Patents

Literature

55results about How to "Has self-healing properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power distribution network integrated protection method merging line self-recovery

ActiveCN107872058APlenty of computing timeHas "self-healing" propertiesEmergency protective circuit arrangementsContigency dealing ac circuit arrangementsSelf recoveryInterconnection

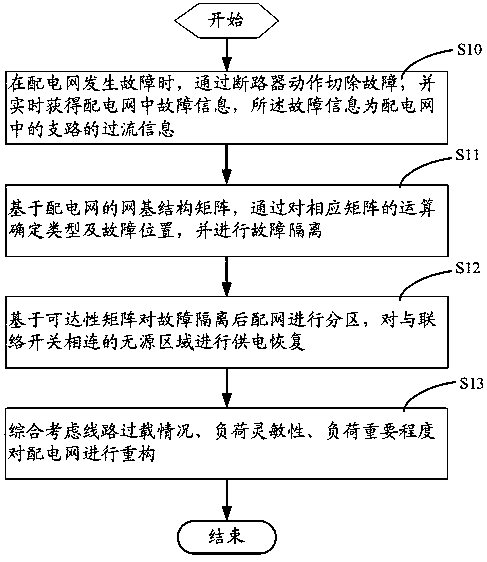

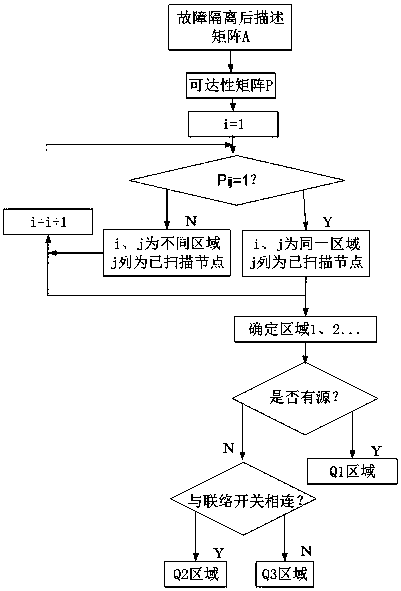

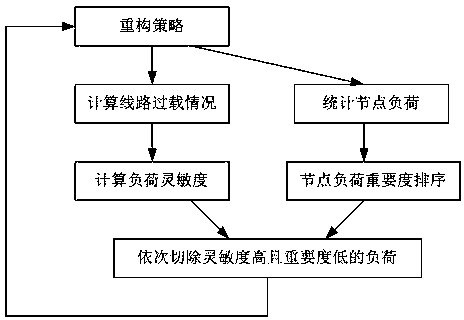

The invention provides a power distribution network integrated protection method merging line self-recovery, the method comprises the following steps: a step S10, when a power distribution network fails, removing fault through breaker operation, and obtaining fault information in the power distribution network in real time, wherein the fault information is an overcurrent information of a branch inthe power distribution network; a step S11, based on a net base structure matrix of the power distribution network, determining type and fault position through computation for corresponding matrix, and performing fault isolation; a step S12, based on an accessibility matrix, partitioning the power distribution network subjected to fault isolation, and recovering power supply of a passive region connected with an interconnection switch; a step S13, comprehensively considering line overload condition, load sensitivity and load importance degree to reconstruct the power distribution network. Byimplementing the power distribution network integrated protection method merging line self-recovery, better protective control performance with 'self-recovery' property can be obtained.

Owner:SHENZHEN POWER SUPPLY BUREAU

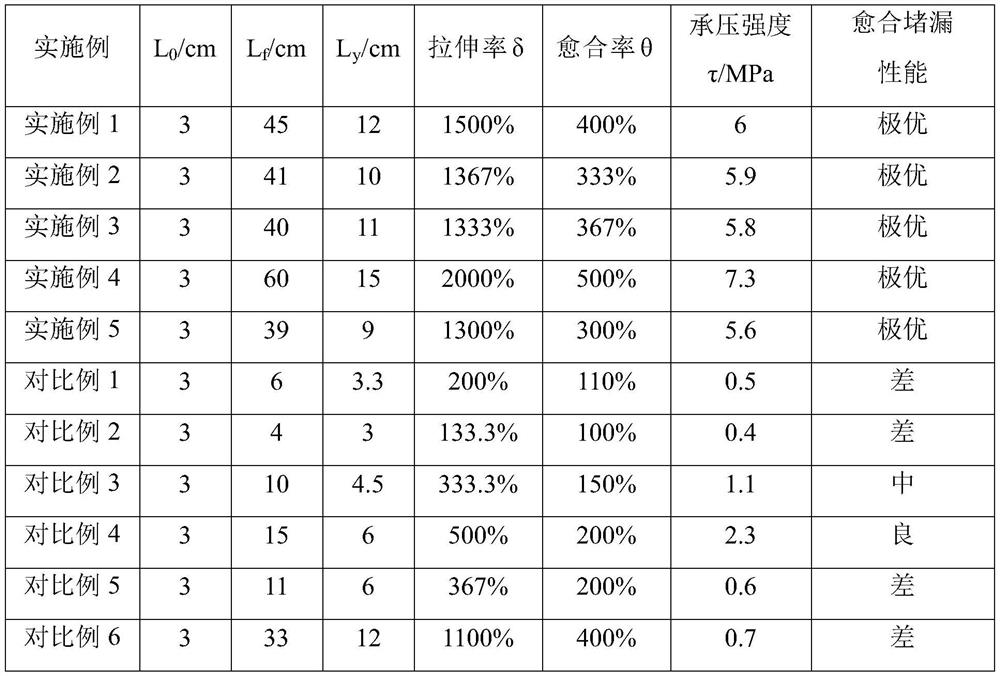

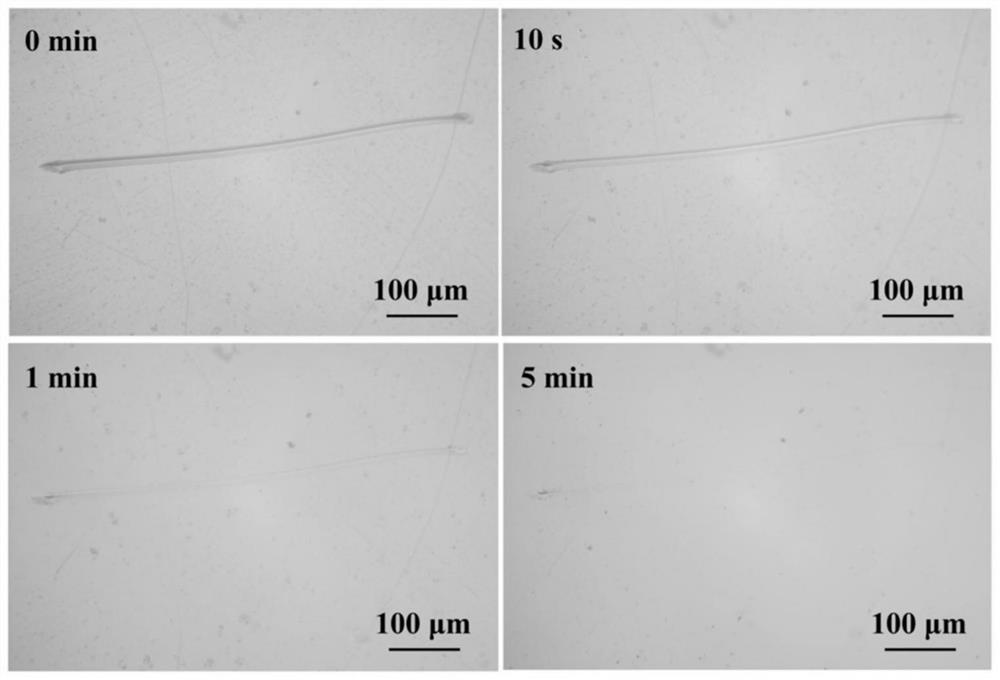

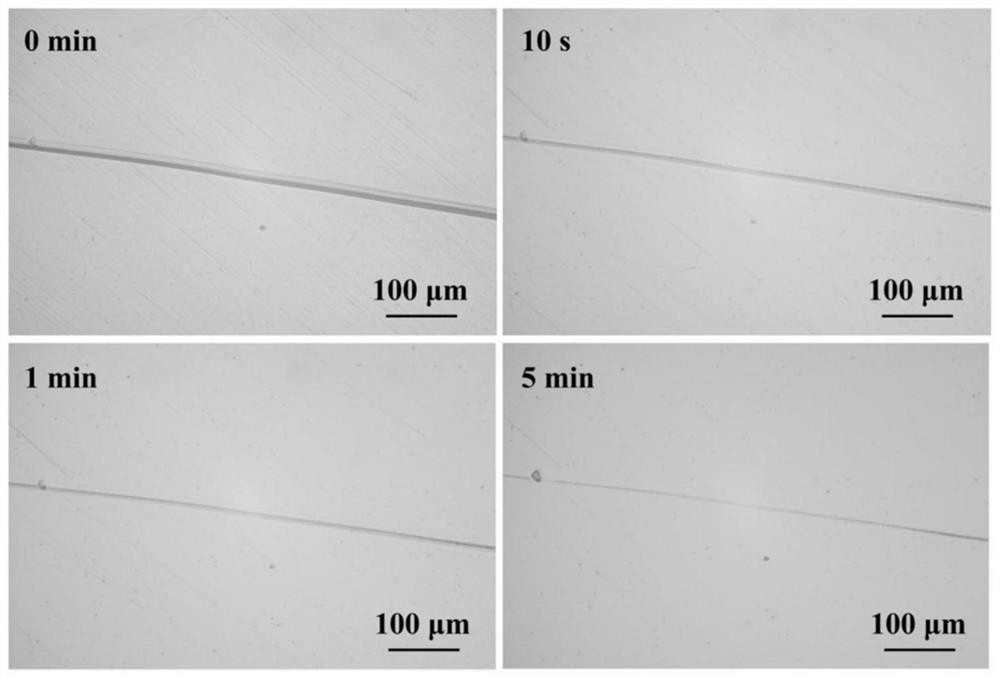

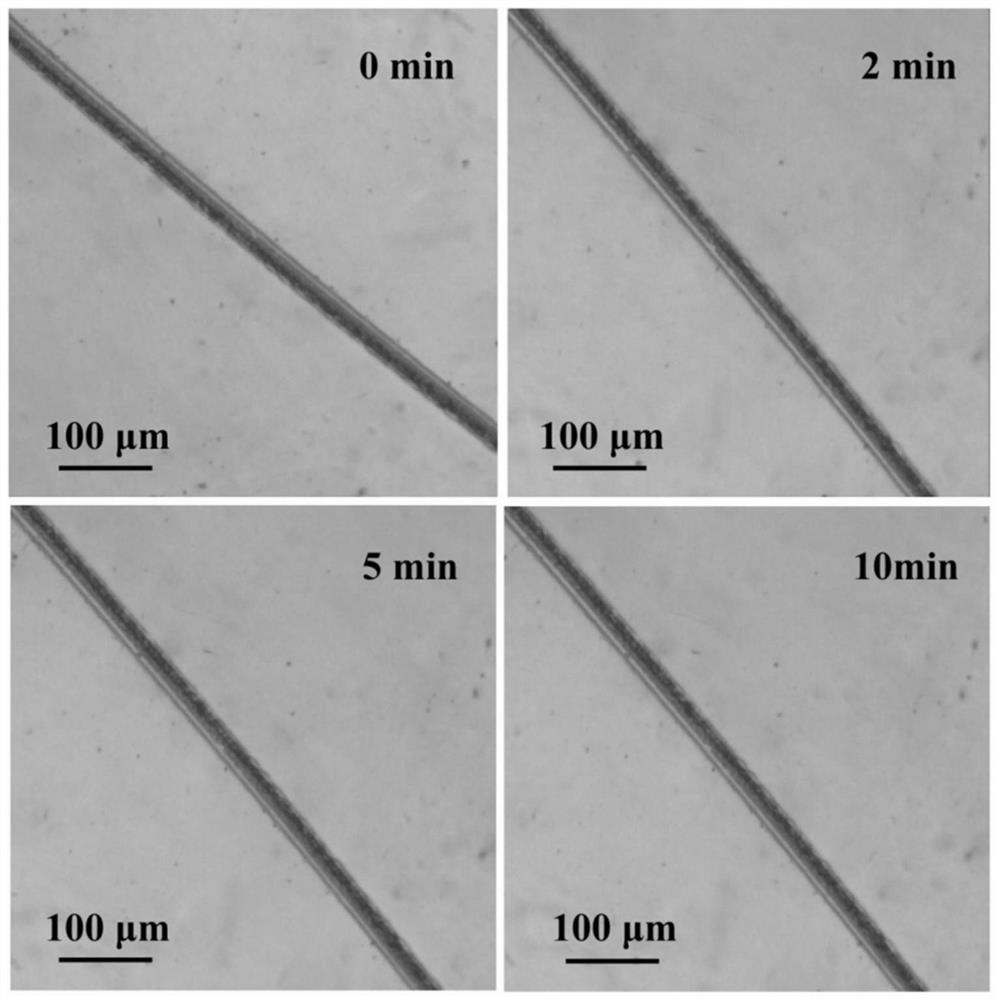

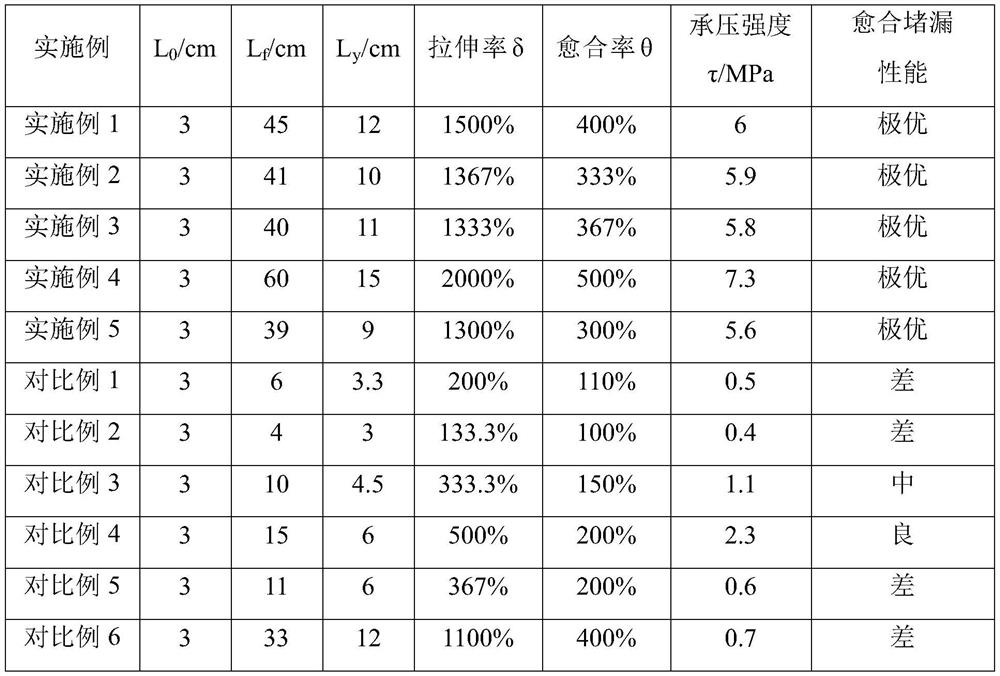

Gel particle plugging agent with self-healing characteristic as well as preparation method and application thereof

ActiveCN112250787AGuaranteed bearing strengthSimple construction processDrilling compositionComposite materialActive agent

The invention provides a gel particle plugging agent with a self-healing characteristic. The gel particle plugging agent is prepared from the following raw materials in parts by mass: 15-35 parts of acopolymerization reaction monomer, 0.1-20 part of a surfactant A, 0.01-0.9 part of an initiator I, 0.01-0.1 part of a cross-linking agent and 0.5-5 part of cationic latex particles; wherein the copolymerization monomer comprises a hydrophilic monomer and a hydrophobic monomer, the hydrophilic monomer is a combination of acrylic acid and an acrylamide monomer, and the hydrophobic monomer is an acrylate monomer. The invention also provides a preparation method and a healing performance evaluation method of the gel particle plugging agent. The self-healing plugging material disclosed by the invention has the characteristic of recoverability after being damaged, is injected into stratum cracks in a particle form, and can form integral gel after being healed, so that the purpose of effectivelyplugging crack pores is achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

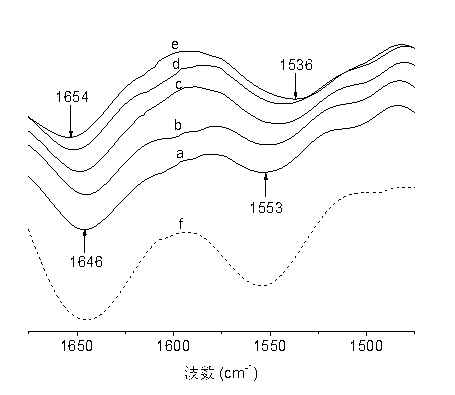

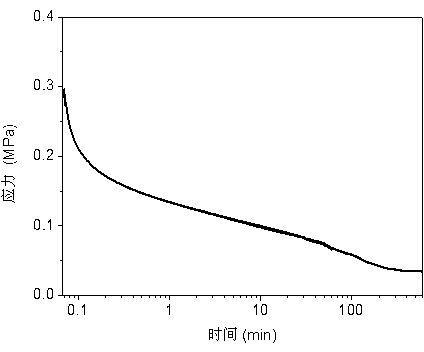

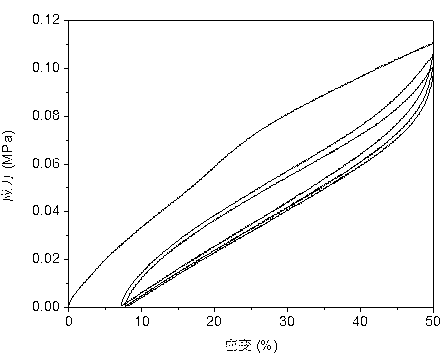

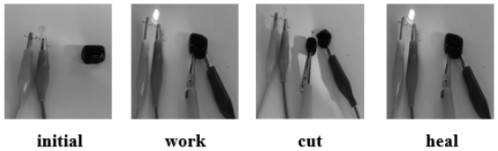

Hyperbranched elastic material capable of self-healing and preparation method thereof

The invention relates to a hyperbranched elastic material capable of self-healing and a preparation method thereof. The preparation method comprises the following steps: reacting a first component containing double bond and carboxyl or ester group with a second component containing more than three amino groups at -20-50 DEG C for 1-72 hours; heating to room temperature to 200 DEG C, continuing the reaction under reduced pressure for 1-72 hours, precipitating the product, filtering, separating, and drying to obtain the hyperbranched polymer of which the molecular chain tail end is amino group; and reacting the hyperbranched polymer of which the molecular chain tail end is amino group with a third component (polybasic acid or polybasic acid mixture or carboxyl-terminated low polymer) at 80-280 DEG C for 1-120 hours to obtain the hyperbranched elastic material capable of self-healing. The hyperbranched material has elasticity at room temperature, and contains abundant amino and amido groups capable of forming reversible hydrogen bonds; and thus, the material has the characteristic of self-healing at room temperature, has thermoplastic property, and can be machined repeatedly.

