Modified bitumen waterproofing membrane

A technology for modifying asphalt and waterproofing membranes, which can be used in asphalt material adhesives, asphalt layered products, adhesive types, etc., and can solve problems such as high temperature resistance, aging resistance, and construction convenience defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

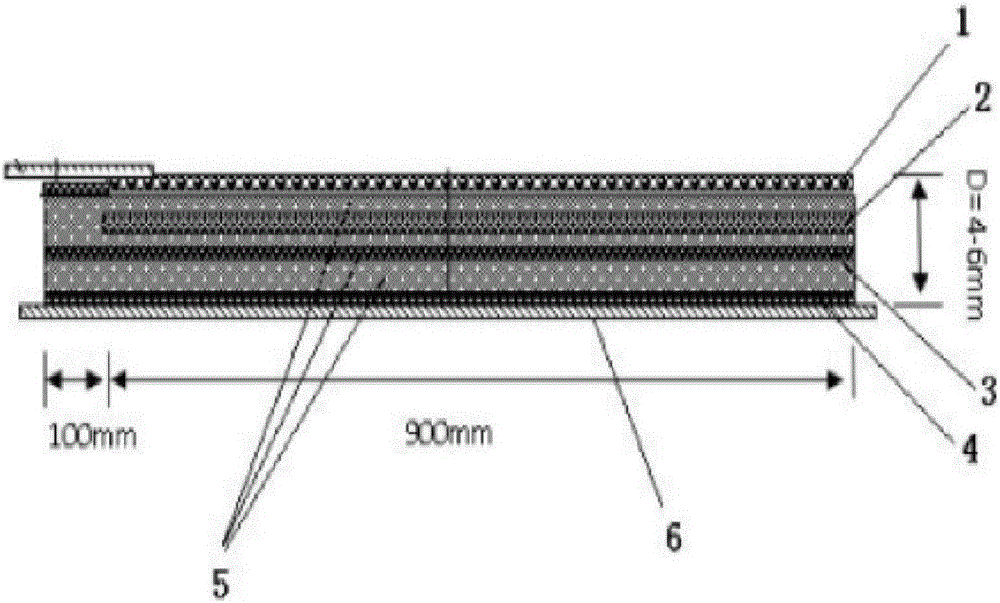

[0046] The thickness of the glass fiber tire used is: 0.45mm, and the weight is 60g / m 2 , the thickness of the polyester tire is 1.0mm, and the weight is 220g / m 2 , the total thickness of the coil is 5mm, of which the thickness of the mineral particles on the upper surface is 1.2mm, the thickness between the two tire bases is 1mm, the thickness of the self-adhesive polymer modified asphalt rubber on the lower surface is 1.35mm, the width of the overlapping edge is 100mm, and the length of the coil is 1000mm .

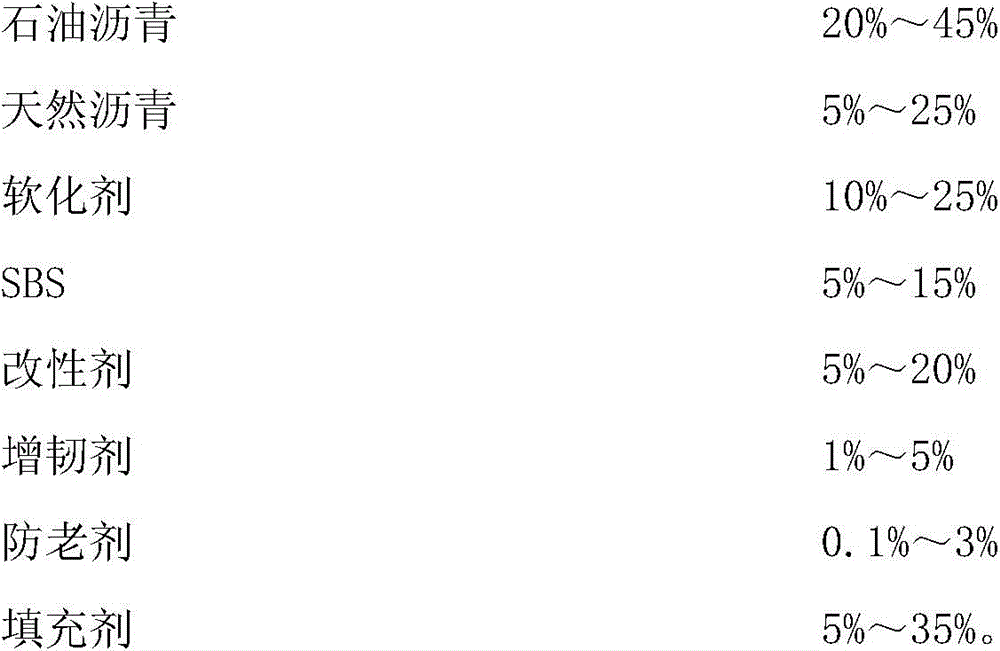

[0047] Among them, the formula of high temperature resistant elastomer (SBS) modified asphalt compound is as follows:

