Continuous batch preparation method of silicone rubber microfibers and microtubes

A silicone rubber, batch technology, applied in the direction of fiber chemical characteristics, tubular goods, rayon manufacturing, etc., can solve the problems of short length, unusable, long molding cycle, etc., to achieve controllable size and shape, broad application prospects, The effect of short molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

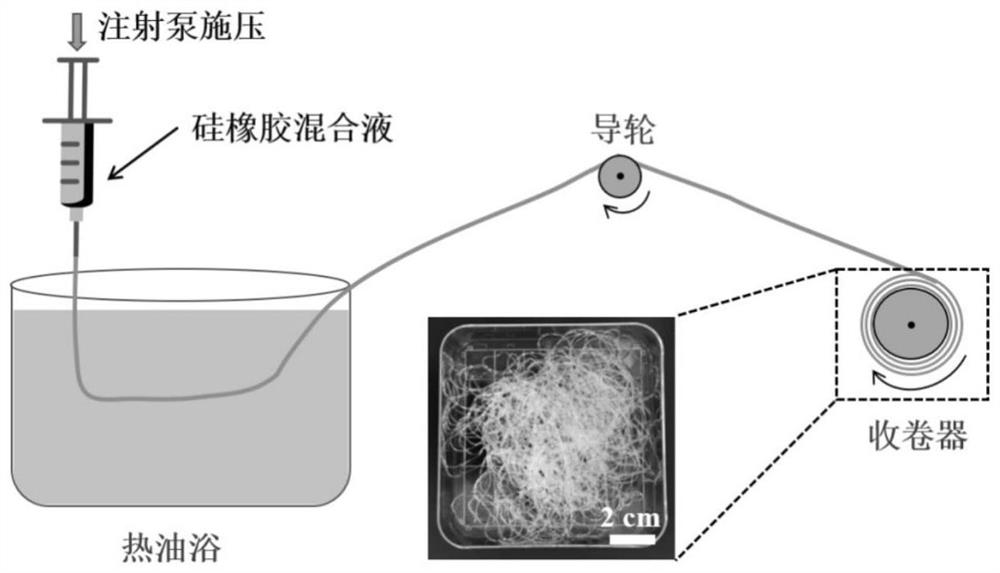

[0039] Embodiments of the present invention provide a continuous batch preparation method of silicone rubber microfibers, which comprises the following steps:

[0040] S1: According to the mass ratio of 10:1, mix the silicone rubber prepolymer and crosslinking agent evenly to obtain a mixed solution, pour it into a 20mL syringe, and vacuum degas for 0.1h;

[0041] S2: preparing a rapeseed oil bath at 80°C;