Owner:SOUTH CHINA UNIV OF TECH

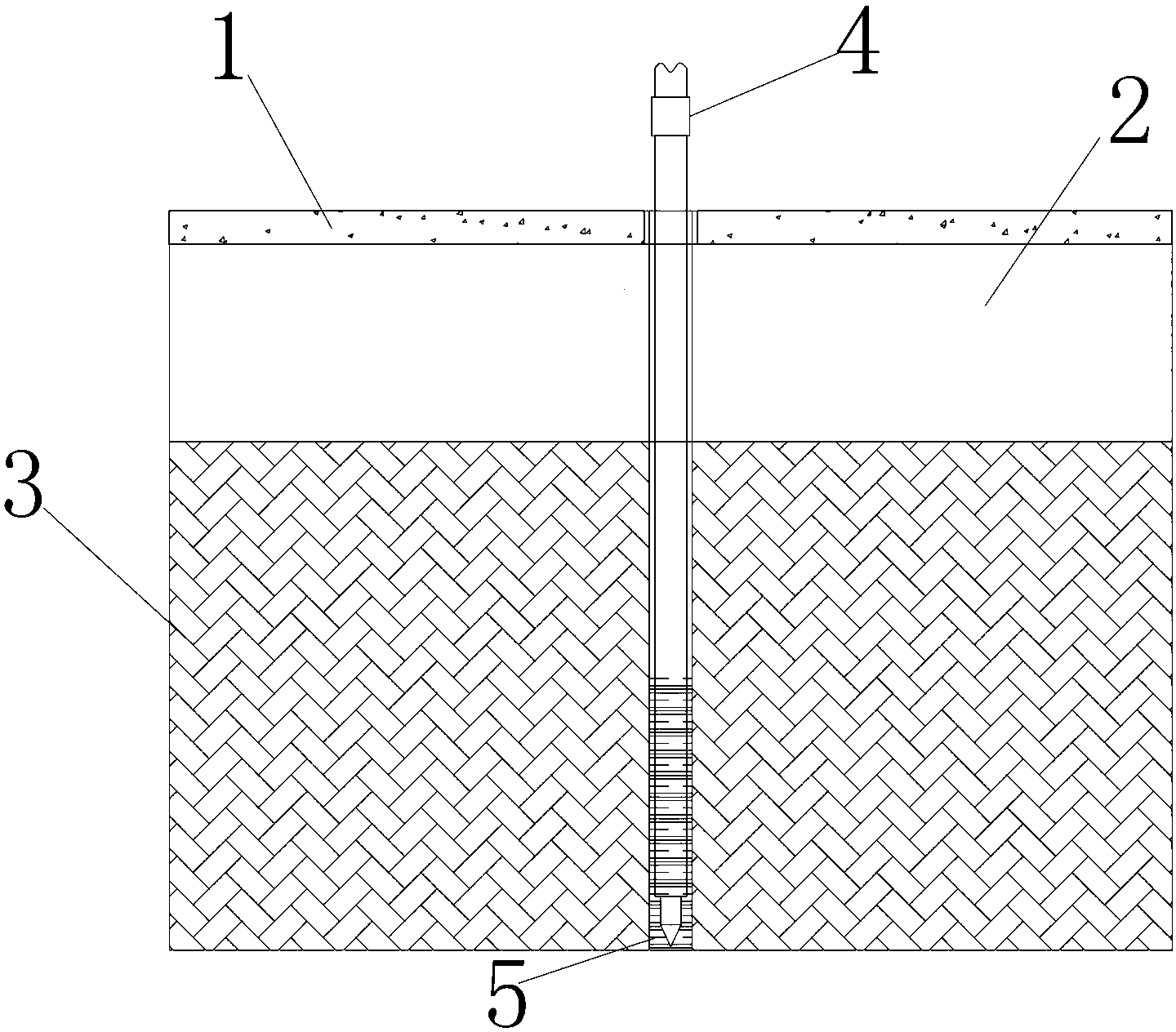

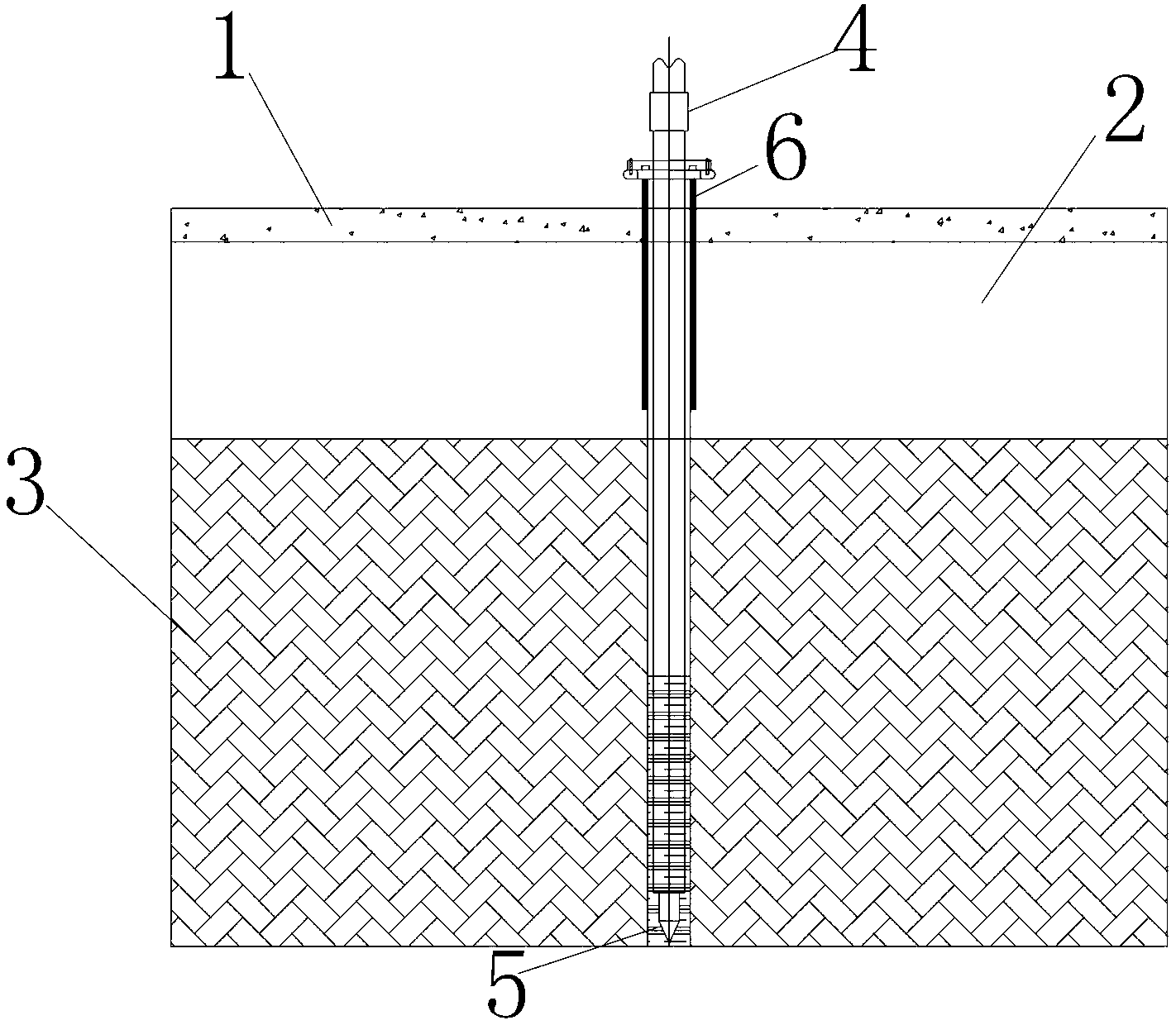

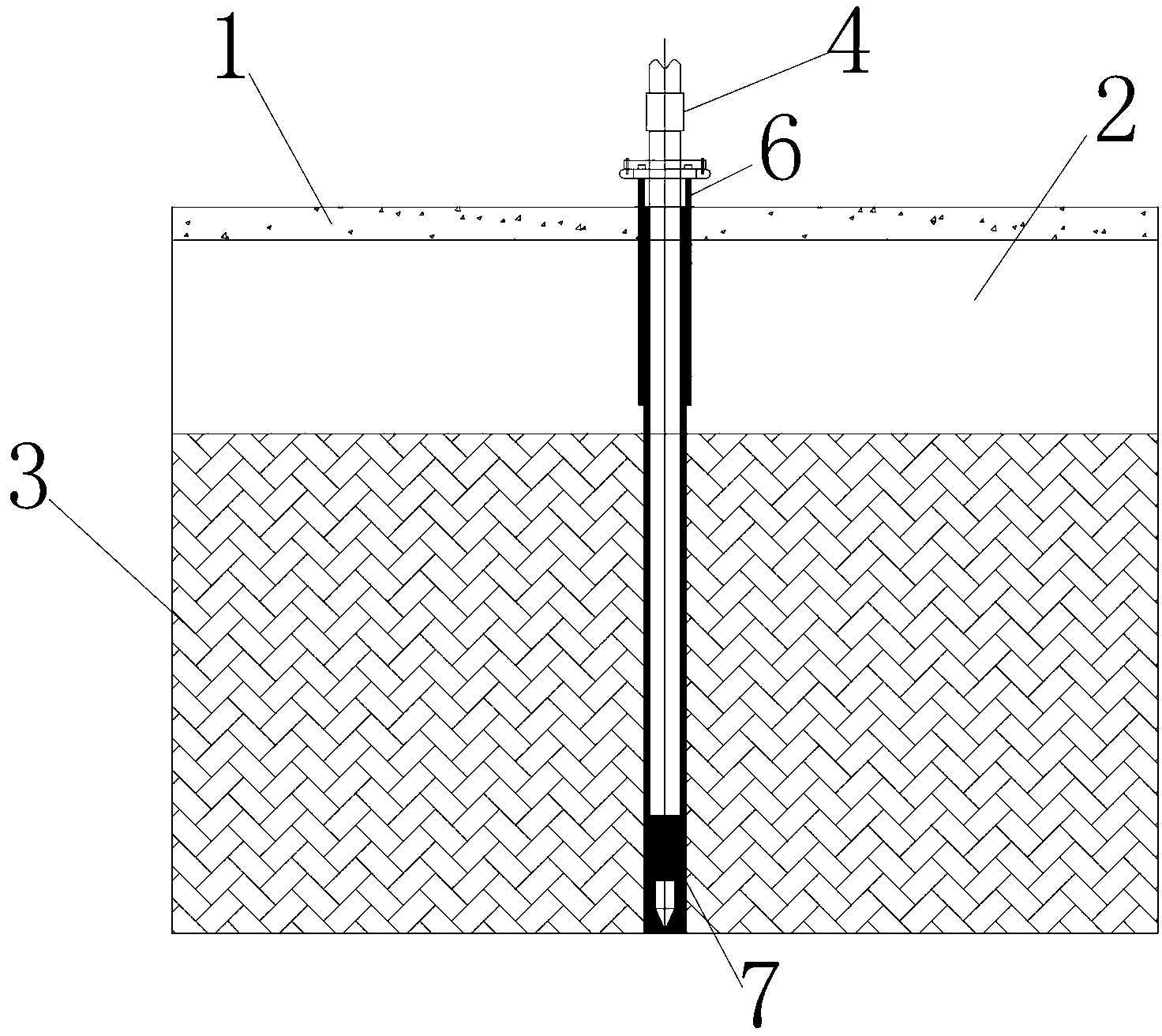

Hole sealing grout stop material and grouting hole sealing process

The invention discloses a hole sealing grout stop material, which is a hole sealing grout stop material for guaranteeing grouting pressurization under the condition of loose permeable rock-soil body, high underground level or confined water. The hole sealing grout stop material is mainly prepared from clay primary grout, cement and sodium metaaluminate, wherein every 2 L of clay primary grout is mixed with 700-900 g of cement and 12.5-17.5 g of sodium metaaluminate. A grouting hole sealing process comprises hole sealing operation and grouting operation, wherein the hole sealing operation specifically comprises the following steps of: after forming a hole, dropping a grouting pipe to the bottom of the hole and mounting a orifice closer; opening the orifice closer and injecting the hole sealing grout stop material; closing the orifice closer and flushing the grouting pipe by using stable grout; and opening the orifice closer, performing grouting operation after solidifying the hole sealing grout stop material, and guaranteeing reliable hole sealing grouting through continuous lift grouting. The grouting hole sealing process has the advantages of simple steps, less equipment investment, high applicability, capabilities of guaranteeing the reliability of the hole sealing grout and increasing the grouting efficiency and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

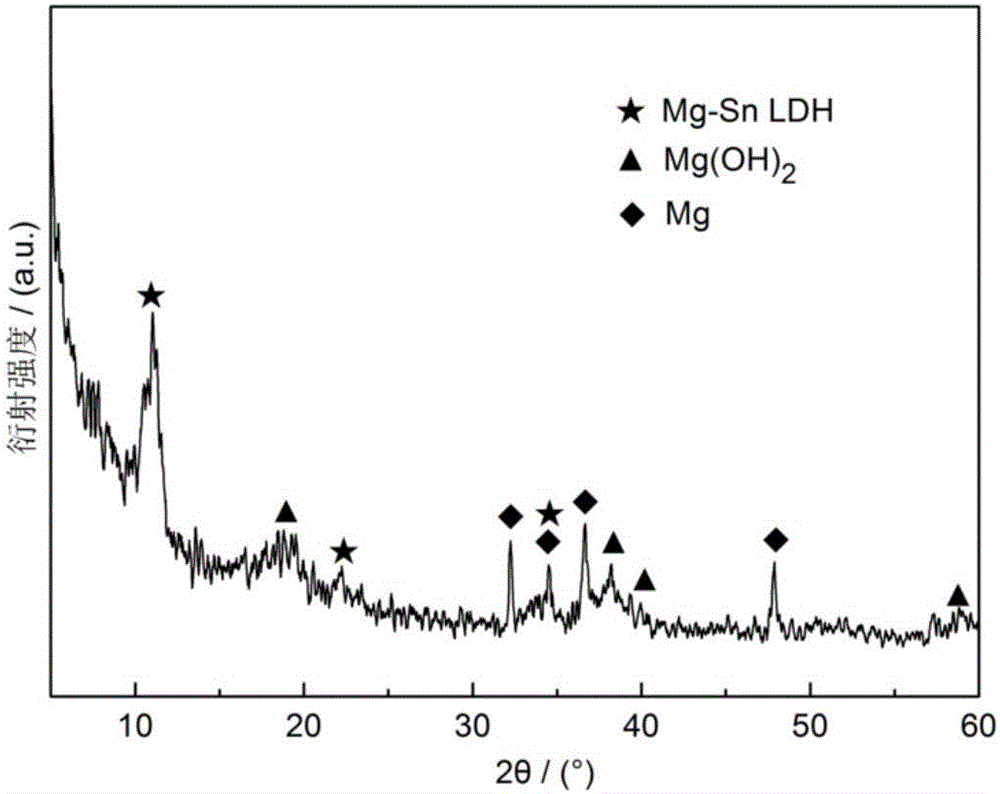

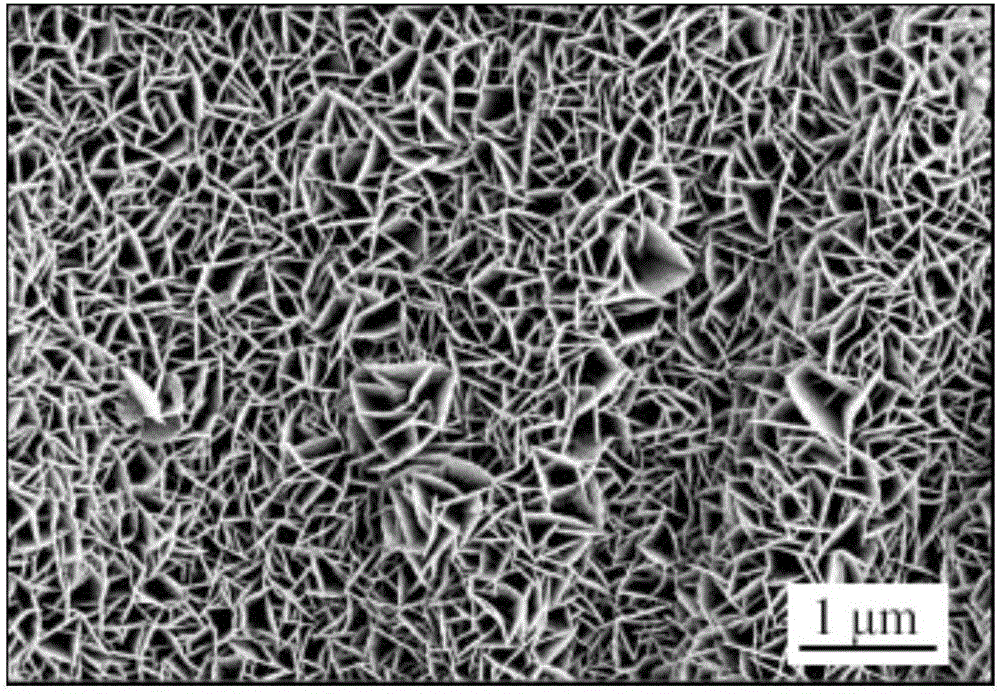

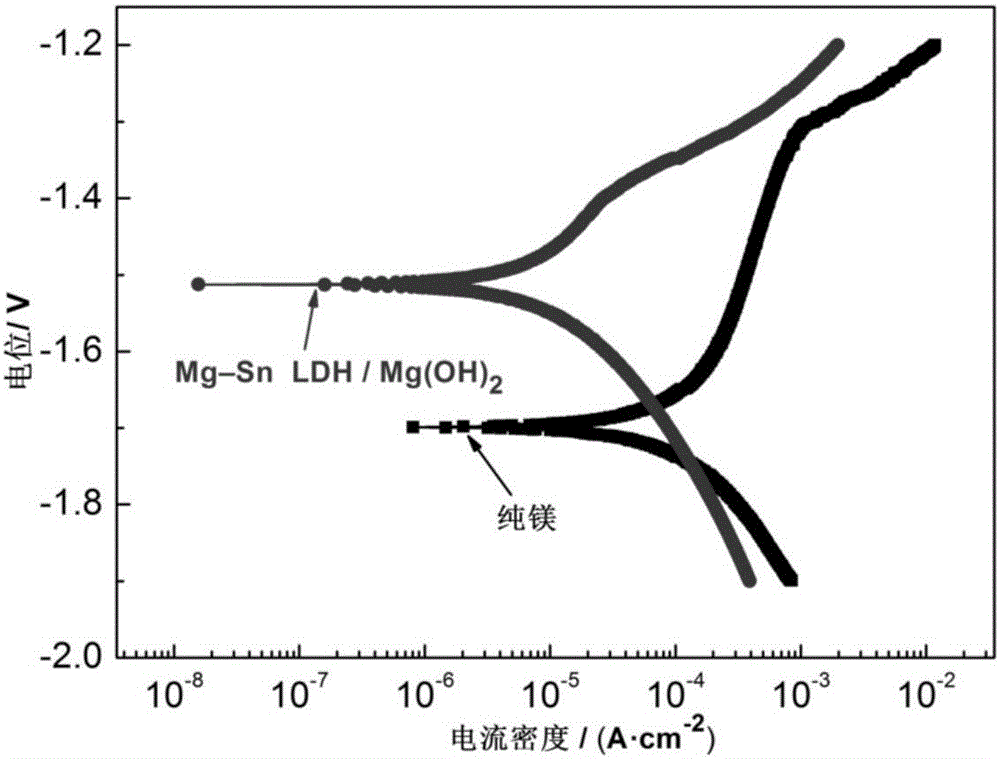

Mg(OH)2/Mg-Sn hydrotalcite composite film having intercalation structure on surface of magnesium and magnesium alloy and preparation method thereof

ActiveCN106283017AStable structureGood bindingMetallic material coating processesHydrotalciteCorrosion

The invention discloses a Mg(OH)2 / Mg-Sn hydrotalcite composite film having an intercalation structure on the surface of magnesium and magnesium alloy and a preparation method thereof, relates to the technical field of the surface of magnesium and magnesium alloy, and aims to improve the corrosion resistance of magnesium and magnesium alloy and widen the application prospects in the fields of biological medicine and the like. The preparation method comprises the following steps: S1, initial treatment of magnesium and magnesium alloy; S2, pretreatment: preparing a Sn4<+> salt solution, regulating the pH value to 4.0 to obtain a pretreatment solution, and putting the magnesium and magnesium alloy in the pretreatment solution with continuously introduced CO2 to obtain a precursor film; S3, posttreatment: soaking the magnesium and magnesium alloy coated with the precursor film in a Na2CO3 solution to grow a Mg(OH)2 / Mg-Sn hydrotalcite composite film on the surface of the magnesium and magnesium alloy; and S4, subsequent cleaning. According to the invention, the Mg(OH)2 / Mg-Sn hydrotalcite composite film containing no aluminum and having biosafety is grown on the surface of magnesium and magnesium alloy in an in-situ generation manner through a two-step method; the corrosion resistance of magnesium and magnesium alloy is improved; and the application of the hydrotalcite film in biological magnesium alloy surface protection is widened.

