Patents

Literature

46results about How to "Rapid curing molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photocured organosilicone elastomer and preparation method and application thereof

InactiveCN106317898AEffective adjustment of mechanical propertiesImprove mechanical propertiesAdditive manufacturing apparatusSemiconductor/solid-state device detailsCross-linkElastomer

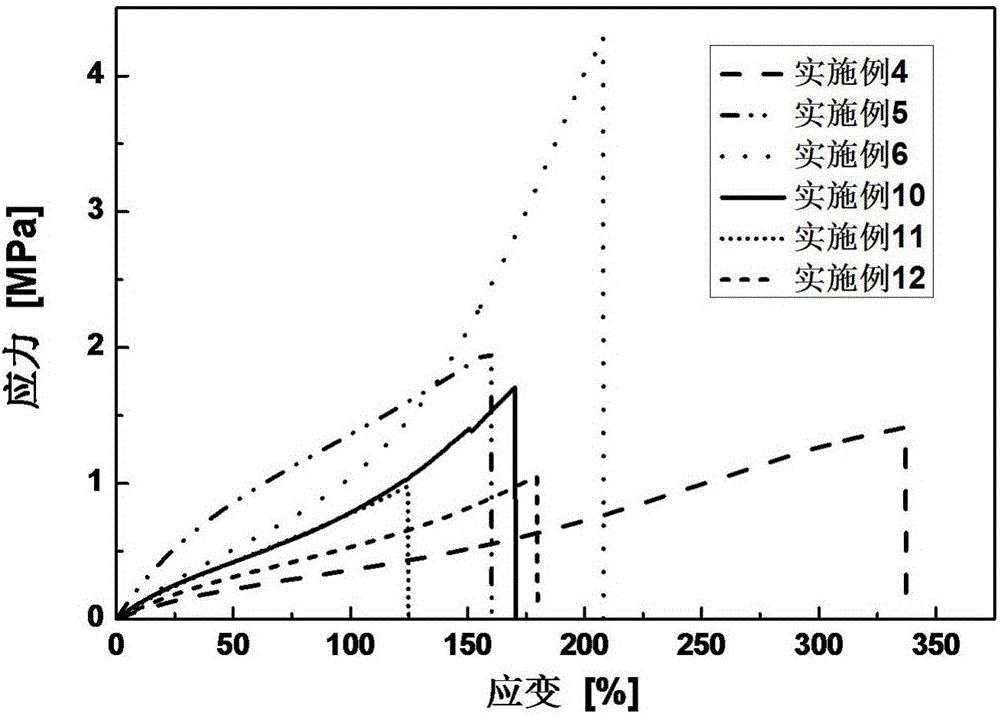

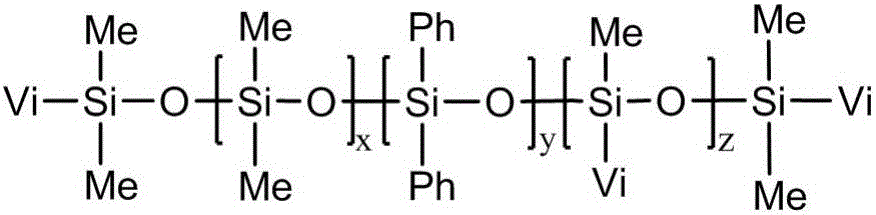

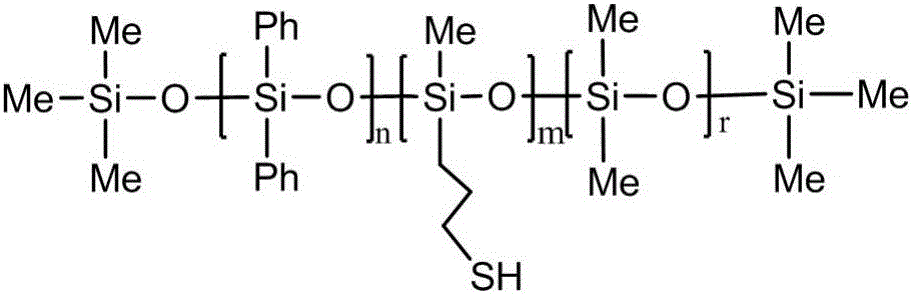

The invention discloses a photocured organosilicone elastomer and a preparation method thereof. The photocured organosilicone elastomer is prepared from, by weight, 50-80 parts of vinyl methyl phenyl polysiloxane, 10-30 parts of mercaptopropyl methyl phenyl polysiloxane, 5-20 parts of mercaptopropyl silicon resin, 0-3 parts of photoinitiator and 0.1-1 part of auxiliary. Vinyl methyl phenyl polysiloxane, mercaptopropyl methyl phenyl polysiloxane, mercaptopropyl silicon resin and the photoinitiator are used as raw materials and mixed and stirred to be uniform, and the photocured organosilicone elastomer is prepared. By adjusting the quantity ratio of methyl segmers and phenyl segmers in polysiloxane and introducing mercaptopropyl silicon resin to serve as a macromolecular cross-linking agent, photocured organosilicone elastomers different in toughness, mechanical strength and refractive index can be prepared, and rapid curing molding is realized within 5-20 s under ultraviolet illumination; the process is simple, efficient and environmentally friendly and saves energy; the photocured organosilicone elastomer can be applied to the fields of electronic packaging materials, optical materials, 3D printing materials and the like.

Owner:GUANGDONG UNIV OF TECH

High adjacent position phenolic resin for toughness reinforcing of elastic body and method for producing the same

The invention discloses high ortho position formaldehyde phenol resin with elastic toughened, wherein, the elastic body reaches nm-level decentralization in the formaldehyde phenol resin, the content of the elastic body is 3 to 10 percent, and the ortho-para-ratio of the resin is 2.5 to 5. The invention also provides a preparation method of the formaldehyde phenol resin. The invention is characterized in that the high ortho position formaldehyde phenol resin with elastic toughened is prepared by adopting the way of in situ polymerization. Compared with the prior art, the high ortho position formaldehyde phenol resin with elastic toughened of the invention has the advantages of good fluidity, rapid curing and shaping, excellent toughness, simple preparation method, easy practice, etc.

