Mask structure of integrated driving position

A driver's station and integrated technology, applied in the field of rail vehicle masks, can solve problems such as uneven fit gaps, increased installation process complexity and installation workload, poor aesthetics, etc., to achieve wide driver's vision and high internal space utilization , the effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be explained below in conjunction with the accompanying drawings.

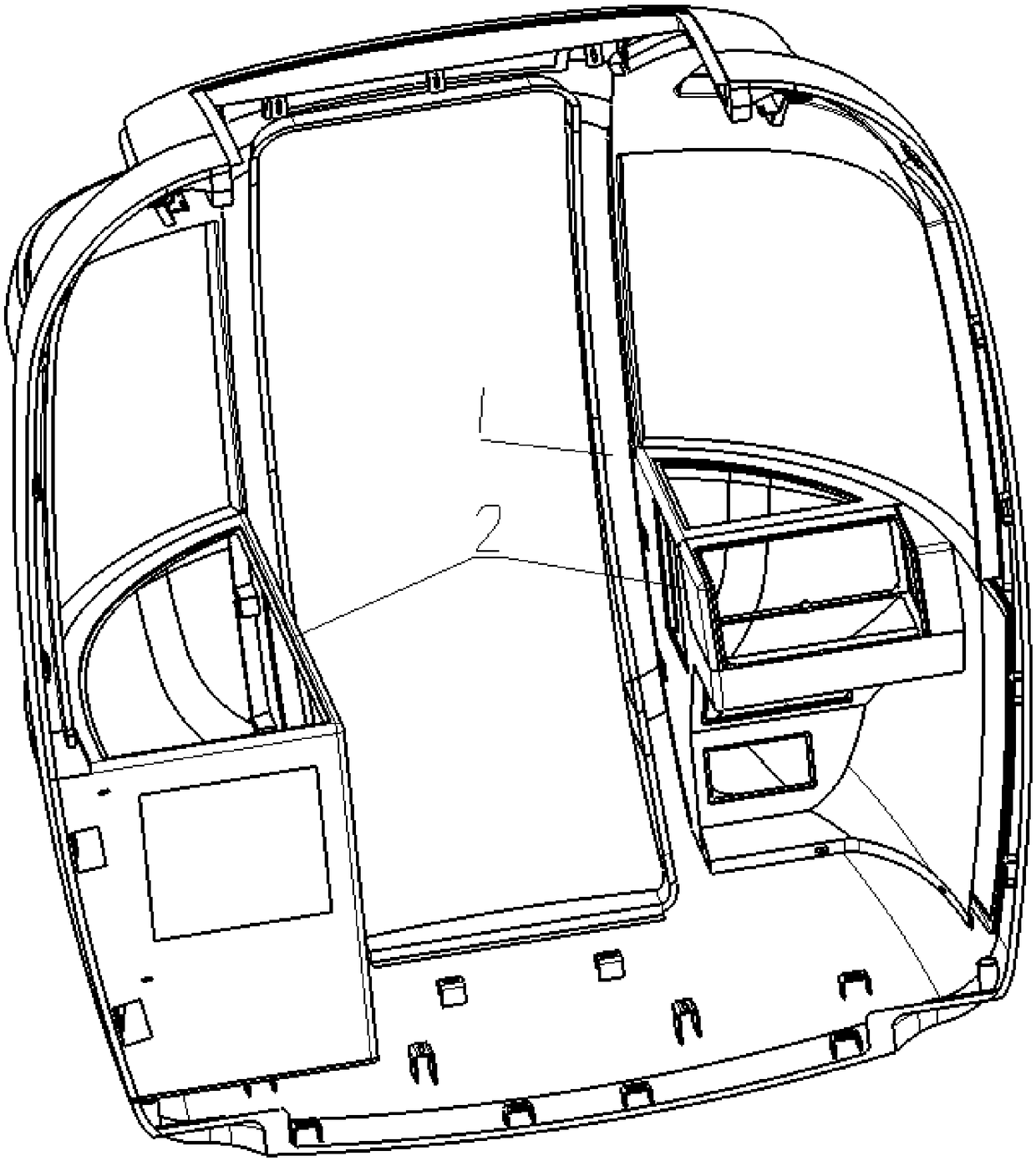