Owner:NANJING INST OF TECH

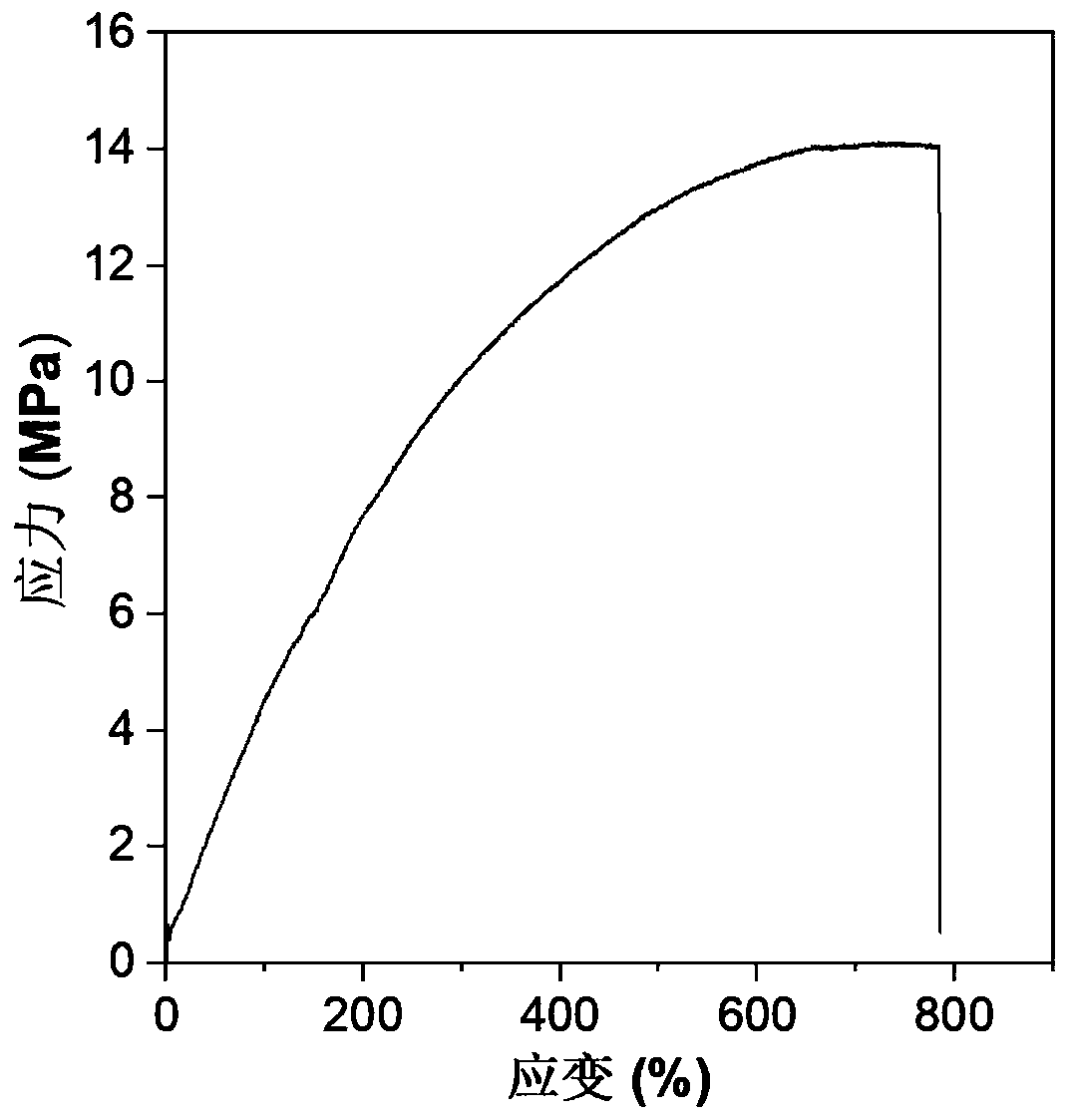

Anti-freeze and self-repairing conductive nano-composite hydrogel fiber and preparation method thereof

ActiveCN110938894AImprove mechanical propertiesImprove conductivityElectroconductive/antistatic filament manufactureArtificial thread manufacturing machinesFiberPolymer science

The invention relates to an anti-freeze and self-repairing conductive nano-composite hydrogel fiber and a preparation method thereof. The fiber is obtained by performing synchronous extrusion-polymerization-stretching on a primary hydrogel, which has not been completely reacted, in an aniline monomer bath through a synchronous polymerization-stretching method. The conductive nano-composite hydrogel fiber with anti-freeze and self-repairing performances prepared by the invention is extensive in application range, low in preparation cost, and convenient for industrial production, and an effective new thought is provided for the designing or preparation of other conductive fiber or fabric.

Owner:DONGHUA UNIV

Surface rare-earth film transforming agent and surface rare-earth film transformation processing method of aluminium alloy

InactiveCN101818339AEvenly dispersedSuitable film forming speedMetallic material coating processesAlcoholCerium

The invention provides a surface rare-earth film transforming agent comprising the following materials by ratio: an alcohol solvent:cerium salt:an oxidant=1 L:[1-10 g]:[1-10 mL]. The invention also discloses a surface rare-earth film transformation processing method of an aluminium alloy, comprising the following steps of: surface preprocessing of the aluminium alloy, surface rare-earth film transformation processing, surface rare-earth film curing, and the like. The surface rare-earth film transforming agent has stable property and convenient use; a generated rare-earth film is compact and firm; and in addition, the surface rare-earth film transformation processing method of the aluminium alloy has simple process, economy, environmental protection and fast film formation, and can obtain good corrosion-resistant rare-earth transformed film.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Dry-type composite-dielectric filter capacitor

InactiveCN101604577AGuaranteed Dielectric StrengthEasy to useAnti-noise capacitorsThin/thick film capacitorPolyesterCapacitance

The invention discloses a dry-type composite-dielectric filter capacitor, which comprises a capacitor core, a pin, and an encapsulation layer coated outside the capacitor core, wherein the capacitor core consists of a polypropylene film plated with a metallic layer and a metallized polyester film which are superposed in turn and are coiled in a non-inductive mode, the metallic layer is a zinc-aluminum composite layer, the metallized film has a 'natural repair' characteristic, small loss and large capacitance, the encapsulation layer is an epoxy resin solidified layer, thus not only the insulation strength of the capacitor is ensured, but also the safe use of the capacitor under a severe condition is ensured.

Owner:ZHEJIANG QIXING CAPACITOR

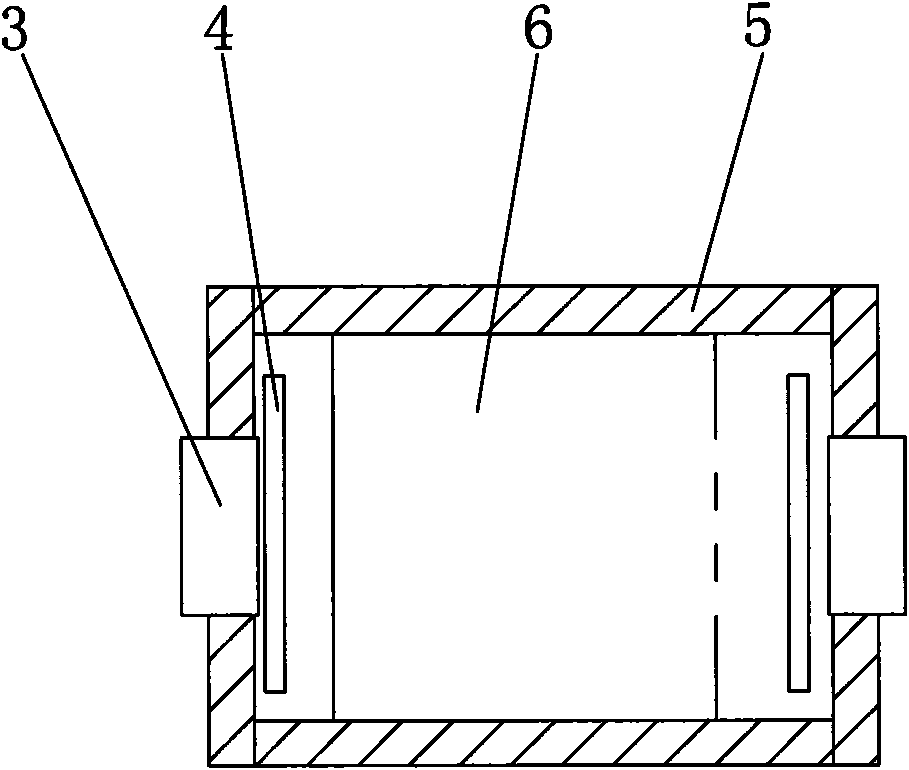

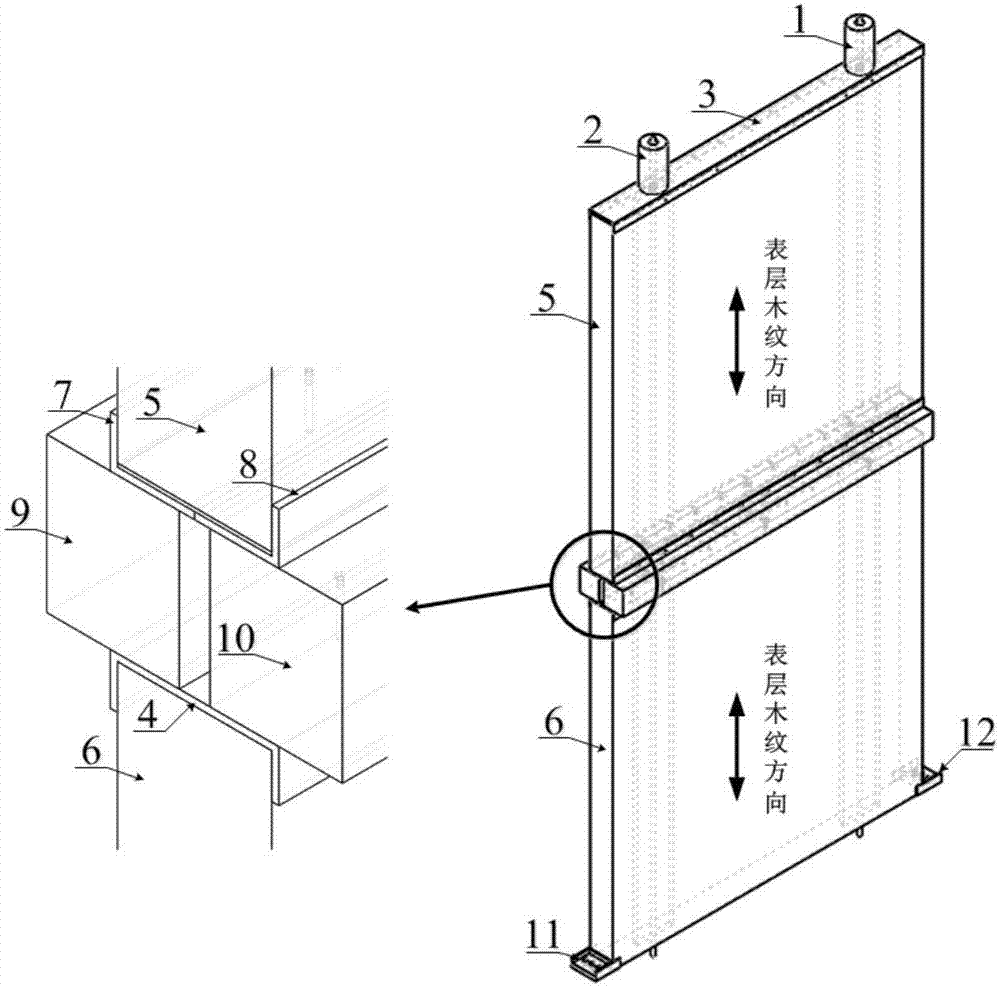

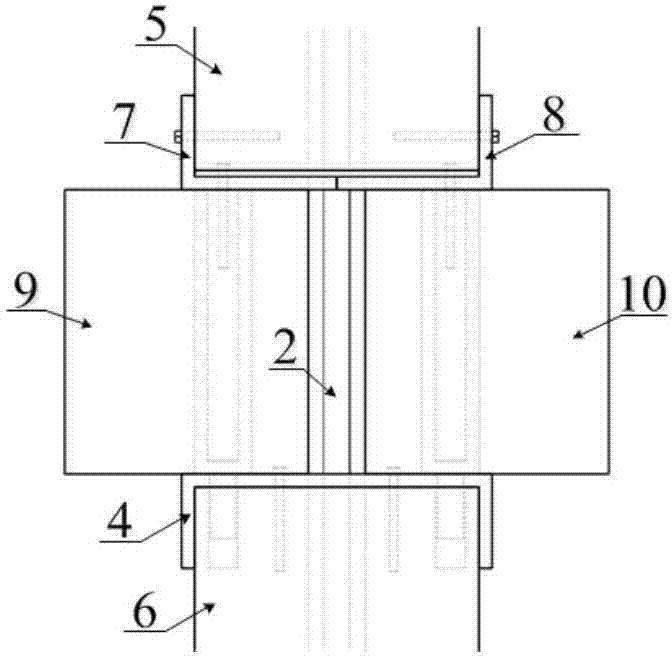

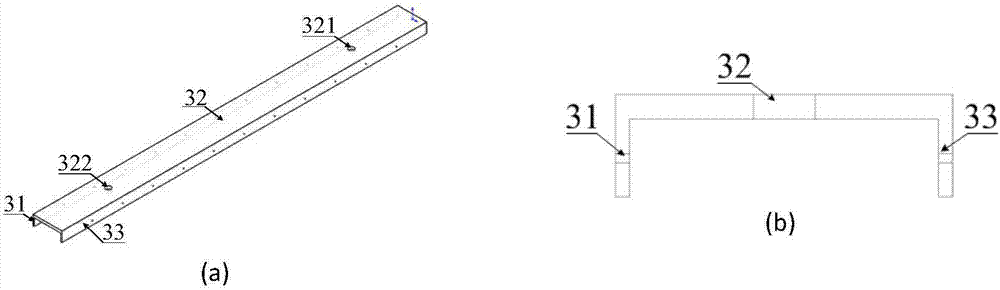

Assembling prestress orthogonal laminated wood shear wall

ActiveCN107574953AIn line with the structural design conceptImprove lateral force resistanceWallsProtective buildings/sheltersPre stressSelf recovery

The invention discloses an assembling prestress orthogonal laminated wood shear wall. The assembling prestress orthogonal laminated wood shear wall comprises bond-free prestress bars, bearing beams, CLT wall plates, slab supporting frames and limiting steel components. The two limiting steel components are connected with a base. The CLT wall plates on the lower layer tightly abut against the basethrough the bond-free prestress bars. The bearing beams on the lower layer are connected with the CLT wall plates on the lower layer. The slab supporting frames on the lower layer are connected with the CLT wall plates on the lower layer and then put on the top of the bearing beams on the lower layer. The CLT wall plates on the upper layer are connected with the two slab supporting frames on the lower layer. The bearing beams on the upper layer are connected with the CLT wall plates on the upper layer. The two bond-free prestress bars penetrate through the CLT wall plates on the upper layer and the lower layer. The CLT shear wall has high initial rigidity, high ultimate bearing capacity and a certain self-recovery characteristic under lateral loads after the bond-free prestress bars are applied, and the common damage mode of weak joints and strong components of a common CLT shear wall is avoided. The assembling prestress orthogonal laminated wood shear wall is high in assembling degree, and prestress loss caused when CLT slabs have big creep deformation under the band stress action can be reduced obviously due to the arrangement of the slab supporting frames on the lower layer.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

