Treatment method for improving corrosion resistance of steel material in lead or lead bismuth

A technology of iron and steel materials and processing methods, which is applied in the fields of metal material coating technology, nuclear power generation, climate sustainability, etc., can solve the problems of oxide layer dissolution, steel matrix erosion, coolant blockage, coolant oxidation, etc., and achieve improvement Anti-corrosion ability, reduce consumption, and enhance the effect of anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

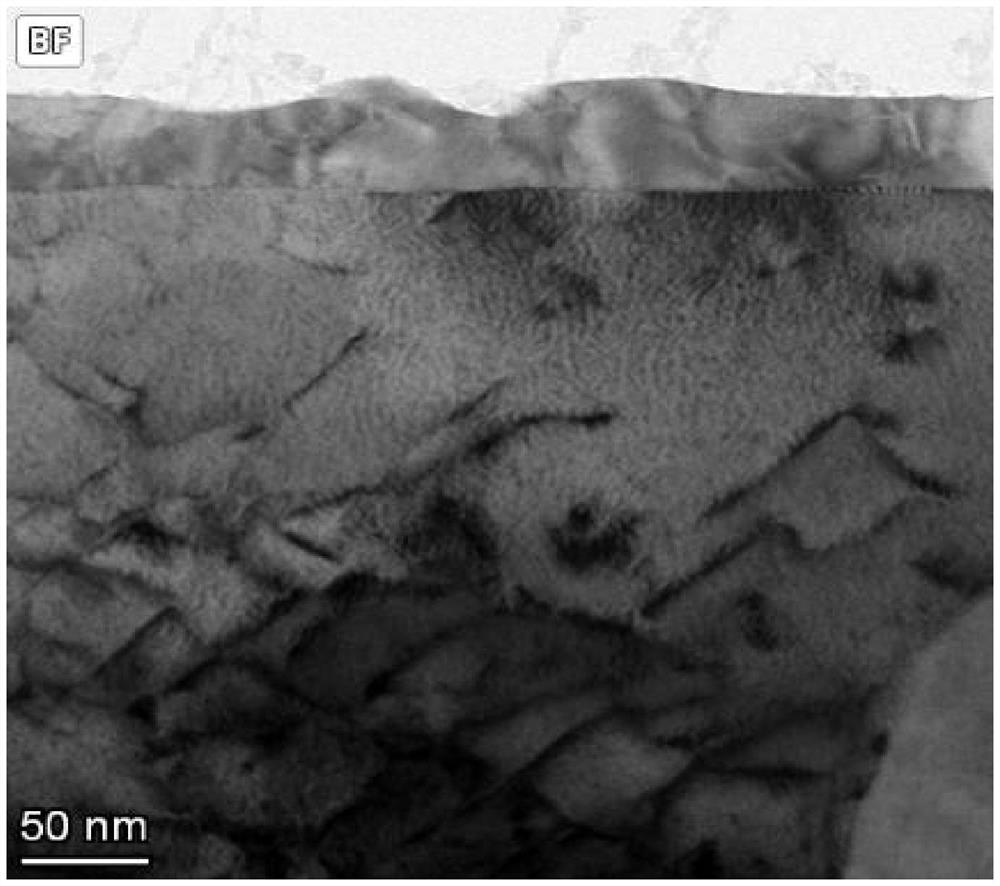

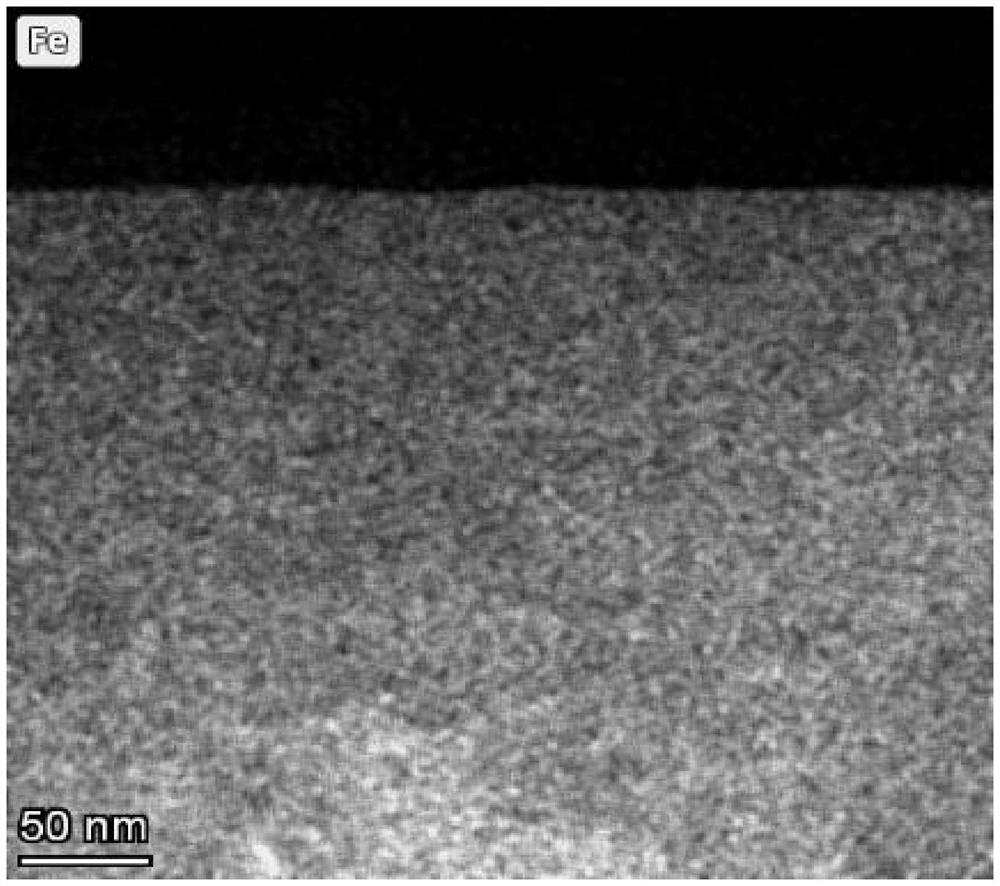

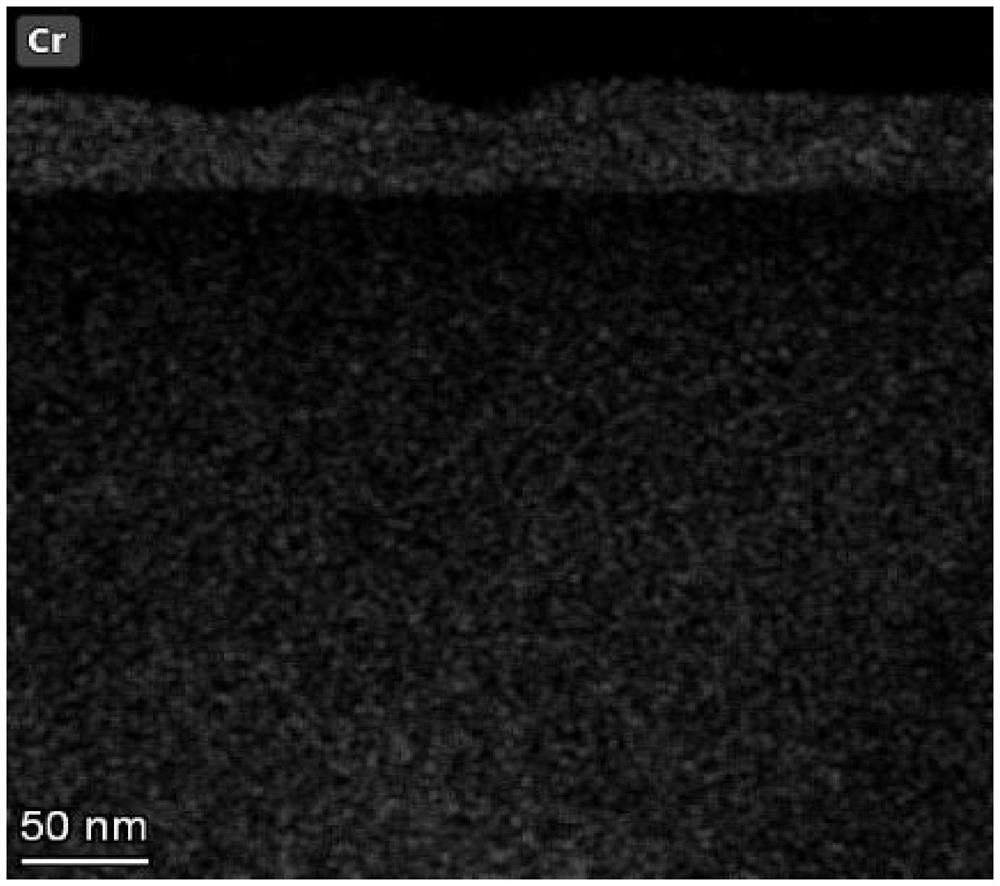

[0028] The invention provides a treatment method for improving the corrosion resistance of iron and steel materials in lead or lead-bismuth, comprising the following steps:

[0029] Using 14MeV high-energy fast neutrons produced by fission, the steel material is irradiated at a temperature of 700°C, and the radiation dose is 700dpa, so that the Mn and Cr elements in the steel material diffuse to the surface of the steel material Forming a dense oxide film, irradiating for 10 minutes until the thickness of the dense oxide film is 30nm, that is, the improvement of the anti-corrosion performance of the steel material is completed;

[0030] Wherein, the steel material is ferritic martensitic steel, and in the ferritic martensitic steel, the content of Cr is 10wt%, and the content of Mn is 1.5wt%.

Embodiment 2

