Method for preparing rubber-metal composite waterproof sheet

A rubber-metal composite, waterproof sheet technology, applied in metal layered products, chemical instruments and methods, flat products, etc., can solve the problems of poor plasticity of waterproof sheets, difficult to fix and fit, affecting project quality, etc. The effect of shaping, ensuring reliability, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

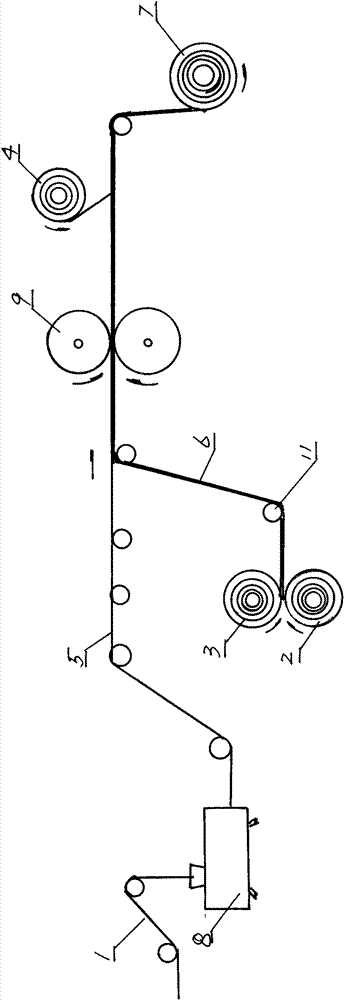

Image

Examples

Embodiment 1

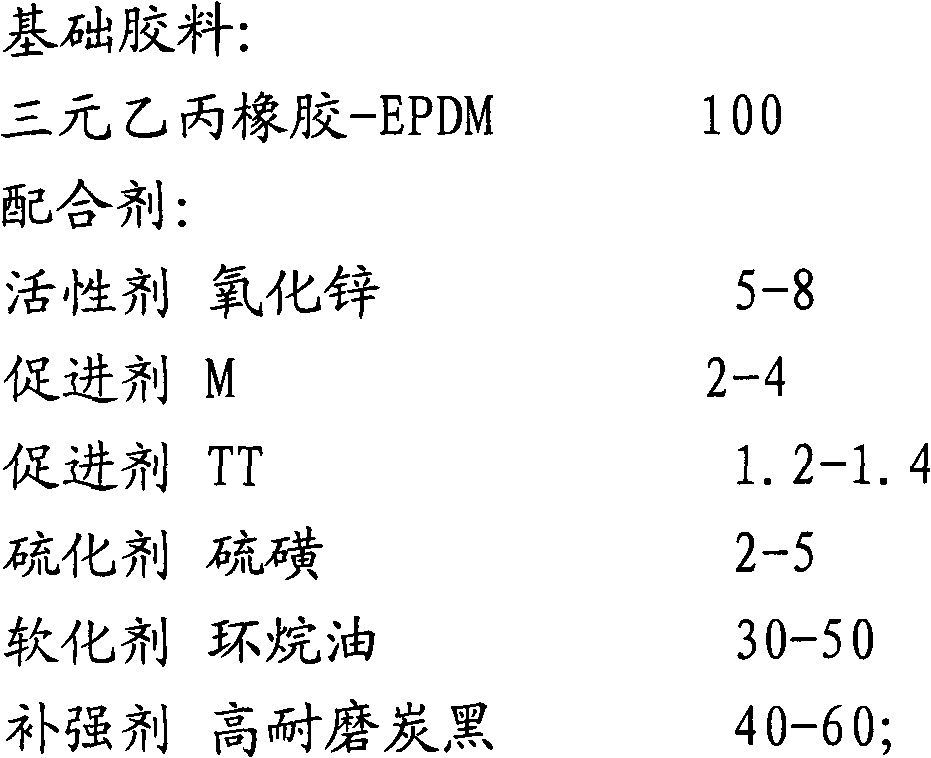

[0038] Preparation of vulcanized rubber waterproof sheet

[0039] Each component is based on EPDM rubber, and is formulated according to the following weight ratio

[0040]

[0041]

[0042] Mix the EPDM rubber, zinc oxide, naphthenic oil, and high wear-resistant carbon black in the above ratio, and mix them with an internal mixer at 100-120°C. After about 15-20 minutes, discharge at a temperature of 80-90°C. , park and cool, filter the rubber, and add accelerator M and accelerator TT on the open rubber mixer at a temperature of 80-90 ° C, and mix evenly with sulfur. After parking for 24 hours, it becomes a mixed rubber.

[0043] Extrude the above compounded rubber from a cold-feed extruder, and vulcanize it through a continuous vulcanization box at a vulcanization temperature of 180°C and a vulcanization speed of 4m / min to form a vulcanized rubber sheet.

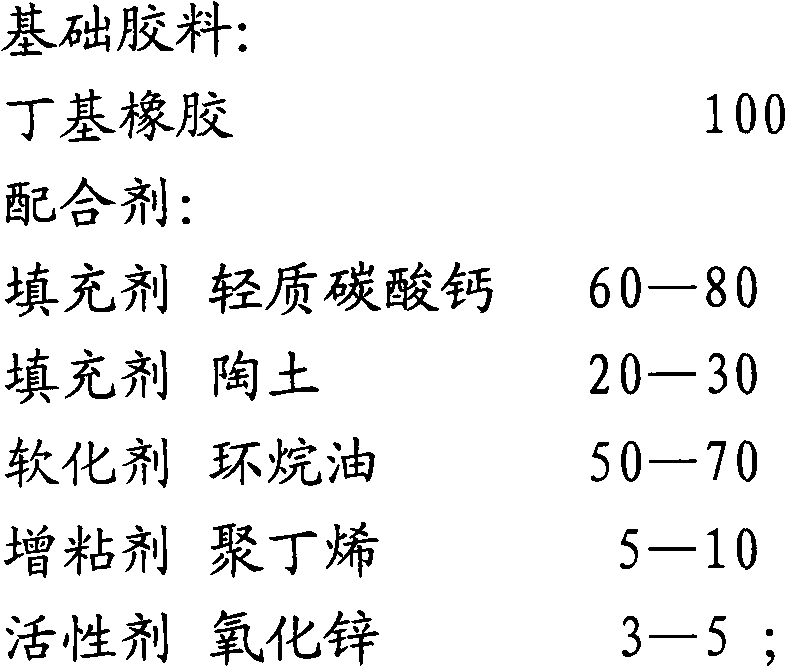

[0044] Preparation of unvulcanized rubber strips:

[0045] According to the following weight ratio ingredients

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com