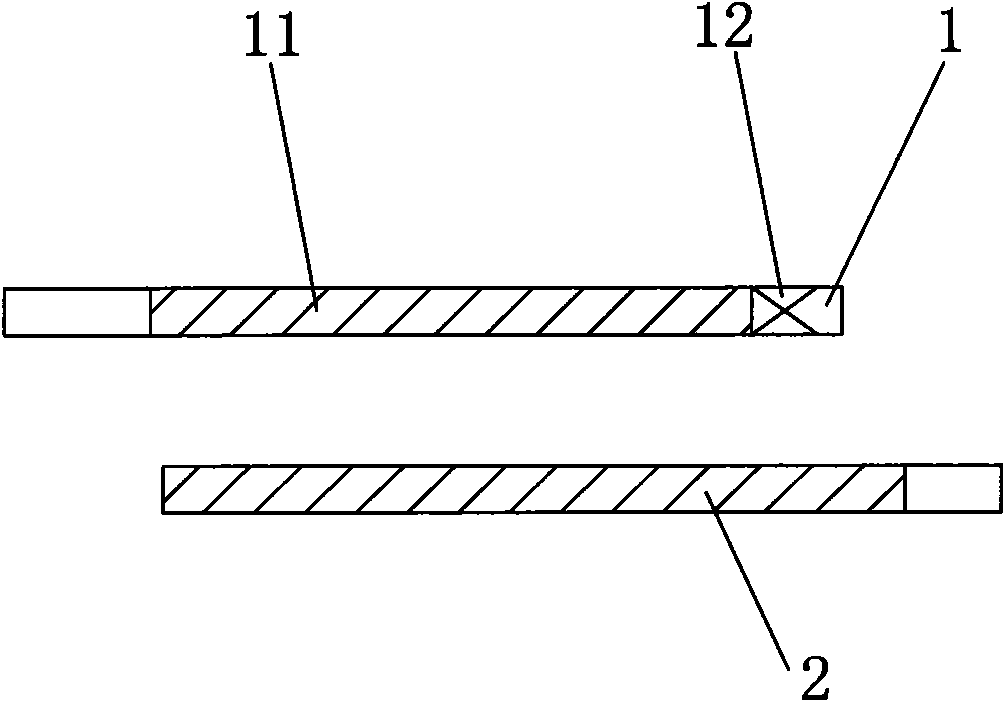

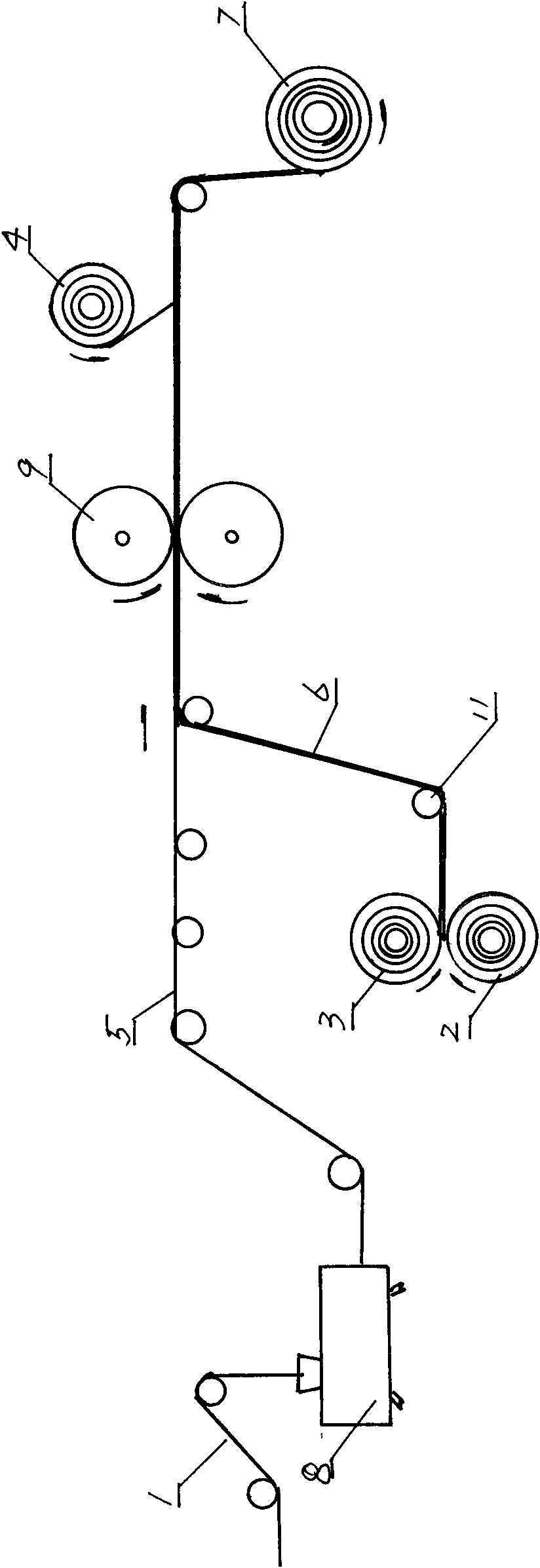

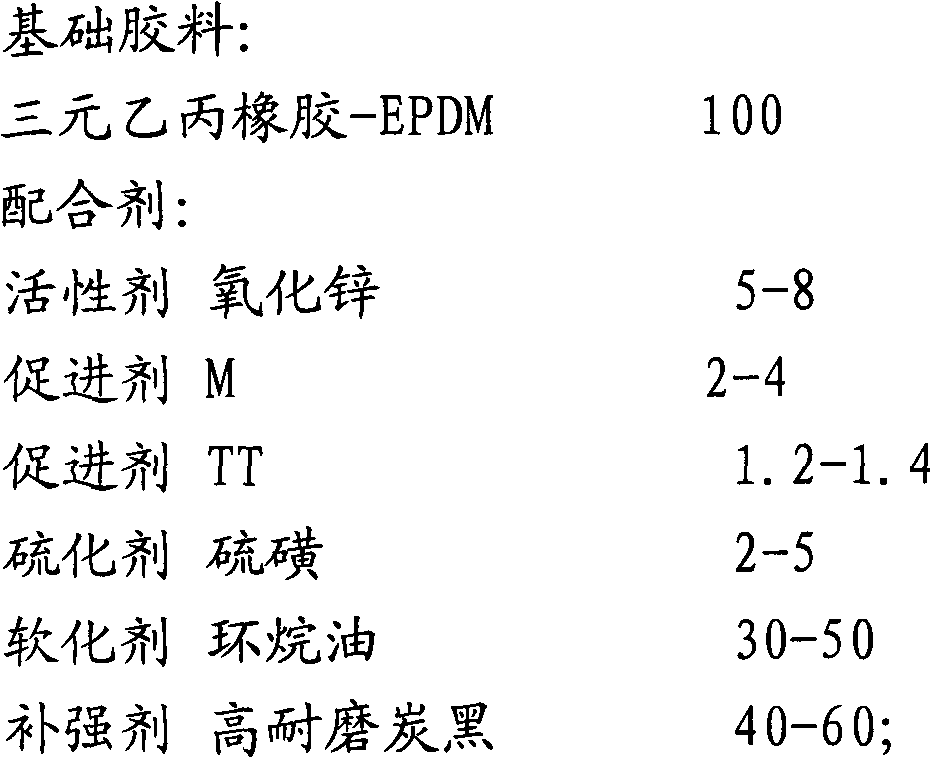

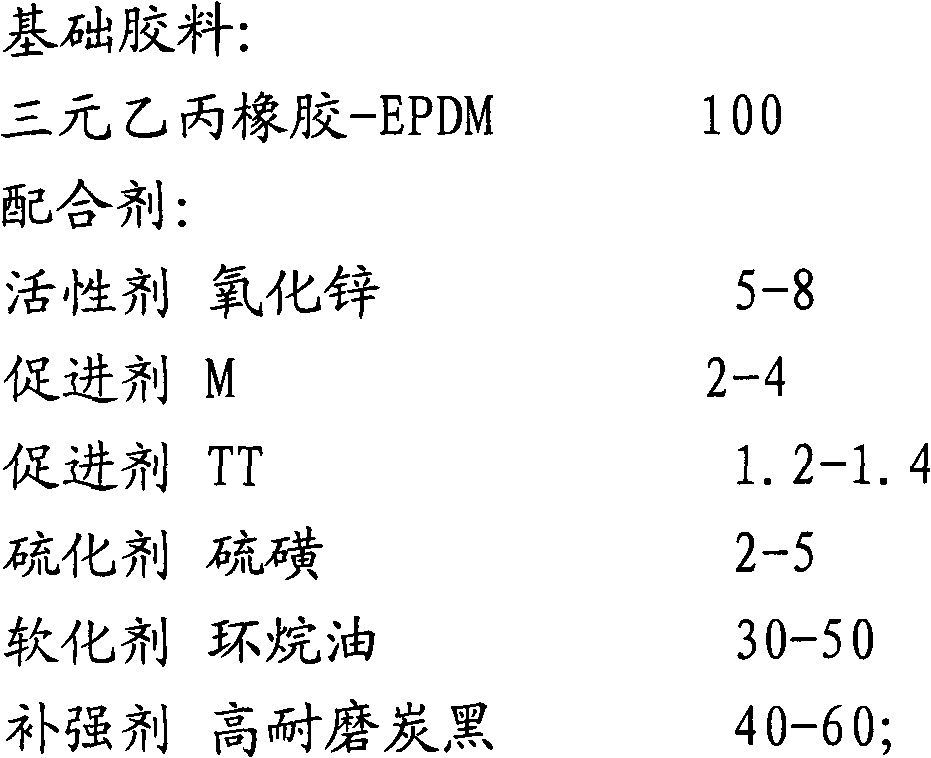

Method for preparing rubber-metal composite waterproof sheet

InactiveCN102127267AHigh strengthHigh extensionFlat articlesMetal layered productsPolymer scienceAdhesive

The invention discloses a method for preparing a rubber-metal composite waterproof sheet, and relates to a method for preparing a rubber composite waterproof sheet. The method has a simple manufacturing process; and the prepared product has high strength, self-healing property and high plasticity, and the construction process is simple without adhesive. The method is characterized by comprising the following steps of: laminating and gluing a 2-8-mesh aluminum mesh and a vulcanized rubber sheet to obtain a laminated sheet of the 2-8-mesh aluminum mesh and the vulcanized rubber sheet; laminating a non-vulcanized rubber sheet with the laminated sheet, and compounding into a composite sheet of the non-vulcanized rubber sheet, the 2-8-mesh aluminum mesh and the vulcanized rubber sheet through a press roll; and compounding an isolating membrane on the composite sheet, laminating and gluing, and winding into a reel on a winding roller to obtain the rubber-metal composite waterproof sheet integrating the vulcanized rubber sheet, the aluminum mesh, the non-vulcanized rubber sheet, and the isolating membrane. The method is used for waterproof sheets in constructional engineering.

Owner:TIANJIN YATENGDA RUBBER & PLASTIC PRODS DEV

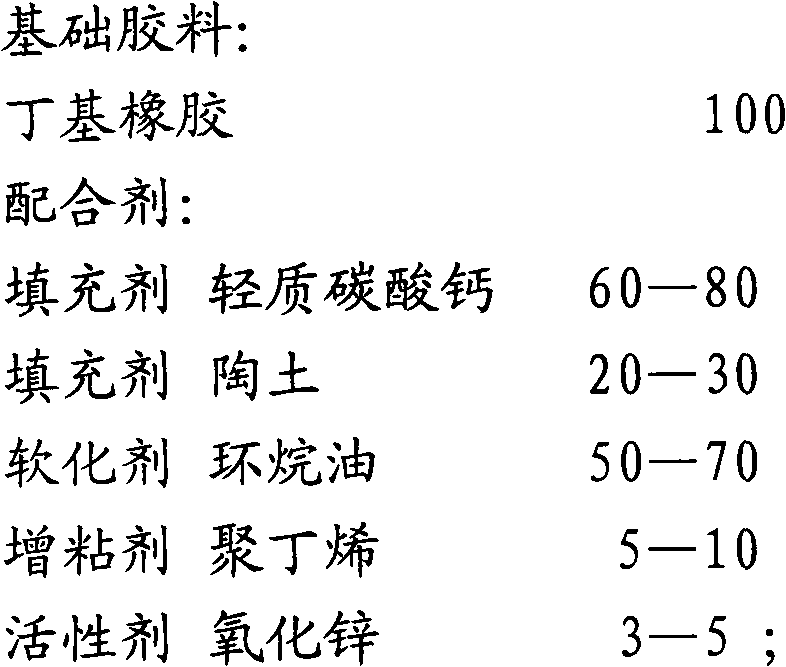

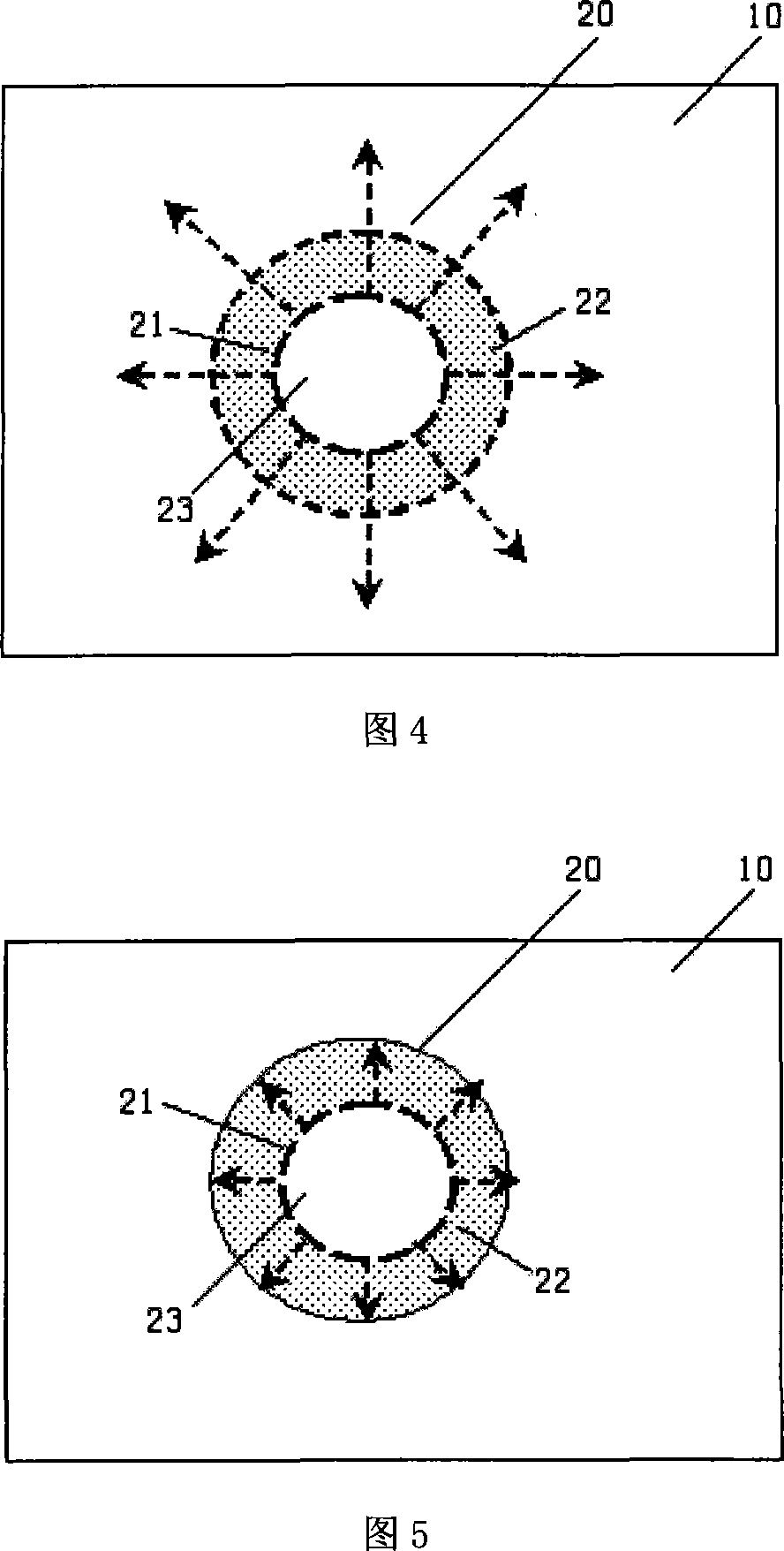

Irrigation system based on water transport quantity automatic control material

InactiveCN101112169AImprove water delivery capacityReduced water delivery performanceSelf-acting watering devicesWatering devicesForest industryAutomatic control

The invention discloses an irrigation system based on delivery automatic-control material, which relates to an irrigation system. The invention adopts a pump (20) to lay out irrigation pipe network in the soil (10); the terminal of the irrigation pipe network is communicated with water source (40) by a valve (30). The structure of the pipe (20) is that the cross section from the inside to outside is provided with an inner pipe (23), a frame (21) and an outer pipe (22) in sequence; the frame (21) is composed of permeable or semipermeable pipe; the outer pipe (22) is an outer delivery automatic-control pipe; the inner pipe (23) is normal hollow pipe or a conveyance pipe made of strongly permeable material. The invention, water transmission property of which can change according to the water content of plant soil, so as to save irrigation water, provide more proper environment for plant growth and is applicable to irrigation fields which relates to elivery automatic-control, such as agriculture, gardens, forestry practice, etc.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

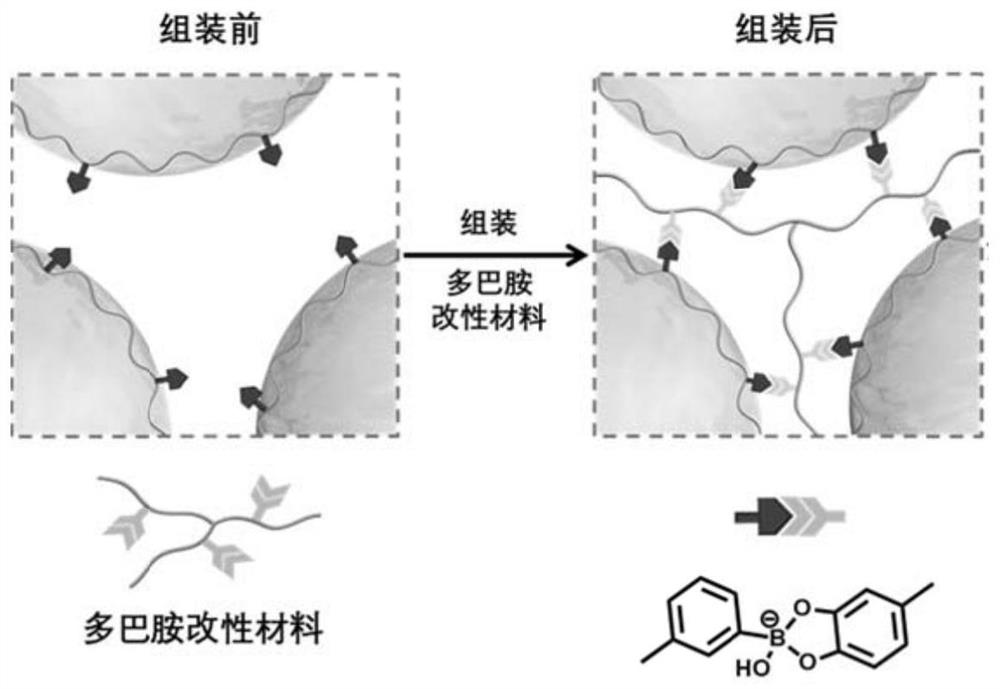

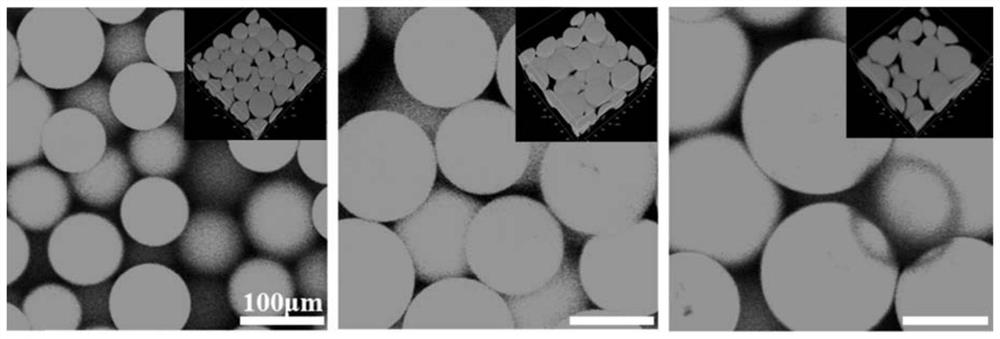

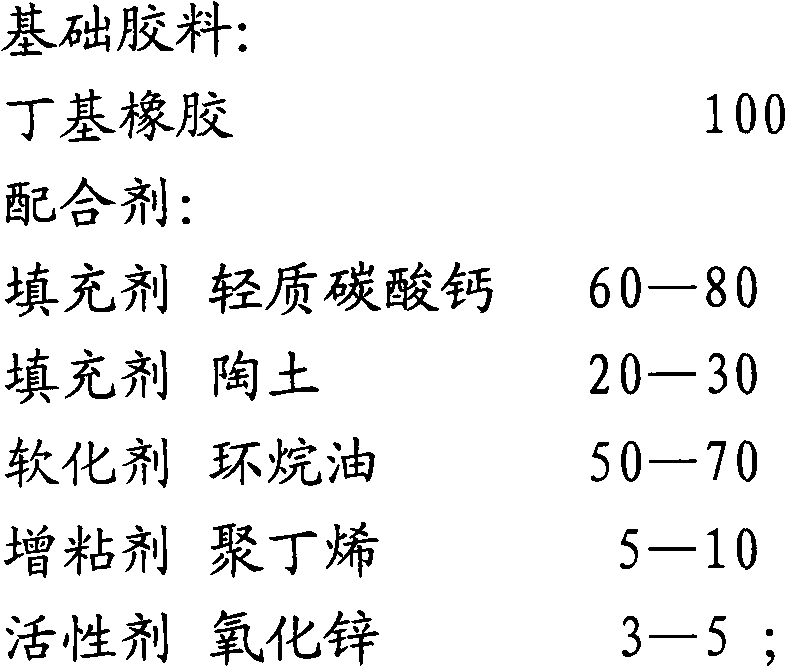

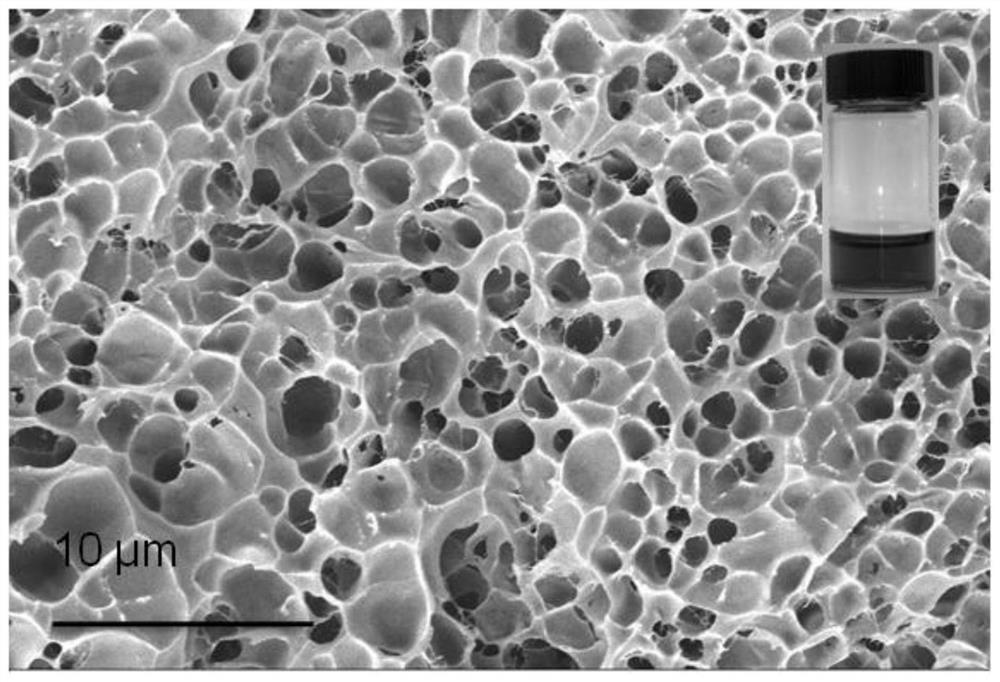

Microgel assembly scaffold for tissue regeneration and repair, and preparation method thereof

ActiveCN112891626AInjectable propertiesHas self-healing propertiesPharmaceutical delivery mechanismProsthesisTissue defectUltraviolet lights

The invention discloses a microgel assembly scaffold for tissue regeneration and repair, and a preparation method thereof. The scaffold has injectability and can be used for minimally invasive treatment of tissue defects and promotion of tissue regeneration and repair. The preparation method of the microgel assembly scaffold comprises the following steps: respectively synthesizing a carbon-carbon double bond and phenylboronic acid dual-modified polymer material and a carbon-carbon double bond modified polymer material; preparing microgel liquid drops by adopting a microfluidic technology, and initiating free radical polymerization by blue light or ultraviolet light to realize internal crosslinking of microgel; and preparing dopamine modified polymer molecules, and assembling the microgel into the scaffold by utilizing a dynamic bonding effect constructed by phenylboronic acid and dopamine. The scaffold has porosity, self-healing property and cell compatibility, can be injected at physiological temperature, is easy to adhere to surrounding tissues, and shows a good tissue regeneration and repair effect.