Owner:ZHEJIANG JIAMIN PLASTIC

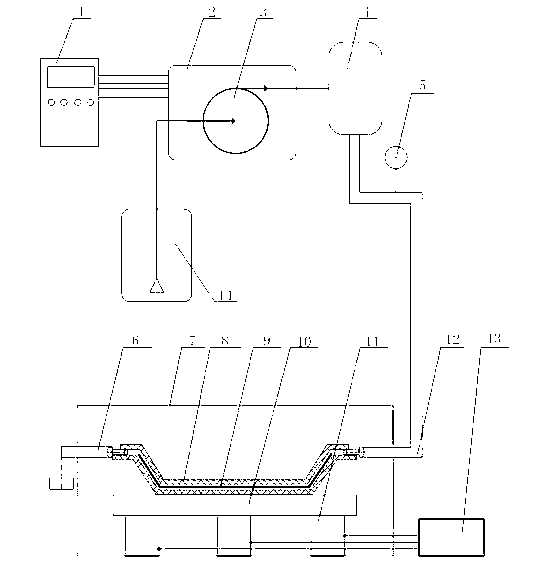

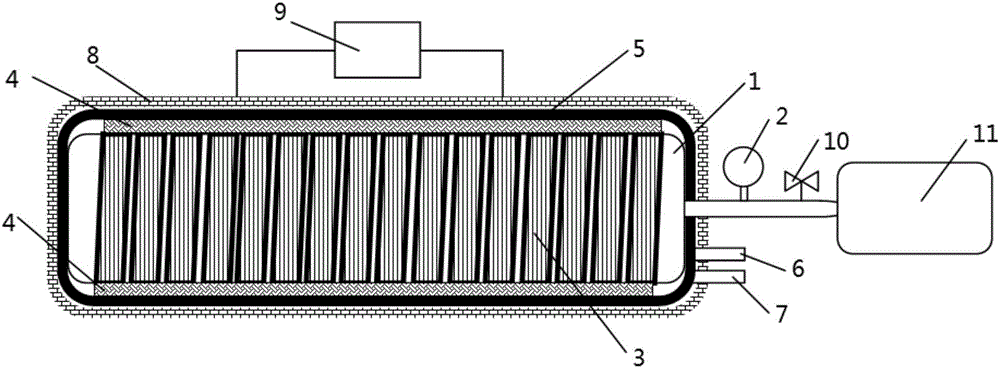

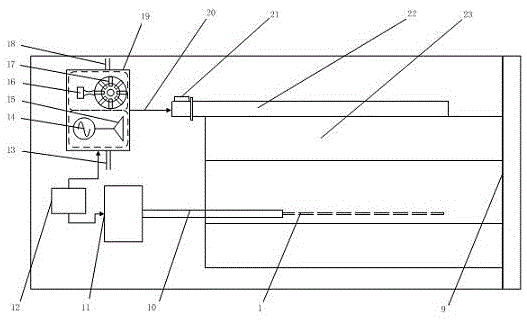

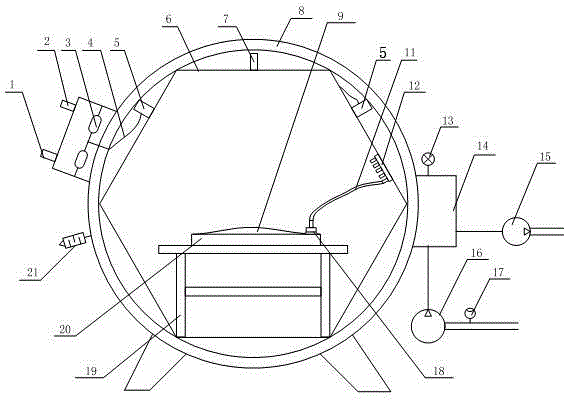

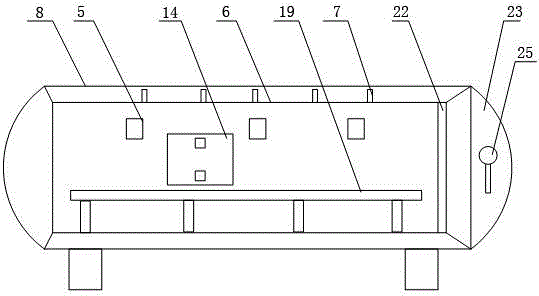

Method for adopting microwave ultrasound solidification fibre reinforced composite component and special device thereof

ActiveCN102990946ASmall internal stressSmall overall deformationMicrowave cavityFiber-reinforced composite

The invention discloses a method for adopting a microwave ultrasound solidification fibre reinforced composite component and a special device thereof. The method comprises the following steps of: firstly placing a prefabricated part in a filling module, wherein the filling module simultaneously uses ultrasonic wave to accelerate a resin to permeate and increase the wettability; and using a microwave heating module after finishing until resin is full solidified. The special device is used for installing a mould in a microwave cavity, the microwave cavity is externally connected with a microwave generator, and the microwave cavity is internally provided with an ultrasonic transducer and is externally connected with an ultrasonic generator. The method and the special device provided by the invention solve the problems that when a fibre reinforced composite material is manufactured by using the traditional composite material forming method, the manufacturing time is long, the energy consumption is high, the fiber soakage is not full and a local region is not filled by a module, and the quality and performance of composite material parts are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

