Explosion-proof heat-insulation TPU film for automobile glass, and preparation method thereof

A technology of automotive glass and absorbent, which is applied in the field of explosion-proof and heat-insulating TPU film and its preparation. It can solve the problems of unsatisfactory adhesion and peeling force, poor weather resistance, poor transparency, etc., and achieve excellent explosion-proof and scratch resistance. The characteristics and preparation method are scientific and reasonable, and are beneficial to the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

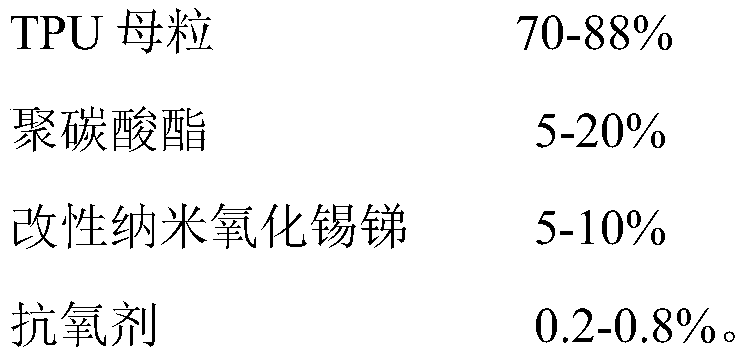

[0051] An explosion-proof and heat-insulating TPU film that can be used for automotive glass and a preparation method thereof, which is made of the following raw materials in mass percentages:

[0052]

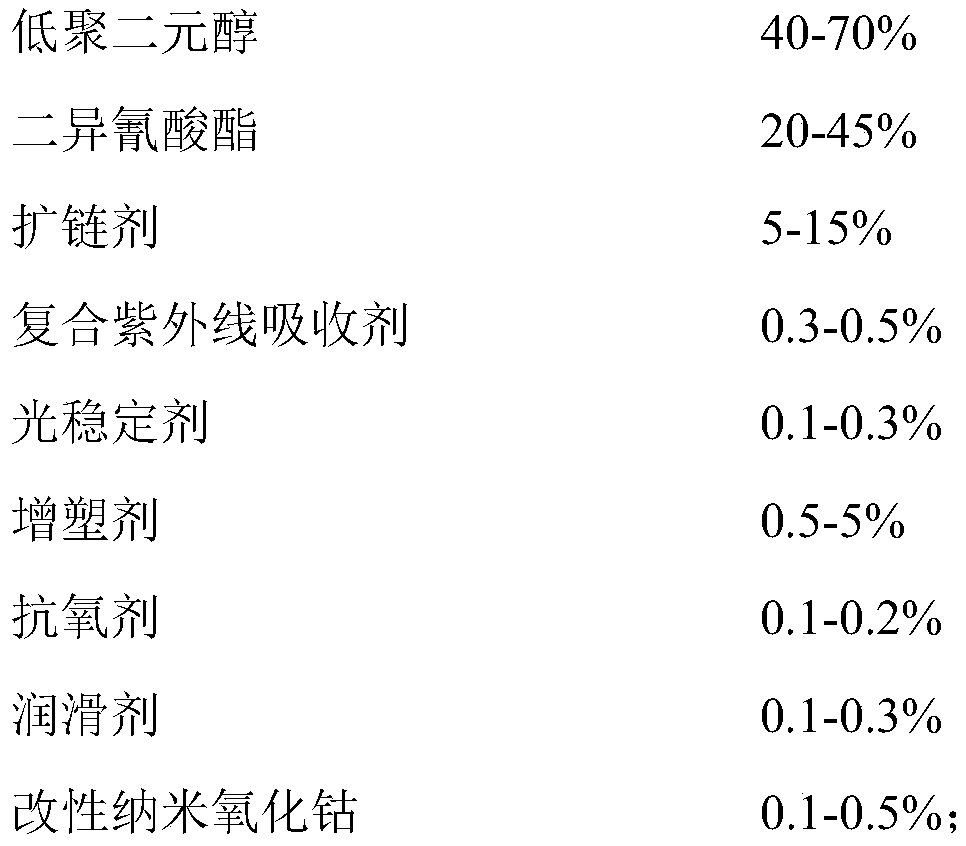

[0053] Among them, the TPU masterbatch is made of the following mass fraction raw materials plus 0.02% catalyst T-9:

[0054]

[0055] Wherein the reaction hard segment is 43%, the r value (NCO / OH molar ratio) is 0.995, and the preparation method is as follows:

[0056] (1) Add oligomeric glycol, ultraviolet absorber, light stabilizer, antioxidant, and plasticizer to reactor A, and control the material temperature at 110°C; add diisocyanate to reactor B, and The temperature is controlled at 75°C; the chain extender is added to the reactor C, and the temperature of the material is controlled at 75°C; then the materials in the three reactors A and B are injected into the small screw in proportion for prepolymerization, and the catalyst is passed through The metering pump is...

Embodiment 2

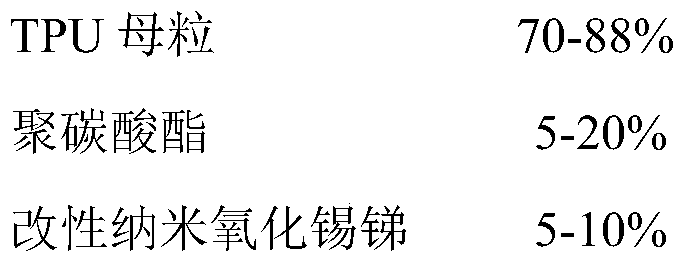

[0059] An explosion-proof and heat-insulating TPU film that can be used for automotive glass and a preparation method thereof, which is made of the following raw materials in mass percentages:

[0060]

[0061] Among them, the TPU masterbatch is made of the following mass fraction raw materials plus 0.02% catalyst T-9:

[0062]

[0063] Wherein the reaction hard segment is 43%, the r value (NCO / OH molar ratio) is 0.995, and the preparation method is the same as that of Example 1.

Embodiment 3

[0065] An explosion-proof and heat-insulating TPU film that can be used for automotive glass and a preparation method thereof, which is made of the following raw materials in mass percentages:

[0066]

[0067]

[0068] Among them, the TPU masterbatch is made of the following mass fraction raw materials plus 0.02% catalyst T-9:

[0069]

[0070] Wherein the reaction hard segment is 43%, the r value (NCO / OH molar ratio) is 0.995, and the preparation method is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com