Polyurethane micro-carrier as well as preparation method and application thereof

A technology of polyurethane microspheres and microcarriers, which is applied in the preparation of microspheres, microcapsule preparations, prostheses, etc., can solve problems such as lack of injectability, poor mechanical properties, and large limitations, and achieve good clinical application prospects, The effect of less environmental pollution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

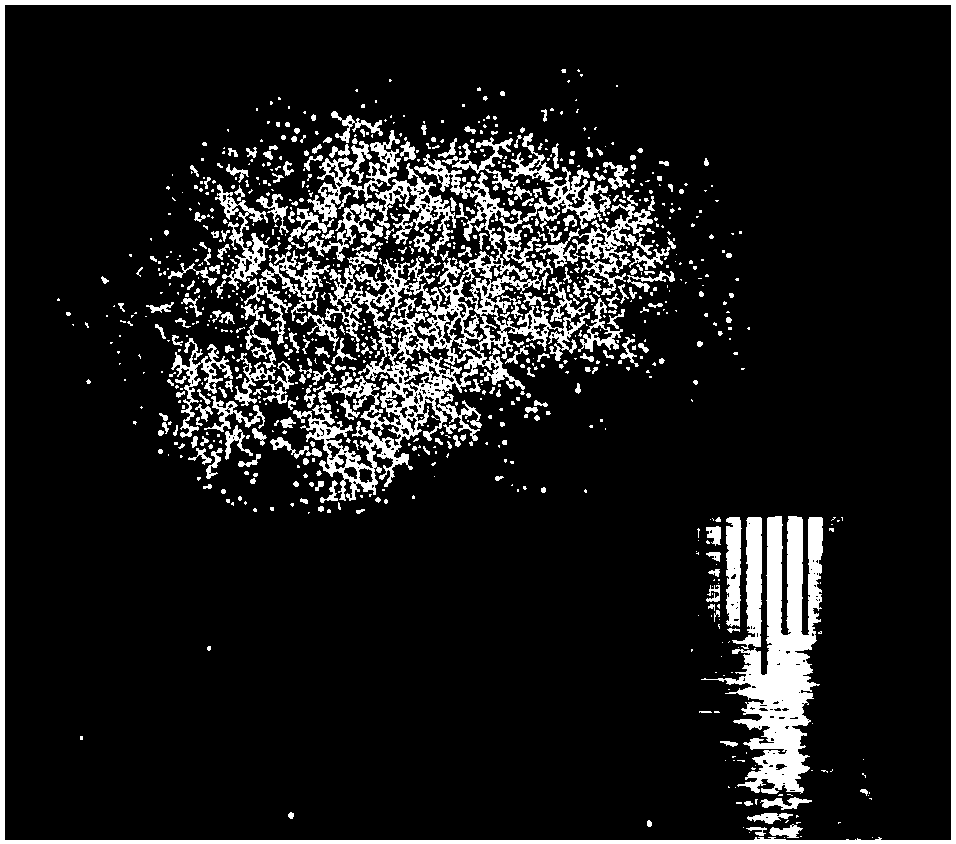

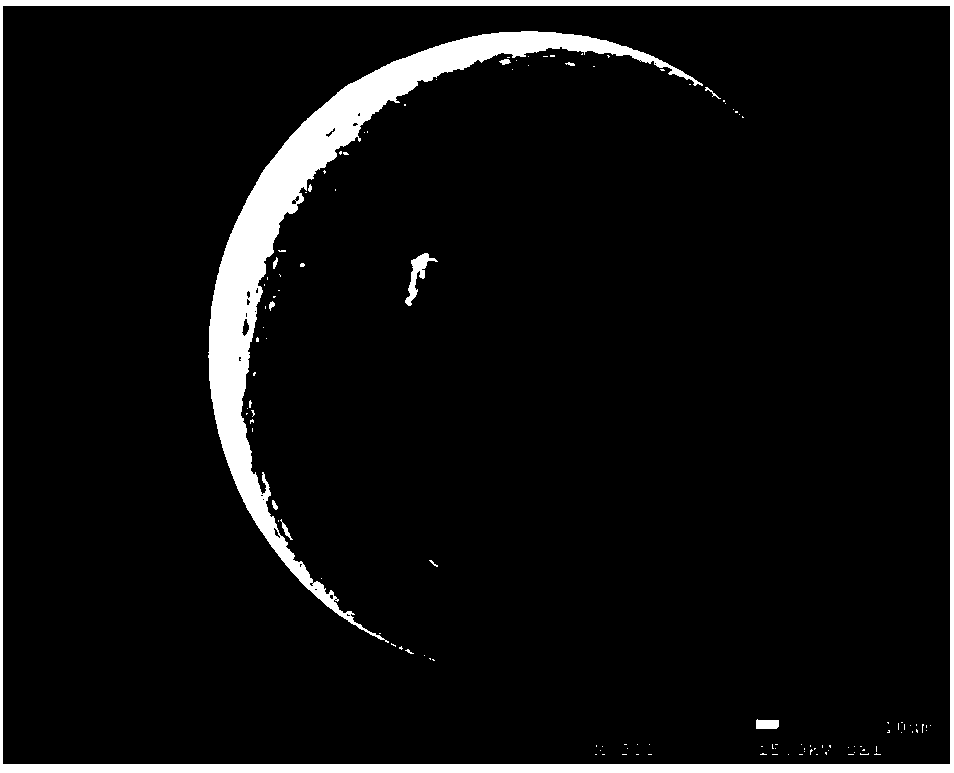

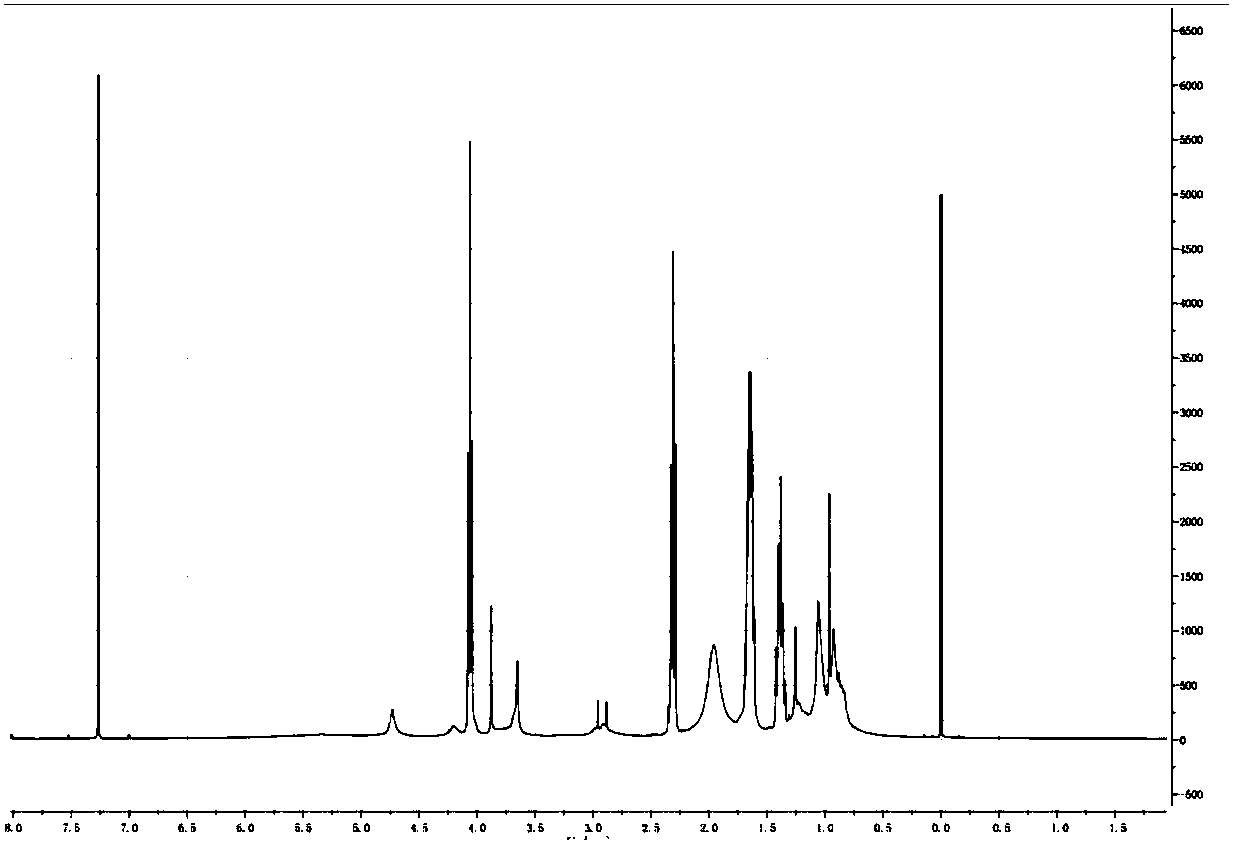

[0073] Embodiment 1 The preparation of polyurethane microspheres of the present invention

[0074] 1. Preparation method

[0075] The preparation method of cell-loaded polyurethane microspheres comprises the following steps:

[0076] (1) Oligomer diol premix

[0077] Add polycaprolactone diol 1000 and PEG200 into the three-necked flask, the molar ratio of the two is 1:1, stir and mix at 70°C;

[0078] (2) Prepolymerization reaction:

[0079] Isophorone diisocyanate and dihydric alcohol in step (1) are raw materials, added in the reaction vessel, stirred at a speed of 300rmp, and reacted for 2h;

