Composite film of inorganic insulating films and polyimide films used for three-pole field emission cathode

A technology of inorganic insulating film and polyimide film, applied in the direction of cathode ray tube/electron beam tube, discharge tube, electrical components, etc., can solve the problem that polyimide film is not suitable for insulating layer and polyimide insulating film Destruction, combined with poor reliability and other problems, to achieve large-area and cheap preparation, reduced chemical damage, and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

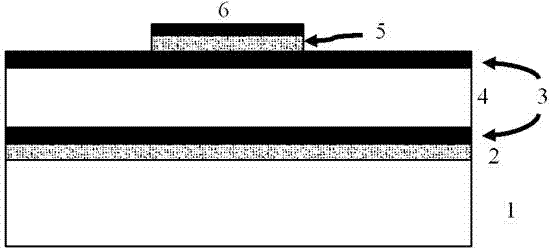

Embodiment 1

[0035] Using clean flat glass as the substrate, the metal grid is prepared by magnetron sputtering, photolithography and wet etching, and the material is Cr. Then reactive magnetron sputtering is used, and a mixed gas of Ar and O2 is used for sputtering to deposit a SiO2 layer with a thickness of about 100 nm. Use biphenyltetralic acid dianhydride and 4,4'-diaminodiphenyl ether with a purity of 99.99% as the dianhydride and diamine monomers of polyimide, dissolved in anhydrous N,N-dimethylformamide A polyamic acid solution with a solid content of 5% was formed in the solvent. The polyamic acid solution was spin-coated on top of the SiO2 layer at 80 o C bake for 2 hours, then respectively at 120 o C. 160 o C. 200 o C. 260 o C. 300 o C heat treatment for 30 minutes, then raised to 350 o C. 400 o C and 450 o Each of C was kept warm for 10 minutes, and finally cooled naturally to take it out to complete the imidization treatment, and the thickness of the polyimide film wa...

Embodiment 2

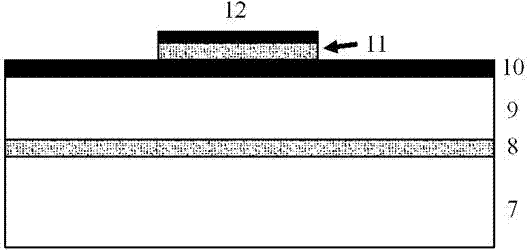

[0038] Using clean flat glass as the substrate, the metal grid is prepared by magnetron sputtering, photolithography and wet etching, and the material is Cr. Then reactive magnetron sputtering is used, and a mixed gas of Ar and N2 is used for sputtering to deposit a Si3N4 layer with a thickness of about 100 nm. Use biphenyltetralic acid dianhydride and 4,4'-diaminodiphenyl ether with a purity of 99.99% as the dianhydride and diamine monomers of polyimide, dissolved in anhydrous N,N-dimethylformamide A polyamic acid solution with a solid content of 5% was formed in the solvent. The polyamic acid solution was spin-coated on the Si3N4 layer, 80 o C bake for 2 hours, then respectively at 120 o C. 160 o C. 200 o C. 260 o C. 300 o C heat treatment for 30 minutes, then raised to 350 o C. 400 o C and 450 o Each of C was kept warm for 10 minutes, and finally cooled naturally to take it out to complete the imidization treatment, and the thickness of the polyimide film was 3 μm....

Embodiment 3

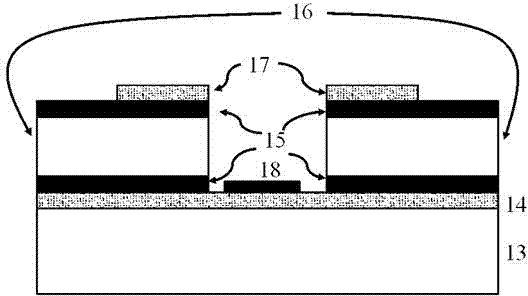

[0041] Using clean flat glass as the substrate, the gate electrode is prepared by magnetron sputtering, photolithography and wet etching, and the material is Cr. Use biphenyltetralic acid dianhydride and 4,4'-diaminodiphenyl ether with a purity of 99.99% as the dianhydride and diamine monomers of polyimide, dissolved in anhydrous N,N-dimethylformamide A polyamic acid solution with a solid content of 5% was formed in the solvent. The polyamic acid solution was sprayed on the glass substrate, 80 o C bake for 2 hours, then respectively at 120 o C. 160 o C. 200 o C. 260 o C. 300 o C heat treatment for 30 minutes, then raised to 350 o C. 400 o C and 450 o C each keep warm for 10 minutes, and finally take it out by natural cooling to complete the imidization treatment, and the thickness of the polyimide film is 4 μm. On the polyimide film, a SiO2 film with a thickness of 200nm was prepared by reactive magnetron sputtering, and then a Cr cathode electrode metal film was depo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com