Owner:SOUTH CHINA UNIV OF TECH

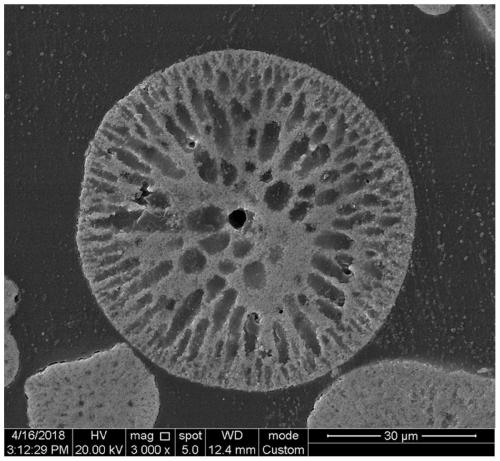

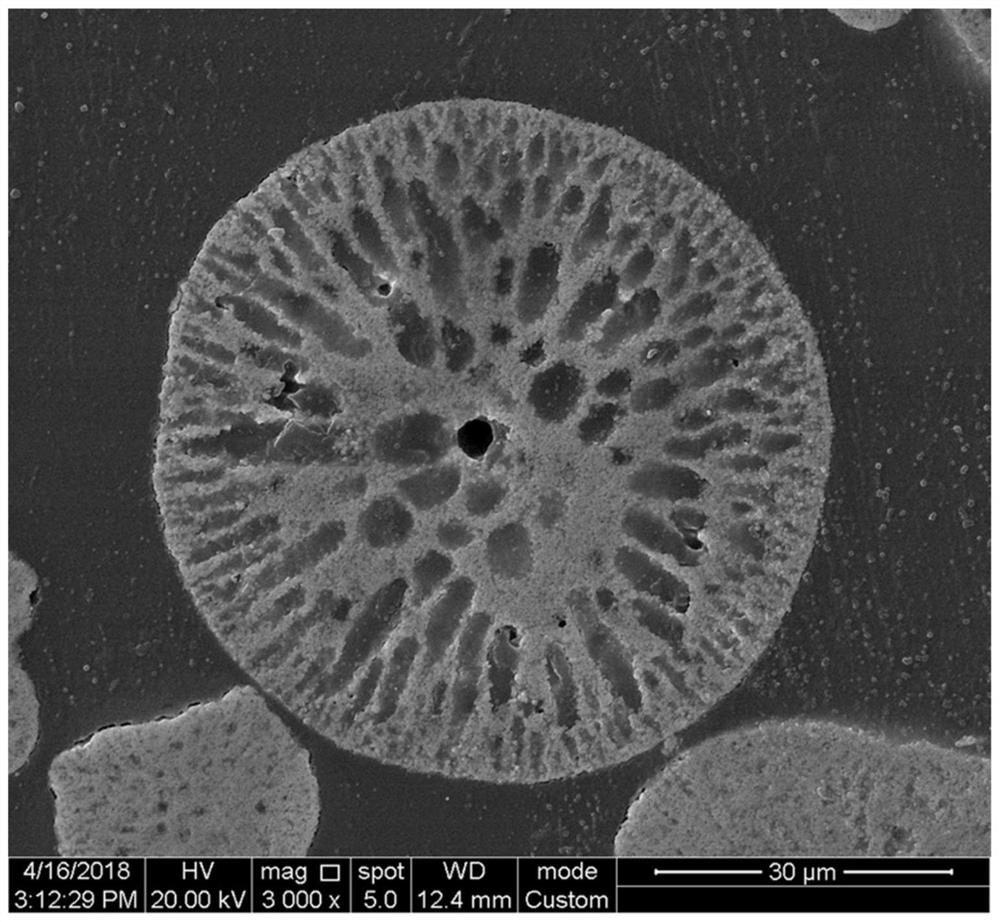

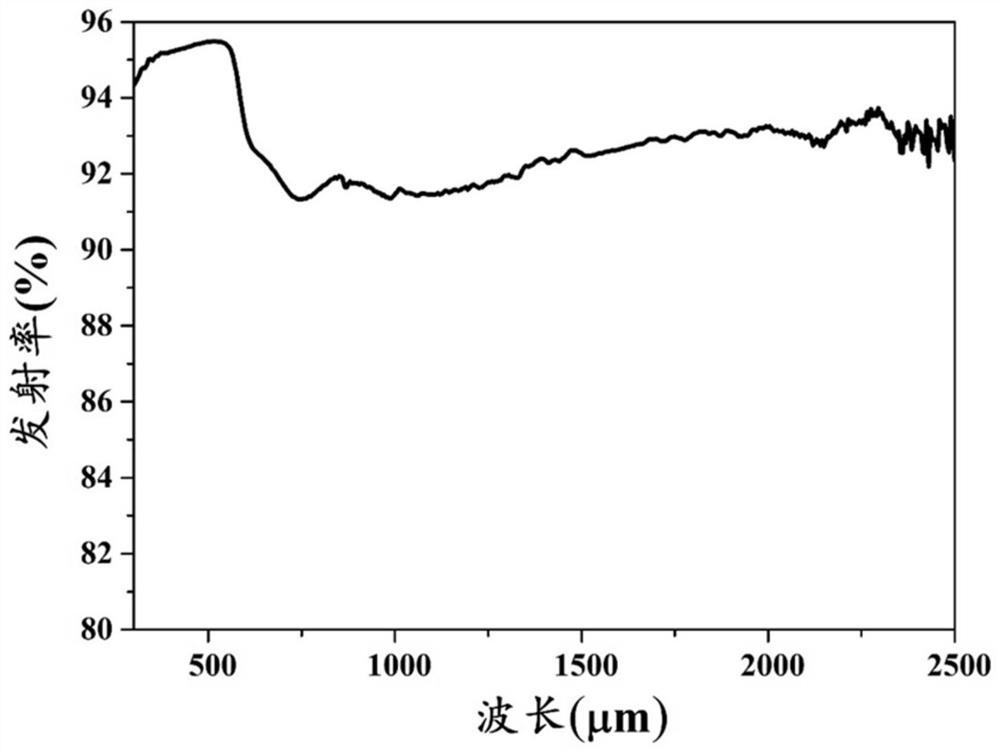

Preparation method of thermal insulation microsphere filler with high emissivity and ablation resistance

ActiveCN110041091AHigh emissivityLarge specific surface areaCeramicwareThermal insulationMicrosphere

The invention relates to a preparation method of thermal insulation microsphere filler with high emissivity and ablation resistance. The preparation method of the thermal insulation microsphere fillerwith high emissivity and ablation resistance comprises the steps as follows: preparation and mixing of powder, preparation of precursor slurry, preparation of precursor powder, sintering and the like. Compared with the prior art, the preparation method has the advantages that the production efficiency is high, the production period is short, equipment is simple, operation is convenient, preparedspray powder has better degree of sphericity and special pore structures, and a coating prepared from microspheres as filler has low mass ablation rate, high self-radiance and good mechanical properties and can effectively resist heat flow impact of 800 kW / m<2> or above and protect matrixes from deformation and failure due to high temperature erosion.

Owner:SHANGHAI JIAO TONG UNIV

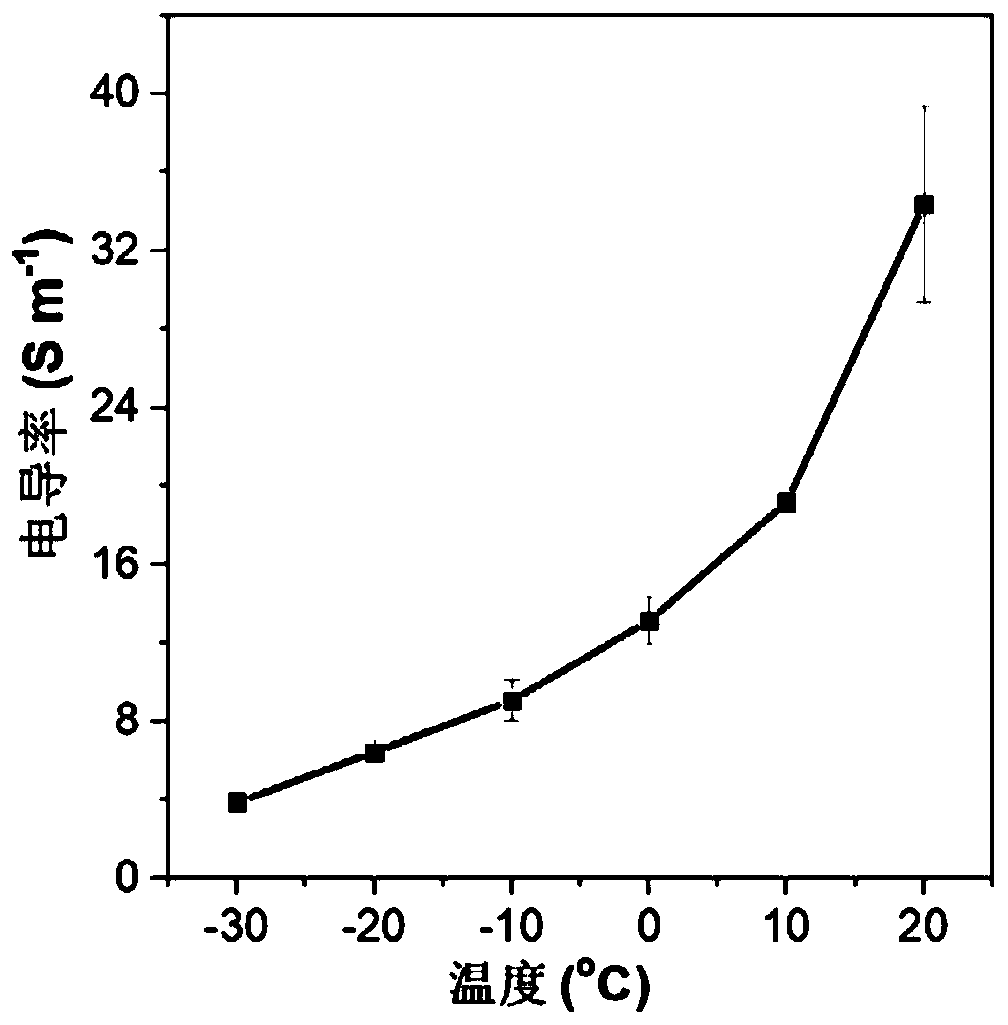

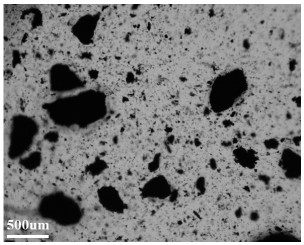

Injectable self-healing hydrogel with conductivity and preparation method thereof

The invention relates to injectable self-healing hydrogel with conductivity and a preparation method thereof. The method comprises the steps that firstly, a methacrylic anhydride modified natural polymer is adopted, then, pyrrole is added into a modified natural polymer solution, stirring is performed for 1-3 h, then, an initiator is added, and after a reaction is ended, dialysis and freeze dryingare performed to obtain a polypyrrole grafted natural polymer; then, the polypyrrole grafted natural polymer is dissolved into ultra pure water, and then, due to the Fe3+ cross linking effect, the injectable self-healing hydrogel with the conductivity is prepared. The prepared self-healing hydrogel has the advantages of conductivity and injectability, the hydrogel can be implanted into the body in a minimally invasive mode, the irregular defect part is restored, and meanwhile wound healing is promoted. The injectable self-healing hydrogel has the potential application prospect in the field ofbiology medicine materials.

Owner:四川创智炜业科技有限公司

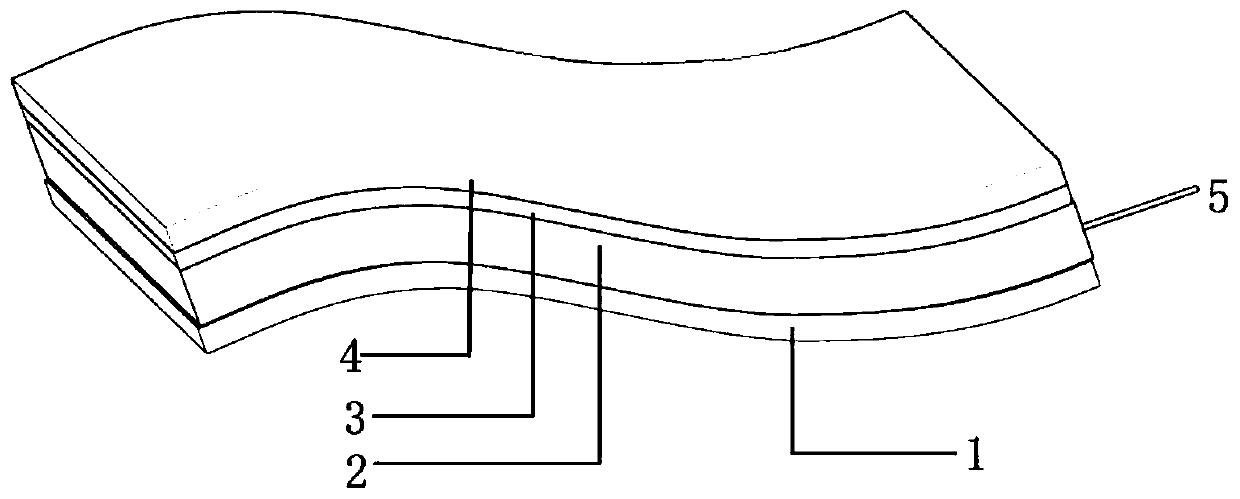

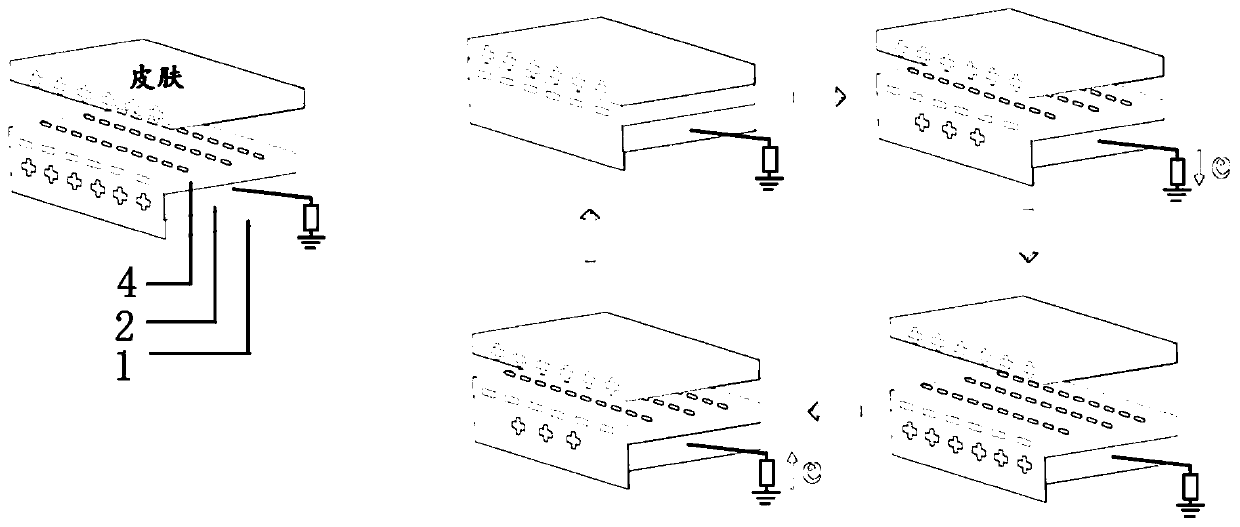

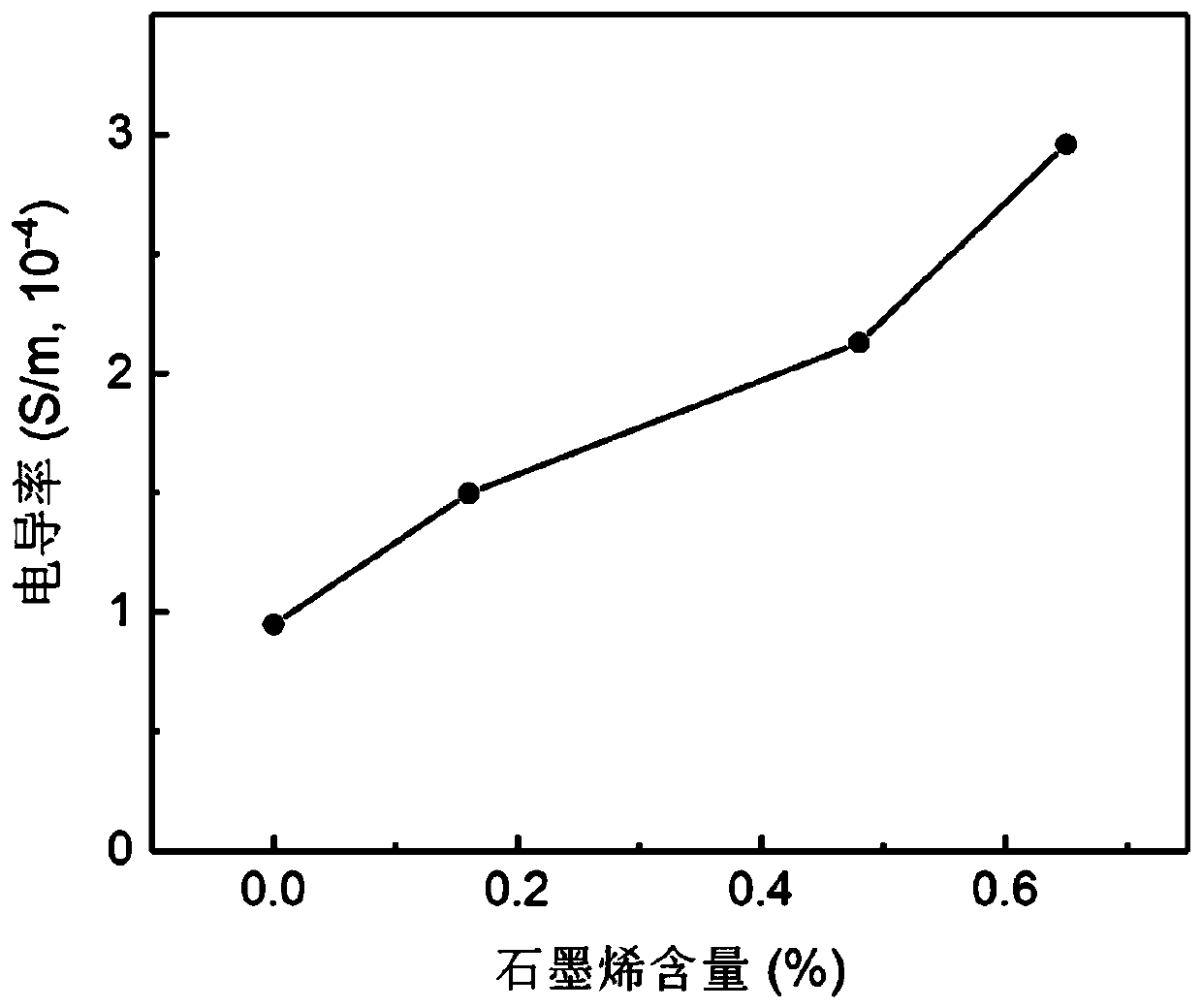

High-output self-healing single-electrode friction nano generator and preparation method thereof

ActiveCN111355402AHigh dielectric constantIncrease surface charge densityFriction generatorsThin membraneElectrically conductive

The invention relates to a high-output self-healing single-electrode friction nano generator and a preparation method thereof, and belongs to the technical field of nano energy. The high-output self-healing single-electrode friction nano generator includes a wire, a triboelectrification layer which is in contact with the skin, and the cross-linking layer, the self-healing electrode layer and the supporting layer which hare sequentially located below the triboelectrification layer. The triboelectrification layer is a CNTs / PDMS composite film; the cross-linking layer is a mixture formed by PDMSand PMHS; the self-healing electrode layer is PVA hydrogel added with graphene and glycerin; the PDMS film serves as support layer. According to the nano-generator, graphene is added into PVA hydrogelto serve as a conductive reinforcing phase, meanwhile, crystal lattices are refined, and the mechanical property of the material is improved; glycerol is added, so that rapid self-healing can be realized in air; CNT is added into PDMS to serve as a reinforcing phase, so that the friction layer has high dielectric property, and the output of the friction nano generator is improved. The cross-linking agent enables the self-healing electrode layer and the friction layer to have good physical cross-linking.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

