Hyperbranched elastic material capable of self-healing and preparation method thereof

An elastic material, self-healing technology, applied in the field of material science, can solve the problem of limited healing times, and achieve the effects of low preparation cost, good controllability and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

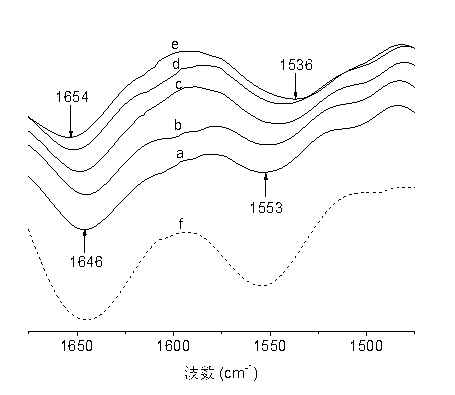

[0028] Mix 0.25mol of diethylenetriamine and 0.25mol of triethylenetetramine with 60mL of anhydrous methanol solvent, add 0.5mol of methyl acrylate and 20mL of anhydrous methanol under nitrogen protection, and react at 20°C After 36 hours, the solvent was distilled off under reduced pressure, and then the temperature was raised to 120°C and reacted for 36 hours under a vacuum of 0.05 MPa. Acetone was used as a precipitant, and after precipitation, filtration, separation, and drying, the product was obtained, which is a hyperbranched product with an amino group at the end of the molecular chain. Polymers were determined for their amine value by acid-base titration. to-NH 2 :-COOH=1:1 molar ratio, mix the above product and linoleic acid dimer acid evenly, react at 160°C for 96h under the protection of nitrogen, and obtain hyperbranched elastic material after vacuum drying. IR(KBr), ν(cm -1 )=3215(ν NH ), 2945(ν as,CH2 ), 2835(ν s,CH2 ), 1646(ν C=O ), 1553(ν CN and δ NH )...

Embodiment example 2

[0036] After mixing acrylic acid and pentaethylenehexamine with a molar ratio of 20:1, react at -20°C for 72 hours under nitrogen protection, then raise the temperature to room temperature and react for 72 hours under a vacuum of 0.095MPa, then use diethyl ether as a precipitant , after precipitation, filtration, separation, and drying, the product is a hyperbranched polymer with amino groups at the end of the molecular chain, and its amine value is determined by acid-base titration. to-NH 2 :-COOH=10:1 molar ratio Take the above product and carboxyl-terminated liquid nitrile rubber and mix evenly, react at 80°C for 120h under nitrogen protection, and obtain a hyperbranched elastic material after vacuum drying.

[0037] Differential scanning calorimetry (DSC) test was carried out on the elastic material sample. Starting from room temperature, the temperature was raised to 100°C at a heating rate of 10°C / min, and kept at a constant temperature for 3 minutes, then cooled to -80°...

Embodiment example 3

[0042] Mix 4.0 mol of triaminobenzene with 80 mL of N, N-dimethylformamide solvent evenly, add a mixture of 0.1 mol of octyl methacrylate and 0.1 mol of isooctyl methacrylate under nitrogen protection, and React at low temperature for 1 hour, remove the solvent by distillation under reduced pressure, then raise the temperature to 180°C and polymerize at a vacuum of 0.03 MPa. After reaction for 1 hour, use methyl ethyl ketone as a precipitating agent. After precipitation, filtration, separation and drying, the product obtained is The hyperbranched polymer of amino group, its amine value is determined by acid-base titration method, expressed as -NH 2 :-COOH=1:8 molar ratio, take the above product and diethylenetriaminepentaacetic acid, react at 280°C for 1h under nitrogen protection, and obtain a hyperbranched elastic material after vacuum drying.

[0043] According to the method described in Example 1, the Tg of the sample is measured to be -10°C, which can maintain the propert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com