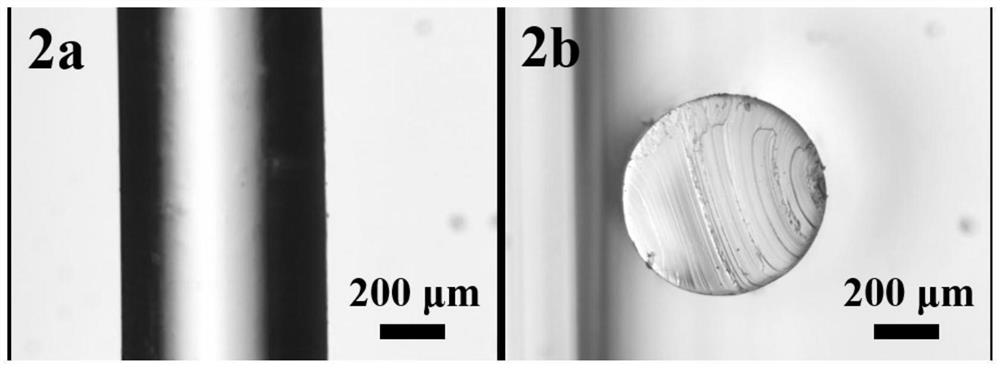

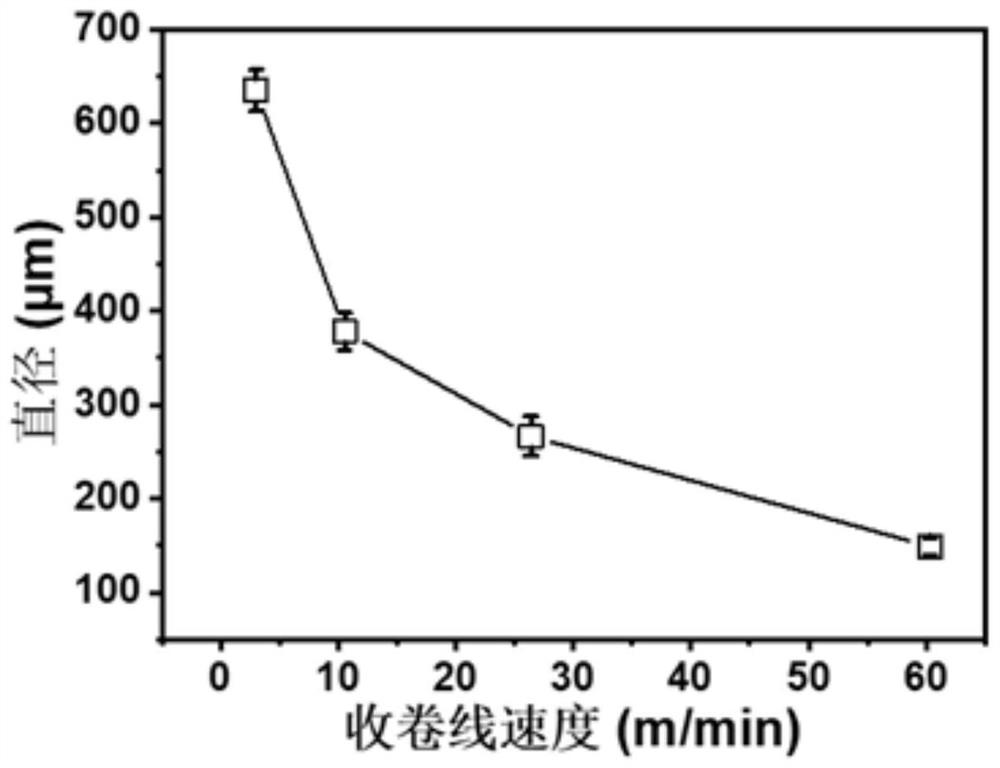

[0042] S3: Inject the silicone rubber mixture into the rapeseed oil bath in step S2 through a catheter and an 8G needle at a constant speed of 1mL / min using a syringe pump to mix the silicone rubber. The liquid flow of the liquid is rapidly heat-cured into fibers in a rapeseed oil bath, and the continuously formed fibers are guided by the guide wheel and collected by the winder at a linear speed of 3.0, 10.6, 26.4 and 60.3 m / min, respectively, and finally obtained Silicone rubber fibers with different diameters. Schematic diagram of the processing process of silicone rub...

Embodiment 2

[0045] Embodiments of the present invention provide a continuous batch preparation method of silicone rubber microfibers, which comprises the following steps:

[0046] S1: According to the mass ratio of 10:1, mix the silicone rubber prepolymer and crosslinking agent evenly to obtain a mixed solution, pour it into a 50mL syringe, and vacuum degas for 1h;

[0047] S2: Prepare an olive oil bath at 120°C;

[0048] S3: Use a syringe pump filled with the silicone rubber mixture in step S1 to inject the silicone rubber mixture through the catheter and a 14G needle into the olive oil in step S2 at a constant speed of 0.3, 0.8, 1.5, and 2 mL / min respectively In the bath, the liquid flow of the silicone rubber mixture is quickly heat-cured into fibers in the olive oil bath, and the continuously formed fibers are guided by the guide wheel and collected by the winder at a line speed of 10.0m / min, and finally the fibers with different diameter silicone rubber fibers.

[0049] The diamete...

Embodiment 3

[0051] Embodiments of the present invention provide a continuous batch preparation method of silicone rubber microfibers, which comprises the following steps:

[0052] S1: According to the mass ratio of 10:1, mix the silicone rubber prepolymer and crosslinking agent evenly to obtain a mixed solution, pour it into a 30mL syringe, and vacuum degas for 0.5h;

[0053] S2: Prepare a diesel bath at 150°C;

[0054] S3: Use the syringe with the silicone rubber mixture in step S1 to inject the silicone rubber mixture through the catheter and the slit-shaped needle, rectangular cross-section needle and triangular cross-section needle at a constant speed with a syringe pump into step S2 In the diesel bath, the liquid flow of the silicone rubber mixture is rapidly thermally solidified into fibers in the diesel bath, and the continuously formed fibers are guided by the guide wheel and collected by the winder at a linear speed of 15.0m / min. Silicone rubber fibers of different cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com