[0032] The invention provides a treatment method for improving the corrosion resistance of iron and steel materials in lead or lead-bismuth, comprising the following steps:

[0033] Using 14MeV high-energy fast neutrons produced by fission, the steel material is irradiated at a temperature of 500°C, and the radiation dose is 300dpa, so that the Mn and Cr elements in the steel material diffuse to the surface of the steel material Forming a dense oxide film, irradiating for 10 hours until the thickness of the dense oxide film is 40nm, that is, the improvement of the corrosion resistance of the steel material is completed;

[0034] Wherein, the steel material is ferritic martensitic steel, and in the ferritic martensitic steel, the content of Cr is 9wt%, and the content of Mn is 1wt%.

Embodiment 3

[0036] The invention provides a treatment method for improving the corrosion resistance of iron and steel materials in lead or lead-bismuth, comprising the following steps:

[0037] Using 14MeV high-energy fast neutrons produced by fission, the steel material is irradiated at a temperature of 400°C, and the radiation dose is 100dpa, so that the Mn and Cr elements in the steel material diffuse to the surface of the steel material Forming a dense oxide film, irradiating for 30 hours until the thickness of the dense oxide film is 50nm, the improvement of the anti-corrosion performance of the steel material is completed;

[0038] Wherein, the steel material is ferritic-martensitic steel, and in the ferritic-martensitic steel, the content of Cr is 8wt%, and the content of Mn is 0.5wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com