A kind of antiaging agent for high temperature resistant infrared coating and preparation method thereof

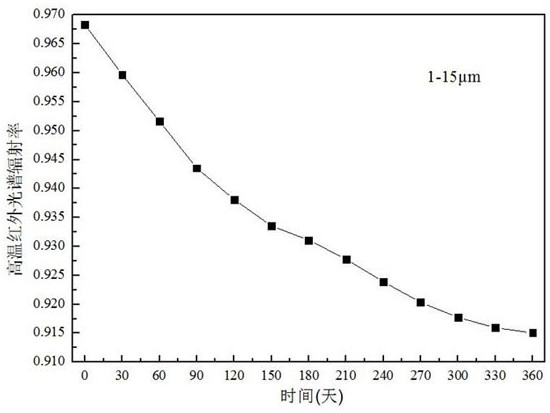

A technology of infrared coating and anti-aging agent, which is applied in the field of high-temperature protection of refractory materials, can solve the problems of poor anti-aging performance, and achieve the effects of simple composition, good high-temperature infrared radiation ability, and simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A anti-aging agent for high temperature infrared coatings, is made of a raw material having a weight fraction ratio of a weight of 40 parts of silica having a average particle diameter of 3 μm, a hexaborant silicon, 23 parts of an average particle size of 0.1 μm. Siliconic silicon glass having an average particle diameter of 2 μm, 5 parts of dioxide, 8 parts of borosilicon glass having an average particle diameter of 8 μm.

[0021] A method for preparing high temperature infrared coatings for anti-aging agents, including the following steps:

[0022] a. Mix each of the raw materials is added to the mixing tank according to the number of weight parts described above.

[0023] b. Add to 3M 3 In the fluidized bed gas flow mill of / min, shaping and mixing is performed at a speed of 1750 r / min at a speed of the gas flow grinding machine, and the average particle size is 2 μm uniform mixed powder;

[0024] c. Then the uniform mixed powder is placed in a high temperature furnac...

Embodiment 2

[0027] An anti-aging agent for high temperature infrared coatings, is made of a raw material having a weight fraction ratio of a weight of 35 parts of a average particle diameter of 2 μm, and 15 parts of a average particle diameter of 2 μm are six borid silicon, 30 average Lixinate, 6 parts of the boron oxide, 6 parts of the boron oxide, and 6 parts of the average particle diameter of 1 μm.

[0028] A method for preparing high temperature infrared coatings for anti-aging agents, including the following steps:

[0029] a. Mix each of the raw materials is mixed in the mixing tank according to the weight of the above weight parts.

[0030] b. Add to the air intake 6m 3 In the fluidized bed gas flow mill of / min, shaping and mixing is performed under the speed of the airflow grinding machine to 2200R / min, and the average particle size is 0.9 μm uniform mixed powder;

[0031] c. The uniform mixed powder is then placed in a high temperature furnace, and the temperature is raised to 8...

Embodiment 3

[0034] An anti-aging agent for high temperature infrared coatings, is made of a raw material having a weight fraction ratio of a weight of 20 parts of silica having an average particle diameter of 0.5 μm, and 30 parts of a hexal boride of 1.6 μm, 15 A hexon silicon glass having an average particle diameter of 1 μm, 1 part of the three oxide, 9 parts of a borosilicon glass having a average particle diameter of 5.5 μm.

[0035] A method for preparing high temperature infrared coatings for anti-aging agents, including the following steps:

[0036] a. Mix each of the raw materials is added to the mixing tank according to the weight of the above weight parts.

[0037] b. Add to the air intake 6M 3 In the fluidized bed airflow mill of / min, shaping and mixing at the airflow mill is 1200r / min, and the average particle size is 2.1 μm uniform mixed powder;

[0038] c. Then the uniform mixed powder is placed in a high temperature furnace, and the temperature is raised to 1000 ° C at 6 ° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com