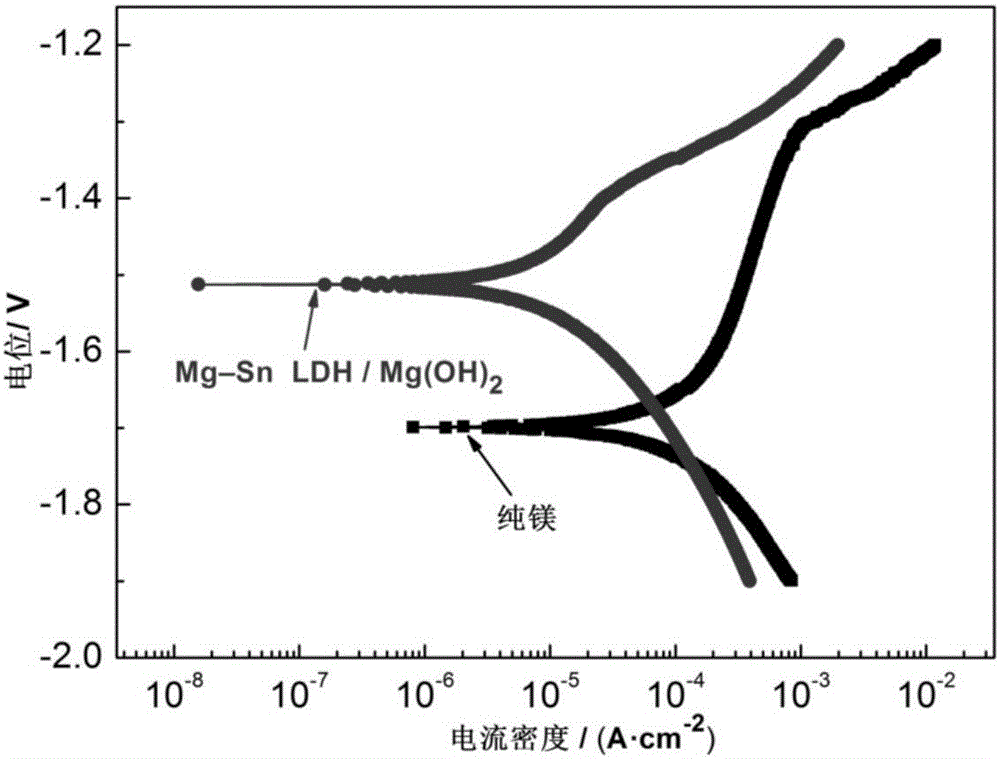

Mg(OH)2/Mg-Sn hydrotalcite composite film having intercalation structure on surface of magnesium and magnesium alloy and preparation method thereof

A magnesium alloy and hydrotalcite technology, which is applied in the direction of metal material coating process, etc., can solve the problems that cannot be used for magnesium alloy protection, Mg-Al hydrotalcite film contains cytotoxic elements, etc., and achieves stable structure, good binding force, Avoid the effect of poor corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