[0048]

[0049]

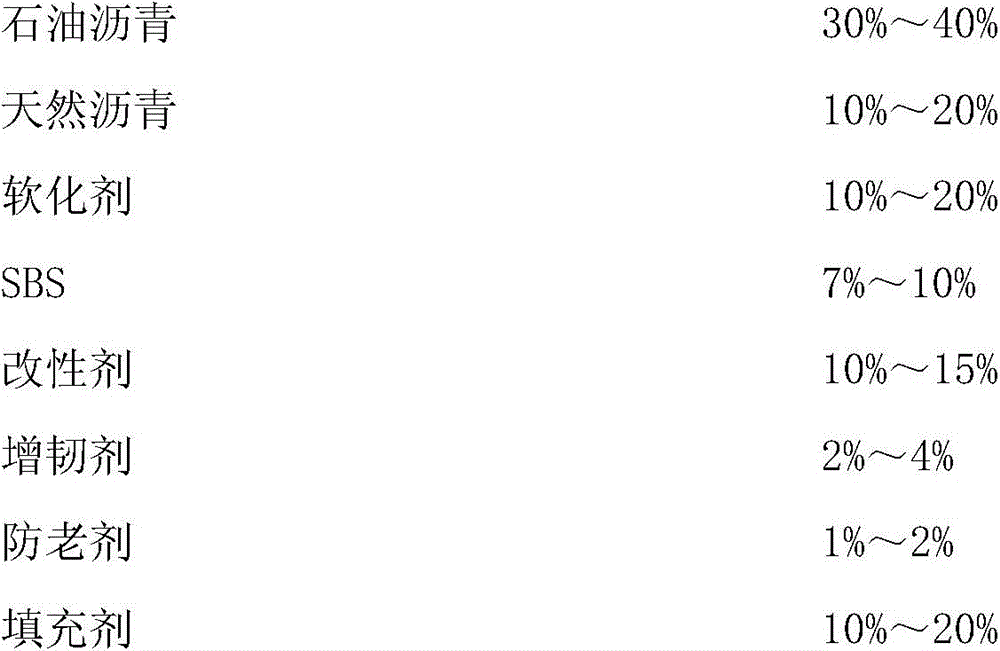

[0050] Among them, the formula of self-adhesive polymer modified asphalt compound is as follows:

[0051]

Embodiment 2

[0053] The thickness of the glass fiber tire used is: 0.4mm, and the weight is 60g / m 2 , the thickness of the polyester tire is 1.0mm, and the weight is 220g / m 2 , the total thickness of the coil is 4mm, of which the thickness of the mineral pellets on the upper surface is 1mm, the thickness between the two tire bases is 1mm, the thickness of the self-adhesive polymer modified asphalt compound on the lower surface is 1.6mm, the width of the lap joint is 100mm, and the length of the coil is 1000mm.

[0054] Among them, the formula of high temperature resistant elastomer (SBS) modified asphalt compound is as follows:

[0055]

[0056]

[0057] Among them, the formula of self-adhesive polymer modified asphalt compound is as follows:

[0058]

Embodiment 3

[0060] The thickness of the glass fiber tire used is: 0.5mm, and the weight is 100g / m 2 , the thickness of the polyester tire is 1.0mm, and the weight is 150g / m 2 , the total thickness of the coil is 6mm, of which the thickness of the mineral pellets on the upper surface is 1mm, the thickness between the two tire bases is 1.5mm, the thickness of the self-adhesive polymer modified asphalt rubber on the lower surface is 2mm, the width of the overlapping edge is 100mm, and the length of the coil is 1000mm.

[0061] Among them, the formula of high temperature resistant elastomer (SBS) modified asphalt compound is as follows:

[0062]

[0063] Among them, the formula of self-adhesive polymer modified asphalt compound is as follows:

[0064]

[0065] The applicant has tested the physical and chemical properties of the above-mentioned waterproof membrane. The test results show that the above-mentioned waterproof membrane has no cracks or cracks at -30°C. The tensile force is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com