Preparation method and application of high solid content low viscosity acrylic resin adhesive

An acrylic resin, high solid content technology, used in adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problem that the production efficiency cannot be improved faster, the surface state is prone to bubbles, and the solvent discharge remains high and other problems, to achieve the effect of reducing pollution and emissions to the atmospheric environment, reducing the use of solvents, and reducing the amount of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

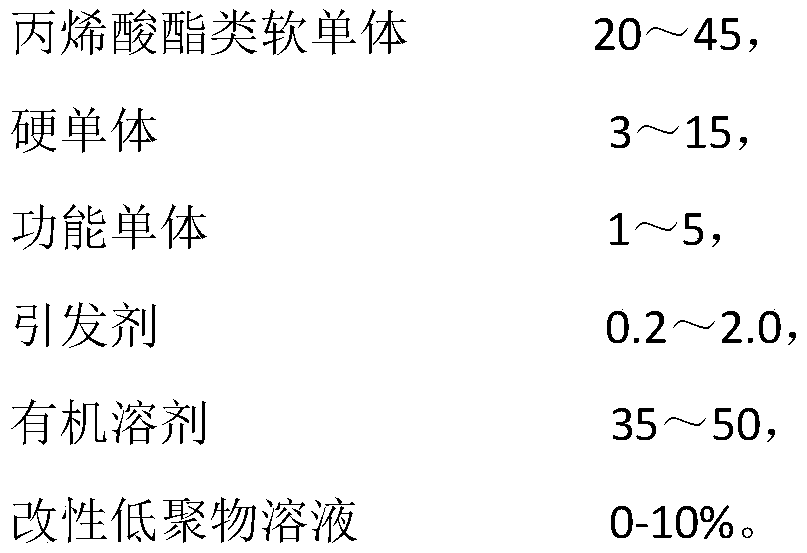

Method used

Image

Examples

Embodiment 1

[0030] (1) The organic solvent is a mixture of ethyl acetate and toluene, wherein the weight percentage of ethyl acetate in the organic solvent is 60%, and the weight of toluene is 40%.

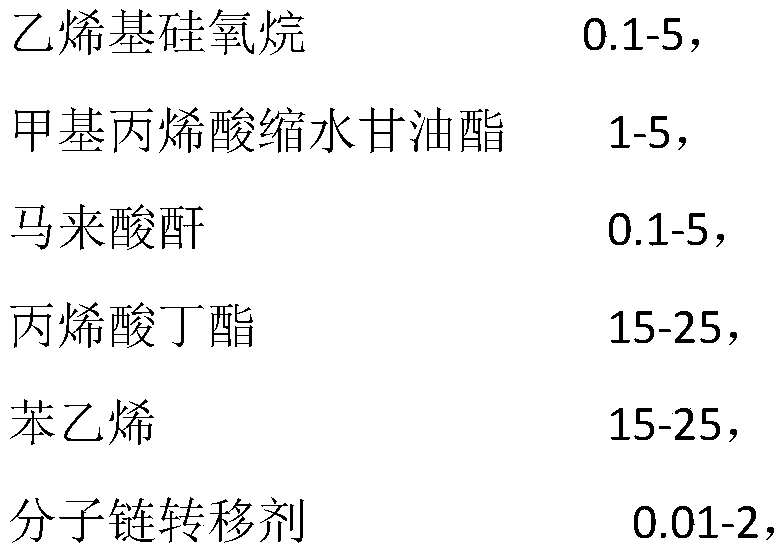

[0031] (2) 3 parts of vinyl triisopropoxysilane, 3 parts of glycidyl methacrylate, 3 parts of maleic anhydride, 20 parts of butyl acrylate, 20 parts of styrene, 1 part of dodecyl mercaptan, 90 36 parts of organic solvent of % weight part, 0.6 part of dilauroyl peroxide of 20% weight part, join at the bottom of reaction kettle, be warmed up to 80 ℃, after reacting for 40 minutes, mix remaining 2.4 parts of dilauroyl peroxide with organic solvent 3 parts were formulated as dilauroyl peroxide solution and added dropwise to the reaction kettle. After 4 hours of dropping, control the temperature to 80°C and keep it warm for 3 hours. Finally, add 1 part of the remaining organic solvent, cool down to 55°C and discharge to obtain modification. oligomer solution 1,

[0032] (3) Put all 35 parts of bu...

Embodiment 2

[0035] (1) The organic solvent is a mixture of ethyl acetate and toluene, wherein the weight percentage of ethyl acetate in the organic solvent is 70%, and the weight percentage of toluene is 30%.

[0036] (2) 5 parts of 3-methacryloxypropyltrimethoxysilane, 5 parts of glycidyl methacrylate, 5 parts of maleic anhydride, 25 parts of butyl acrylate, 25 parts of styrene, 3-mercaptopropane 2 parts of isooctyl esters, 40 parts of organic solvents of 80% by weight, and 1.5 parts of azobisisobutyronitrile of 30% by weight are added to the bottom of the reaction kettle, and the temperature is raised to 85 ° C. After 30 minutes of reaction, the remaining azobisisobutyronitrile 3.5 parts of azobisisobutyronitrile and 8 parts of organic solvent are formulated into azobisisobutyronitrile solution and added dropwise to the reaction kettle. After dropping for 3 hours, control the temperature to 83°C and keep it warm for 2 hours. Finally, add the remaining 2 parts of organic solvent , cooled...

Embodiment 3

[0040](1) The organic solvent is a mixture of ethyl acetate and toluene, wherein the weight percentage of ethyl acetate in the organic solvent is 80%, and the weight percentage of toluene is 20%.

[0041] (2) 0.1 part of triethoxysilane, 1 part of glycidyl methacrylate, 0.1 part of maleic anhydride, 15 parts of butyl acrylate, 15 parts of styrene, 0.01 part of α-methylstyrene linear dimer, 34 parts of organic solvents of 85% by weight, 0.01 part of azobisisoheptanonitrile of 5% by weight should be added to the bottom of the kettle, the temperature was raised to 78 ° C, and after 60 minutes of reaction, 0.19 parts of remaining azobisisoheptanonitrile was mixed with organic solvent 5 parts were added to the reaction kettle, and after 5 hours of dropwise addition, the temperature was controlled to 76°C and kept for 3 hours, and finally 1 part of the remaining organic solvent was added and the solvent was lowered to 50°C to discharge, and the modified oligomer solution 3 was obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com