Process based on molten-salt growth method for metallizing surface of ceramic base composite material member

A composite material component and surface metal technology, which is applied in the field of surface metallization of ceramic matrix composite material components, can solve the problems of composite material mechanical properties decline, uneven deposition thickness, complex surface properties, etc., and achieve fast preparation speed and high bonding strength , the effect of high binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

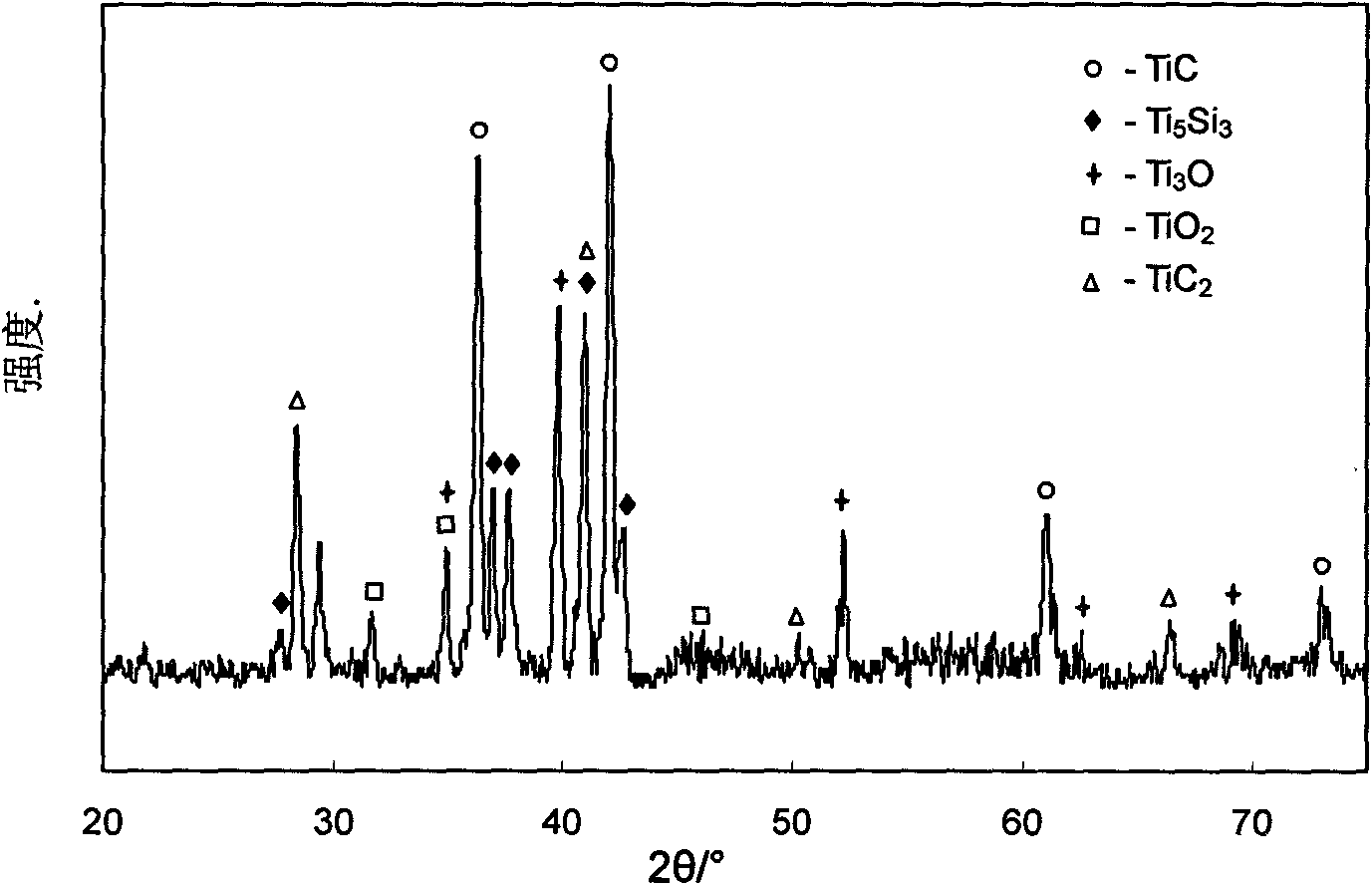

[0021] Example 1: C f / Ti metallization on the surface of SiC composites

[0022] The metallization process of the composite material in this embodiment is as follows:

[0023] 1. Prepare molten salt raw materials of the following quality: NaCl 340g, KCl 430g, K 2 TiF 6 330g and Ti powder 200g;

[0024] 2. Mix the molten salt raw materials prepared above evenly, place them in the crucible boiler, and then put C f The surface of the / SiC composite component is cleaned, dried and embedded in molten salt mixed raw materials. Under the protection of Ar gas atmosphere, the temperature is raised to 1000 °C at a rate of 10 °C / min, and after holding for 5 hours, it is cooled to room temperature with the furnace;

[0025] 3. Replace the above C f / SiC composite components were taken out, washed repeatedly in water, then ultrasonically cleaned with ethanol for 15 min, taken out and dried to obtain Ti-metallized C f / SiC composite components.

