Preparation of nano-composite hydrogel ink and application of nano-composite hydrogel ink in 3D printing

A nanocomposite and 3D printing technology, applied in the field of nanomaterials, can solve problems such as nozzle clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

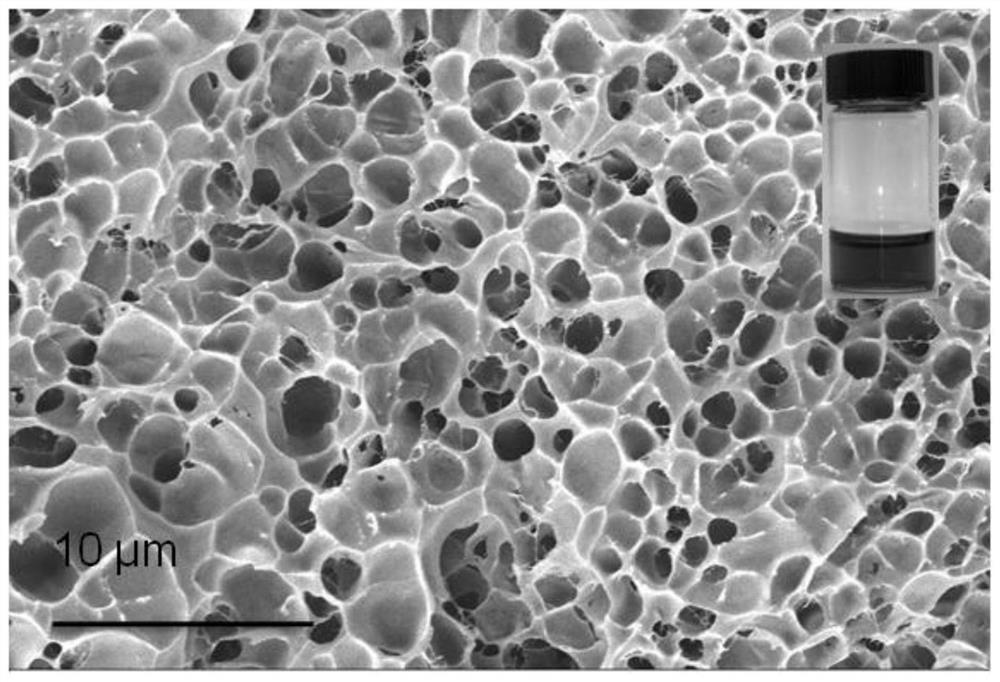

[0027] Embodiment 1: the preparation of inorganic metal nanomaterial

[0028] Add 0.6mL of 0.2mol / L chloroauric acid and 49.4mL of deionized water into a 100mL round-bottomed flask, heat and stir the flask in an oil bath at 100°C for 10min, and mix well. Then quickly add 1mL sodium citrate solution with a mass fraction of 1%, continue to stir at 100°C to make the reaction fully complete, rinse with cold water to room temperature after 5min, and obtain inorganic metal nanomaterials with uniform particle shape.

Embodiment 2

[0030] 1. Surface modification of inorganic metal nanomaterials

[0031] The 50ppm inorganic metal nanomaterial prepared in Example 1 is mixed with 2-methyl-1-[4-methylmercaptophenyl]-2-morpholine acetone, wherein 2-methyl-1-[4-methylmercapto Phenyl]-2-morpholine acetone is added as a functional modifier, the mass of which is 0.1% of the mass of the inorganic metal nanomaterial dispersion liquid, and the modified inorganic metal nanomaterial is obtained by ultrasonication for 30 s at room temperature;

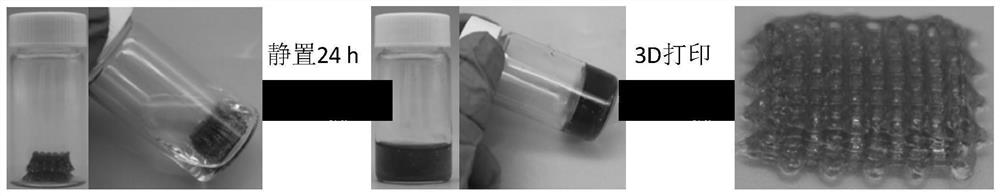

[0032] 2. Synthesis of 3D printed nanocomposite hydrogel inks

[0033] Add the hydrophilic monomer acrylamide to the modified inorganic metal nanomaterial obtained in step 1 of Example 2, dissolve it by ultrasonication for 40 s under the protection of nitrogen, and place it in a vacuum drying oven to remove dissolved oxygen in the solution ; Then place it in a UV light box for 40 minutes of polymerization reaction, and after it is cooled to room temperature, the 3D printing na...

