Cable-suspended type rail locomotive

A rail locomotive and cable-suspension technology, applied in locomotives, motor vehicles, cable railways, etc., can solve the problems of poor passability, large restrictions, small climbing degree, etc., and achieve small visual environment impact, small workload, and construction period. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

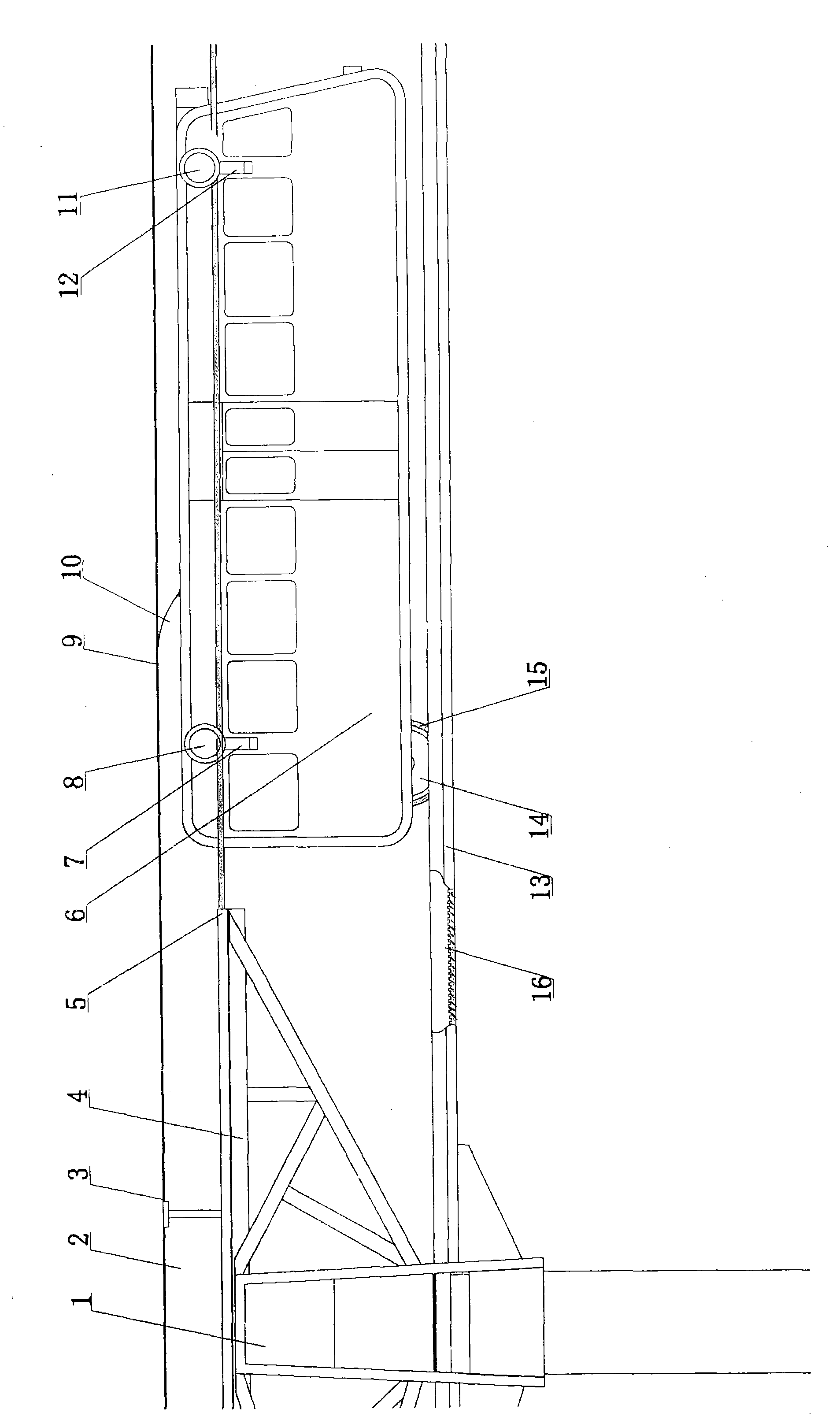

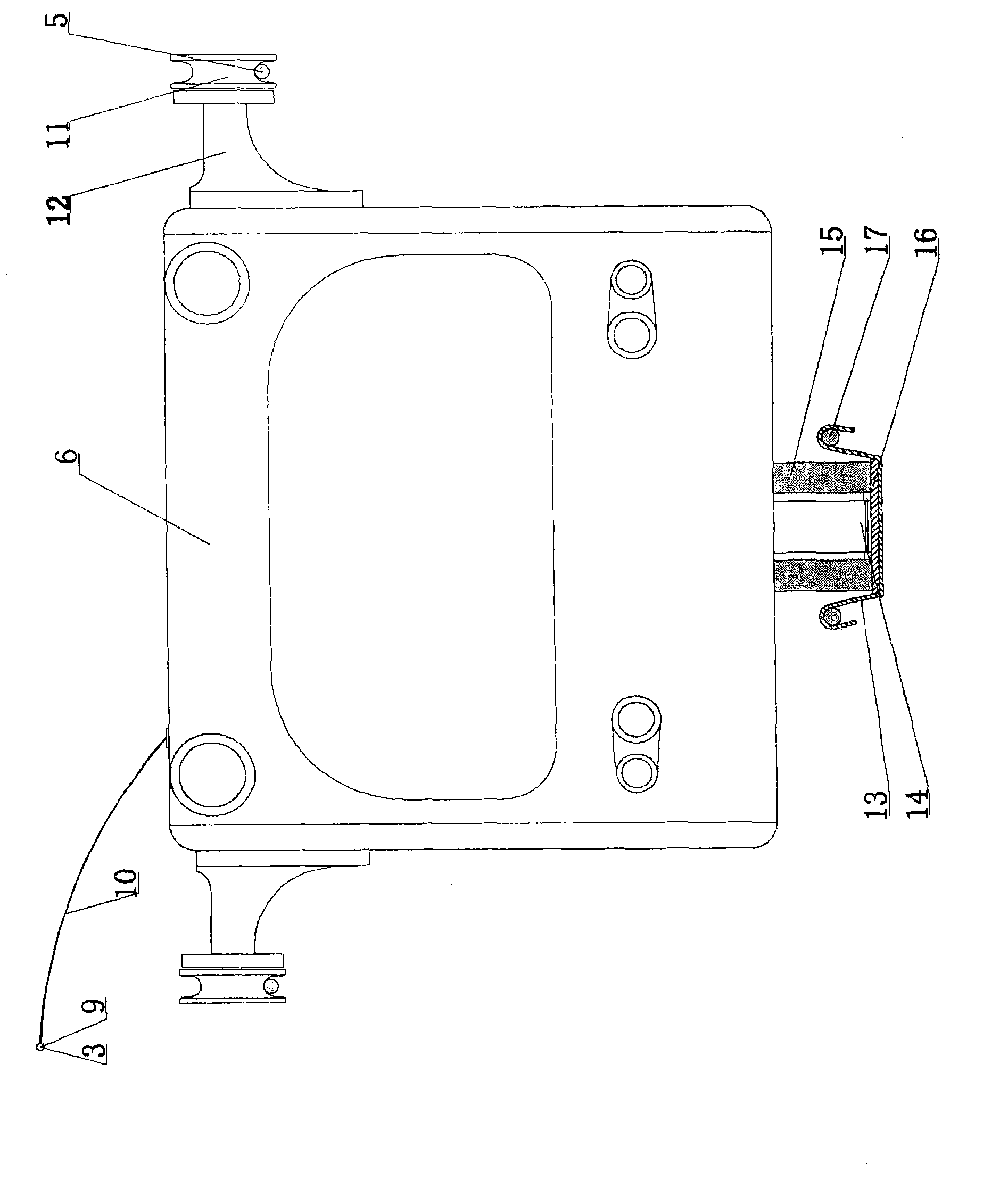

[0038] exist figure 1 In the middle, the track column 1 is erected, the main suspension cable 5 is installed on the rigid track 4, and the locomotive carriage 6 is suspended on the main load-bearing steel through the rear sheave arm 7, the front sheave arm 12, the rear sheave 8, and the front sheave 11. on the cable. The friction cable 3 is installed on the cable bracket 2, the external power supply passes through the friction cable 3, and the external power supply supplies power to the locomotive through the friction cable 3 and the carbon brush 9. At this time, the main load-bearing steel cable 5 acts as a conductor of the one-phase power supply and The friction cables 3 together form a power supply circuit. The gear teeth of the gear-shaped driving wheel 14 mesh with the rack 16 in the concave steel plate 13 , and the driving wheel limiting hub 15 ensures the meshing gap between the gear teeth of the gear-shaped driving wheel 14 and the rack 16 .