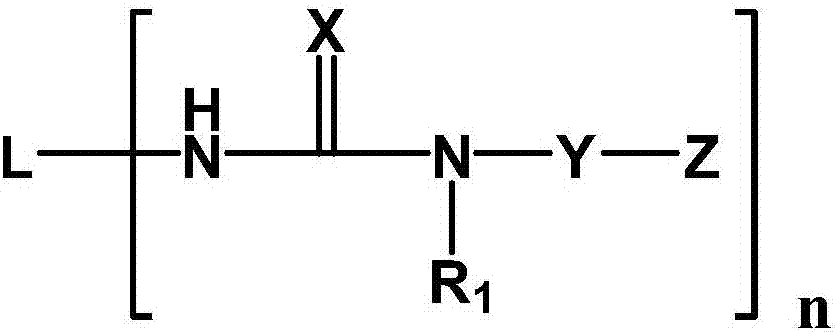

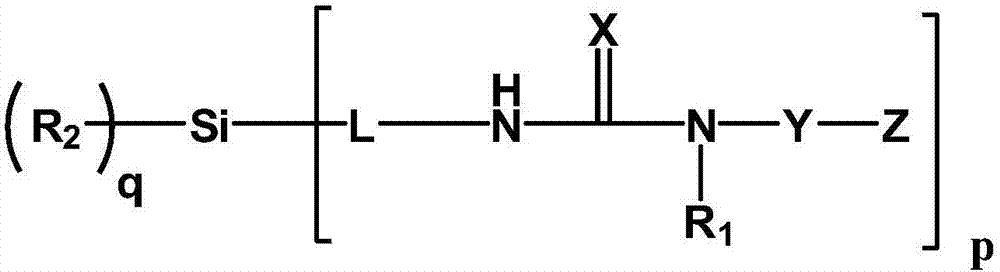

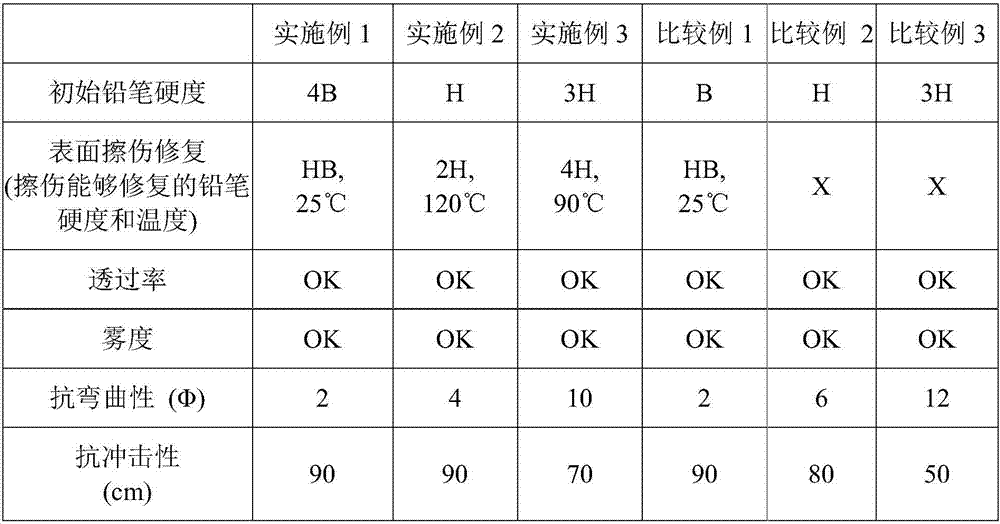

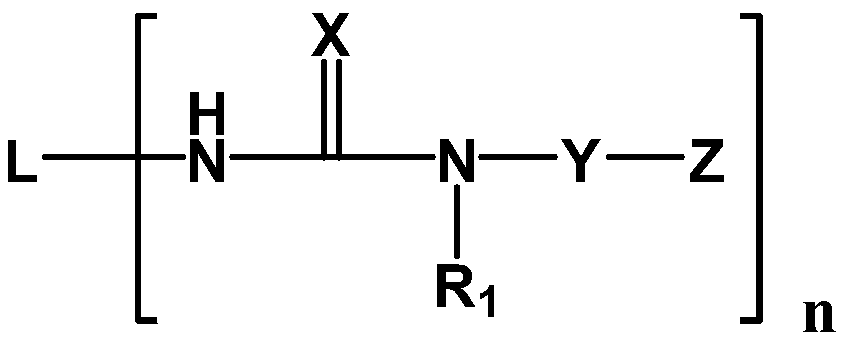

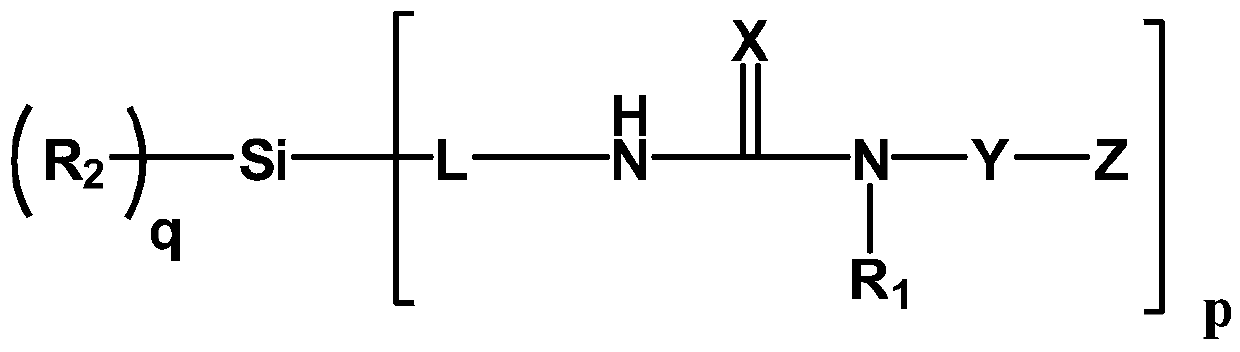

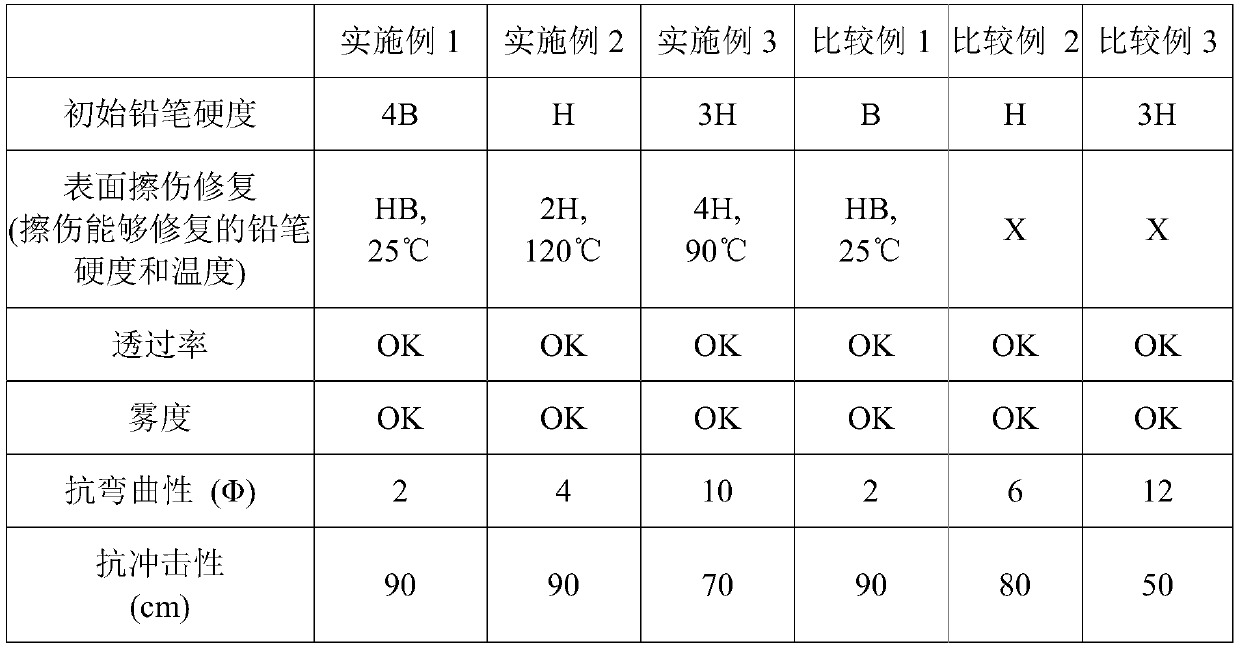

Composition for forming coating layer having self-healing characteristics, coating layer, and coating film

ActiveCN107075275APromotes self-healingImprove mechanical propertiesPolyurea/polyurethane coatingsSelf-healingOrganic solvent

The present invention relates to: a composition for forming a coating layer having self-healing characteristics, containing a photoinitiator, an organic solvent, and a reversible covalent bond compound comprising a (thio)urea functional group comprising one or more sterically hindered (thio)urea bonds and a (meth)acrylate-based or vinyl-based functional group bound to the (thio)urea functional group; a coating film prepared from the composition; a coating film comprising the coating film; and an electric home appliance and a display device comprising the coating film.

Owner:LG CHEM LTD

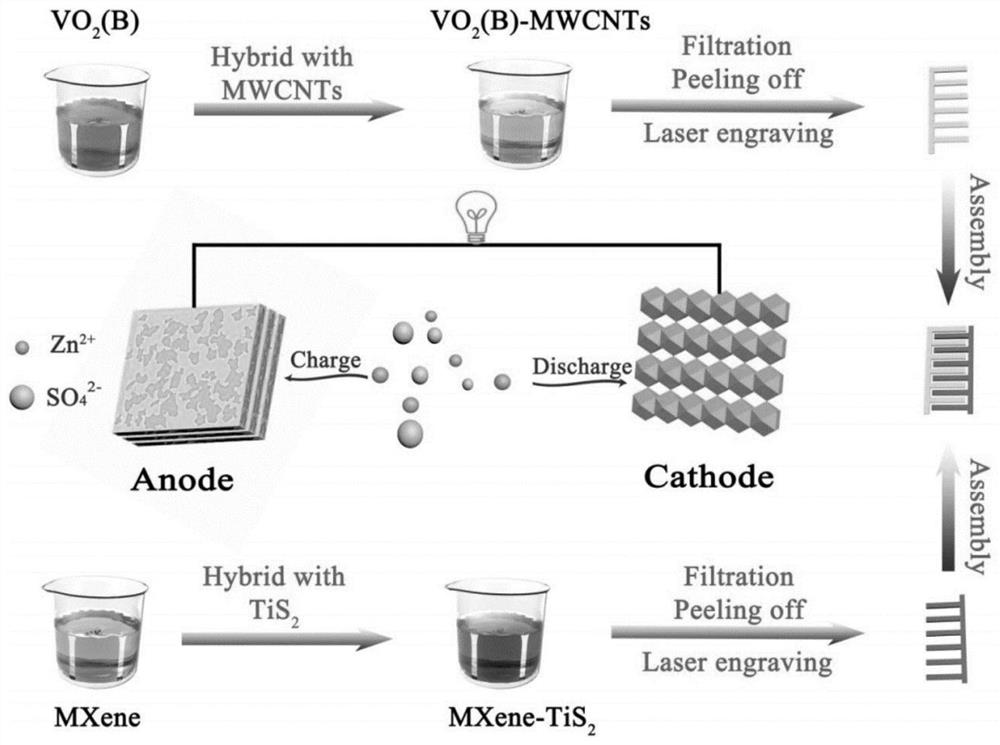

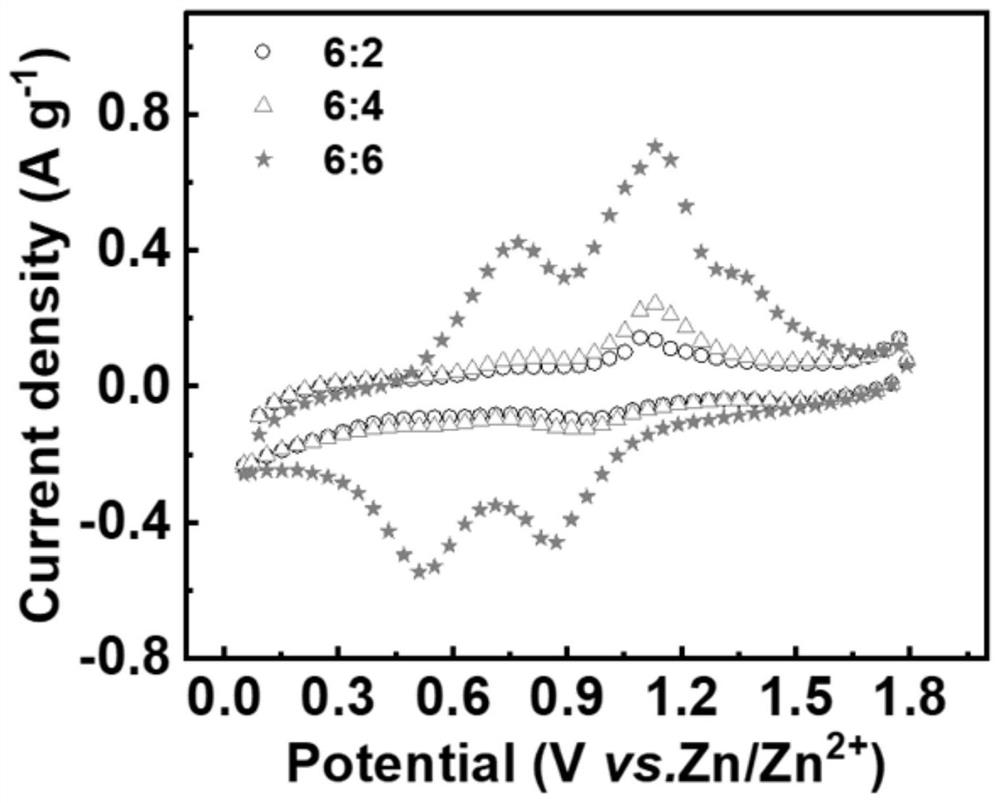

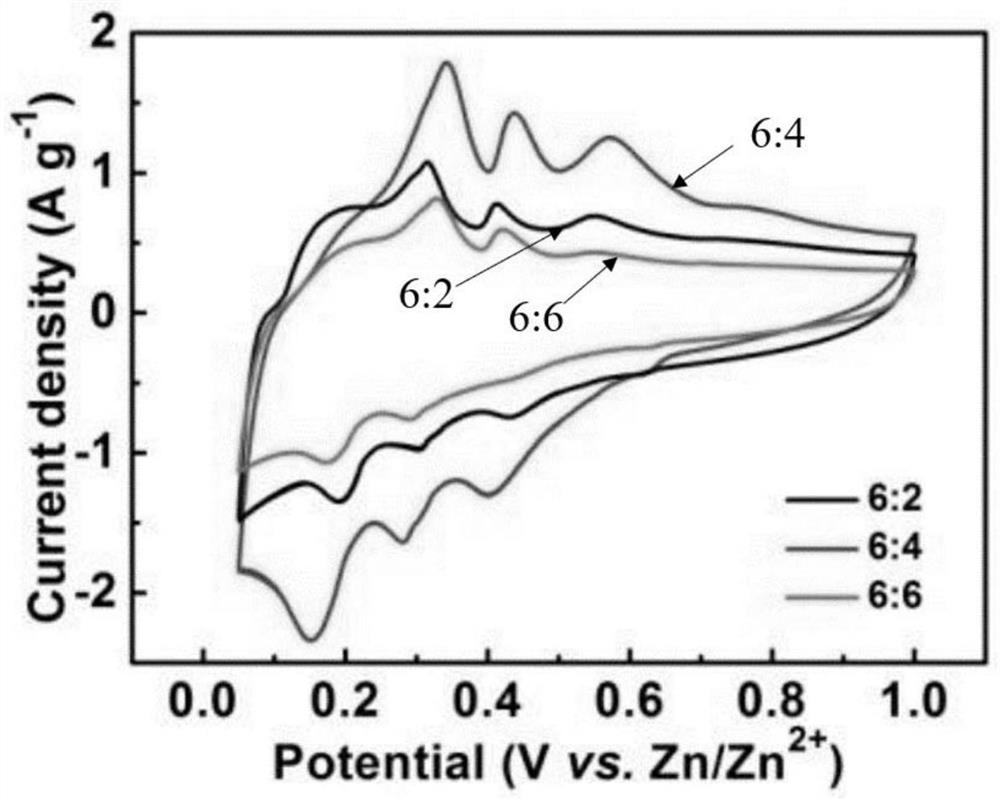

Multifunctional zinc ion micro battery and preparation method and application thereof

ActiveCN112928342AImprove electrochemical performanceImprove flexibilityCell electrodesSecondary cellsHigh energyEngineering

The invention discloses a multifunctional zinc ion micro battery and a preparation method thereof. The multifunctional micro zinc ion battery is mainly composed of an MWCNTs-VO2 (B) positive electrode, an MXene-TiS2 negative electrode and a PAM-ZnSO4 hydrogel electrolyte. The preparation method of the multifunctional micro zinc ion battery mainly comprises the following steps: S1, preparing the MWCNTs-VO2 (B) positive electrode; s2, preparing an MXene-TiS2 negative electrode; S3, preparing a PAM-ZnSO4 hydrogel electrolyte is carried out; and S4, packaging the zinc ion micro battery. The multifunctional micro zinc ion battery provided by the invention has the advantages of high energy density, excellent flexibility, high safety, variable specifications and high temperature resistance, and meanwhile, the preparation process is simple and the cost is low.

Owner:ANHUI UNIVERSITY

Method for preparing rubber-metal composite waterproof sheet

InactiveCN102127267BHigh strengthHigh extensionFlat articlesMetal layered productsPolymer scienceAdhesive

Owner:TIANJIN YATENGDA RUBBER & PLASTIC PRODS DEV

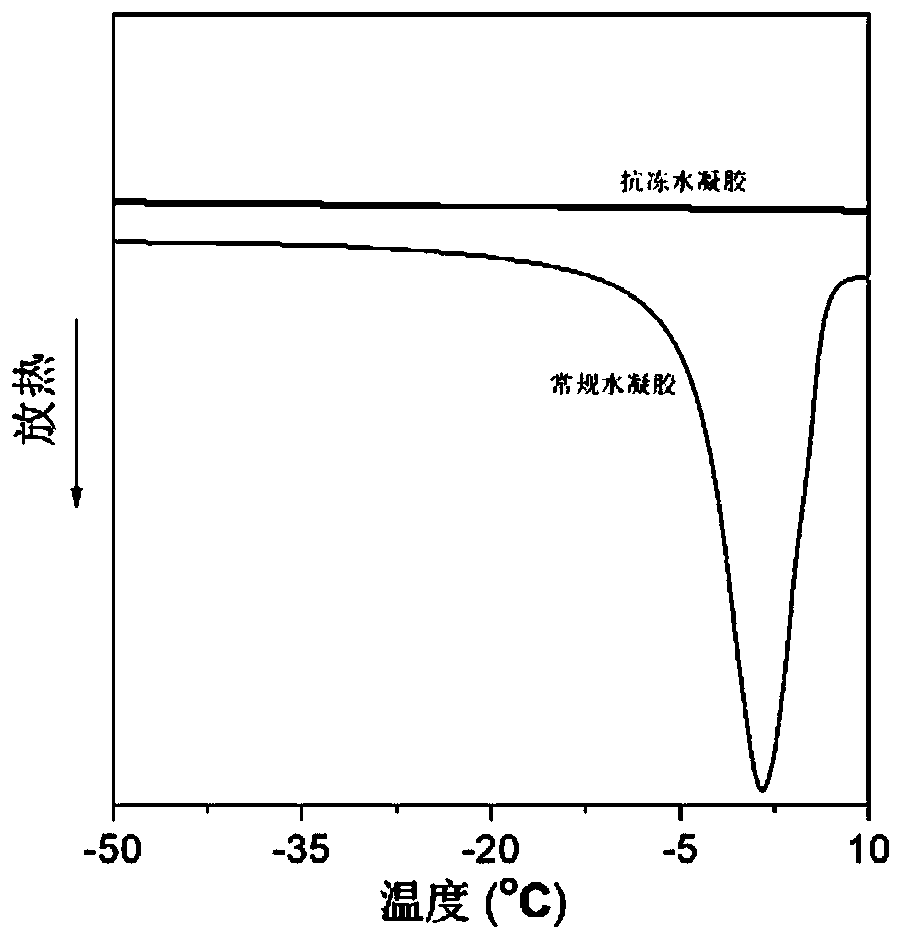

Self-healing anti-freezing conductive fibroin hydrogel and preparation method thereof

The invention discloses self-healing anti-freezing conductive fibroin hydrogel and a preparation method thereof, and belongs to the field of flexible electronic materials. The preparation method comprises the following steps: firstly, modifying pyrrole by adopting dopamine, polymerizing in an acid environment to obtain dopamine modified polypyrrole, then taking MAX powder as a raw material, etching under hydrofluoric acid and hydrochloric acid to obtain an MXene material, then respectively adding the dopamine modified polypyrrole and the MXene material into a polyvinyl alcohol aqueous solution, uniformly mixing, then adding a fibroin aqueous solution, further mixing, and finally, preparing the modified polypyrrole / MXene composite material. And finally, dropwise adding a mixed aqueous solution of borax and glycerol into the mixed solution to prepare the self-healing anti-freezing conductive fibroin hydrogel. The self-healing anti-freezing conductive fibroin hydrogel has the advantages of self-healing, freezing resistance, air permeability and good conductivity, overcomes the three defects of no freezing resistance, no self-healing and non-uniform conductive material distribution of common fibroin hydrogel, and has a wide application prospect in the field of flexible electronic products.