Embodiment 3

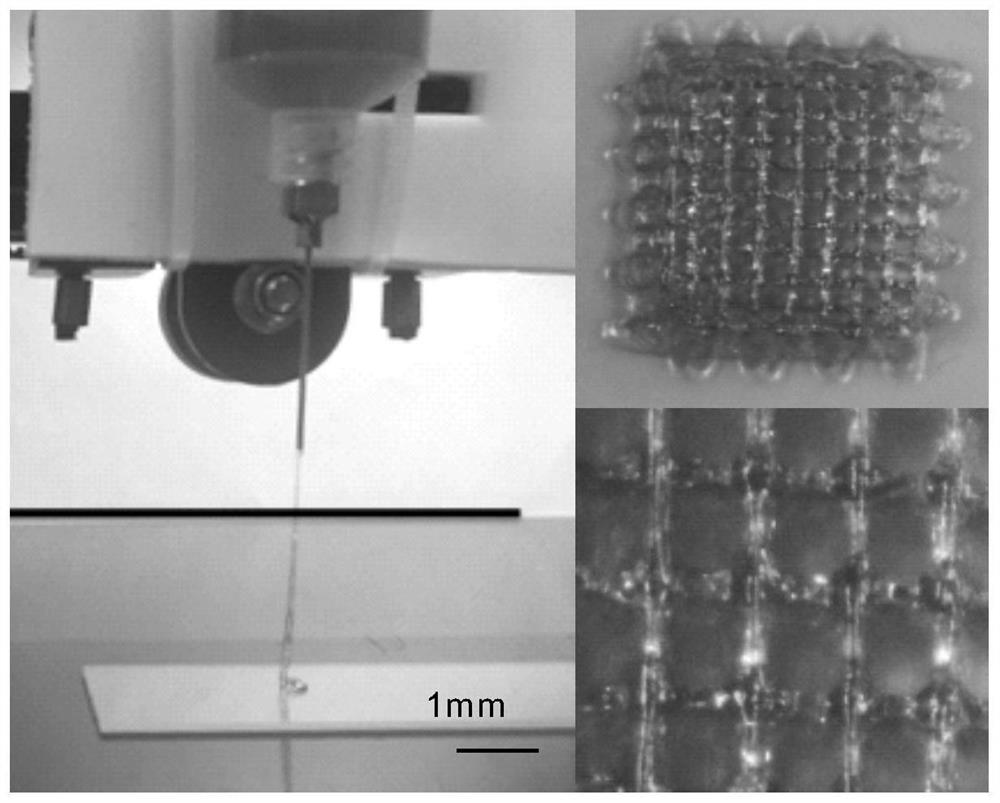

[0036] 1. Draw 3D printing model slices

[0037] Use 3D max software to draw a 3D model, export the model and pour it into the slicing processing software, adjust the printing parameters, and export it in the .gocde file format to obtain 3D printed model slices;

[0038] 2. 3D printing of nanocomposite hydrogel ink

[0039] The printable nanocomposite hydrogel ink synthesized in Step 2 of Example 2 was transferred to a 30 ml syringe, and centrifuged at 4500 rpm for 5 min to remove air bubbles in the ink. Install the injection device in an improved 3D printing platform system, use a stepper motor to control the injection device, 3D printable nanocomposite hydrogel ink is extruded through a 25G needle, adjust the extrusion pressure and moving speed to make the ink uniform written on the substrate. The printing path is controlled by the G code file generated by the slicing software, and the movement speed and distance in the xyz direction of the 3D printer are controlled by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com