Polymer sponge microsphere and preparation method thereof

A polymer and sponge technology, applied in pharmaceutical formulations, drug delivery, medical science, etc., can solve the problems of difficulty in obtaining uniform size, polymer sponge microspheres are difficult to remove toxicity, time-consuming, etc., and achieve the ability to promote cell proliferation. , good adhesion and proliferation characteristics, efficient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

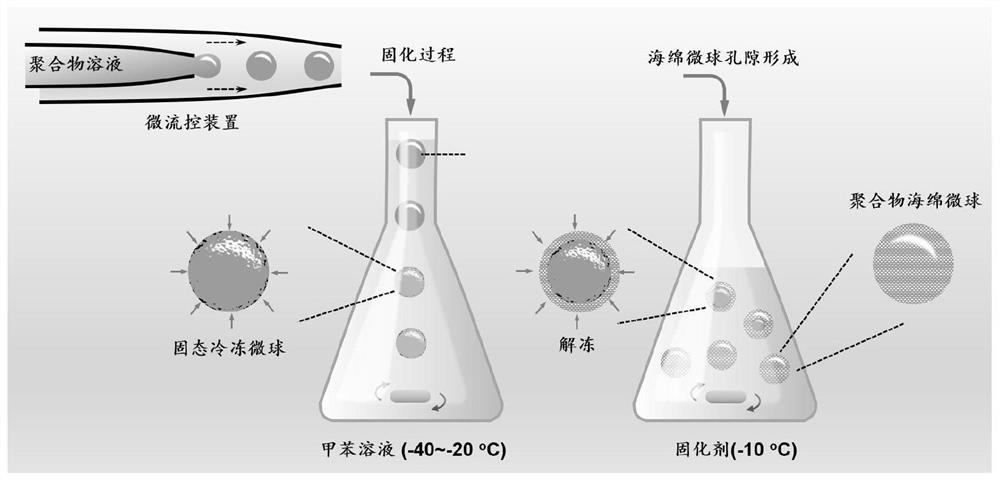

[0030] Such as Figure 1-7 As shown, the present invention provides a kind of technical scheme: a kind of polymer sponge microsphere and preparation method thereof, this polymer sponge microsphere and preparation method thereof comprise the following steps:

[0031] S1. The emulsified polymer droplets are frozen in situ by the freezing liquid, the size of the polymer droplets is 100-1000 microns, and the polymer is one of chitosan, silk protein, collagen, sodium alginate and gelatin or several, the mass fraction of the polymer solution is 0.20-5%, based on the weight of pure water, preferably 0.5%, 1% and 2%, the example is 1%, the solution frozen in situ is toluene, xylene, One or two kinds of solutions such as chloroform;

[0032] S2, followed by mixing with the fixative solution and performing physical crosslinking, the fixative contains sodium hydroxide of Alcohol solution, alcohol solution of calcium chloride, alcohol solution of potassium hydroxide, alcohol solution of...

Embodiment 1

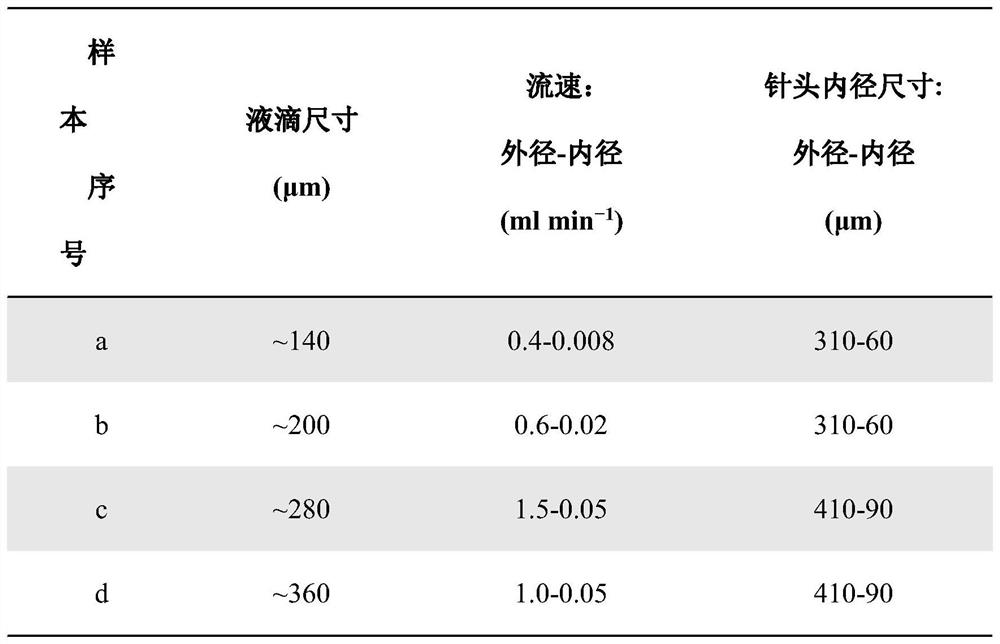

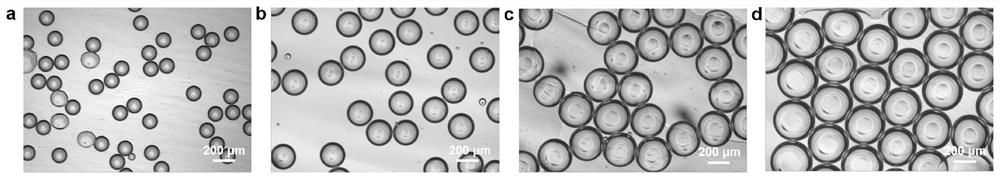

[0035] Embodiment 1: the preparation of porous chitosan sponge microsphere

[0036] Weigh 1g of chitosan solution into 100ml of 1% acetic acid aqueous solution to prepare a 1% chitosan solution with a mass fraction, and draw 8ml of prepared chitosan solution using a 10ml syringe. Directly connected to the inner tube (inner diameter of 60 microns) on the microfluidic device, and set the extrusion speed to 0.008ml / min, use a 50ml syringe to extract 40ml of 3% (V / V) Span-80 cyclohexane solution As the extrusion phase, it was connected to the outer tube (with an inner diameter of 310 μm) on the microfluidic device, and the extrusion speed was set to 0.4 ml / min. The extruded droplets are frozen into solid microspheres in toluene pre-cooled by liquid nitrogen (-40°C ~ -20°C), and 0.1mol / L NaOH ethanol solution is prepared as a solution containing a fixative, and the fixative is pre- Cool to -10°C, mix and cross-link the obtained frozen solid chitosan microspheres with a fixative so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com