Polyurethane adhesive containing catechol group as well as preparation method and application of polyurethane adhesive

A catechol and adhesive technology, which is applied in the field of polyurethane adhesive and its preparation, can solve the problems of underwater adhesion performance and biocompatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

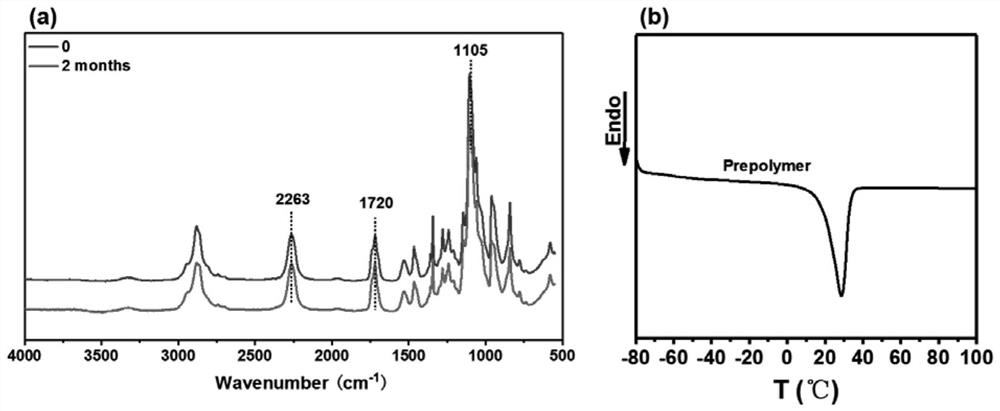

[0060] Embodiment 1, the preparation of adhesive system and adhesive of the present invention

[0061] 1. According to the mass fraction in Table 2, LDA-2HCl, L 3 DA-4HCl is dissolved in water containing triethanolamine to form a solution (triethanolamine has two effects: 1, for removing LDA and L 3 DA combined hydrochloride; 2, increase the viscosity of the solution).

