Surface rare-earth film transforming agent and surface rare-earth film transformation processing method of aluminium alloy

A technology of aluminum alloy surface and conversion treatment, applied in the direction of metal material coating process, etc., can solve the problems of long process cycle unfavorable practical application, unfavorable engineering practical application, complicated solution formula, etc., and achieve the elimination of electrochemical deposition equipment, film formation The effect of high speed and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

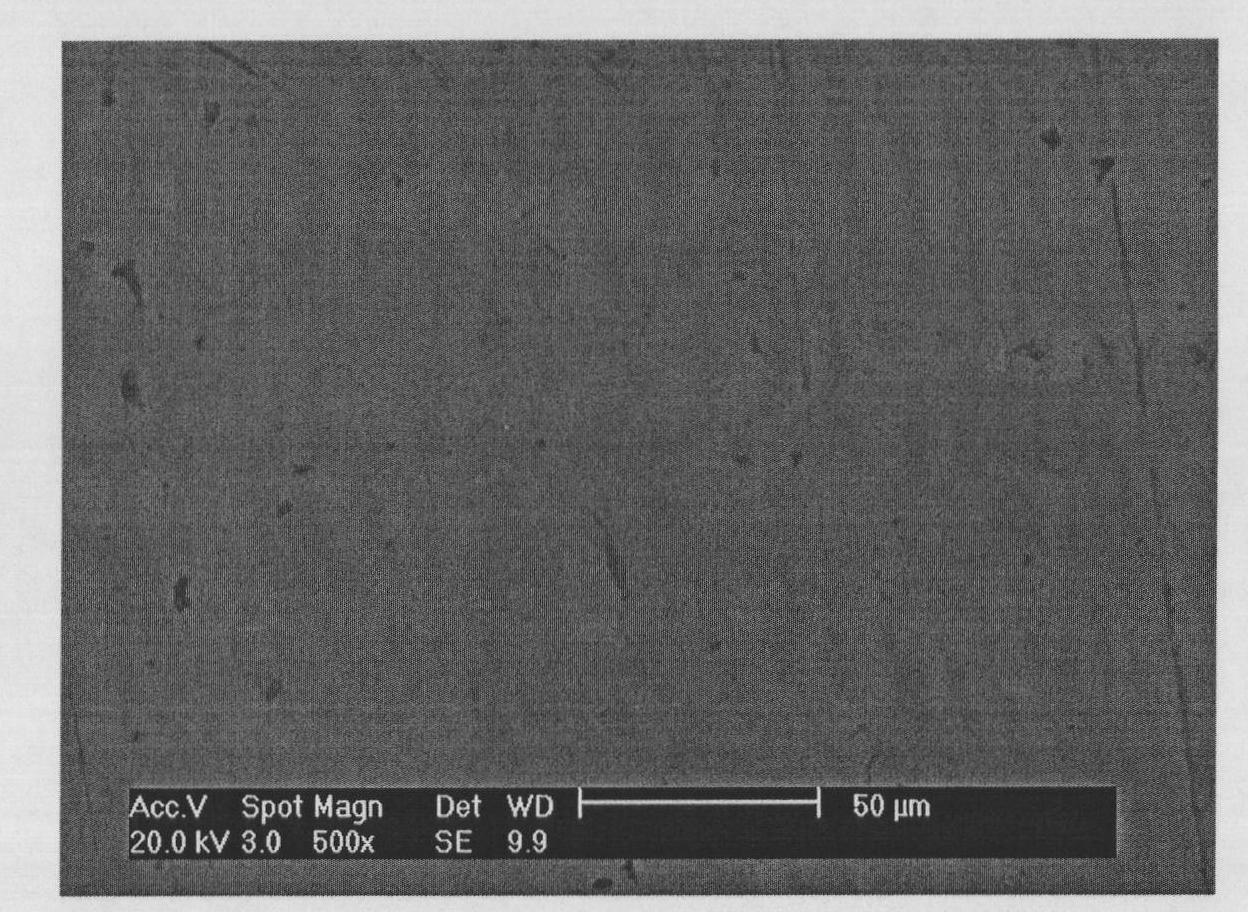

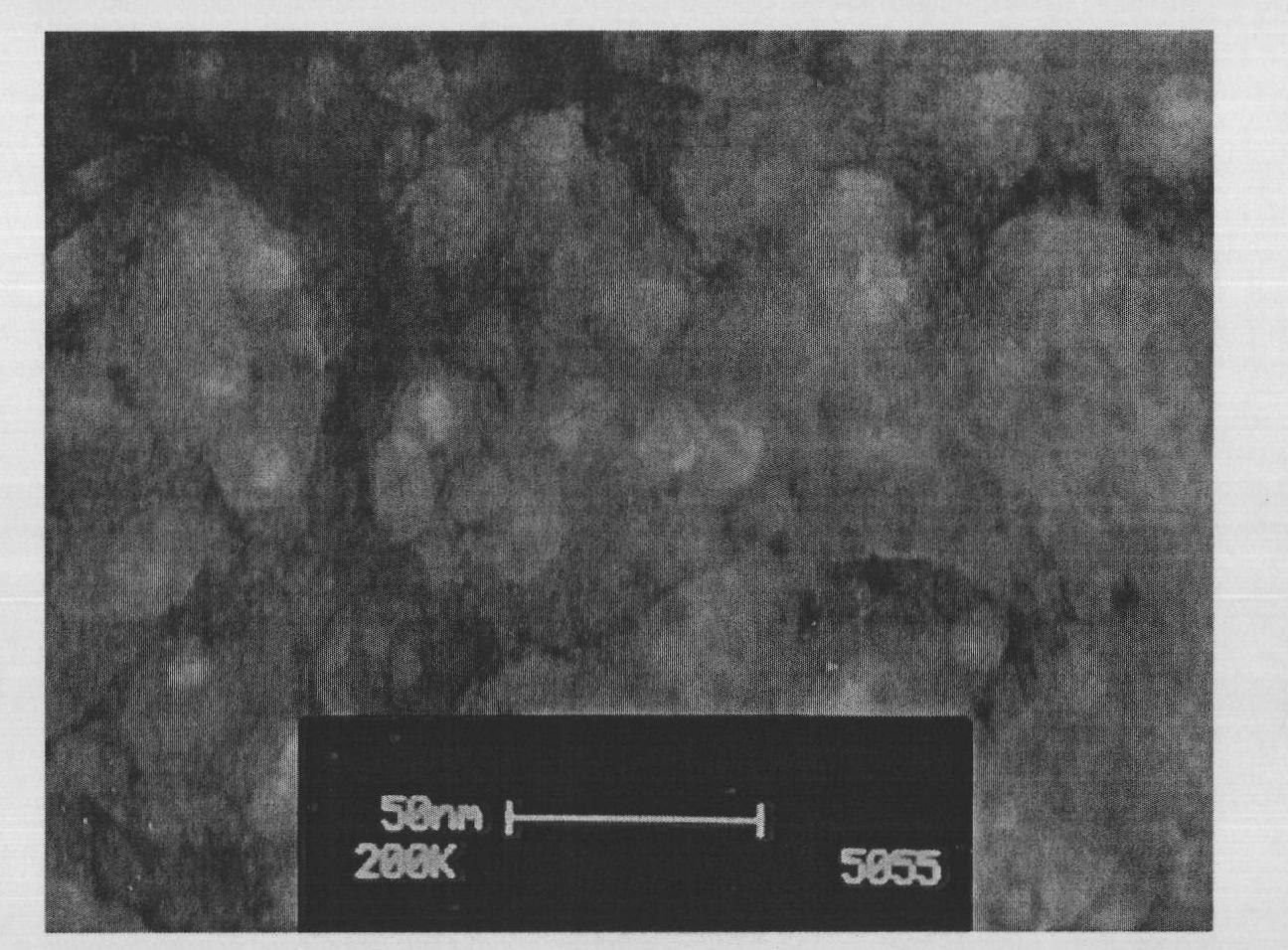

[0046] Surface Rare Earth Film Conversion Treatment on AA5083 Aluminum Alloy

[0047] (1) Mechanically polish and degrease the AA5083 aluminum alloy: mechanically polish the AA5083 aluminum alloy workpiece that needs surface treatment until the Ra is 0.075 μm and degrease, and then clean the surface;

[0048] (2) Alkaline cleaning: Soak in an alkaline cleaning solution at 50°C for 1 minute. The alkaline cleaning solution contains 30g / L of NaOH, 2.5g / L of NaCl, and 0.5ml / L of dodecane Sodium phenyl sulfonate surfactant;

[0049] (3) Washing: Wash the surface of the processed AA5083 aluminum alloy workpiece with clear water, and then dry it naturally;

[0050] (4) surface rare earth film conversion treatment: the dry AA5083 aluminum alloy is immersed in the surface rare earth film conversion agent for 3 hours, and the surface rare earth film conversion agent contains 1 (L): 4 (g): 10 (m L) ethanol solvent of proportioning, cerium nitrate hexahydrate and hydrogen peroxide three...

