Method for preparing rubber-metal composite waterproof sheet

A rubber-metal composite, waterproof sheet technology, applied in metal layered products, chemical instruments and methods, flat products, etc. The effect of shaping, simplifying the production process, and improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

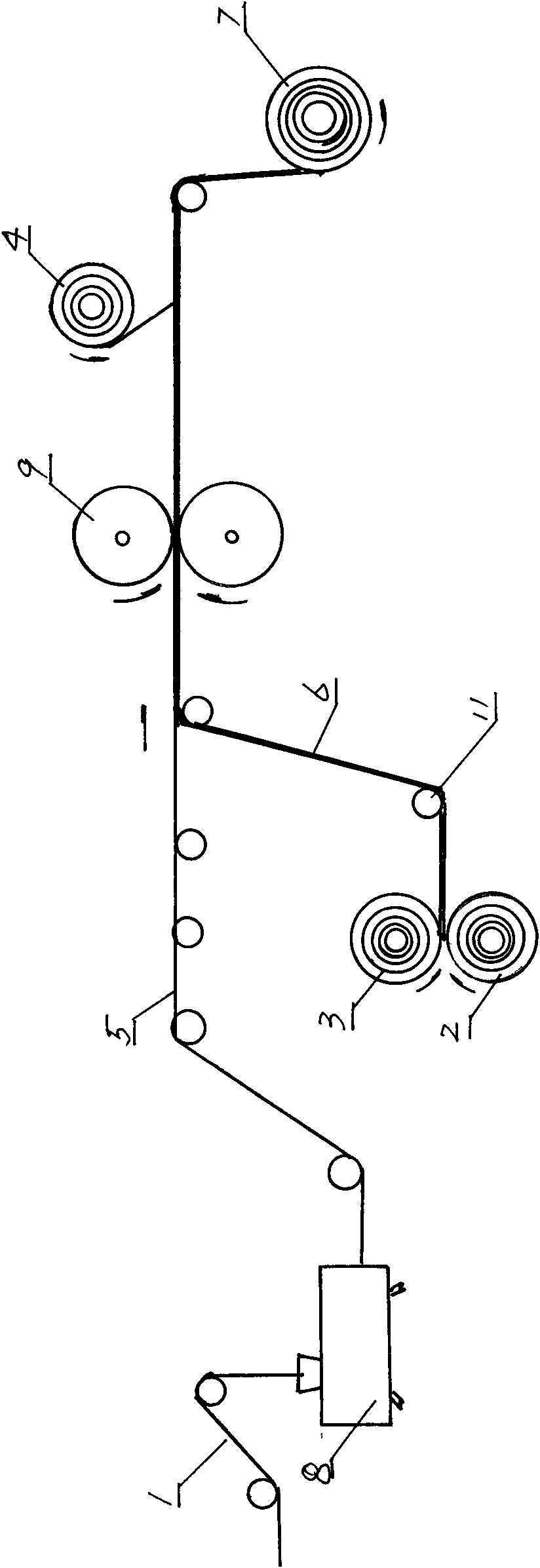

Image

Examples

Embodiment 1

[0038] Preparation of vulcanized rubber waterproof sheet

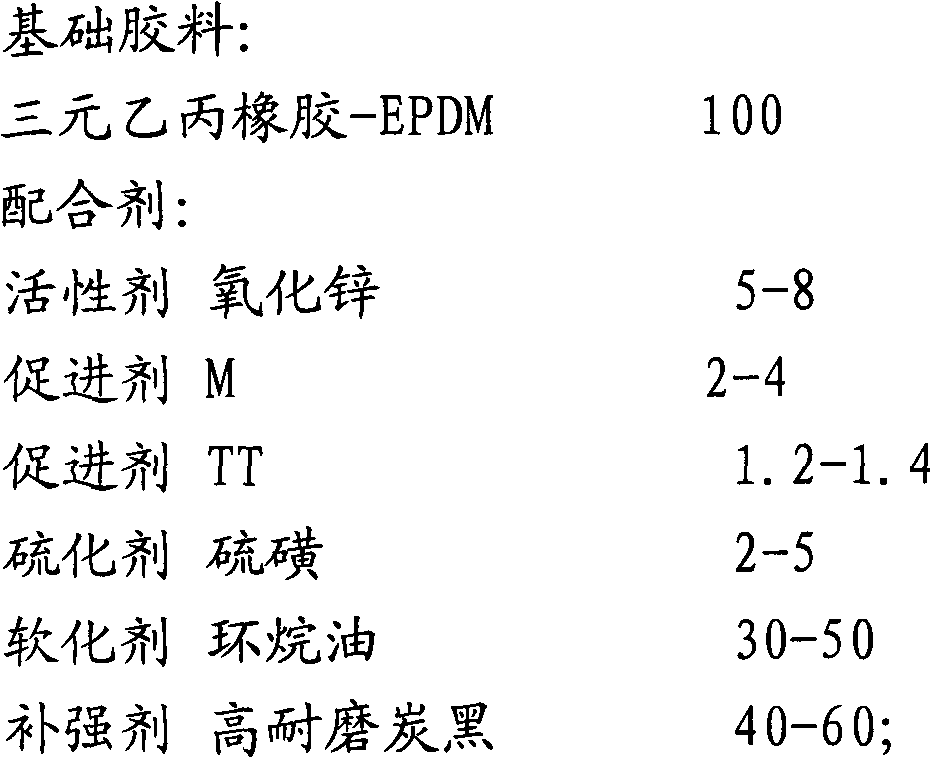

[0039] Each component is based on EPDM rubber, and is formulated according to the following weight ratio

[0040]

[0041]

[0042] Mix the EPDM rubber, zinc oxide, naphthenic oil, and high wear-resistant carbon black in the above ratio, and mix them with an