Photocured organosilicone elastomer and preparation method and application thereof

A technology of elastomer and silicone, which is applied in the field of light-cured silicone elastomer and its preparation, can solve the problems of poor mechanical properties of light-cured elastomers, poor mechanical properties of transparent materials, and affecting the optical properties of materials, etc. Effect of curing rate, increasing crosslink density and mechanical strength, improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

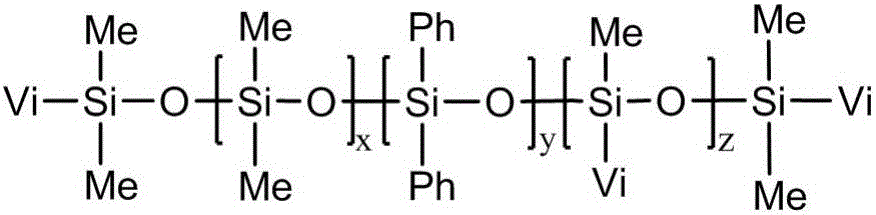

[0036] The preparation of embodiment 1 vinylmethylphenyl polysiloxane

[0037] 30g divinyltetramethyldisiloxane, 50g tetramethyltetravinylcyclotetrasiloxane, 100g octamethylcyclotetrasiloxane and 30g octaphenylcyclotetrasiloxane were added to the flask, and then Then add 0.08% tetramethylammonium hydroxide of the total amount of the above four substances, perform ring-opening polymerization reaction at 110°C for 4 hours, then raise the temperature to 180°C to decompose the catalyst, and vacuumize to remove the low-boiling point substances to obtain Vinylmethylphenylpolysiloxane, the yield was 93.21%.

[0038] Gained vinylmethylphenylpolysiloxane molecular structural formula is as follows:

[0039]

[0040] Wherein, x:y:z=136:16:60.

Embodiment 2

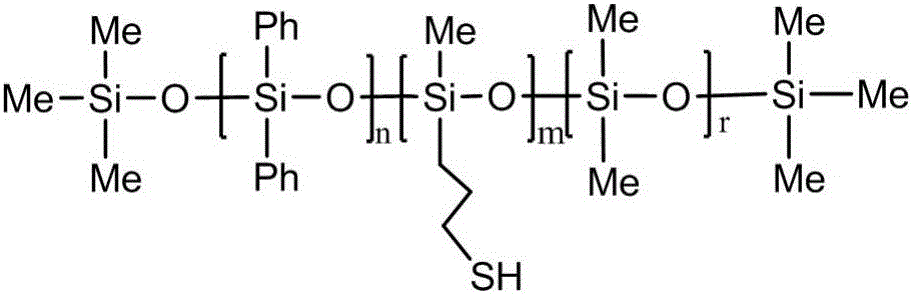

[0041] The preparation of embodiment 2 mercaptopropylmethylphenylpolysiloxane

[0042] Add 30g of hexamethyldisiloxane, 30g of mercaptopropylmethyldiethoxysilane, 75g of diphenyldiethoxysilane, and 90g of dimethyldiethoxysilane into a three-necked flask, and then use hydrochloric acid to The pH of the reaction system was adjusted to 5, the hydrolysis-condensation reaction was carried out at 70° C. for 3 hours, and the water and solvent were distilled off to obtain mercaptopropylmethylphenylpolysiloxane with a yield of 89.74%.

[0043] Gained mercaptopropylmethylphenylpolysiloxane molecular structural formula is as follows:

[0044]

[0045] Wherein, n:m:r=27:17:61.

Embodiment 3

[0046] Preparation of embodiment 3 mercaptopropyl silicone resin

[0047] Add 30g of hexamethyldisiloxane, 150g of mercaptopropyltriethoxysilane, and 75g of phenyltriethoxysilane into a three-necked flask, then add hydrochloric acid to control the pH of the reaction system at 4.5, and then Co-hydrolysis-polycondensation reaction was carried out for 5 hours, and finally the temperature was raised to 120° C. to remove low boilers by vacuuming to obtain mercaptopropyl silicone resin with a yield of 83.27%.

[0048] The molar ratio of the mercaptopropyl segment, the phenyl segment and the trimethyl silicon segment in the obtained mercaptopropyl silicone resin molecule is 0.63:0.3:0.37.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com