Gel particle plugging agent with self-healing characteristic as well as preparation method and application thereof

A gel particle and self-healing technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as complex preparation process, low pressure plugging temperature, and complex formula of smart gel particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

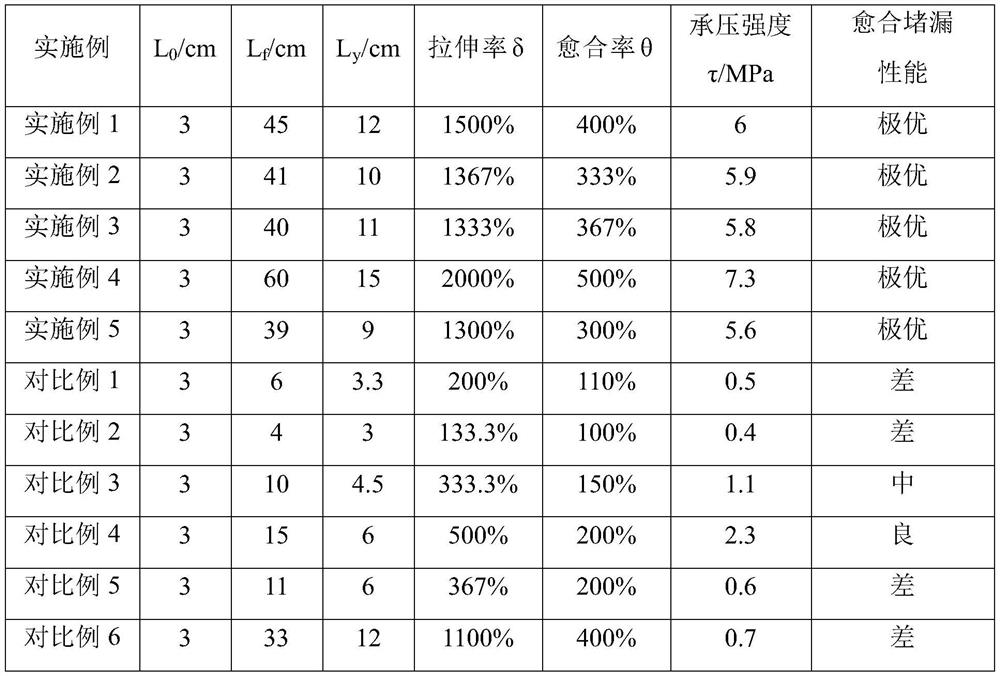

Examples

Embodiment 1

[0069] A gel particle plugging agent with self-healing properties, comprising the following raw materials in parts by mass: 25 parts of comonomer, 10 parts of surfactant A, 0.01 part of initiator I, and 0.04 part of crosslinking agent , 2 parts of cationic latex particles.

[0070] The copolymerization monomer is a combination of octadecyl methacrylate, acrylic acid and acrylamide, and the mass ratio of octadecyl methacrylate, acrylic acid and acrylamide is 3:50:50.

[0071] Described surfactant A is sodium lauryl sulfate.

[0072] The initiator I is an oxidation-reduction initiator, the oxidizing agent is ammonium persulfate, the reducing agent is sodium bisulfite, and the mass ratio of the oxidizing agent to the reducing agent is 1:1.

[0073] The crosslinking agent is N, N-methylenebisacrylamide.

[0074] The preparation method of the above-mentioned gel particle plugging agent with self-healing properties comprises the following steps:

[0075] Disperse the comonomer, s...

Embodiment 2

[0094] A gel particle plugging agent with self-healing properties, comprising the following raw materials in parts by mass: 35 parts of comonomers, 10 parts of surfactant A, 0.05 parts of initiator I, and 0.02 parts of crosslinking agent , 2 parts of cationic latex particles.

[0095] The types of the comonomer, surfactant A, initiator I, and crosslinking agent are as described in Example 1.

[0096] The preparation method of the gel particle plugging agent with self-healing properties is as described in Example 1, except that the amount of deionized water is 112 parts.

[0097] The method for evaluating the healing and plugging performance of the above-mentioned self-healing gel plugging material is as described in Example 1, and its healing and plugging performance is shown in Table 1.

Embodiment 3

[0099] A gel particle plugging agent with self-healing properties, comprising the following raw materials in parts by mass: 15 parts of comonomer, 10 parts of surfactant A, 0.01 part of initiator I, and 0.02 parts of crosslinking agent 1 part of cationic latex particles.

[0100] The types of the comonomer, surfactant A, initiator I, and crosslinking agent are as described in Example 1.

[0101] The preparation method of the gel particle plugging agent with self-healing properties is as described in Example 1, except that 50 parts of deionized water is used.

[0102] The method for evaluating the healing and plugging performance of the above-mentioned self-healing gel plugging material is as described in Example 1, and its healing and plugging performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com