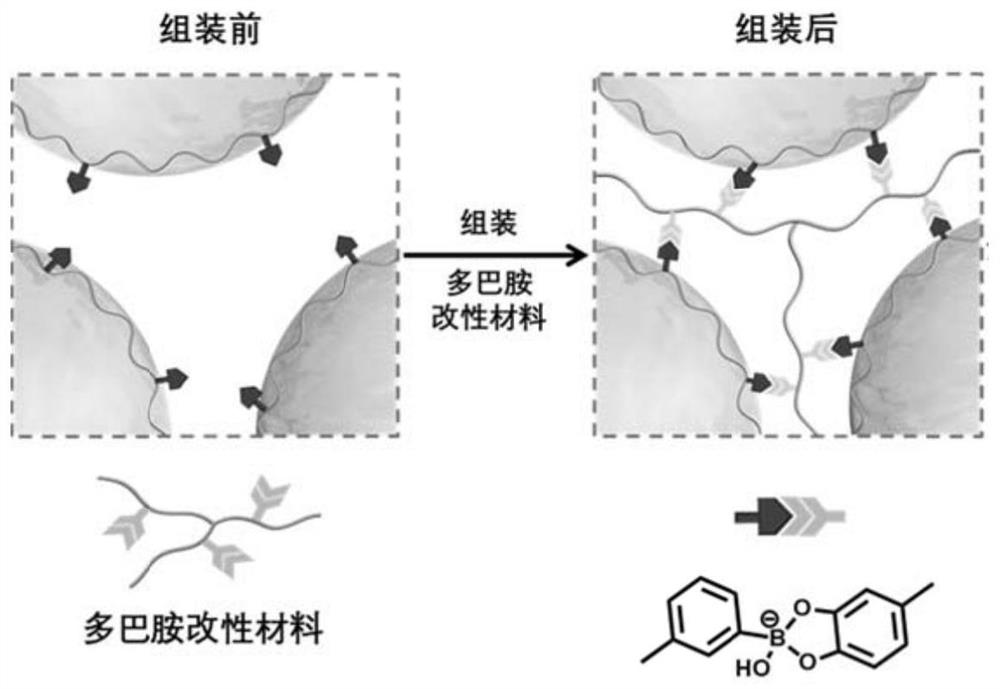

Microgel assembly scaffold for tissue regeneration and repair, and preparation method thereof

A tissue regeneration and microgel technology, applied in the direction of prosthesis, pharmaceutical formulation, pharmaceutical science, etc., can solve the problems of weak interaction force, poor reproducibility, large surgical wound, etc., to avoid displacement and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation of the hyaluronic acid modified by the carbon-carbon double bond used below comprises the following steps:

[0040] Weigh 2g of hyaluronic acid with a molecular weight of 100,000 and dissolve it in 200ml of deionized water at 40°C. After returning to room temperature, 4ml of methacrylic anhydride was added, and the pH was stabilized at 8 with 1mol / L NaOH solution. After 2 hours of reaction, it was stirred overnight at 4°C. The solution was dialyzed with deionized water for 3 days by using a dialysis bag with a molecular weight of 8000-12000, and then freeze-dried to obtain hyaluronic acid modified by a carbon-carbon double bond.

[0041] The preparation of the hyaluronic acid modified by dopamine used below comprises the following steps:

[0042] (1) Take 21.34g of 2-(N-morpholine)ethanesulfonic acid solid and dissolve it in 1L of deionized water to obtain MES buffer;

[0043] (2) Weigh 1 g of hyaluronic acid with a molecular weight of 100,000 and dissol...

Embodiment 1

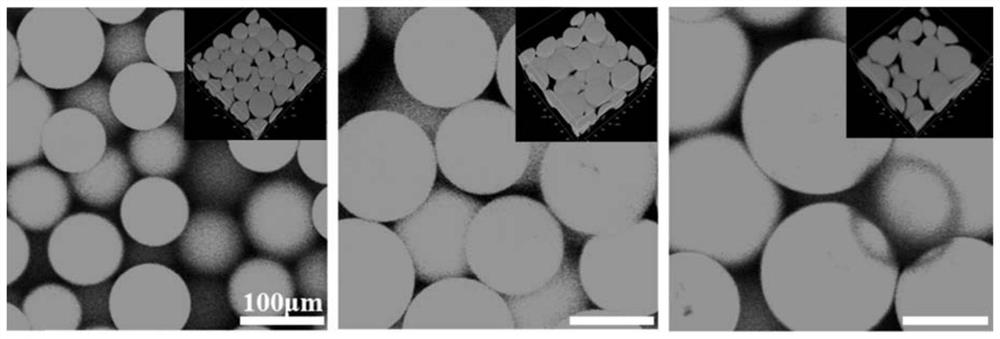

[0055] (1) Add 30mg of carbon-carbon double bond and phenylboronic acid double-modified gelatin and 50mg of carbon-carbon double bond-modified hyaluronic acid into 2ml of PBS solution, heat up to 40°C and stir to dissolve, then add 0.5mol / L NaOH to adjust The pH is 7, after stirring, add 5 mg of photoinitiator phenyl-2,4,6-trimethylbenzoyl lithium phosphonate (Lap), and stir to obtain the aqueous dispersed phase;

[0056] (2) Dilute the 2% Fluo-Surf 7500 solution ten times with fluorinated oil HFE7500 to a concentration of 0.2wt%, as the oil phase continuous phase;

[0057] (3) The two phases are introduced into the T-shaped microfluidic chip. Adjust and control the flow rate of the dispersed phase to be 0.4ml / h, 1ml / h and 1.6ml / h respectively, and the flow rate of the stationary continuous phase to be 6ml / h, and obtain three kinds of microemulsion droplets with different sizes and diameters of water-in-oil by shearing. The prepared droplets were collected in 0.2wt% fluorinat...

Embodiment 2

[0062] (1) Add 40mg of hyaluronic acid modified with carbon-carbon double bonds and phenylboronic acid, and 40mg of collagen modified with carbon-carbon double bonds into 2ml of PBS solution, heat up to 40°C and stir to dissolve, then add 0.5mol / L NaOH to adjust the pH 7, after stirring, add 3 mg of photoinitiator phenyl-2,4,6-trimethylbenzoyl lithium phosphonate (Lap), and then mix with the cells to make an aqueous dispersion with a cell density of 1.5 million / mL ;

[0063] (2) Dilute 2wt% fluorinated oil HFE7500 with fluorinated oil ten times to a concentration of 0.2wt%, as the oil phase continuous phase;

[0064] (3) The two phases are introduced into the cross-shaped microfluidic chip. Among them, the flow rates of the dispersed phase and the continuous phase are adjusted and controlled to be 0.5ml / h and 4ml / h respectively, and water-in-oil single emulsion droplets are obtained by shearing. The prepared droplets were collected in 0.2wt% fluorinated oil HFE7500, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com