0053] The above raw materials are mixed evenly by ball milling process. The ball milling process parameters are: ball milling speed 500, ball milling time 0.5h. The resulting mixture was cured at 200° C. for 3 h to obtain the final thermal interface material.

Embodiment 2

[0055] This embodiment provides a thermal interface material and a preparation method thereof. The thermal interface material is formed by components including the following mass percentages:

[0056] Spherical boron nitride: 70%, 200μm in diameter;

[0057] Thermosetting resin: 20% bisphenol F type liquid epoxy resin;

[0058] Curing agent: 4% tetraethylenepentamine and 1% N,N-dimethylbenzylamine;

[0059] Coupling agent: 1% KH550 silane coupling agent;

[0060] Diluent: 4% 1,4-butanediol diglycidyl ether.

[0061] The preparation method of the thermal interface material comprises the following steps:

[0062] The above raw materials are mixed evenly by ball milling process. The ball milling process parameters are: ball milling speed 200, ball milling time 2h. The obtained mixture was cured at 200° C. for 2 h to obtain the final thermal interface material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com