Embodiment 2

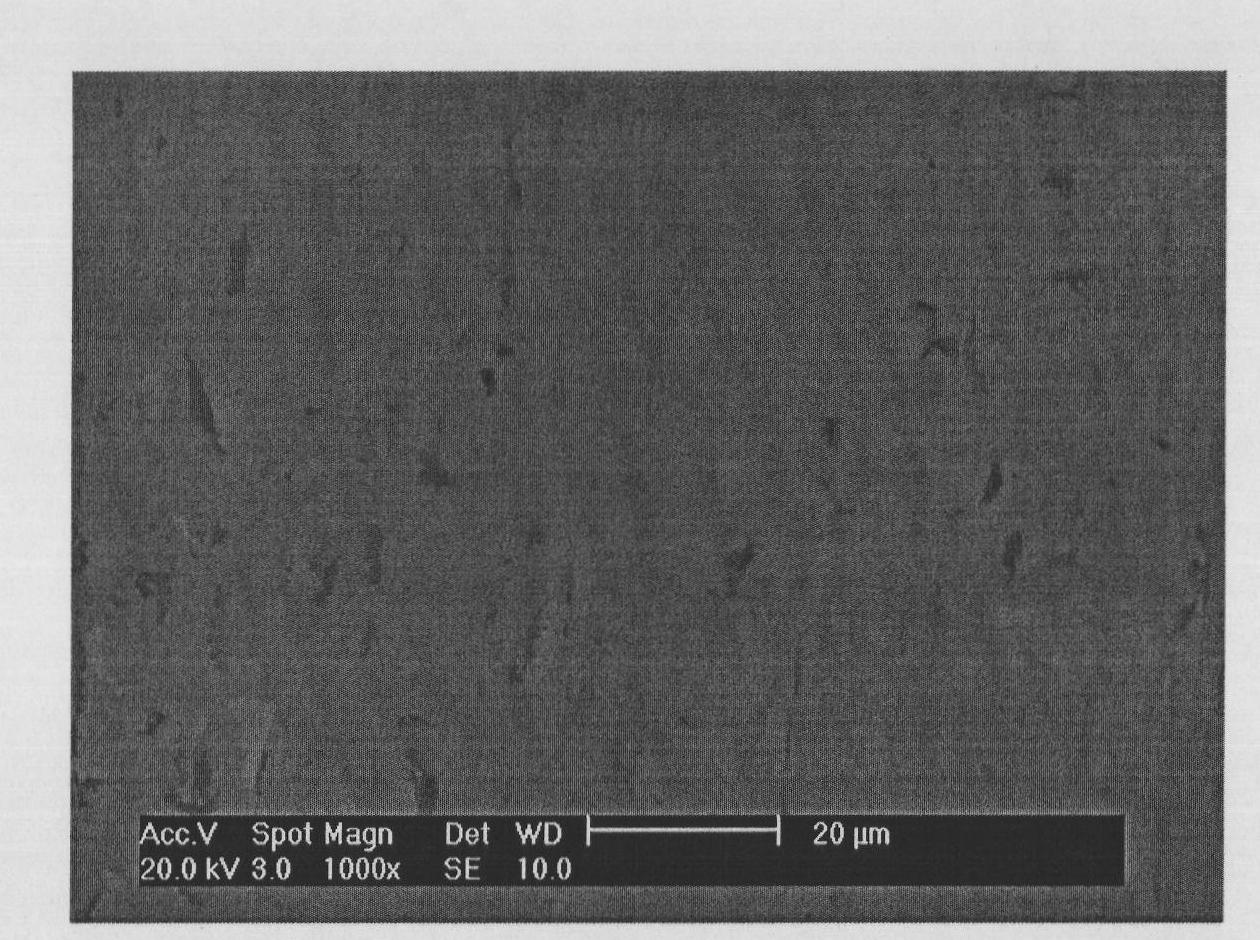

[0054] AA5083 Aluminum Alloy Surface Rare Earth Film Conversion Treatment

[0055] (1) Mechanically polish and degrease the AA5083 aluminum alloy: mechanically polish the AA5083 aluminum alloy workpiece that needs surface treatment to Ra0.025μm and degrease, and then clean the surface;

[0056] (2) Alkaline cleaning: Soak in an alkaline cleaning solution at 40°C for 1 minute. The alkaline cleaning solution contains 50g / L of NaOH, 0.5g / L of NaCl, 1ml / L of quaternary ammonium compounds and Betaine type mixed surfactant in volume ratio 1:1;

[0057] (3) Washing: the surface of the treated AA5083 aluminum alloy workpiece is cleaned with water, and then dried with a fan;

[0058] (4) surface rare earth film conversion treatment: the dry AA5083 aluminum alloy is immersed in the surface rare earth film conversion agent for 2 hours, and the surface rare earth film conversion agent contains 1 (L): 1 (g): 5 (mL ) ethanol solvent, cerium chloride and performic acid three components;

...

Embodiment 3

[0061] AA5083 Aluminum Alloy Surface Rare Earth Film Conversion Treatment

[0062] (1) Mechanically polish and degrease the AA5083 aluminum alloy: mechanically polish the AA5083 aluminum alloy workpiece that needs surface treatment until the Ra is 0.01 μm and degrease, and then clean the surface;

[0063] (2) Alkaline cleaning: Soak in an alkaline cleaning solution at 60°C for 5 minutes. The alkaline cleaning solution contains 10g / L NaOH, 5g / L NaCl, and 0.1ml / L polysorbate surface active agent;

[0064] (3) Washing: Wash the surface of the processed AA5083 aluminum alloy workpiece with clear water, and then dry it naturally;

[0065] (4) Surface rare earth film conversion treatment: the dry AA5083 aluminum alloy is immersed in the surface rare earth film conversion agent for 4 hours, and the surface rare earth film conversion agent contains 1 (L): 10 (g): 1 (m L) methanol alcohol solvent, cerium nitrate hexahydrate, hydrogen peroxide and methyl ethyl ketone peroxide mixed ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com