High-output self-healing single-electrode friction nano generator and preparation method thereof

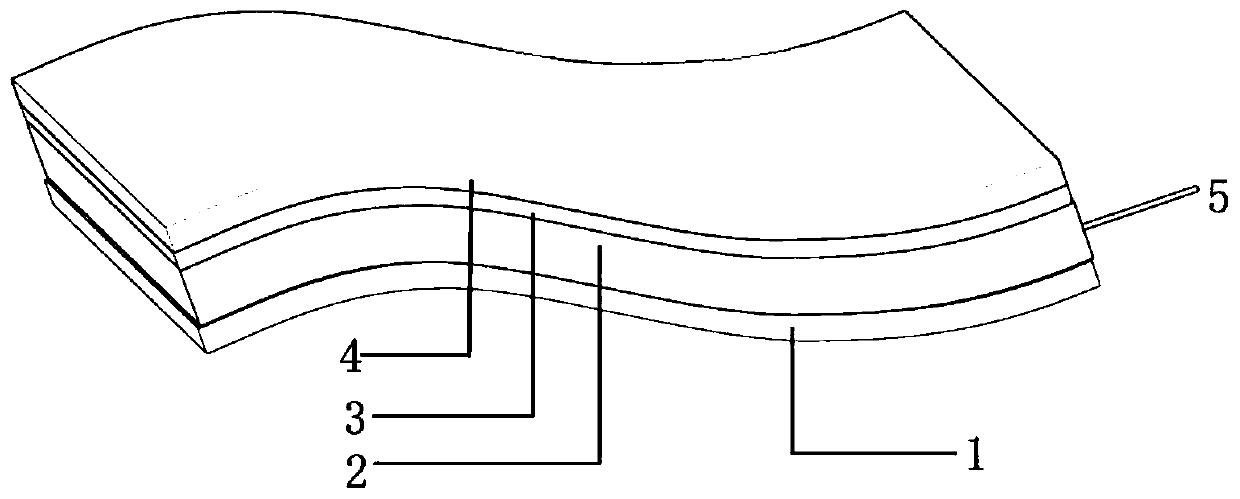

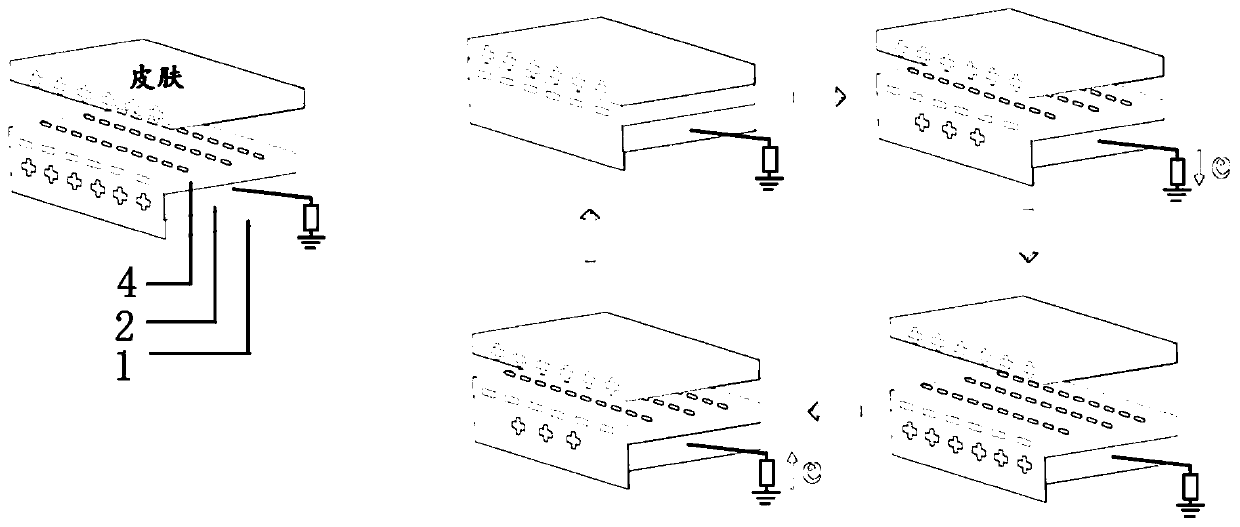

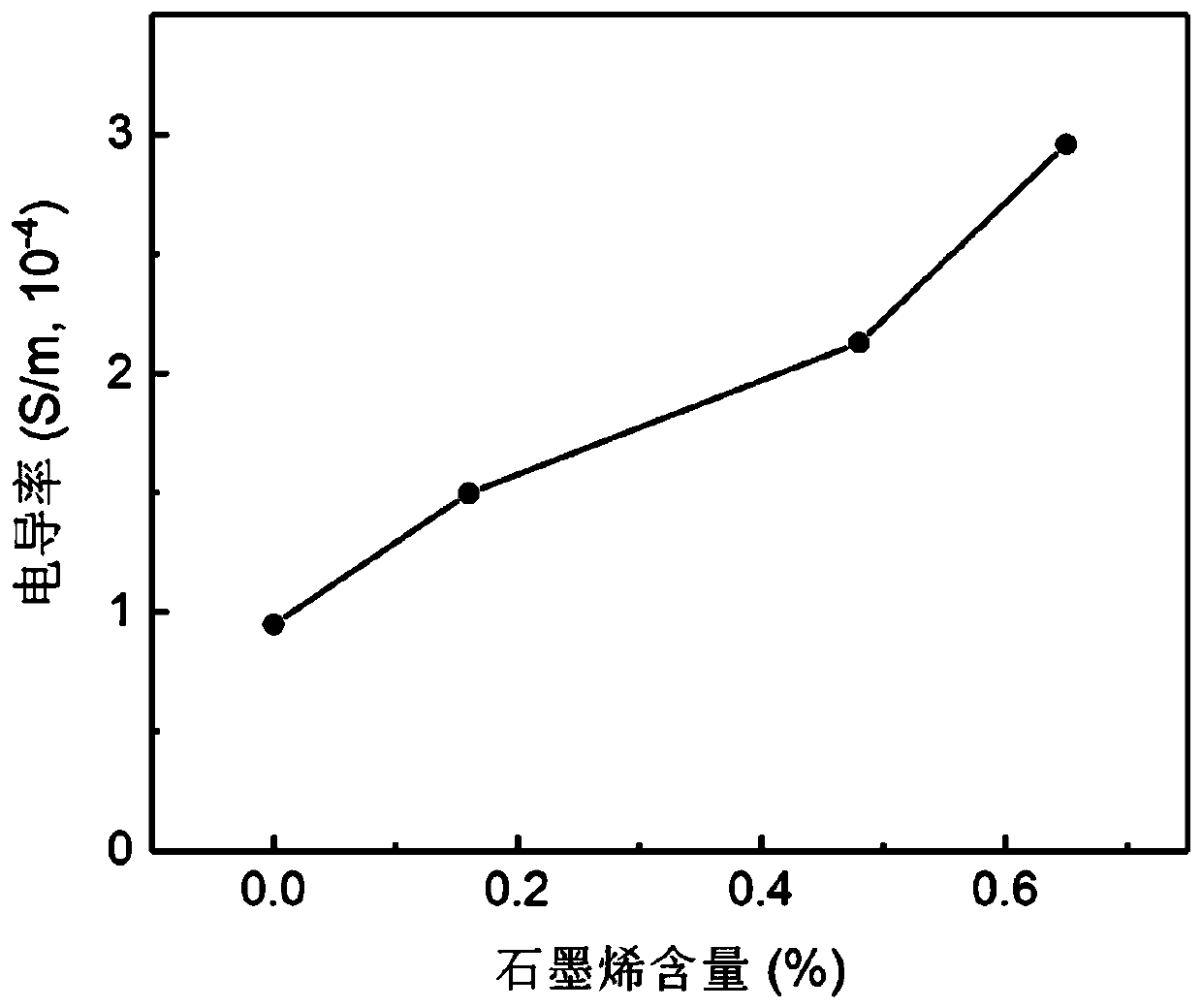

A nano-generator, high-output technology, applied in triboelectric generators and other directions, can solve problems such as not achieving good self-healing, and achieve the effects of improving mechanical stability and tensile properties, increasing dielectric constant, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A method for preparing a high-output self-healing single-electrode friction nanogenerator, the steps of the method are as follows:

[0064] (1) Preparation of triboelectric layer 4

[0065] ①Hydrophobic treatment of the glass sheet is convenient for subsequent spin-coating and film removal: take a petri dish, put the glass sheet, pour trimethylchlorosilane (TMCS), immerse the glass sheet, treat it in the fume hood for 15 minutes, and then use it separately Ionized water, ethanol, and dry with a hair dryer for later use.

[0066] ② Take PDMS prepolymer (Dow Corning 184 silicone rubber component A) and add it to chloroform, stir magnetically, dilute PDMS, add carbon nanotubes (CNTs) dispersion solution (carbon nanotubes concentration is 30mg / 250mL), at 75 ℃ , magnetically stirred for 2 hours, the solvent was evaporated, and the mixed solution was placed in an air-blast drying oven at 80°C for 1.5 hours to ensure that the solvent was completely evaporated. Then add PDMS ...

Embodiment 2

[0075] A method for preparing a high-output self-healing single-electrode friction nanogenerator, the steps of the method are as follows:

[0076] (1) Preparation of triboelectric layer 4

[0077] ① Hydrophobic treatment is performed on the glass sheet to facilitate subsequent spin-coating and film removal: take a petri dish, put the glass sheet, pour TMCS, immerse the glass sheet, and treat it in a fume hood for 15 minutes, then wash it with deionized water and absolute ethanol respectively , and dry with a hair dryer for later use.

[0078] ② Take the PDMS prepolymer (Dow Corning 184 silicone rubber component A) and add it to chloroform, stir magnetically, dilute PDMS, add carbon nanotubes (CNTs) predispersion solution (the concentration of carbon nanotubes is 30mg / 250mL), at 70℃ Stir for 3 hours under magnetic force to evaporate the solvent, and put the mixed solution in a blast drying oven at 85° C. for 1 hour to ensure that the solvent is completely evaporated. Then add...

Embodiment 3

[0087] A method for preparing a high-output self-healing single-electrode triboelectric nanogenerator is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Spin coating thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com