Preparation method of microneedles

A technology of microneedles and needle tips, which is applied in the field of preparing microneedle arrays, can solve the problems of low efficiency, high cost, complicated preparation process, etc., and achieve the effect of simple and efficient method, controllable shape and size, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

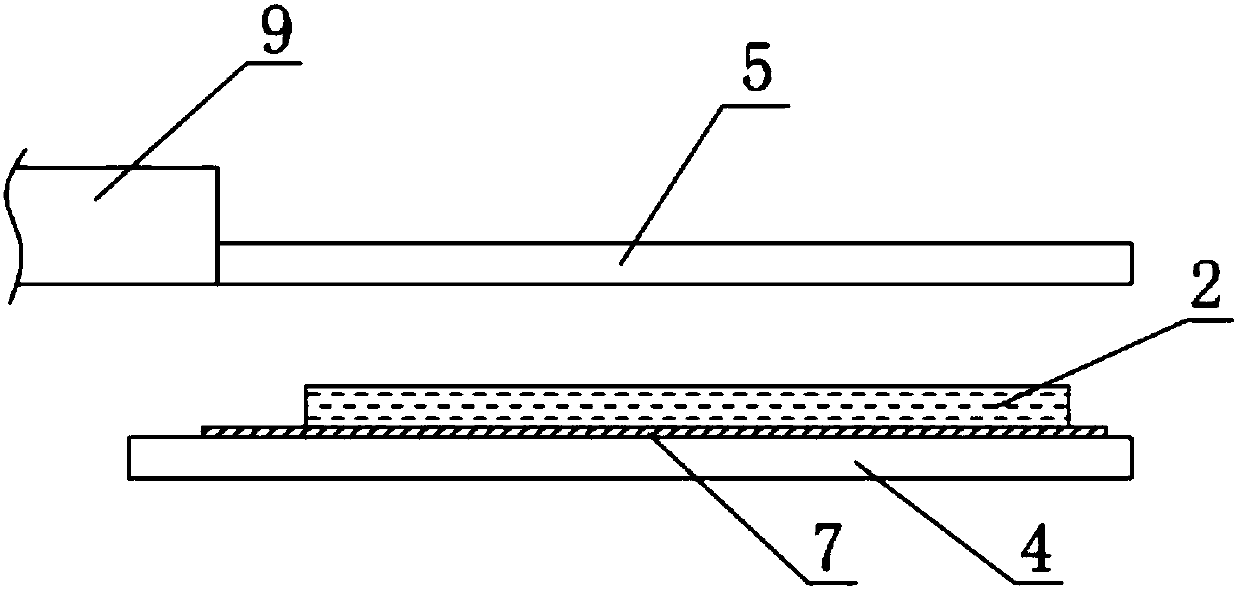

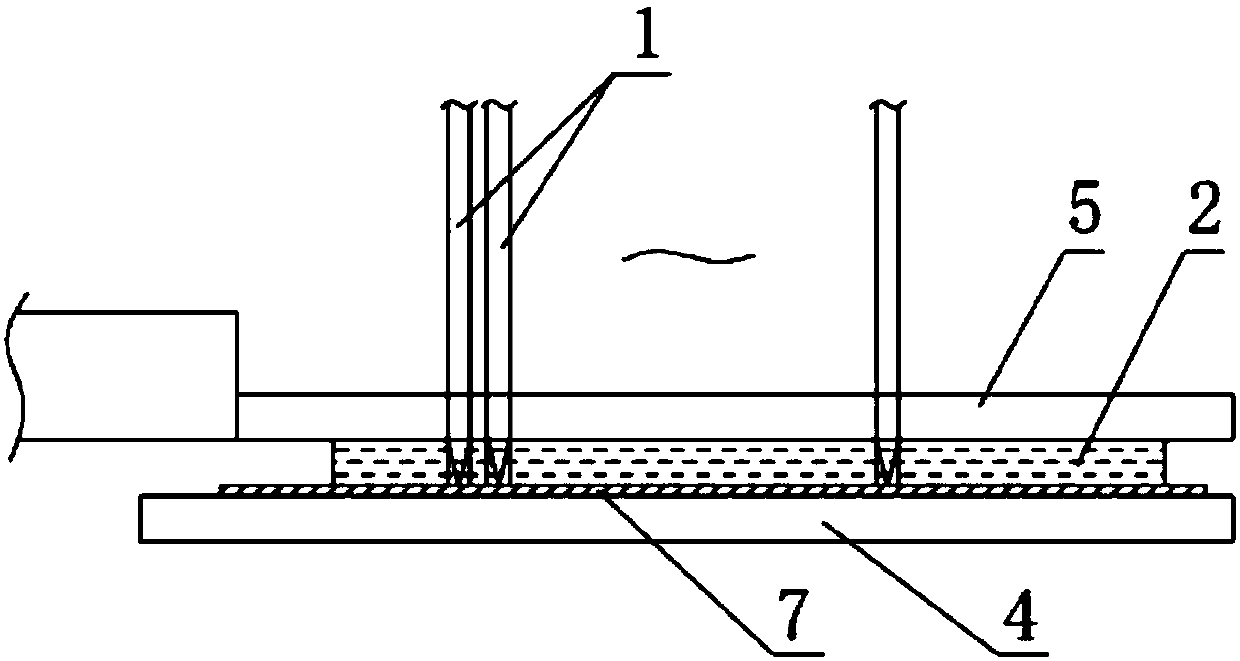

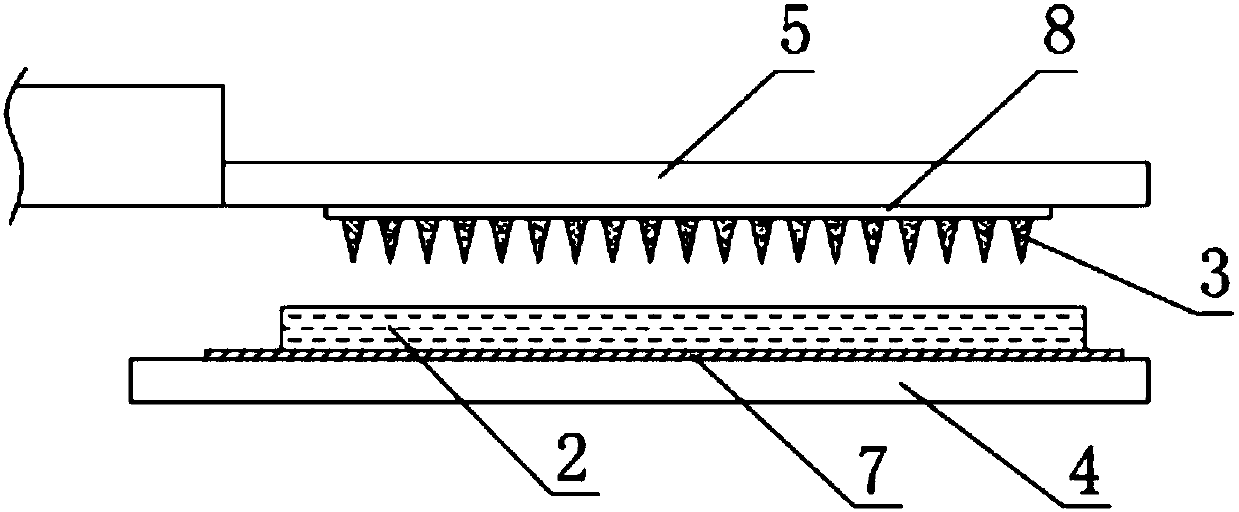

Embodiment 1

[0038] Embodiment 1, select lipophilic material, such as 3D printing photosensitive resin material as the printing material of the printing material layer 2 and drop it on the surface of the printing platform 4 with a silica gel film as the non-stick cushion layer 7, and avoid the formation of air bubbles during the liquid addition process After the exposure and molding of the microneedles are affected, the slide glass 5 is installed on the adjustment platform 9, and the distance between the slide glass 5 and the printing platform 4 is adjusted to be 1mm by controlling the adjustment platform 9; observe the distance between the slide glass 5 and the printing platform 4 Whether it is kept in a horizontal state and the slide glass 5 is fully in contact with the photosensitive material to ensure that the height of the needle tip structure 3 formed by exposure is consistent. Then start the 3D printer to project the pre-set printing beam 1, and control the exposure of the printing b...

Embodiment 2

[0039] Embodiment 2, select hydrophilic material, such as 30% PEGDA, 2.1% Lap material as the printing material of printing material layer 2 and drip onto the surface of printing platform 4 with silica gel film as non-stick cushion layer 7, in the process of adding liquid The generation of air bubbles should be avoided to affect the exposure molding of microneedles. Then slide glass 5 is installed on the adjusting table 9 again, and the distance between the slide glass 5 and the printing platform 4 is 1mm by controlling the adjusting table 9; The slide glass 5 is fully contacted with the photosensitive material to ensure that the needle point structure 3 formed by exposure is highly consistent. Then start the 3D printer, project the pre-set printing beam 1, and control the exposure of the printing beam 1 for 15 seconds before ending.

[0040] According to the microneedle preparation method of the present invention, according to the photosensitive material selected, the thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com