[0026] C after metallization of the ...

Embodiment 2

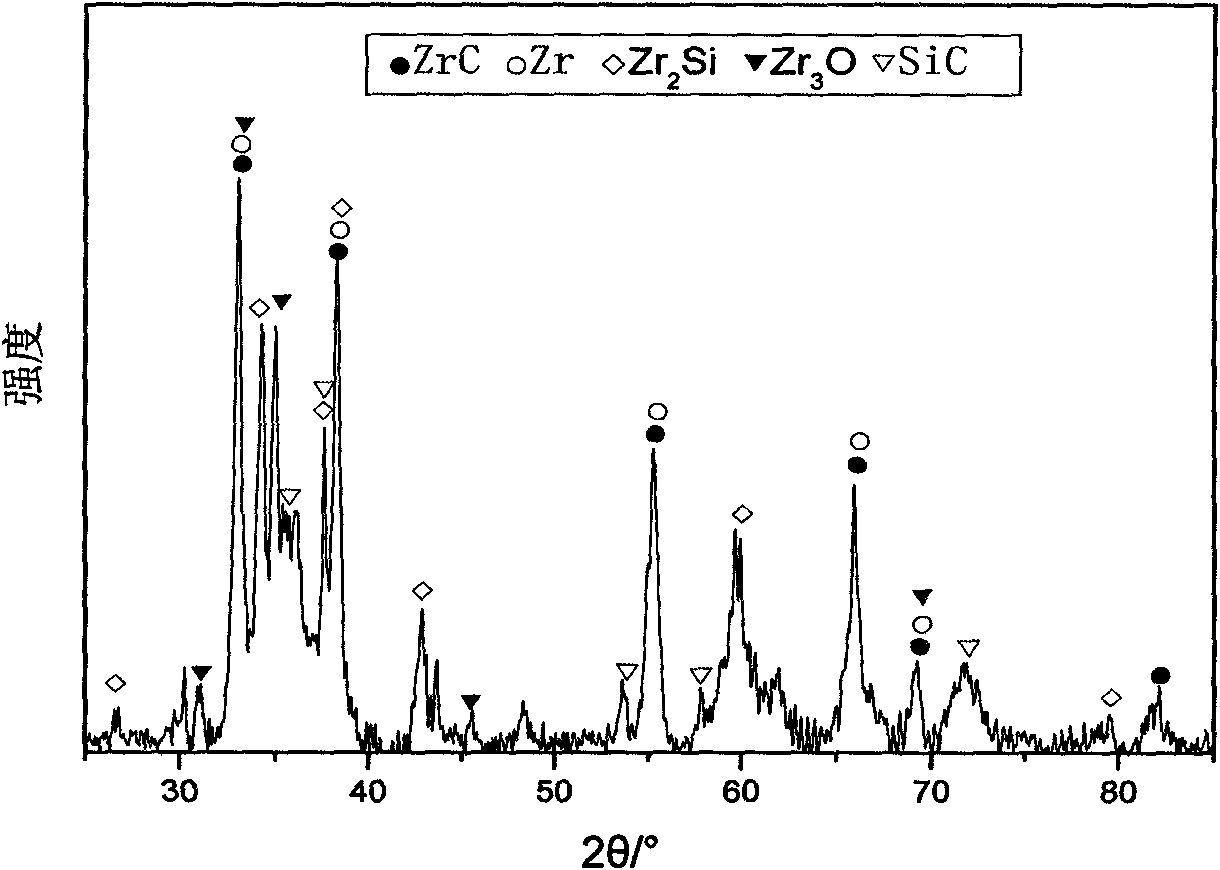

[0027] Example 2: C f Zr Metallization on the Surface of SiC Composites

[0028] The metallization process of the composite material in this embodiment is as follows:

[0029] 1. Prepare molten salt raw materials of the following quality: NaCl 400g, KCl 500g, K 2 ZrF 6 385g and Zr powder 370g;

[0030] 2. Mix the molten salt raw materials prepared above evenly, place them in the crucible boiler, and then put C f The surface of the / SiC composite component is cleaned, dried and embedded in molten salt mixed raw materials. Under the protection of Ar gas atmosphere, the temperature is raised to 1100 °C at a rate of 10 °C / min, kept for 3 hours, and then cooled to room temperature with the furnace;

[0031] 3. Replace the above C f / SiC composite components were taken out, washed repeatedly in water, then ultrasonically cleaned with ethanol for 15 min, taken out and dried to obtain Zr-metallized C f / SiC composite components.

[0032] C after metallizing the above surface Zr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com