Owner:FUZHOU UNIV

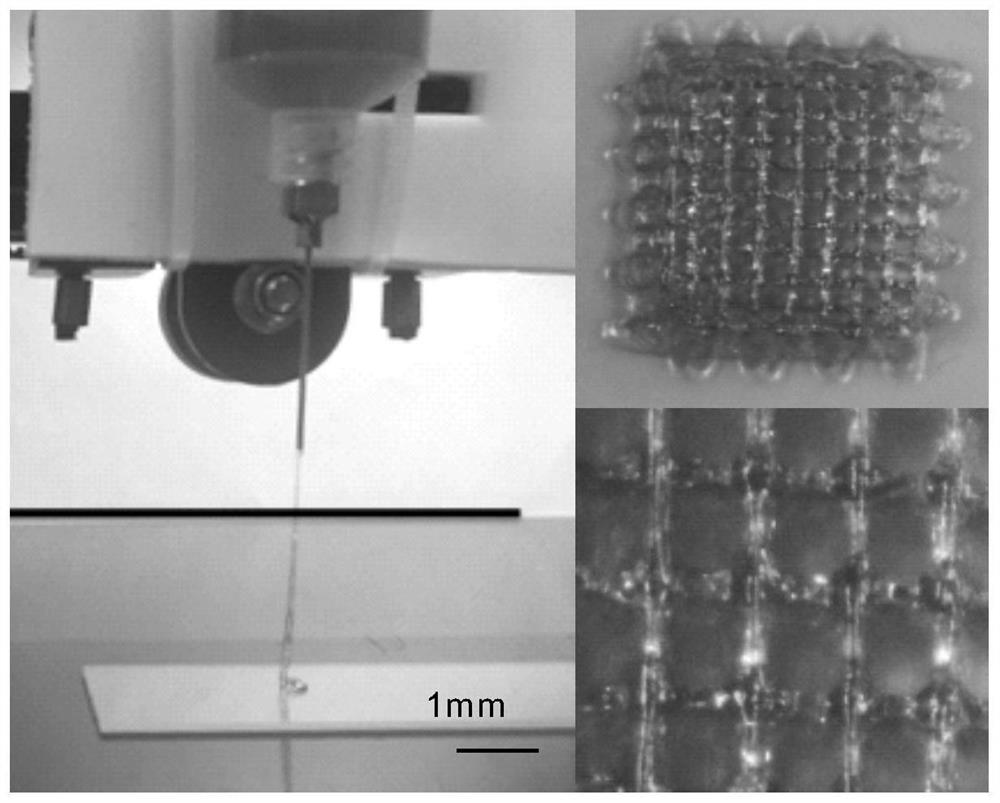

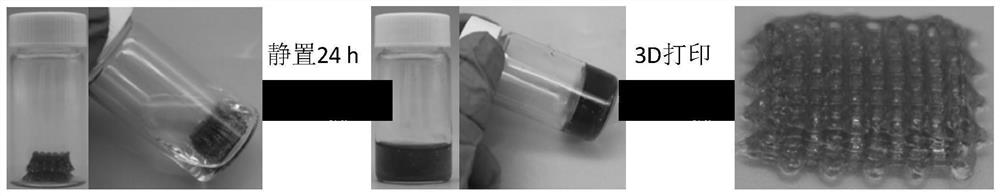

Preparation of nano-composite hydrogel ink and application of nano-composite hydrogel ink in 3D printing

ActiveCN112795235AHas discontinuityRealize splicingAdditive manufacturing apparatusInksComposite materialPolymer chemistry

The invention discloses preparation of nano-composite hydrogel ink and application of the nano-composite hydrogel ink in 3D printing. The preparation comprises the following steps: firstly, compounding a free radical initiator and an inorganic metal nano-material in a dynamic covalent bond mode to obtain a nano-composite; and then, in the presence of a polymerizable monomer, initiating a local rapid free radical polymerization reaction of the nano-composite to obtain the nano-composite hydrogel ink. The 3D printing of the ink is realized by taking dynamic coordination as a crosslinking mode and utilizing intermolecular chain and chain hydrogen bond interaction, and a 3D printing hydrogel model with self-repairing property, repeated recycling property, stretchability and excellent photo-thermal performance is prepared.

Owner:HEFEI UNIV OF TECH

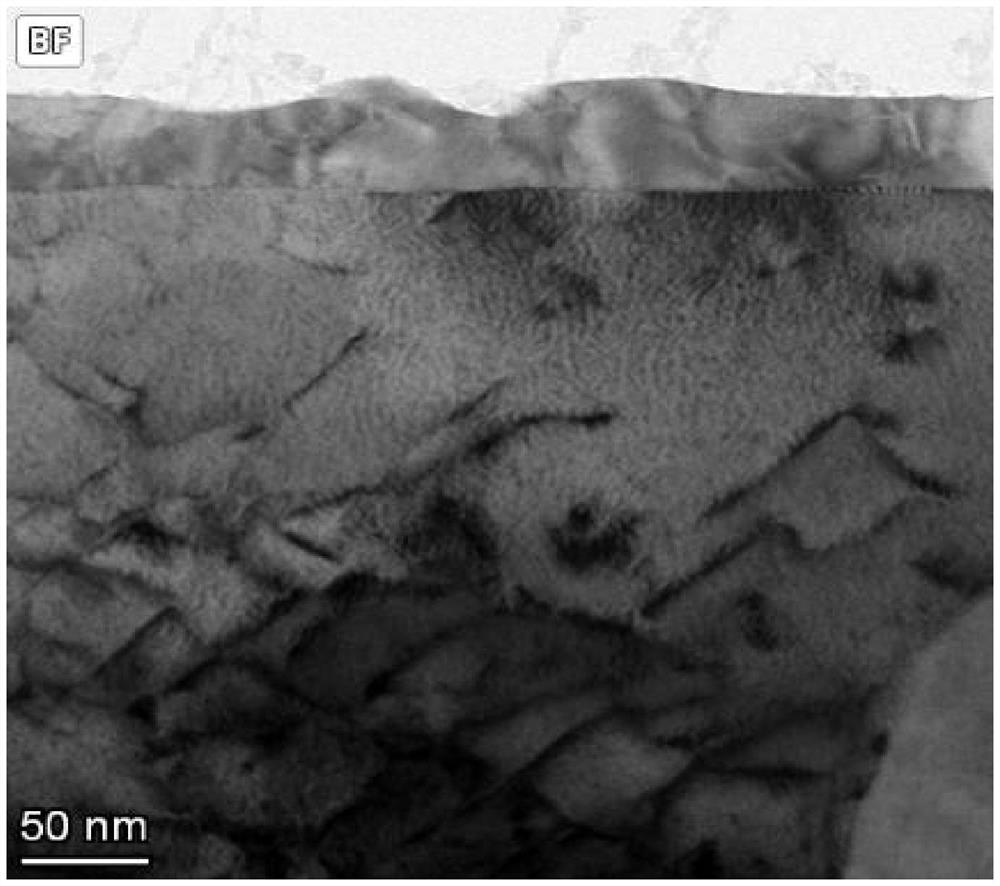

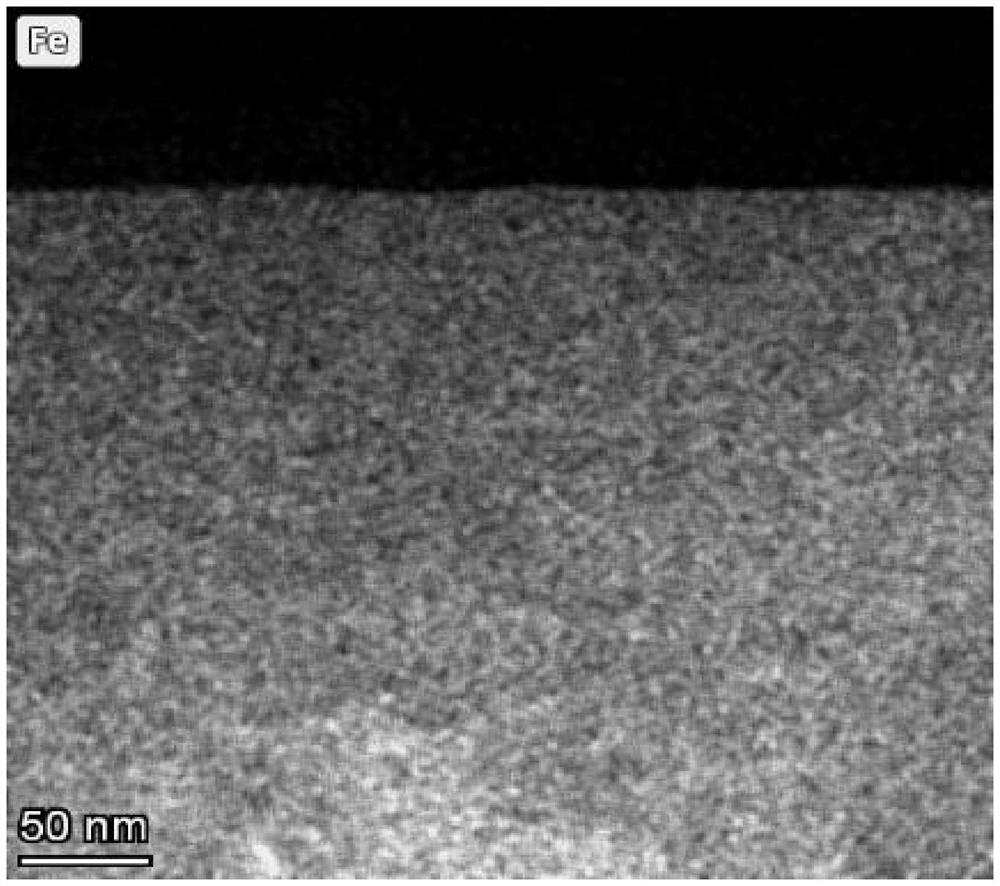

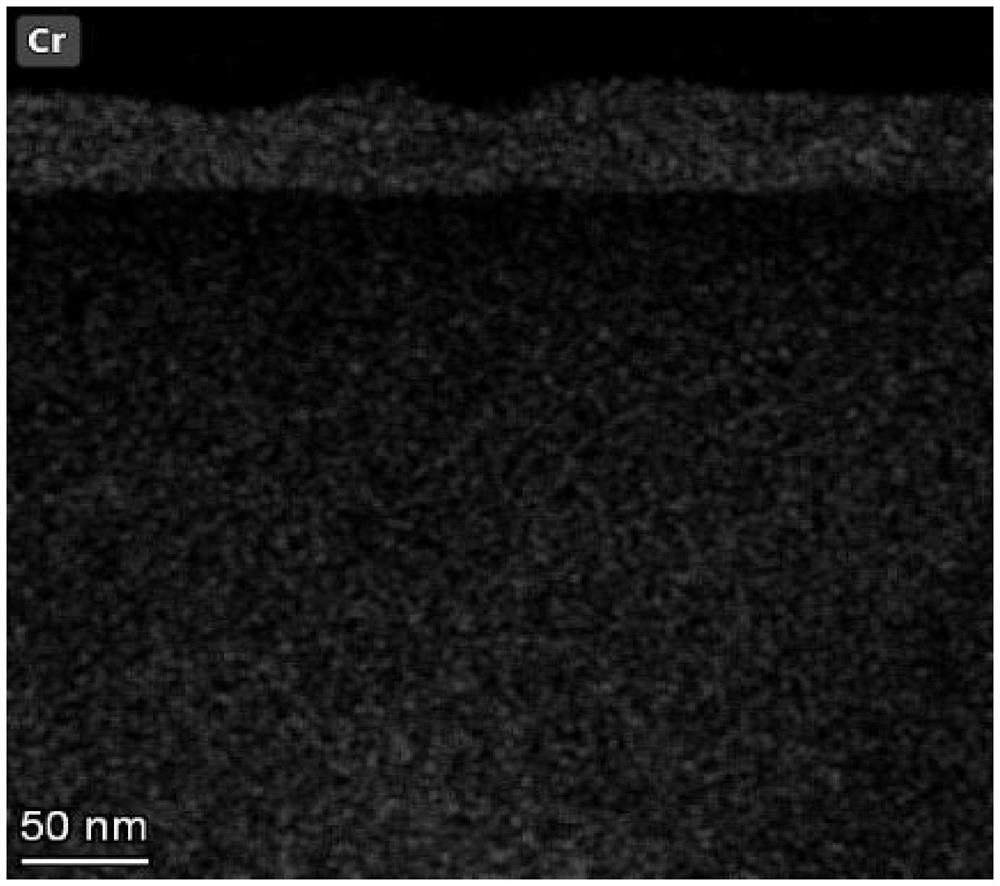

Treatment method for improving corrosion resistance of steel material in lead or lead bismuth

ActiveCN114561614AFacilitated DiffusionPrevent continuous thinningNuclear energy generationFast fission reactorsLead bismuthNuclear reactor

The invention belongs to the technical field of nuclear reactor materials, and discloses a treatment method for improving the corrosion resistance of a steel and iron material in lead or lead bismuth, the steel and iron material containing Mn element and Cr element is selected, high-energy fast neutrons generated by fission are adopted as an irradiation source, the steel and iron material is irradiated, and the corrosion resistance of the steel and iron material in lead or lead bismuth is improved. And the Mn element and the Cr element in the steel and iron material are diffused to the surface of the steel and iron material to form a compact oxidation film, and the corrosion resistance of the steel and iron material is improved. Formation of the oxidation layer with a compact structure is enhanced through irradiation, the oxidation layer has good protectiveness and has the self-repairing characteristic in the irradiation environment, and a new solution thought is provided for enhancing the corrosion resistance of the steel in the lead and lead bismuth coolant fast reactor.

Owner:XI AN JIAOTONG UNIV

Compositions, coatings and coating films for forming self-healing coatings

ActiveCN107075275BPromotes self-healingImprove mechanical propertiesPolyurea/polyurethane coatingsDisplay deviceMethyl group

The present invention relates to a composition for forming a coating with self-healing properties, a coating film prepared from the composition, a coating film comprising the coating film, and a household appliance and a display device comprising the coating film, the The composition comprises: a reversible copolymer comprising a (thio)urea functional group comprising one or more hindered (thio)urea linkages and a (meth)acrylate or vinylic functional group attached to said (thio)urea functional group. valent compounds; photoinitiators; and organic solvents.

Owner:LG CHEM LTD

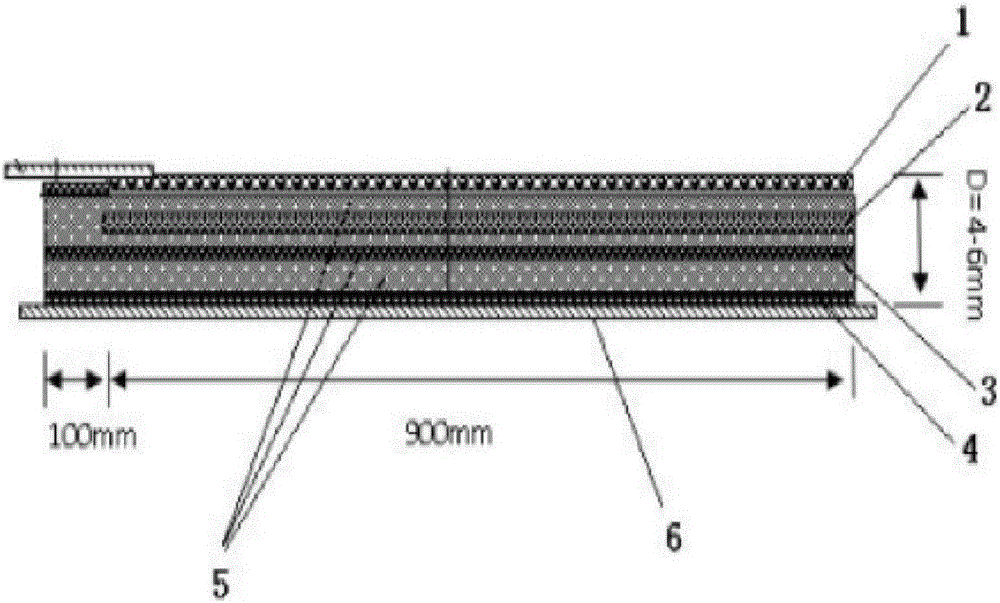

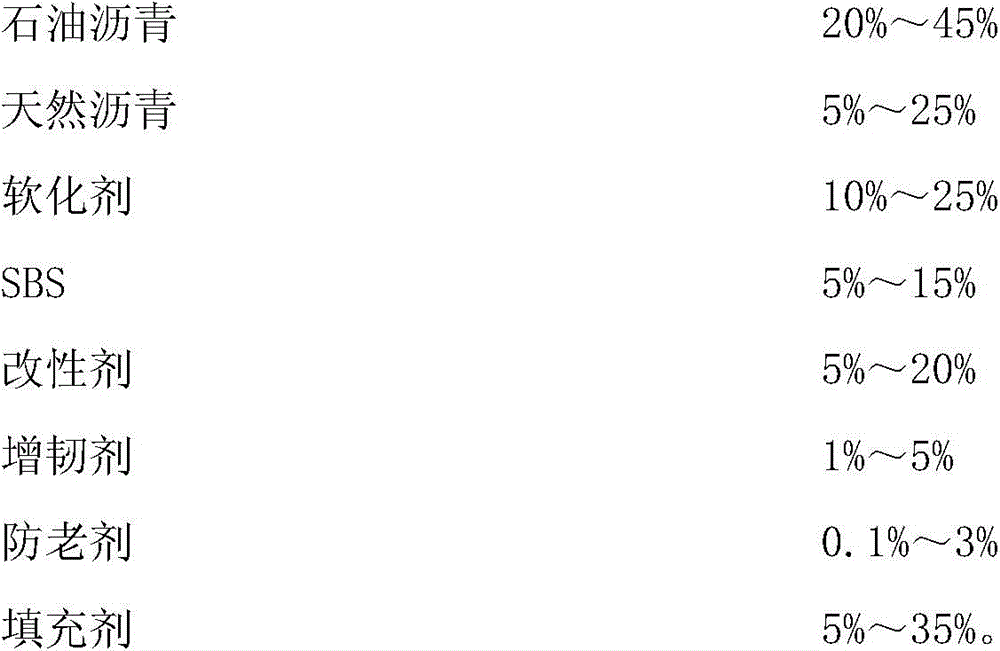

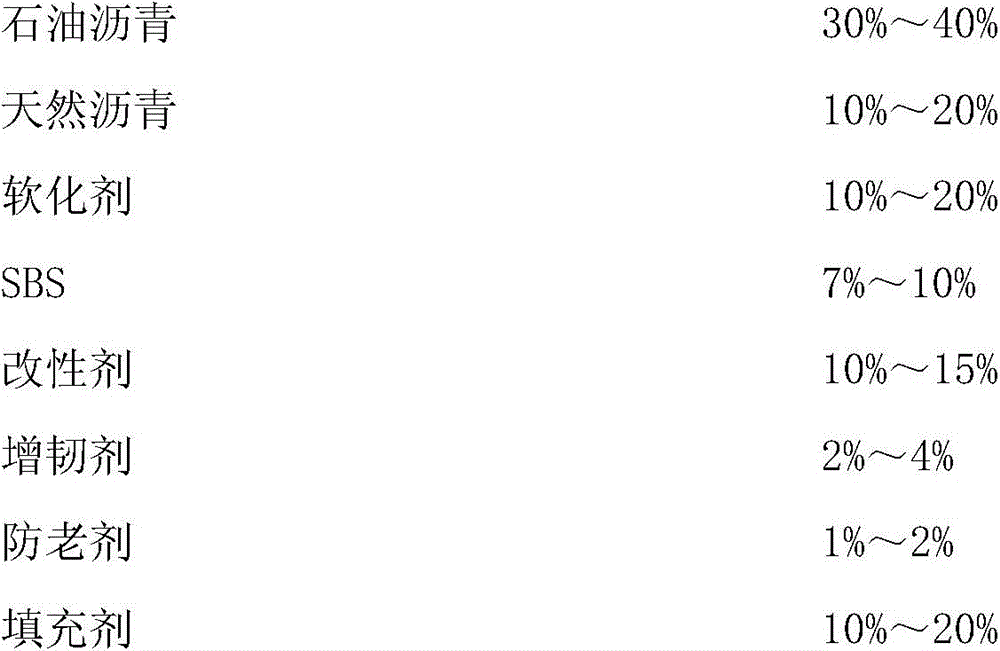

Modified bitumen waterproofing membrane

ActiveCN103802380BHigh tensile strengthGood dimensional stabilityNon-macromolecular adhesive additivesSynthetic resin layered productsElastomerPolyester

