A preparation method of self-healing polyurethane hydrogel based on double selenium dynamic covalent bond

A dynamic covalent bond and hydrogel technology, applied in prosthetics, medical science, etc., to achieve good biocompatibility, good molecular structure designability, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

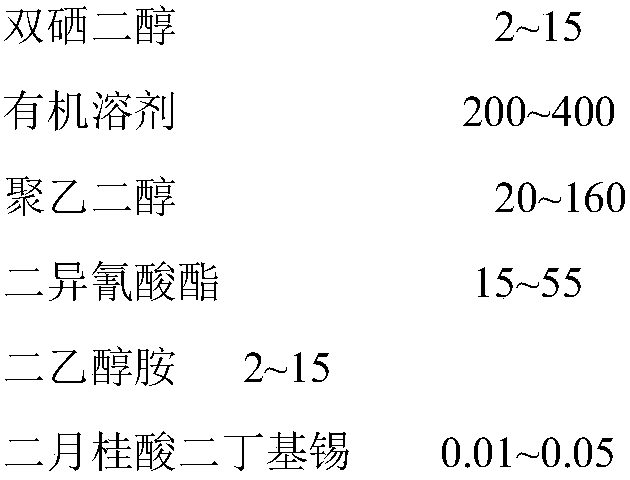

Embodiment 1

[0022] Distill polyethylene glycol under reduced pressure for 8 hours at 90°C and a vacuum of 0.09 MPa to remove water; add 20 g of polyethylene glycol with a number-average molecular weight of 4000, 2.23 g of isofor to a three-necked flask in sequence Ketone diisocyanate, 15ml of N,N-dimethylformamide, 1 drop of dibutyltin dilaurate, heated to 85°C under magnetic stirring, and reacted for 3 hours; added 0.62g of diselenide, and continued to react for 3 hours Hours; turn off the heating, cool naturally to 20°C, add 0.57g diethanolamine, and react for 2 hours; add 1.12g isophorone diisocyanate to the product, mix evenly, and move it into a mold, and put it in an oven at 40°C for 48 hours Cross-linking and curing: demould the shaped block gel, soak it in deionized water, change the water every 6 hours, and obtain a self-healing polyurethane hydrogel based on the dynamic covalent bond of double selenium after 48 hours.

Embodiment 2

[0024] Distill polyethylene glycol under reduced pressure for 10 hours at 90°C and a vacuum of 0.09 MPa to remove moisture; add 5.1 g of polyethylene glycol with a number average molecular weight of 1000, 2.27 g of iso Phorone diisocyanate, 20ml tetrahydrofuran, 1 drop of dibutyltin dilaurate, heated to 40°C under magnetic stirring, reacted for 7 hours; added 0.57g diselenodiol, maintained the temperature and continued to react for 7 hours; turned off the heating and cooled naturally to 20°C, add 0.63g diethanolamine, and react for 1.5 hours; add 1.27g isophorone diisocyanate to the product, mix evenly, and move it into a mold, and undergo cross-linking and curing in an oven at 40°C for 36 hours; the formed The block gel was removed from the mold, soaked in deionized water, and the water was changed every 6 hours. After 48 hours, the self-healing polyurethane hydrogel based on the dynamic covalent bond of double selenium could be obtained.

Embodiment 3

[0026] Distill polyethylene glycol under reduced pressure for 8 hours at 80°C and a vacuum of 0.09 MPa to remove moisture; add 3.8 g of polyethylene glycol with a number average molecular weight of 750, 2.27 g of iso Phorne diisocyanate, 15ml of acetone, 1 drop of dibutyltin dilaurate, heated to 50°C under magnetic stirring, and reacted for 8 hours; added 0.67g of diselenodiol, and continued to react for 8 hours at the temperature; turn off the heating, and put it in an ice bath Cool to 3°C, add 0.62g diethanolamine, keep the reaction in ice bath for 2 hours; add 1.52g isophorone diisocyanate to the product, mix evenly, and move it into a mold, and cross-link and mature in an oven at 30°C for 48 hours Demoulding the formed block gel, soaking it in deionized water, changing the water every 6 hours, after 48 hours, a self-healing polyurethane hydrogel based on the dynamic covalent bond of double selenium can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com