[0080] The mol ratio of isophorone isocyanate to total oligomer diol is 2:1;

[0081] (3) Chain extension reaction

[0082] Add 2,2-dimethylolpropionic acid after the above step (2), cool down to 45°C, and react for 2 hours at a stirring speed of 700rmp;

[0083] Wherein the mol ratio of chain extender and isocyanate in step (2) is 0.1:1;

[0084] (4) neutralization:

[0085] ...

Embodiment 2

[0091] The preparation of embodiment 2 polyurethane microspheres of the present invention

[0092] 1. Preparation method

[0093] The preparation method of cell-loaded polyurethane microspheres comprises the following steps:

[0094] (1) Oligomer diol premix

[0095] Add polytetrahydrofuran and PEG200 into a three-necked flask, the molar ratio of the two is 1.5:1, stir and mix at 70°C;

[0096] (2) Prepolymerization reaction:

[0097] Isophorone diisocyanate and dihydric alcohol in step (1) are raw materials, added in the reaction vessel, stirred at a speed of 700rmp, and reacted for 3h;

[0098] The mol ratio of isophorone isocyanate and total oligomer glycol is 2.5:1;

[0099] (3) Chain extension reaction

[0100] Add 2,2-dimethylolpropionic acid after the above step (2), cool down to 50°C, and react for 3 hours at a stirring speed of 300rmp;

[0101] Wherein the mol ratio of chain extender and isocyanate in step (2) is 1:1;

[0102] (4) neutralization:

[0103] Add ...

Embodiment 3

[0109] The preparation of embodiment 3 polyurethane microspheres of the present invention

[0110] 1. Preparation method

[0111] The preparation method of cell-loaded polyurethane microspheres comprises the following steps:

[0112] (1) Oligomer diol premix

[0113] Add polycaprolactone diol 1000 and PEG200 into a three-necked flask, the molar ratio of the two is 2:1, stir and mix at 70°C;

[0114] (2) Prepolymerization reaction:

[0115] Isophorone diisocyanate and dibasic alcohol in step (1) are raw materials, added in the reaction vessel, stirred at a speed of 380rmp, and reacted for 4h;

[0116] The mol ratio of isophorone isocyanate and total oligomer glycol is 2.5:1;

[0117] (3) Chain extension reaction

[0118] After the above step (2), add 2,2-dimethylolpropionic acid, while cooling down to 55°C, and react at a stirring speed of 380rmp for 2h;

[0119] Wherein the mol ratio of chain extender and isocyanate in step (2) is 1:1;

[0120] (4) neutralization:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com