Hole sealing grout stop material and grouting hole sealing process

A technology for sealing holes and stopping grouting, which is applied in basic structure engineering, soil protection, construction, etc. It can solve problems affecting grouting work efficiency and cost, high hardness of grouting plugs, and difficulty in plugging, and achieves adjustable setting time and guaranteed The effect of grouting pressure and strong self-healing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

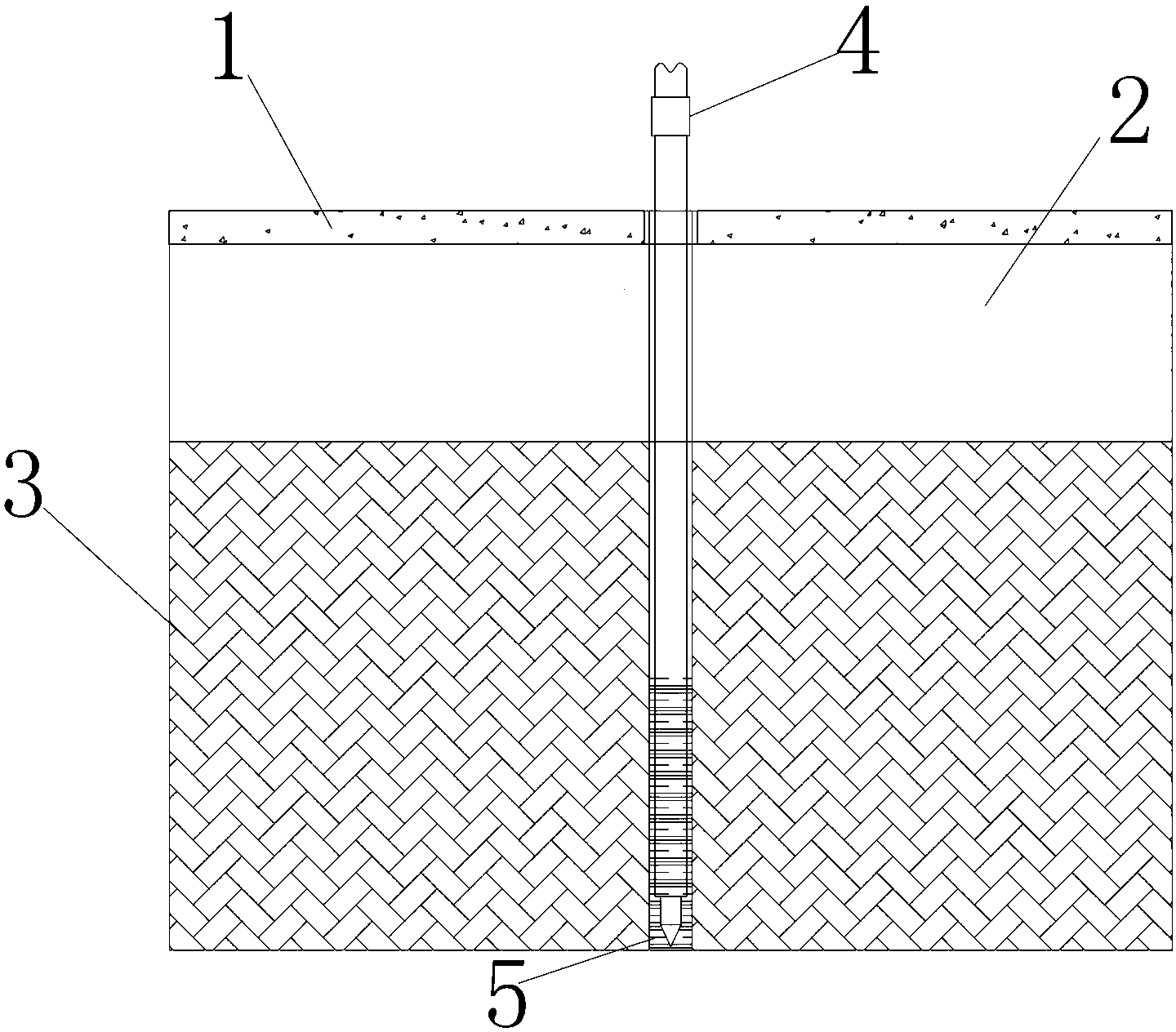

