Compositions, coatings and coating films for forming self-healing coatings

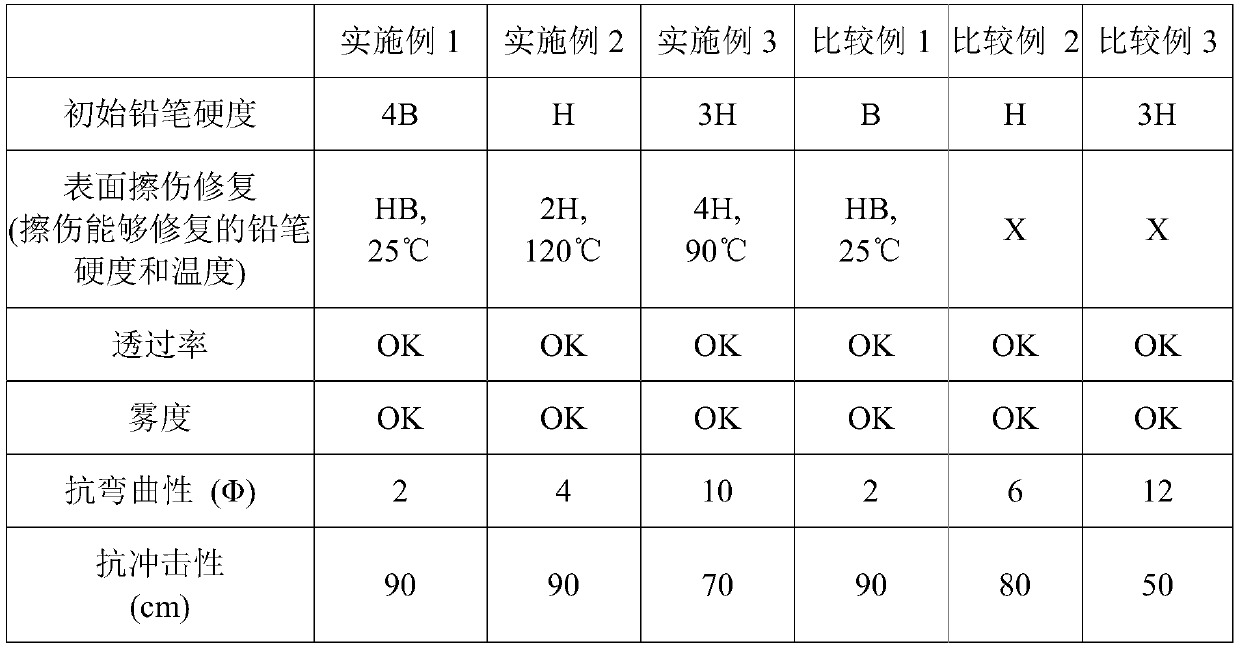

A composition and self-repairing technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the loss of self-repairing properties, coating mechanical properties such as hardness, wear resistance or insufficient coating strength, coating damage, etc. problems, achieve high hardness, ensure toughness, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0075] 25 g of methyl ethyl ketone and 59.23 g of urethane-based isocyanate Duranate E402-90T (Asahi Kasei) were mixed, and then stirred to make a homogeneous state. While stirring the homogeneous solution, 21.69 g of tert-butylaminoethyl methacrylate (TBAEMA) was added dropwise. After complete addition, the solution was stirred at room temperature for an additional 1 day, confirming the isocyanate peak in the IR spectrum (wavenumber ~ 2270 cm -1 )Disappeared.

preparation example 2

[0077] 25 g of methyl ethyl ketone and 48.45 g of hexamethylene diisocyanate / isophorone diisocyanate-based isocyanate Duranate MHG-80B (Asahi Kasei) were mixed, and stirred to make a homogeneous state. While stirring the homogeneous solution, 36.24 g of TBAEMA was added dropwise. After complete addition, the solution was stirred at room temperature for an additional 1 day, confirming the isocyanate peak in the IR spectrum (wavenumber ~ 2270 cm -1 )Disappeared.

preparation example 3

[0079] While stirring, 42.82 g of TBAEMA was added dropwise to 57.18 g of KBE-9007 (3-isocyanatopropyltriethoxysilane, Shin-Etsu). The solution was stirred at room temperature for an additional 1 day, and the isocyanate peak was confirmed in the IR spectrum (wavenumber ~ 2270 cm -1 )Disappeared. 1.48 g of the prepared solution was added to 98.52 g of a silica particle dispersion liquid IPA-ST (Nissan Chemical), and the solution was stirred for 3 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com