Owner:KUNMING FENGXING WATERPROOF MATERIAL +1

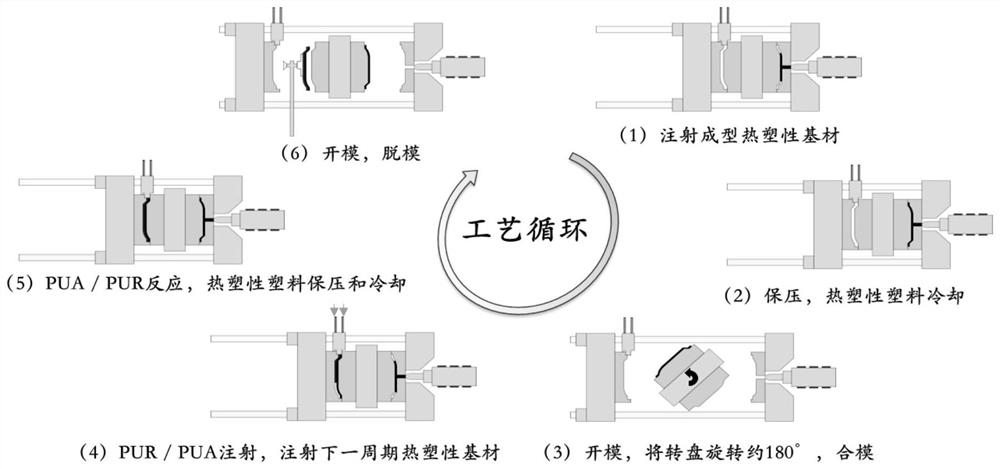

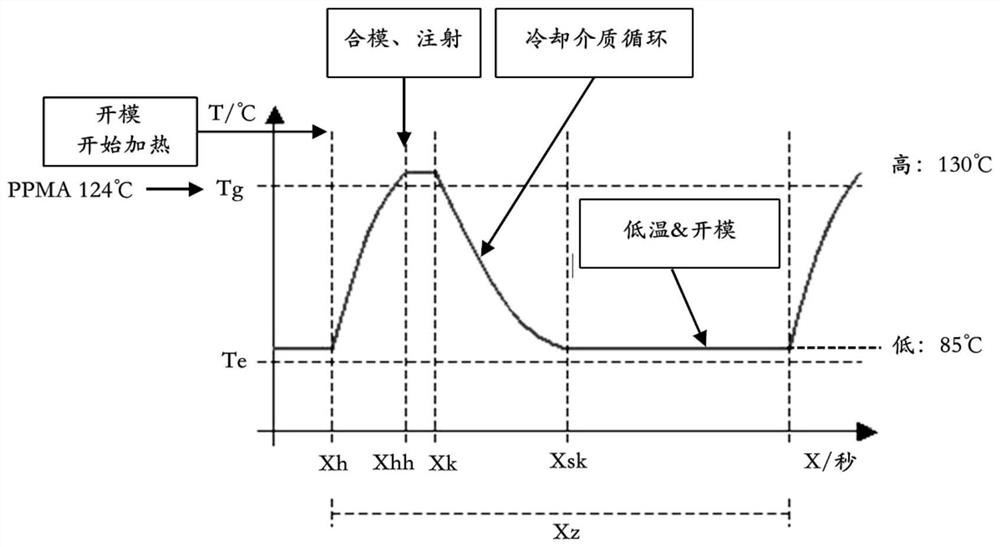

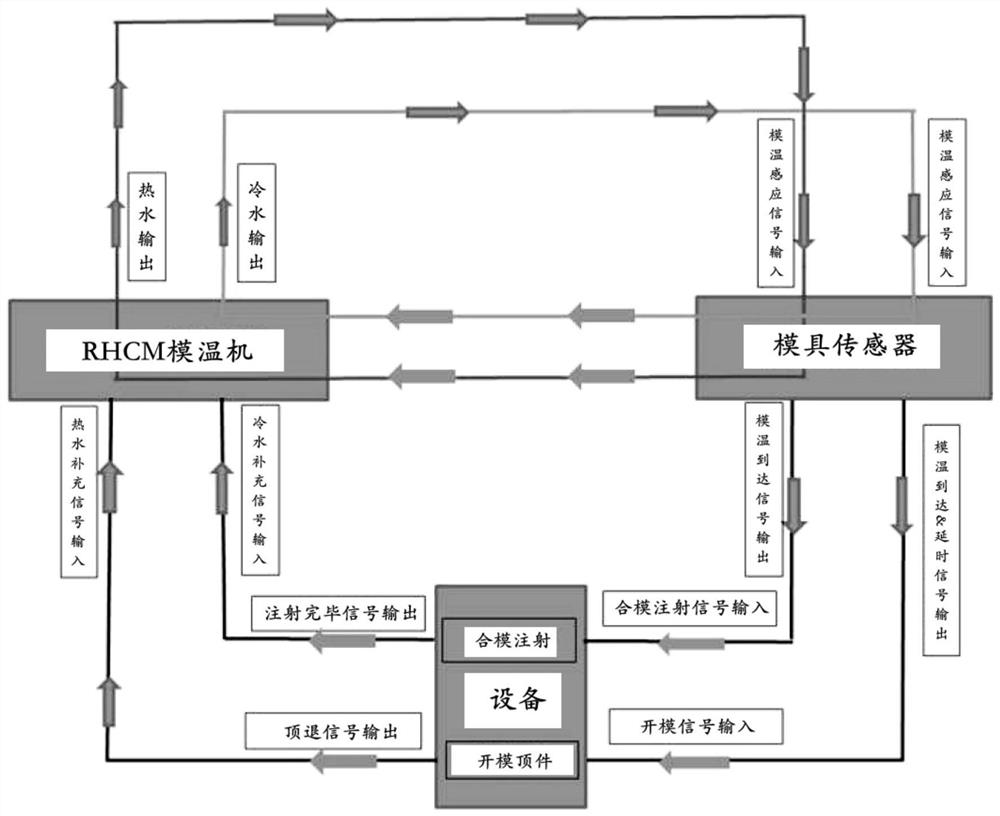

Rapid in-mold simulation surface decoration process

The invention belongs to the field of automobile part manufacturing processes, and particularly relates to a rapid in-mold simulation surface decoration process. The forming process of an injection molding part comprises the following steps that a thermoplastic base material is subjected to injection molding in a first mold cavity through a rapid cooling and rapid heating process to form the highlight injection molding part, wherein nanometer or femtosecond laser textures are pre-machined on the inner surface of the first mold cavity so that the highlight injection molding part can have a nanometer or femtosecond laser texture structure; the first mold cavity is quenched and opened, a rotary table is approximately rotated by 180 degrees, and a second mold cavity is closed; the highlight injection molding part is directly cast and coated with a two-component coating in the second mold cavity, and the two-component coating reacts and is cured in the second mold cavity, so that a transparent coating is formed on the surface of the highlight injection molding part; and the second mold cavity is cooled and opened, and the highlight injection molding part with the nanometer or femtosecond laser texture structure and the scratch-resistant surface is formed. The rapid in-mold simulation surface decoration process has the obvious cost advantage, and the surface coating of the formed highlight injection molding part is attractive, ideal in hardness and good in scratch resistance; and in addition, due to the combination of the nanometer or femtosecond laser texture structure and the external transparent coating, the highlight injection molding part has a three-dimensional decorative effect on the whole, and the product has more advantages and competitiveness.

Owner:长春恒兴集团有限公司

High-steric-hindrance urea bond-containing curing agent as well as preparation method and application thereof

PendingCN114773576AGood mechanical propertiesImprove thermal stabilityPolymer scienceHalohydrocarbon

The invention discloses a curing agent containing a large-steric-hindrance urea bond as well as a preparation method and application of the curing agent. The method mainly comprises the following steps: dissolving bifunctional aromatic amine and alkali in a solvent, adding halogenated hydrocarbon at 70-85 DEG C, and reacting for 8-12 hours to obtain an intermediate product secondary amine; the preparation method comprises the following steps: adding diol and an anhydrous solvent into bifunctional isocyanate, and reacting at 50-60 DEG C for 2-6 hours to obtain a polyurethane prepolymer; and adding secondary amine and an anhydrous solvent into the polyurethane prepolymer, and reacting at 50-60 DEG C for 6-8 hours to obtain the large-steric-hindrance urea bond-containing curing agent. The prepared curing agent containing the large-steric-hindrance urea bonds can overcome the defects of other dynamic covalent bonds, and epoxy resin prepared based on the curing agent containing the large-steric-hindrance urea bonds is good in mechanical property, thermal stability and solvent-resistant chemical stability; the large-steric-hindrance urea bond-containing curing agent can also be used for preparing electronic packaging materials.

Owner:国科广化精细化工孵化器(南雄)有限公司 +3

A gel particle plugging agent with self-healing properties and its preparation method and application

ActiveCN112250787BGuaranteed bearing strengthSimple construction processDrilling compositionHydrophilic monomerPolymer science

The invention provides a gel particle plugging agent with self-healing properties. The gel particle plugging agent comprises the following raw materials in parts by mass: 15-35 parts of copolymerization monomer, 0.1-35 parts of surfactant A 20 parts, 0.01-0.9 part of initiator I, 0.01-0.1 part of crosslinking agent, 0.5-5 part of cationic latex particles; the copolymerization monomer comprises hydrophilic monomer and hydrophobic monomer, and the hydrophilic monomer is A combination of acrylic acid and acrylamide monomers, the hydrophobic monomer is an acrylate monomer. The invention also provides a preparation method and a healing performance evaluation method of the gel particle plugging agent. The self-healing plugging material of the present invention has the characteristic of being recoverable after being damaged, and is injected into formation cracks in the form of particles, and can form an integral gel after healing, thereby achieving the purpose of effectively plugging cracks and pores.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

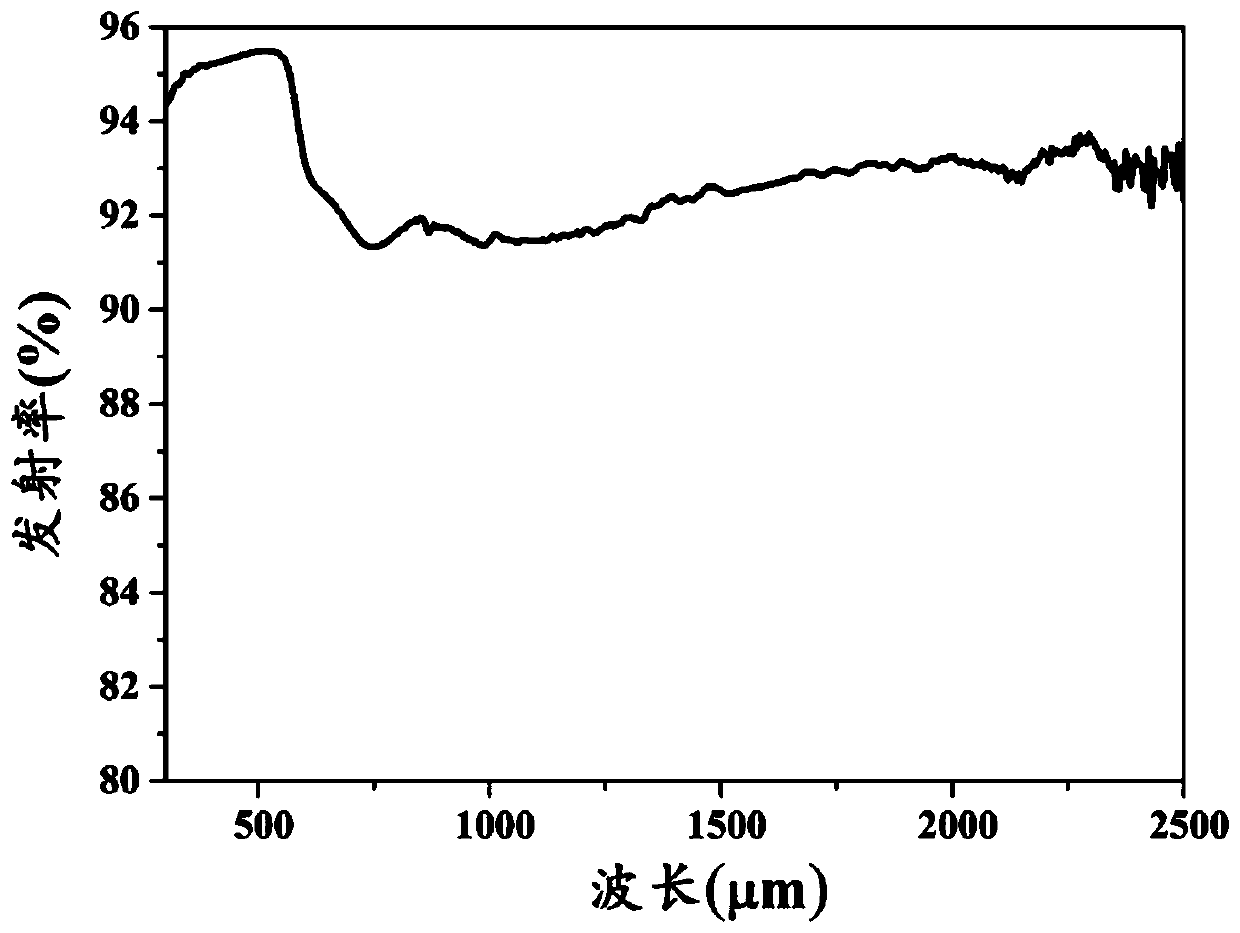

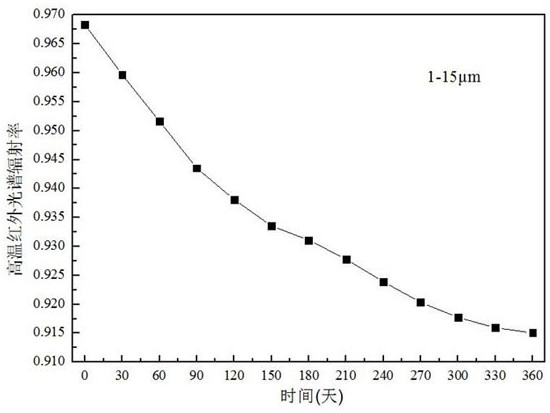

A kind of antiaging agent for high temperature resistant infrared coating and preparation method thereof

An antiaging agent for high-temperature resistant infrared coatings and a preparation method thereof, characterized in that: a. In parts by weight, 20-50 parts of silicon dioxide, 15-32 parts of silicon hexaboride, 15-32 parts of hexaboron Calcium chloride, 1-8 parts of boron trioxide, 3-12 parts of borosilicate glass are mixed and then added to the mixing tank for pre-mixing for 5-30 minutes; b. Then the mixture is added to the fluidized bed jet mill for shaping and mixing, and the classifier 1200~2300r / min, to obtain mixed powder with an average particle size of 0.1~4μm; c. The mixed powder is placed in a high-temperature furnace, heated to 850~1100℃ at 2~7℃ / min, kept for 1~3h, and sintered with furnace cooling d. The sintered material is crushed to an average particle size of 0.5-5mm, added to a fluidized bed jet mill for ultra-fine, and the classifier is 2400-3000r / min to obtain a high-temperature-resistant infrared coating with an average particle size of 0.1-2μm. Aging agent. The invention has simple composition and convenient preparation steps; it is stable and has good high-temperature infrared radiation ability, anti-oxidation ability and anti-washing ability in high-temperature complex atmosphere.

Owner:SHENZHEN TRIUMPH TECH ENG +1

Self-repairing air purification gel and preparation method thereof

The invention provides a self-repairing air purifying gel and a preparation method thereof. The self-repairing air purifying gel comprises the following components in percentage by mass: 0.01-90% of essential oil, 0.01-50% of an air purifying agent, 1-10% of an oily gel agent, and 0.0001-0.2% of an oily pigment, with the balance being an oily solvent. According to the self-repairing air purification gel disclosed by the invention, aluminum isooctanoate or aluminum ions contained in aluminum isooctanoate and prepared by a reaction and high-electronegativity hydrocarbon chain segments in the oily solvent or essential oil form hydrogen bonds, so the gel is formed. A gel network with such a structure can realize self-crosslinking and self-repairing under the condition of normal temperature after being damaged and broken by external force, so the gel network has a self-repairing characteristic; and a gel state is not influenced by extreme weather such as high temperature and low temperature. Furthermore, by adjusting the parameters of all the components of the liquid gel, the physical states such as the fluidity, the repair time and the viscoelasticity of the air purification gel can beadjusted.

Owner:JIANGMEN HEXIN ESSENCE TECH

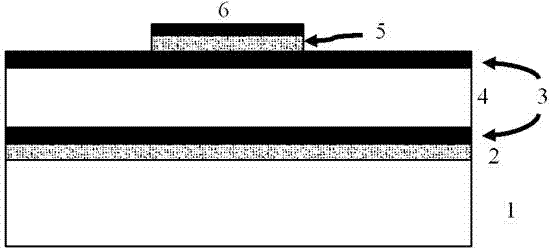

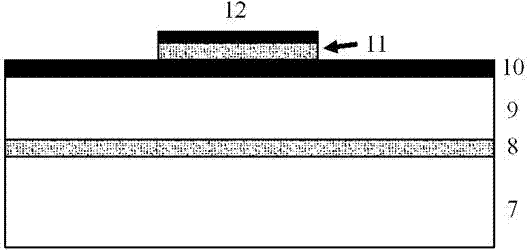

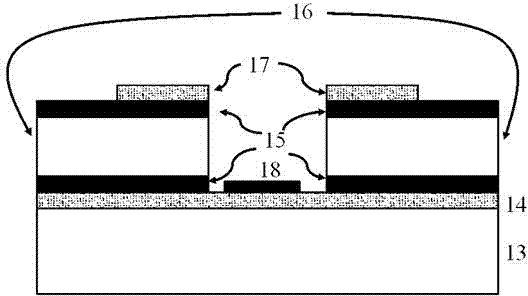

Composite film of inorganic insulating films and polyimide films used for three-pole field emission cathode

ActiveCN101853761BImprove insulation performanceHas self-healing propertiesCathode ray tubes/electron beam tubesComposite filmDisplay device

Owner:FUZHOU UNIV

A kind of preparation method of high emissivity ablation-resistant heat-insulating microsphere filler

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com