Preparation method of thermal insulation microsphere filler with high emissivity and ablation resistance

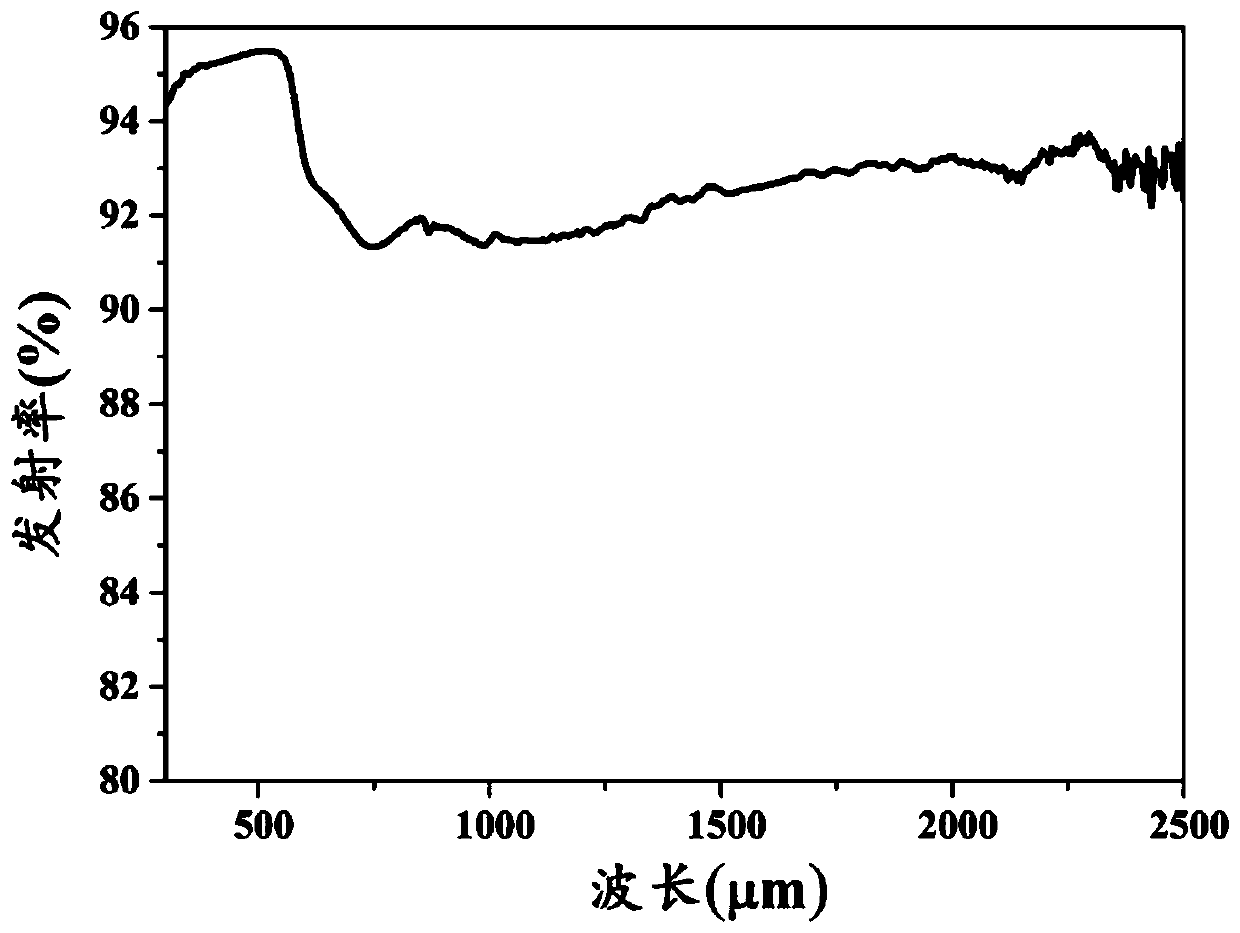

A high emissivity, microsphere filler technology, applied in ceramic products, other household appliances, household appliances, etc., can solve problems such as catastrophic damage, thermal shock failure, etc., achieve high emissivity, good mechanical properties, high specific strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

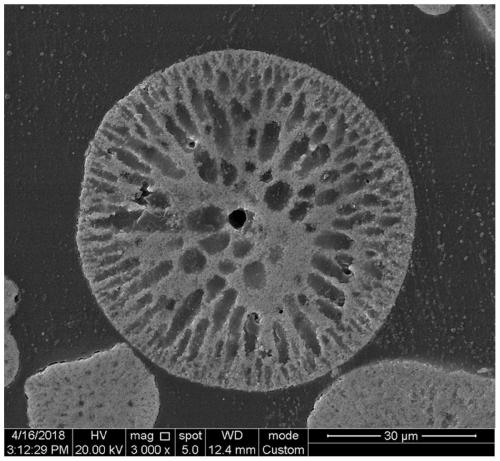

[0031] This embodiment realizes above-mentioned performance through following technical solution:

[0032] (1) Powder preparation and mixing: use isopropanol or ethanol as the grinding medium, and use high-energy ball milling to grind UHTC components, high-emissivity self-healing components and sintering aids at a mass ratio of 50:50:5 Ball milling and mixing, the ball milling time is 36h, the ball milling speed is 2000r / min, after the ball milling, dry the obtained slurry for 24h to constant weight, grind and sieve to get the mixed powder, the primary particle size of the powder after ball milling should not be greater than 200nm ;

[0033] (2) Preparation of precursor slurry: put the powder obtained in step (1) into an organic solvent with a mass ratio of 3:9 to fully stir and disperse, and then put it into an ultrasonic pulverizer for ultrasonic dispersion for 30 minutes to eliminate nano-powder The physical agglomeration between them can obtain a uniform powder suspension...

Embodiment 2

[0050] The present invention realizes above-mentioned performance through following technical scheme:

[0051](1) Powder preparation and mixing: use isopropanol or ethanol as the grinding medium, and use high-energy ball milling to grind UHTCs components, high-emissivity self-healing components and sintering aids at a mass ratio of 20:80:10 Ball milling and mixing, the ball milling time is 24h, the ball milling rate is 1000r / min, after the ball milling is completed, dry the obtained slurry for 24h to constant weight, grind and sieve to obtain the mixed powder, the primary particle size of the powder after ball milling should not be greater than 200nm ;

[0052] (2) Preparation of precursor slurry: put the powder obtained in step (1) into an organic solvent with a mass ratio of 1:7 to fully stir and disperse, and then put it into an ultrasonic pulverizer for ultrasonic dispersion for 10 minutes to eliminate nano-powder The physical agglomeration between them can obtain a unifo...

Embodiment 3

[0066] The present invention realizes above-mentioned performance through following technical scheme:

[0067] (1) Powder preparation and mixing: use isopropanol or ethanol as the grinding medium, and use high-energy ball milling to grind UHTCs components, high-emissivity self-healing components and sintering aids at a mass ratio of 80:80:7 Ball milling and mixing, the ball milling time is 48h, the ball milling speed is 4000r / min, after the ball milling is completed, dry the obtained slurry for 24h to constant weight, grind and sieve to obtain the mixed powder, the primary particle size of the powder after ball milling should not be greater than 200nm ;

[0068] (2) Preparation of precursor slurry: put the powder obtained in step (1) into an organic solvent with a mass ratio of 6:7 to fully stir and disperse, and then put it into an ultrasonic pulverizer for ultrasonic dispersion for 60 minutes to eliminate nano-powder The physical agglomeration between them can obtain a unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com