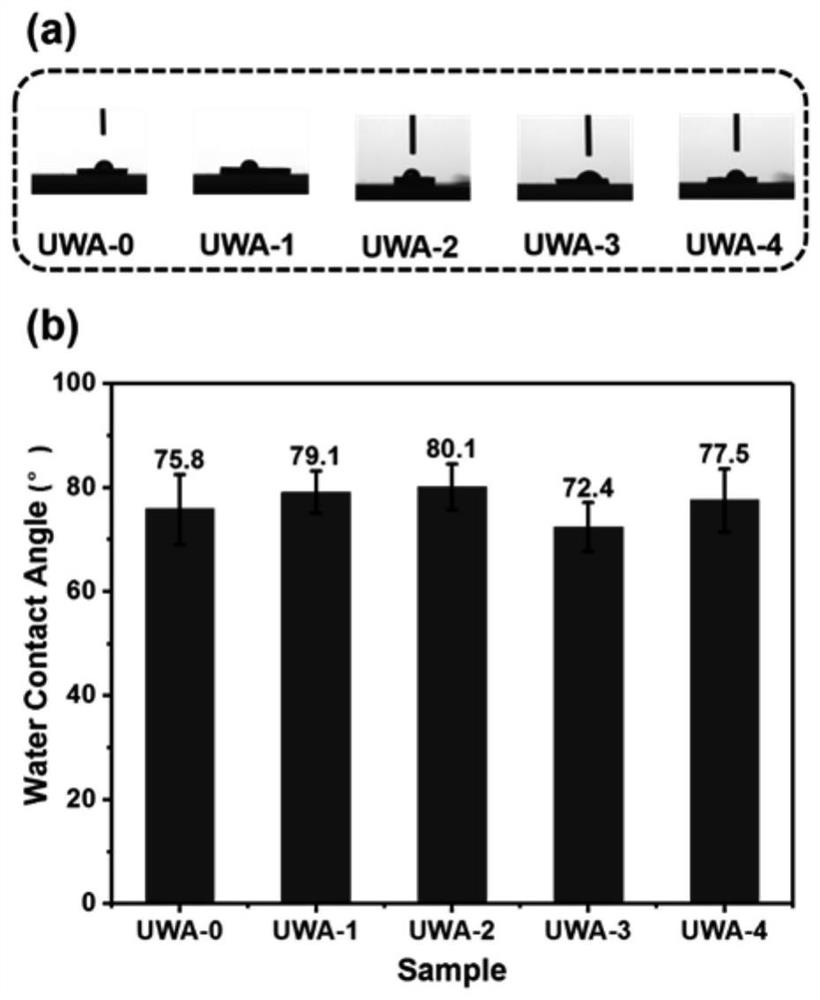

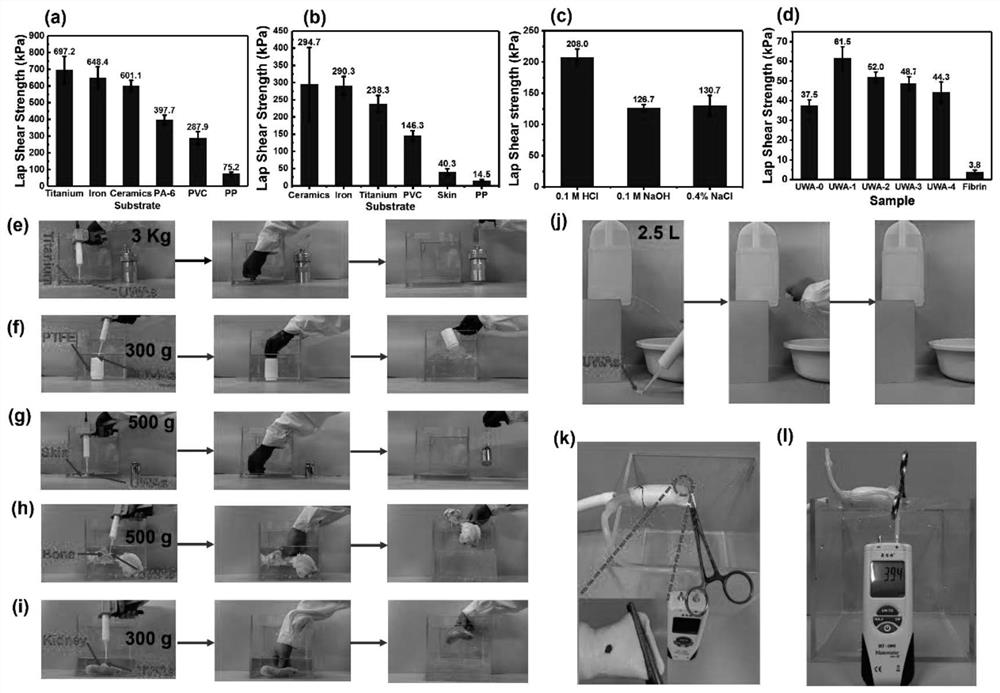

[0062] 2. Take the prepolymer A and heat it to 30°C to melt into a liquid state, and mix it with the solution prepared in step 1, which is the adhesive system of the present invention. It is the adhesive of the present invention when it is left to stand for 10 seconds to solidify. According to L 3 Five different adhesives were obtained with different DA content, namely UWA-0, UWA-1, UWA-2, UWA-3, UWA-4.

[0063] Formulation (mass fraction wt%) of table 2 underwater adhesive (UWAs)

[0064]

Embodiment 2

[0065] Embodiment 2, the preparation of adhesive system and adhesive of the present invention

[0066] Use prepolymer B, LDA-2HCl, L 3 The consumption of DA-4HCl, prepolymer, water and triethanolamine is different from Example 1, and the mass fraction of consumption is as follows: LDA-2HCl 15.36wt%, prepolymer B 64.21wt%, water 7.50wt%, triethanolamine 12.93wt% ; All the other preparation method steps are with reference to embodiment 1.

[0067] The bonding strength of the prepared adhesive DMPUA-1 to titanium material is 210.5kPa (dry state); 90.3kPa (underwater); the bonding strength to pigskin is 16.0kPa (dry state); 9.2kPa (water Down)

Embodiment 3

[0068] Embodiment 3, the preparation of adhesive system and adhesive of the present invention

[0069] Use prepolymer B, LDA-2HCl, L 3 The consumption of DA-4HCl, prepolymer, water and triethanolamine is different from embodiment 1, and consumption mass fraction is as follows: LDA-2HCl 14.80wt%, L 3 DA-4HCl 0.55wt%, prepolymer B 64.22wt%, water 7.50wt%, triethanolamine mass fraction 12.93wt%; the rest of the preparation method steps refer to Example 1.

[0070] The bonding strength of the prepared adhesive DMPUA-2 to titanium material is 630.7kPa (dry state), 230.1kPa (underwater); the bonding strength to pigskin is 52.7kPa (dry state), 39.1kPa (water Down).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com