internal mixer at 100-120°C. After about 15-20 minutes, discharge at a temperature of 80-90°C. , park and cool, filter the rubber, and add accelerator M and accelerator TT on the open rubber mixer at a temperature of 80-90 ° C, and mix evenly with sulfur. After parking for 24 hours, it becomes a mixed rubber.

[0043] Extrude the above compounded rubber from a cold-feed extruder, and vulcanize it through a continuous vulcanization box at a vulcanization temperature of 180°C and a vulcanization speed of 4m / min to form a vulcanized rubber sheet.

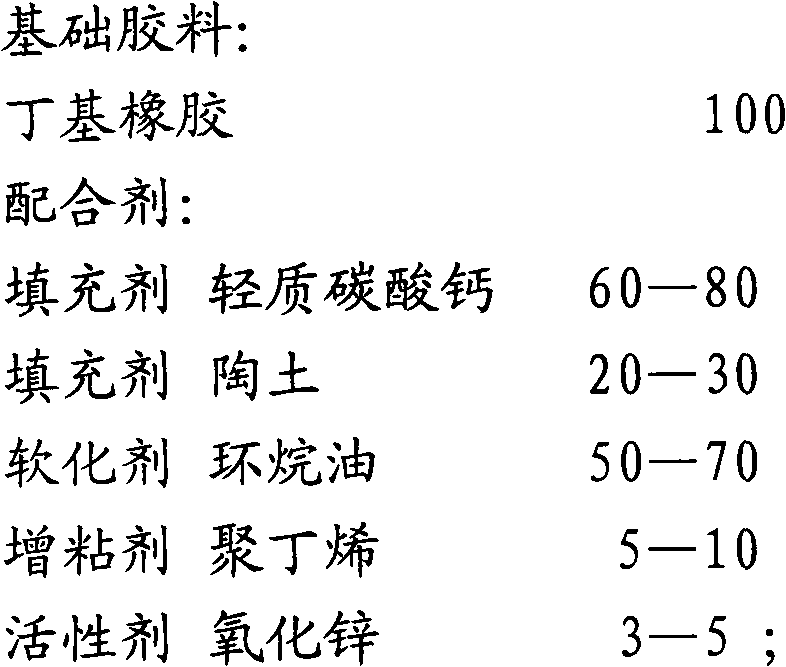

[0044] Preparation of unvulcanized rubber strips:

[0045] According to the following weight ratio ingredients

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com