Crosslinked polyurea elastomer with self-repairing property and preparation method thereof

A technology of cross-linked polyurea and self-repair, which is applied in the field of self-repair materials, can solve problems such as the inability to realize coating repair and the limitation of reprocessing performance of polyurea elastomers, and achieve self-repair reprocessing performance, excellent mechanical properties, To achieve the effect of destruction and reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

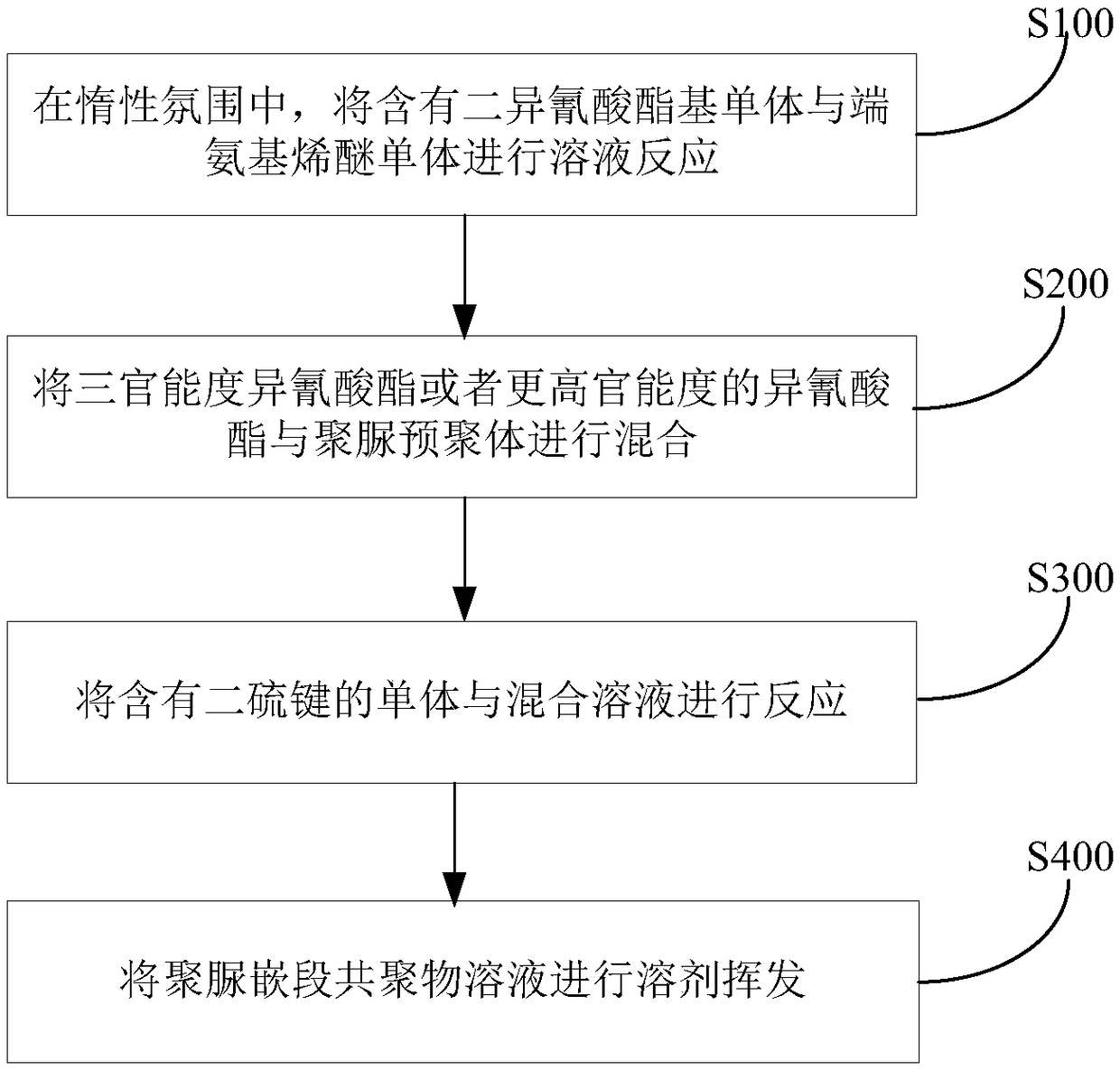

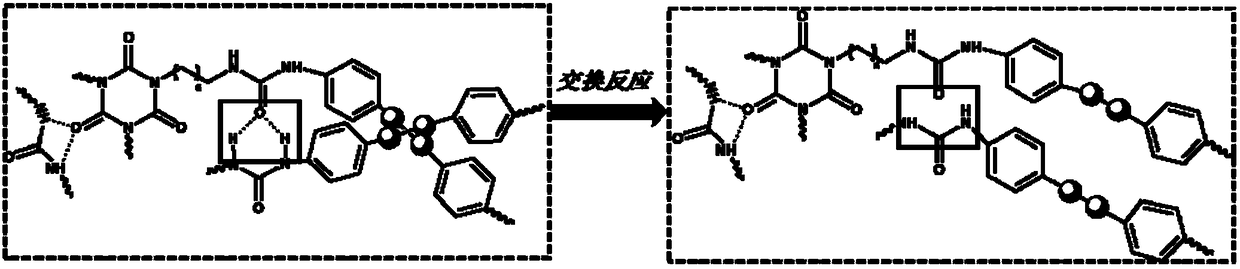

[0040] The method for preparing a cross-linked polyurea elastomer with self-healing properties according to an embodiment of the present invention uses a trifunctional isocyanate or a higher-functional isocyanate as a cross-linking agent to connect a monomer containing a disulfide bond to a multifunctional polyurea elastomer. On the isocyanate, the dynamic cross-linking point of the polyurea system is constructed in a novel form, and a cross-linked polyurea elastomer containing disulfide bonds and hydrogen bonds is prepared, and the resulting cross-linked polyurea elastomer containing disulfide bonds and hydrogen bonds The disulfide bonds in the body can realize rapid dynamic exchange reaction at a certain temperature, so as to realize the destruction and reorganization of dynamic cross-linking points. At the same time, the hydrogen bonds in the system can also be dissociated and rebuilt under the action of temperature, promoting the whole new The reconstruction of the polyurea...

Embodiment 1