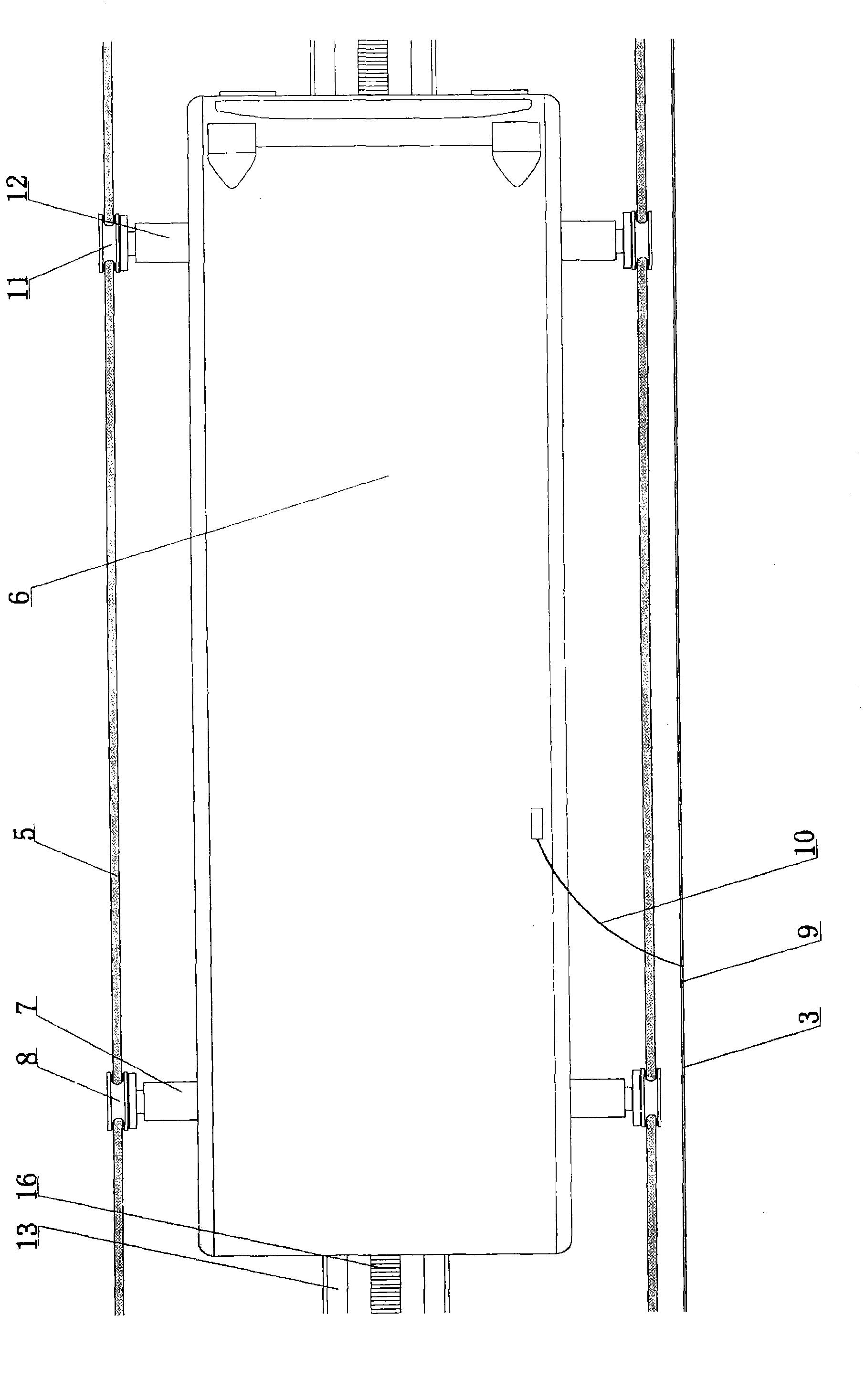

[0039] exist figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com