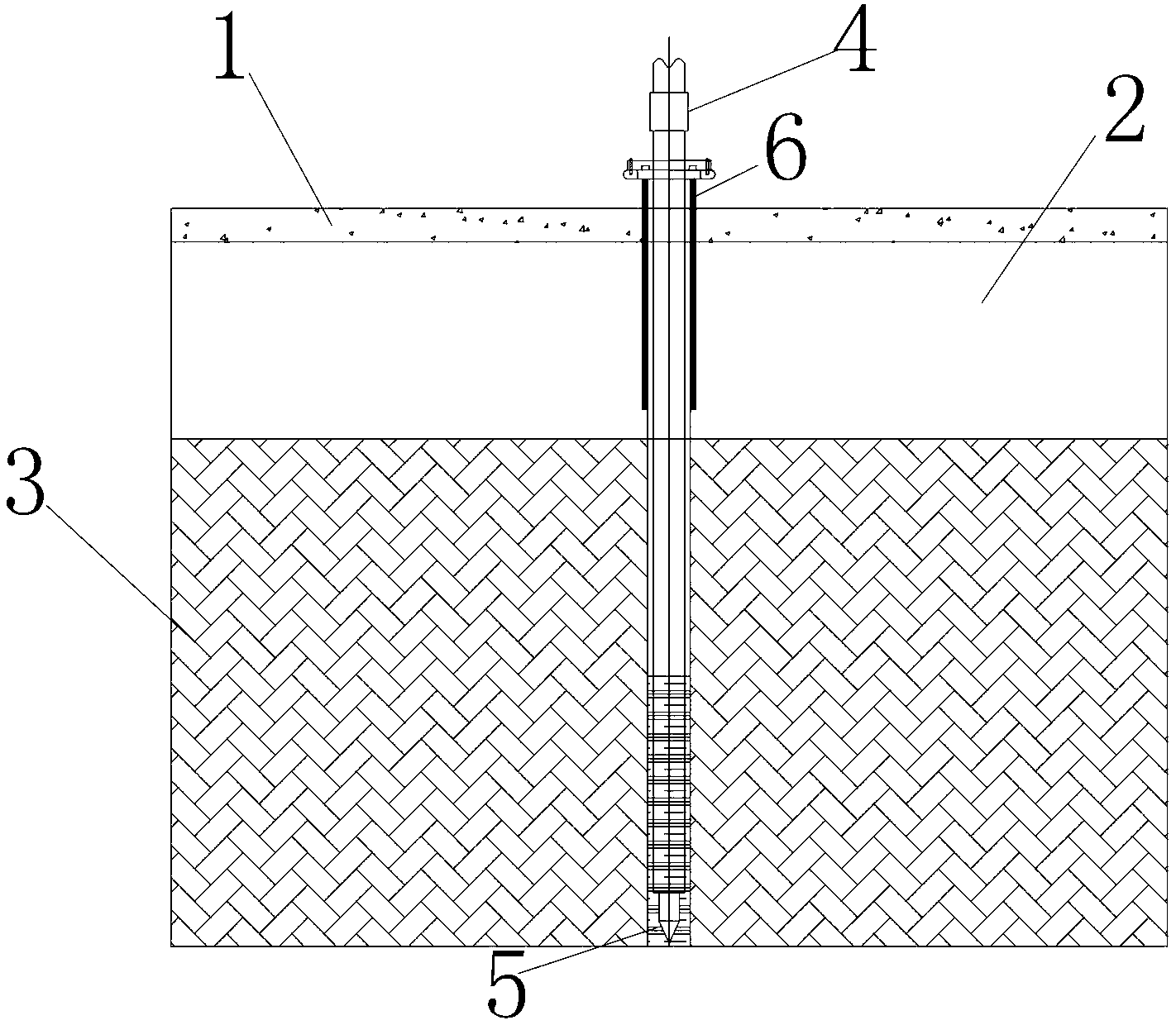

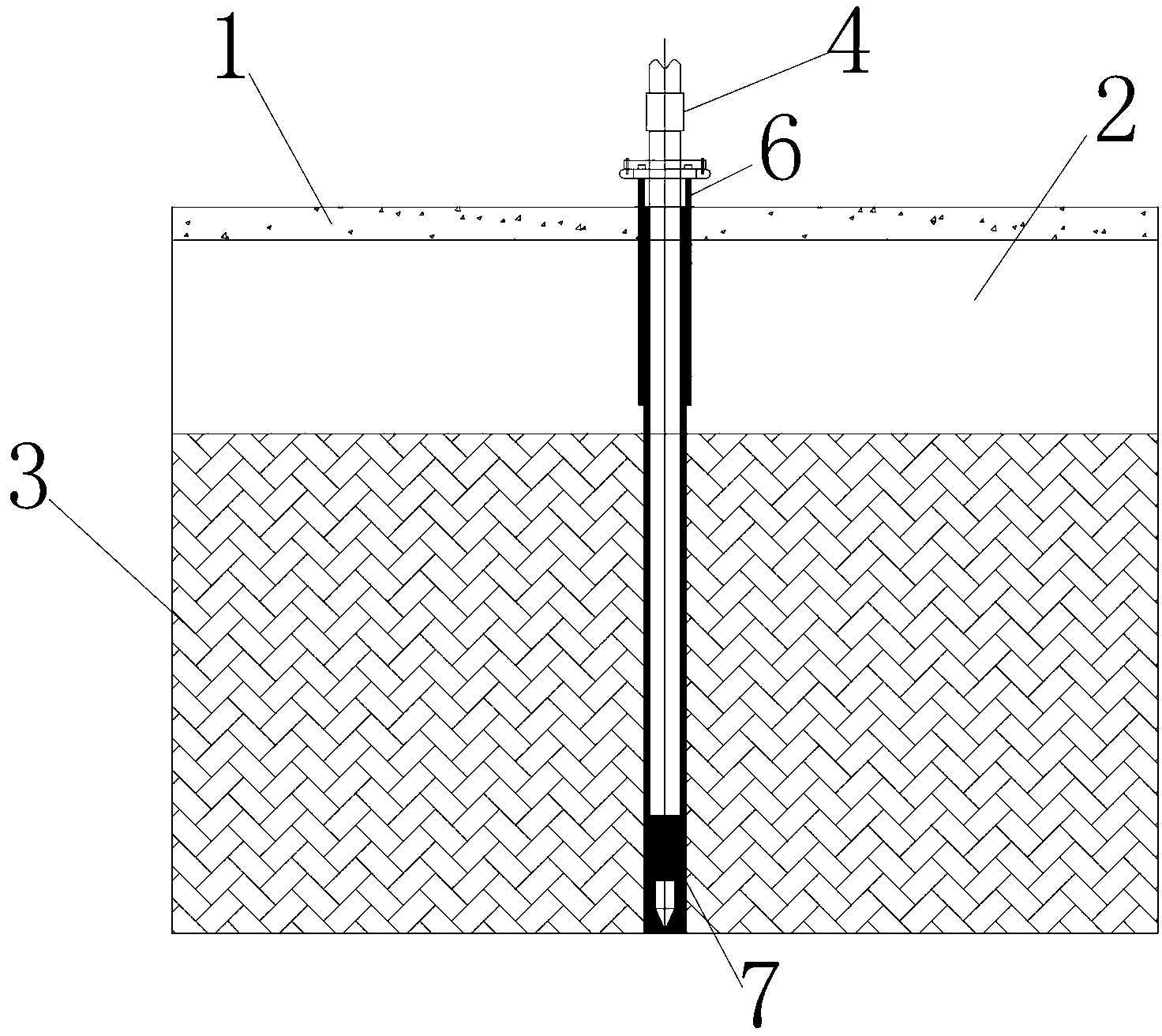

[0032] A sealing and grout-stopping material of the present invention, which is mainly prepared from clay puree, cement and sodium metaaluminate, and the clay puree is mainly made by stirring clay and water, and its specific gravity is 1.25 (1.25-1.35 can be ). The sealing and anti-grouting material is used to ensure the pressure of grouting under the condition of soft permeable rock and soil, high groundwater level or pressurized water. Every 2L of clay slurry is mixed with 840g of cement (P42.5 Ordinary Portland cement) and 16.8g of sodium metaaluminate.

[0033] The above-mentioned sealing and grouting material of this embodiment can ensure the grouting pressure, has strong resistance to water dilution, and can be pumped in the initial stage, and the consistency of the sealing material (measured by a mortar consistency meter) is within the pumpable period (20min-35min) Keep above 76mm and decrease rapidly after the pumpable period; the viscosity of the sealing material (me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com