Novel perspective film and preparation method thereof

A kind of see-through film, a new technology, applied in the field of see-through film, to achieve the effects of simple structure, simplified process procedures, and reduced glue cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

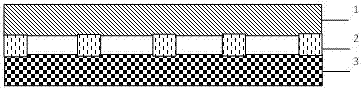

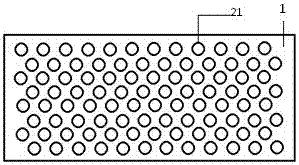

[0037] Embodiment 1: as figure 1 and figure 2 As shown, a novel see-through film according to the present invention comprises a transparent film layer 1 and a glue layer 2, and the glue layer 2 is a white pressure-sensitive adhesive layer, which consists of several circular glue points 21 with the same diameter according to the honeycomb Arranged in an orderly porous form, the glue layer 2 is provided with an anti-adhesive layer 3 below.

[0038] The glue layer 2 is a water-based pressure-sensitive adhesive.

[0039] The diameter of the circular glue point 21 of the glue layer 2 is ф2.0mm.

[0040] The distance between the centers of two adjacent circular glue dots 21 in the glue layer 2 is 2.5 mm.

[0041] The thickness of the glue layer 2 is 0.25mm.

[0042] The transparent film layer 1 is transparent PVC.

[0043] The release layer 3 is CCK release paper.

[0044] The preparation method and steps of a novel see-through film of the present invention are as follows:

...

Embodiment 2

[0051] Embodiment 2: as figure 1 and figure 2 As shown, a novel see-through film according to the present invention includes a transparent film layer 1 and a glue layer 2, and the glue layer 2 is a gray pressure-sensitive adhesive layer with pearlescent luster, which consists of several round glue dots with the same diameter. 21 are arranged in a honeycomb-like ordered porous form, and an anti-adhesive layer 3 is provided under the glue layer 2 .

[0052] The glue layer 2 is a water-based pressure-sensitive adhesive.

[0053] The diameter of the circular glue point 21 of the glue layer 2 is ф2.0mm.

[0054] The distance between the centers of two adjacent circular glue dots 21 in the glue layer 2 is 2.5 mm.

[0055] The thickness of the glue layer 2 is 0.25mm.

[0056] The transparent film layer 1 is transparent PVC.

[0057] The release layer 3 is a frosted PET release film.

[0058] The preparation method and steps of a novel see-through film of the present invention ...

Embodiment 3

[0065] Embodiment 3: as figure 1 and figure 2 As shown, a novel see-through film of the present invention comprises a transparent film layer 1 and a glue layer 2, and the glue layer 2 is a white pressure-sensitive adhesive layer, which consists of several round glue spots 21 with the same diameter in a honeycomb shape. Arranged in an orderly porous form, an anti-adhesive layer 3 is provided under the glue layer 2 .

[0066] The glue layer 2 is a hot-melt pressure-sensitive adhesive.

[0067] The diameter of the circular glue point 21 of the glue layer 2 is ф5.0mm.

[0068] The distance between the centers of two adjacent circular glue dots 21 in the glue layer 2 is 10.0mm.

[0069] The thickness of the glue layer 2 is 0.4mm.

[0070] The transparent film layer 1 is transparent TPU.

[0071] The release layer 3 is a PET release film.

[0072] The preparation method and steps of a novel see-through film of the present invention are as follows:

[0073] (1) Unwinding of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com