[0044] (1) Take 0.84g (5.0mmol) of 1,6-hexamethylene diisocyanate and dissolve it in tetrahydrofuran solvent, pour it into a flask, and then take 5.00g (2.50mmol) of amino-terminated polyoxypropylene ether monomer and dissolve it in In tetrahydrofuran solvent, slowly drop into the flask, under the stirring of 300rpm at room temperature, pass through nitrogen to react for 1h, and carry out solution reaction to obtain polyurea prepolymer terminated by isocyanate group;

[0045] (2) Take 0.96g (1.67mmol) of 1,6-hexamethylene diisocyanate trimer and dissolve it in tetrahydrofuran solvent, then add it to the polyurea prepolymer solution obtained above, and mix well;

[0046] (3) Dissolve 1.24g (5.00mmol) of 4,4'-diaminodiphenyl disulfide in a tetrahydrofuran solvent, add it to the above mixed solution, and react for 0.5h to obtain a polyurea elastomer solution;

[0047] (4) Pour the above-mentioned product solution into a polytetrafluoroethylene mold, put it into a vacuum oven at 8...

Embodiment 2

[0049] (1) Dissolve 1.39g (5.00mmol) of 4,4'-diphenylmethane diisocyanate in tetrahydrofuran solvent, pour it into a flask, and then take 5.03g (2.50mmol) of amino-terminated polyoxypropylene ether monomer to dissolve In tetrahydrofuran solvent, slowly drop into the flask, under stirring at 300rpm at room temperature, pass through nitrogen to react for 1h, and perform solution reaction to obtain isocyanate group-terminated polyurea prepolymer;

[0050] (2) Take 0.96g (1.67mmol) of 1,6-hexamethylene diisocyanate trimer and dissolve it in tetrahydrofuran solvent, then add it to the polyurea prepolymer solution obtained above, and mix well;

[0051] (3) Dissolve 1.24g (5.0mmol) of 2,2'-diaminodiphenyl disulfide in tetrahydrofuran solvent, add it to the above mixed solution, and react for 0.5h to obtain a polyurea elastomer solution;

[0052] (4) Pour the above-mentioned product solution into a polytetrafluoroethylene mold, put it into a vacuum oven at 85°C for solvent volatilizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com