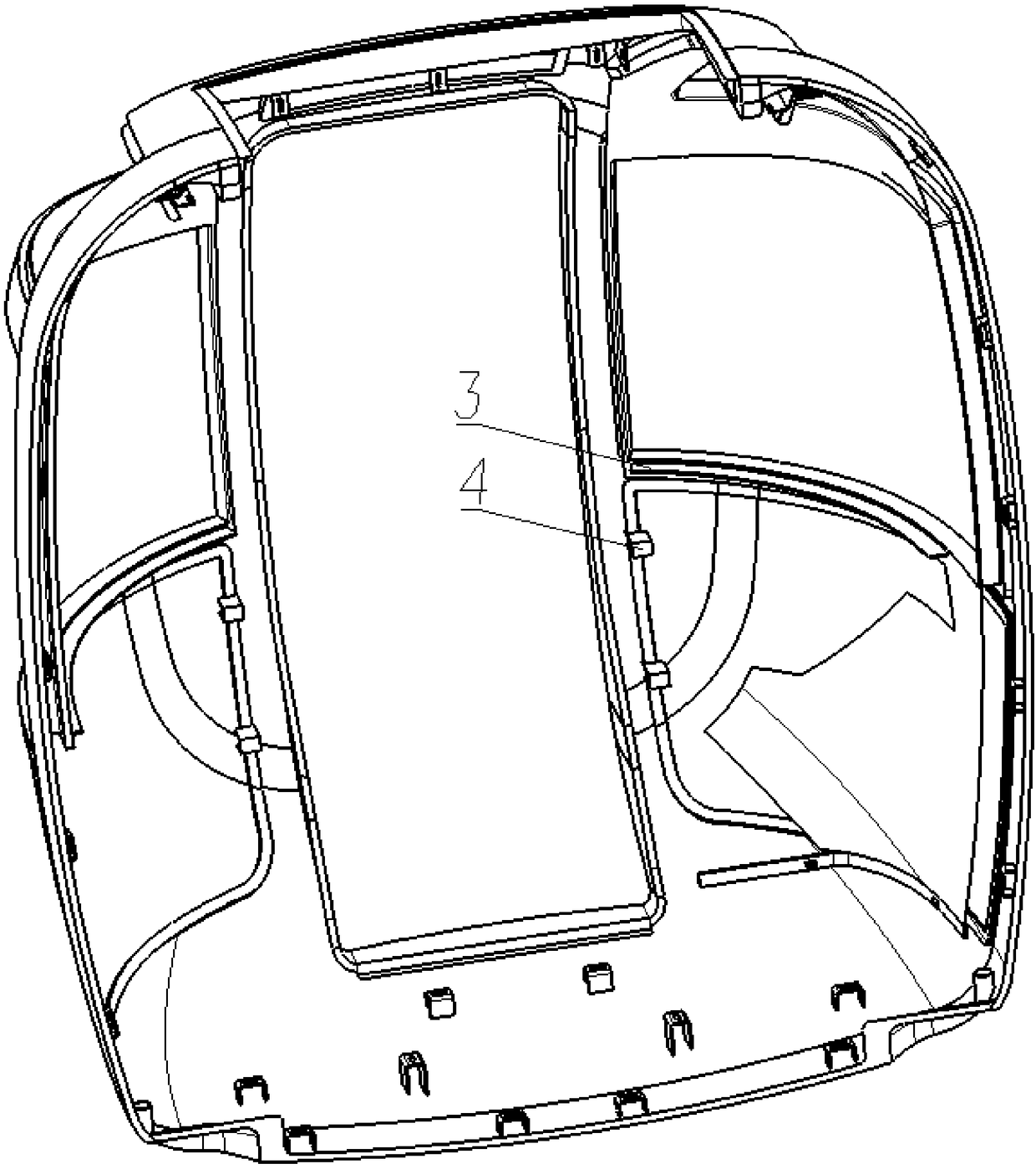

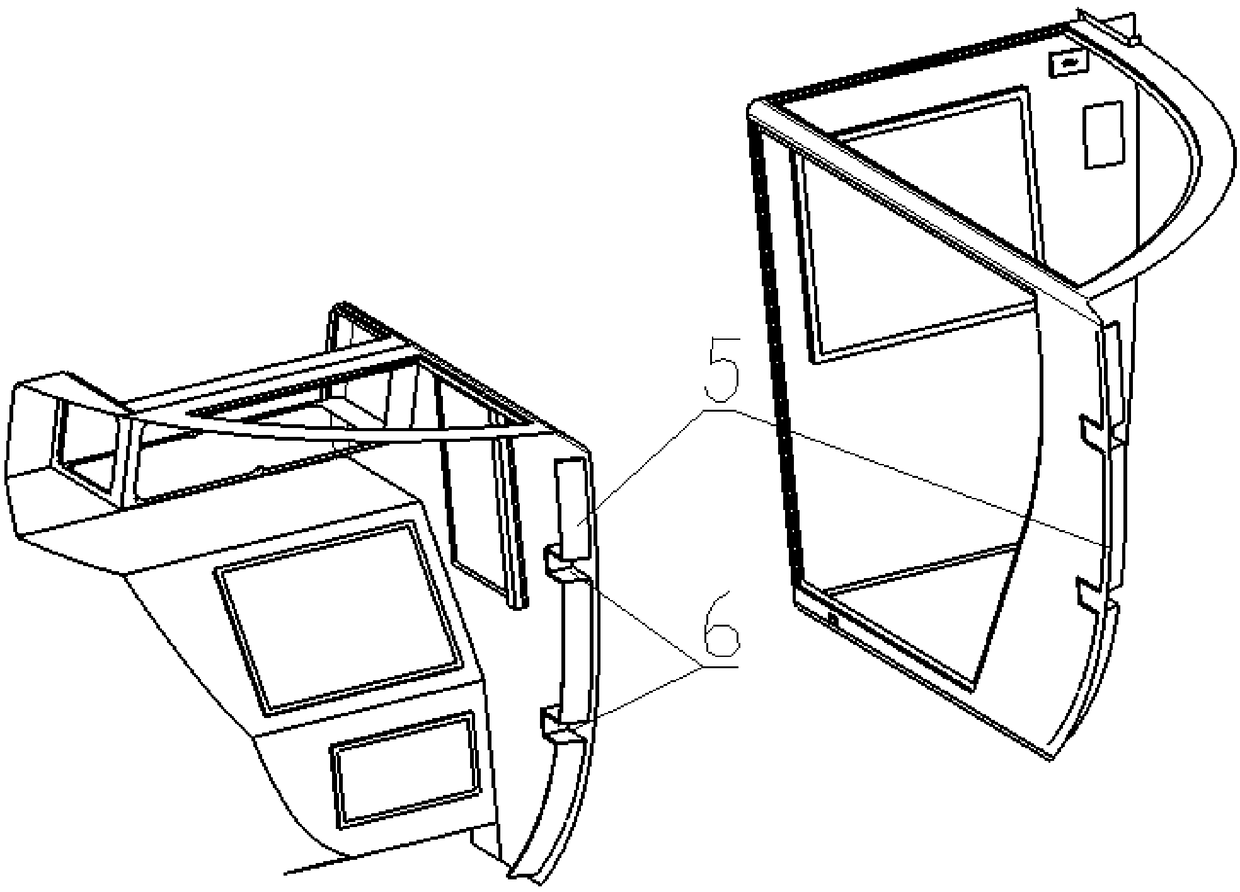

[0024] Such as Figures 1 to 3 As shown, the mask structure of the present embodiment is an integrated driver's station, including a mask 1 and a driver's station 2, and the driver's station 2 is divided into two parts, which are respectively located on both sides of the escape door. A plug interface is arranged between the mask 1 and the driver's console 2 . Specifically, the inner side of the mask (both sides of the escape door) is provided with a boss 4, and the driver's platform is provided with a groove 6 matched with it. The boss 4 and the groove 6 constitute the plug interface, through which Realize the positioning of the driver's station in the mask. Face shield 1 is provided with the mask bonding flange 3 extending in the car below the window, and the driver's console 2 front portion is provided with vertical driver's console bonding flange 5; The su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com