Dry-type composite-dielectric filter capacitor

A dielectric filter and dry composite technology, applied in feedthrough capacitors, multilayer capacitors, wire wound capacitors, etc., can solve the problem of reducing the service life of capacitors, and achieve the effect of ensuring safe use, high energy storage density, and low loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

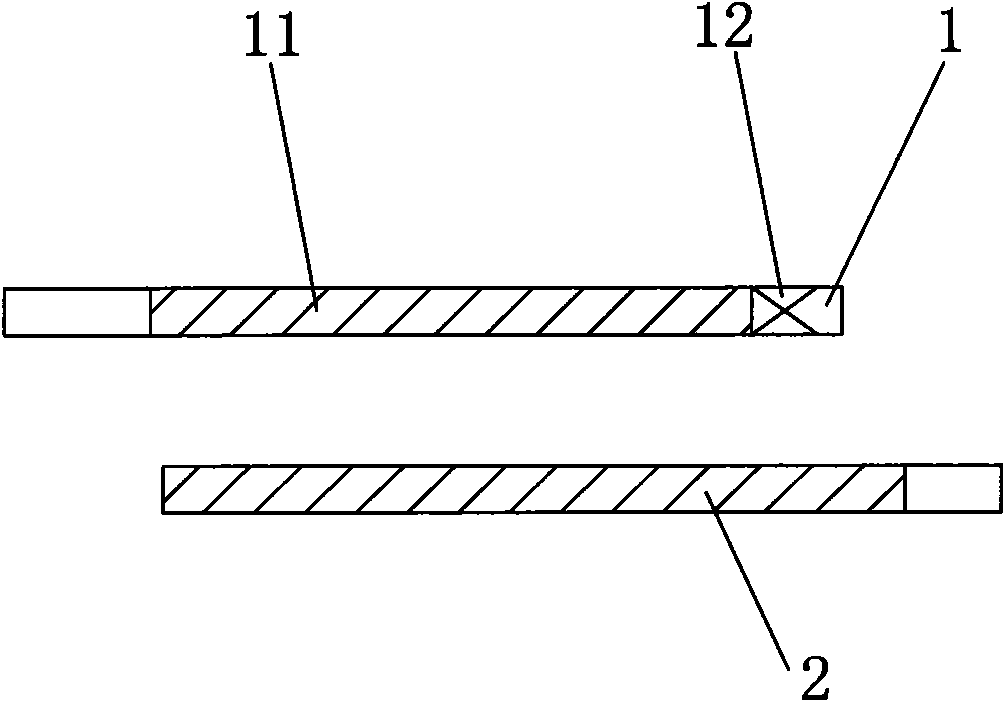

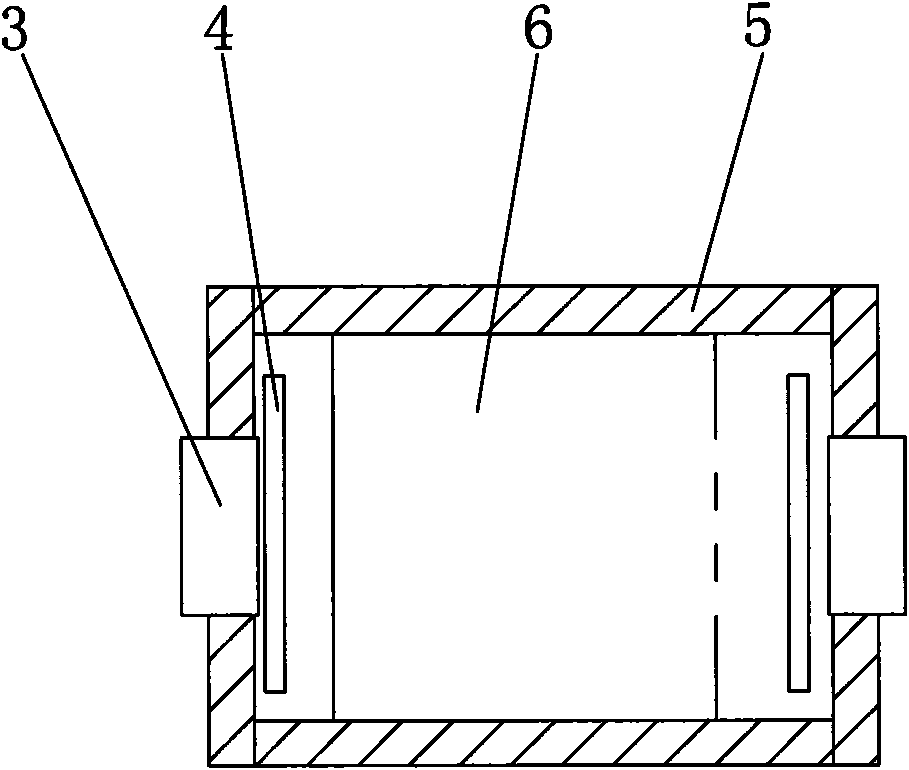

[0015] Such as figure 1 , figure 2 As shown, the dry-type composite dielectric filter capacitor of the present invention includes a capacitor core 6, pins 3 and a potting layer 5 coated on the outside of the capacitor core 6, and the capacitor core 6 is made of metal-plated The polypropylene film 1 and the metallized polyester film 2 are compounded and non-inductively wound. The metal layer is composed of an aluminum metal layer 11 and a zinc metal layer 12. The polypropylene film 1 and the zinc-aluminum composite layer are laminated with a single edge. The aluminum metal layer 11 is an electrode surface, and the zinc metal layer 12 is a reinforcing edge. The potting layer 5 is an epoxy resin cured layer.

[0016] After the capacitor core 6 is heat-set, one end surface of the metal layer of the polypropylene film 1 and one end surface of the metallized polyester film 2 are respectively sprayed with a gold-sprayed layer made of zinc, antimony, tin and copper. 4. It is conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com