Self-healing anti-freezing conductive fibroin hydrogel and preparation method thereof

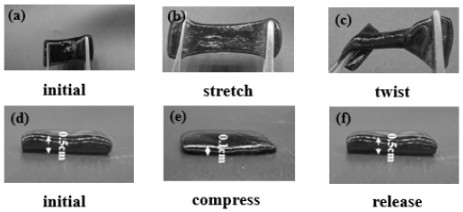

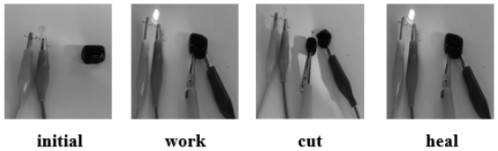

A conductive thread and self-healing technology, which is applied in the field of self-healing antifreeze conductive silk fibroin hydrogel and its preparation, can solve the problems of affecting the application range, reducing wearing comfort, and poor flexibility, achieving broad application prospects, Excellent breathability and comfortable wearing experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038](1) Preparation of silk fibroin aqueous solution: evenly chop silk cocoons and add them to 2wt% sodium carbonate aqueous solution (the weight ratio of silkworm cocoons to sodium carbonate aqueous solution is 1:30), boil for 3 times, each time for 30min, and then Repeated scrubbing with deionized water for 3 times, drying at 60°C for 24 hours after washing, dissolving the dried degummed silkworm cocoons in a ternary solvent (the weight ratio of silkworm cocoons to ternary solvent is 1:10), and The obtained solution was put into a dialysis bag with a molecular weight of 14KD, and then dialyzed in deionized water for 48 hours, and the deionized water was changed every 4 hours to obtain an aqueous silk fibroin solution, which was diluted to a concentration of 2wt%.

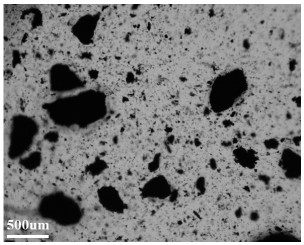

[0039] (2) Preparation of dopamine-modified self-polymerized pyrrole material: Add 40 mg of pyrrole and 4 mg of dopamine to 20 mL of 1M hydrochloric acid aqueous solution, and stir for 12 hours in an ice-water ba...

Embodiment 2

[0043] (1) Preparation of silk fibroin aqueous solution: evenly cut silk cocoons into pieces and added them to 2wt% sodium carbonate aqueous solution for degumming. The mass ratio of silkworm cocoons to anhydrous sodium carbonate aqueous solution was 1:30. 30min, then repeatedly washed with deionized water 3 times, dried at 60°C for 24h after washing; dissolved the dried degummed silkworm cocoons in a ternary solvent (the weight ratio of silkworm cocoons to ternary solvent was 1:10 ), put the resulting solution into a dialysis bag with a molecular weight of 14KD, put it into deionized water for dialysis for 60 hours, and change the deionized water every 4 hours to obtain an aqueous silk fibroin solution, and dilute it to a concentration of 2.5wt%.

[0044] (2) Preparation of dopamine-modified self-polymerized pyrrole material: Add 24 mg pyrrole and 10 mg dopamine to 20 mL of 1M hydrochloric acid aqueous solution, and stir for 12 hours in an ice-water bath to obtain a mixed solu...

Embodiment 3

[0048] (1) Preparation of silk fibroin aqueous solution: evenly chop silk cocoons and add them to 2wt% sodium carbonate aqueous solution for degumming. The mass ratio of silkworm cocoons to sodium carbonate aqueous solution is 1:30, and boil them for 3 times, each time for 30 minutes. Then scrub with deionized water repeatedly for 3 times, and dry at 60°C for 24 hours after washing. Dissolve the dried degummed silkworm cocoons in a ternary solvent (the weight ratio of silkworm cocoons to ternary solvent is 1:10), put the obtained solution into a dialysis bag with a molecular weight of 14KD, and then dialyze it in deionized water for 72 hours. The deionized water was changed every 4 hours to obtain an aqueous silk fibroin solution, which was diluted to a concentration of 3 wt%.

[0049] (2) Preparation of dopamine-modified self-polymerized pyrrole material: Add 420 mg of pyrrole and 16 mg of dopamine to 20 mL of 1M hydrochloric acid aqueous solution, and stir for 12 hours in an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com