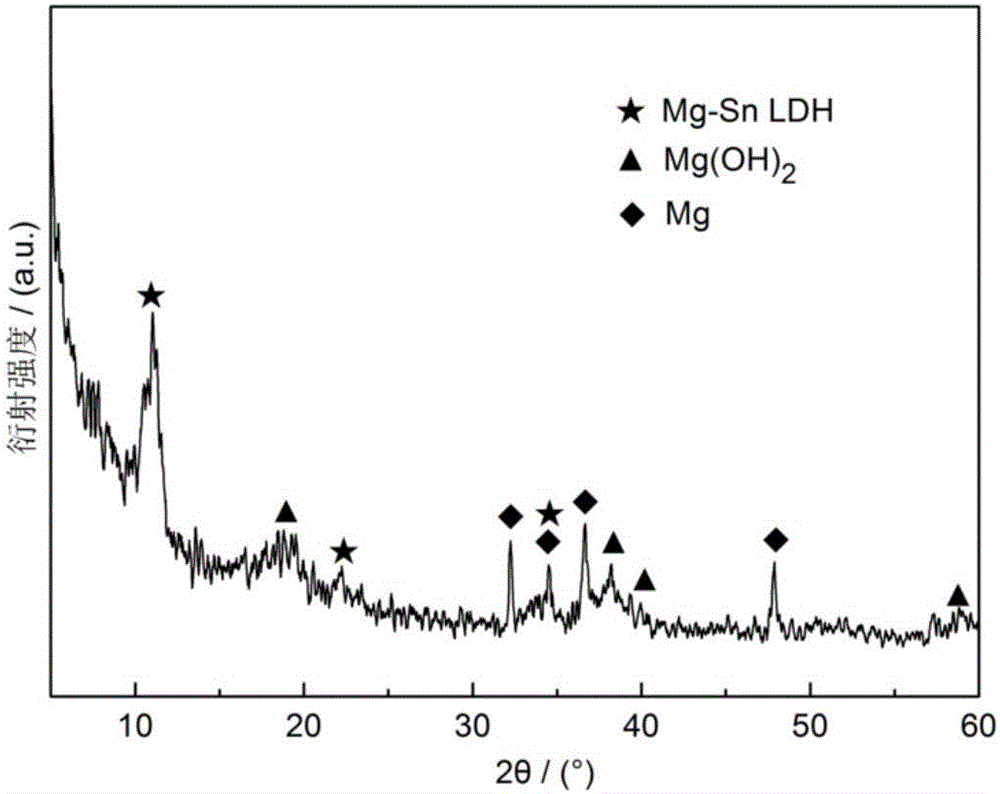

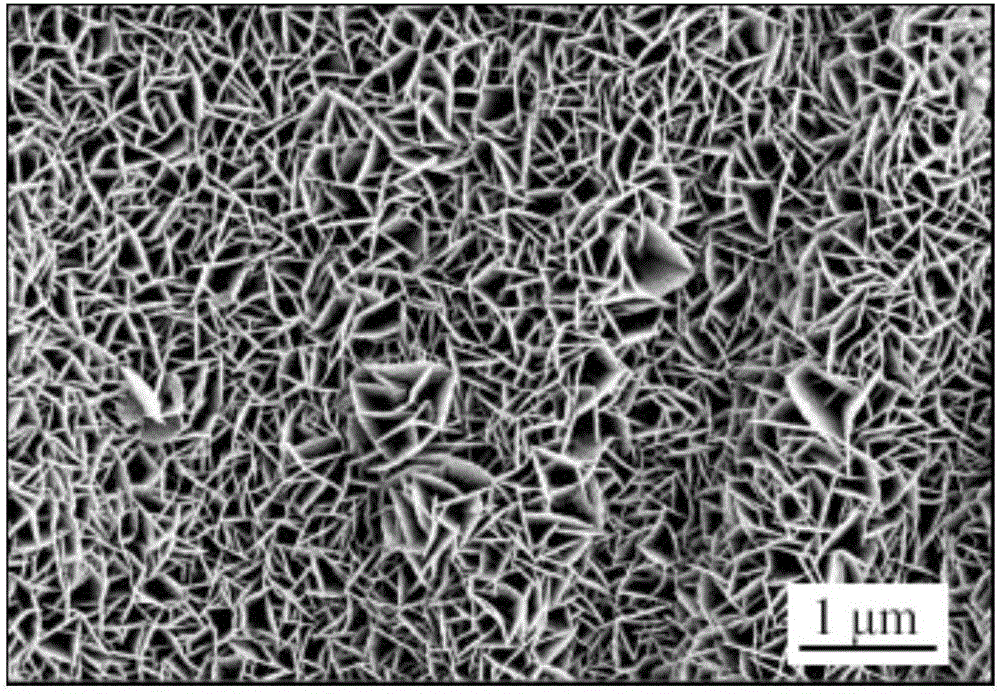

[0030] A kind of Mg(OH) with intercalation structure on the surface of magnesium and magnesium alloy 2 The preparation method of / Mg-Sn class hydrotalcite composite membrane comprises the steps:

[0031] S1. Pretreatment of magnesium and magnesium alloy samples: including grinding and cleaning. Use 400, 800 and 1000 mesh metallographic sandpaper for mechanical grinding in sequence, then ultrasonically clean the polished magnesium and magnesium alloy samples in absolute ethanol for 5-10 minutes, and then ultrasonically clean them in deionized water for 5-10 minutes; Magnesium and magnesium alloys treated by this process include Mg-Zn series, Mg-RE series, Mg-Ca series, Mg-Sn series, Mg-Mn series alloys and pure magnesium;

[0032] S2. Perform pretreatment on the pretreated samples: prepare 0.01-0.04mol / L tin ion salt solution, wherein the tin ion salt solution is SnCl 4 or Sn(SO 4 ) 2 , and use 0~2mol / L NaOH / KOH and 0.5~1mol / L Na 2 CO 3 / NaHCO 3 / K 2 CO 3 / KHCO 3 Adjus...

Embodiment 1

[0037] The magnesium and magnesium alloy samples used in this embodiment are pure magnesium.

[0038] S1. Pretreatment of magnesium and magnesium alloy samples: including grinding and cleaning. The pure magnesium was mechanically polished with 400, 800 and 1000-mesh metallographic sandpaper in sequence, and then the polished pure magnesium sample was ultrasonically cleaned in absolute ethanol for 5 minutes, and then placed in ionized water for 5 minutes.

[0039] S2. Perform pretreatment on the pretreated sample: prepare 0.02mol / L SnCl 4 solution, and with 1mol / LNaOH and 0.5mol / L NaOH 2 CO 3 The mixed solution was adjusted to pH 3.8 to prepare a pretreatment solution. The pure magnesium sample was placed in a continuous flow of CO 2 Soak in the pretreatment solution for 1 hour, the treatment temperature is 25°C, the ratio of the surface area of the sample to the volume of the pretreatment solution is 1:40, and the precursor film is grown on the surface of the sample.

...

Embodiment 2

[0043] With embodiment 1, difference is: present embodiment adopts Mg-2Zn magnesium alloy (being the magnesium alloy containing 2wt%Zn); Prepare 0.01mol / L Sn(SO in step S2 4 ) 2 solution, and with 1mol / L NaOH and 1mol / L Na 2 CO 3 Adjust the pH of the mixed solution to 5.0 to prepare a pretreatment solution; the pretreatment temperature is 40°C, the time is 2h, the ratio of the sample surface area to the volume of the pretreatment solution is 1:30; the posttreatment solution in step S3 is 1mol / L NaHCO 3 The pH of the solution was adjusted to ~13 by NaOH, the post-treatment temperature was 70°C, the time was 12 hours, and the ratio of the sample surface area to the volume of the post-treatment solution was 1:30.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com