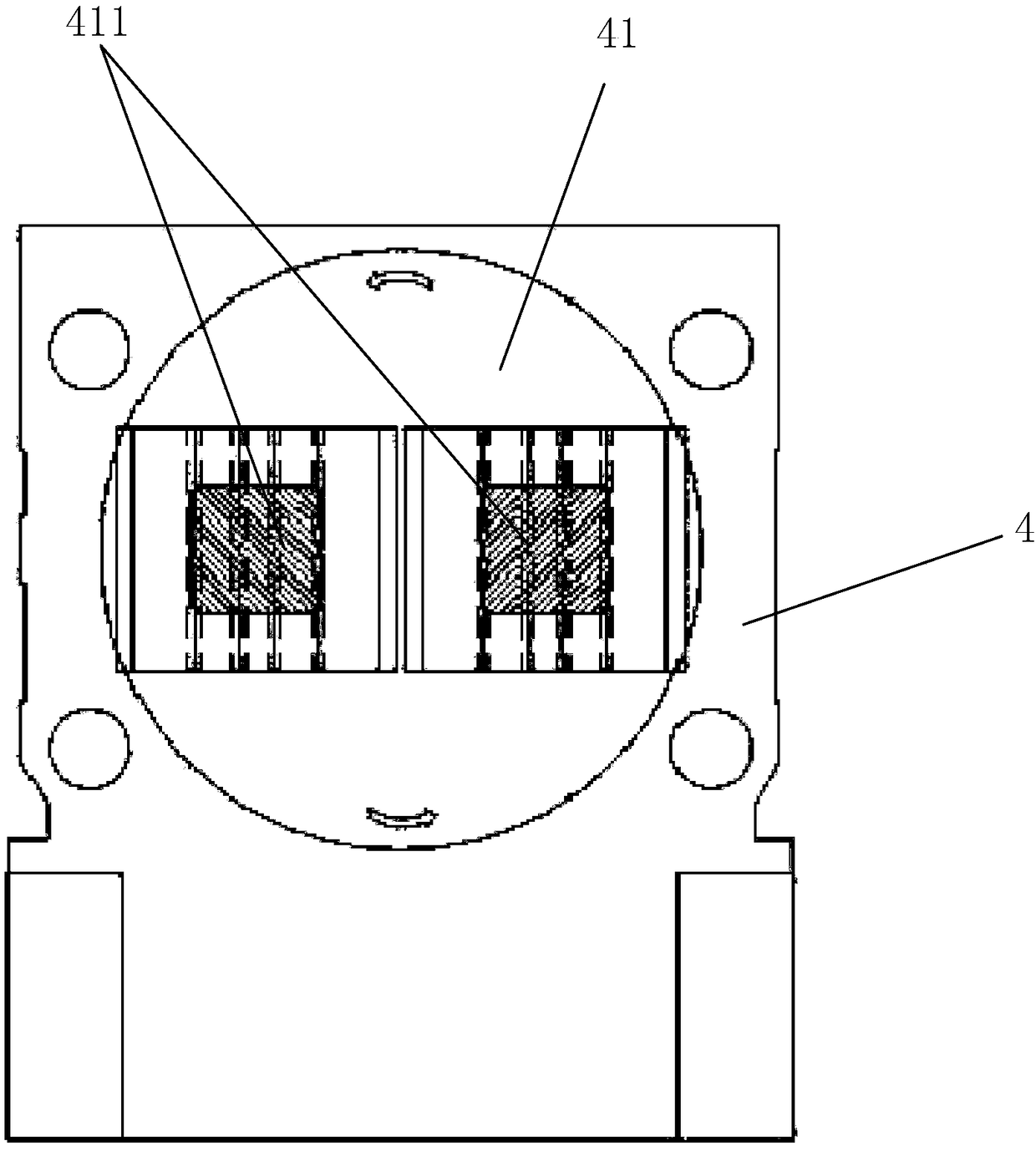

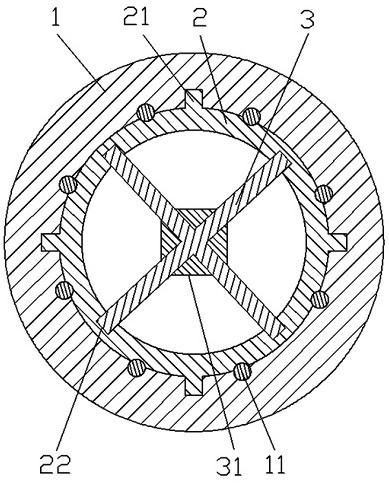

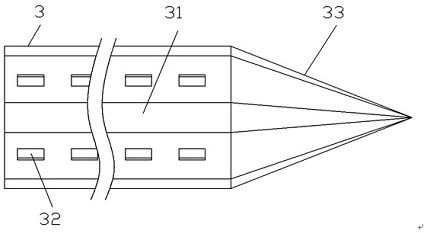

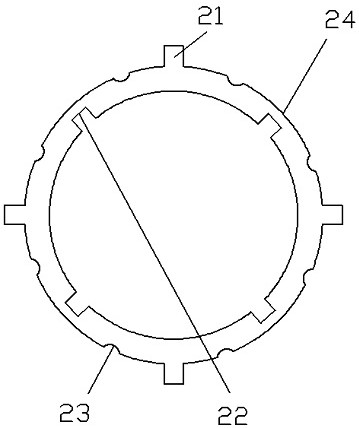

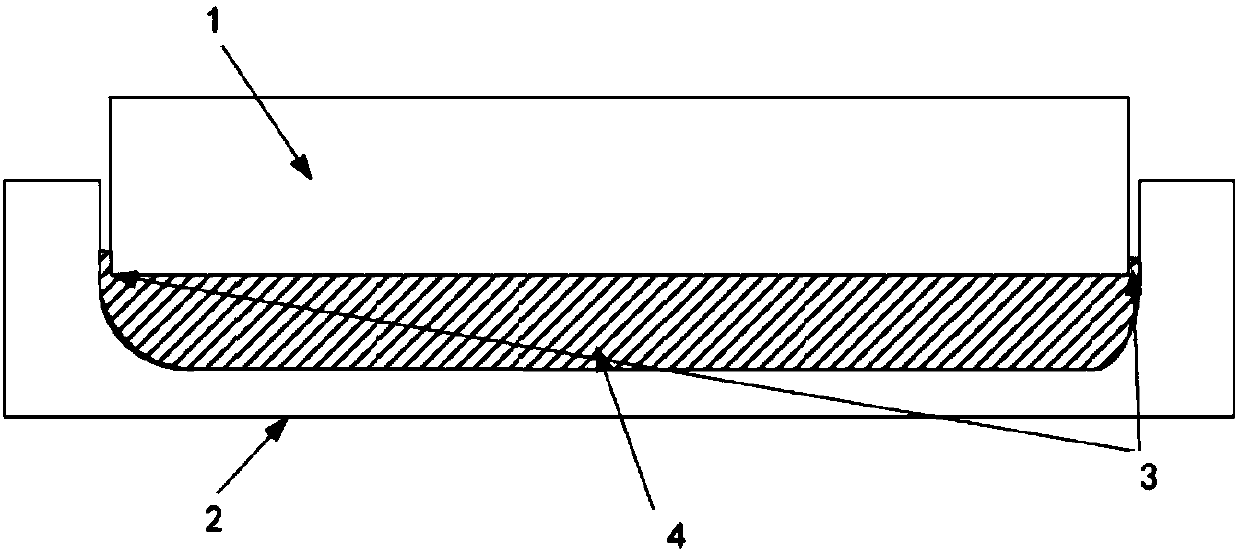

Forming device and forming method for tubular three-dimensional braided composite product

The invention relates to a forming device and a forming method for a tubular three-dimensional braided composite product. The forming device comprises a flexible core mold, an inward-contracting demolding device, a flexible RTM outer mold, a mold curing device and a medium circulation device, wherein the inward-contracting demolding device is arranged between the flexible RTM outer mold and the flexible core mold; the flexible curing device is arranged on the outer side of the flexible RTM outer mold; and the flexible core mold is connected with the medium circulation device. The forming device is applicable to forming of the tubular three-dimensional braided composite product; by adoption of the forming device, a curved tubular three-dimensional braided composite with various uniform interfaces and various irregular variable cross sections can be prepared; meanwhile, after preform fabric is subjected to braided molding, resin RTM impregnation and rapid curing molding can be performed continuously; and besides, the forming device has the function of quickly demolding the tubular three-dimensional braided composite product. Accordingly, the problem that a conventional metal or wood core mold is cumbersome in molding process, single in function and relatively low in production efficiency can be effectively solved.

Owner:SHANDONG UNIV

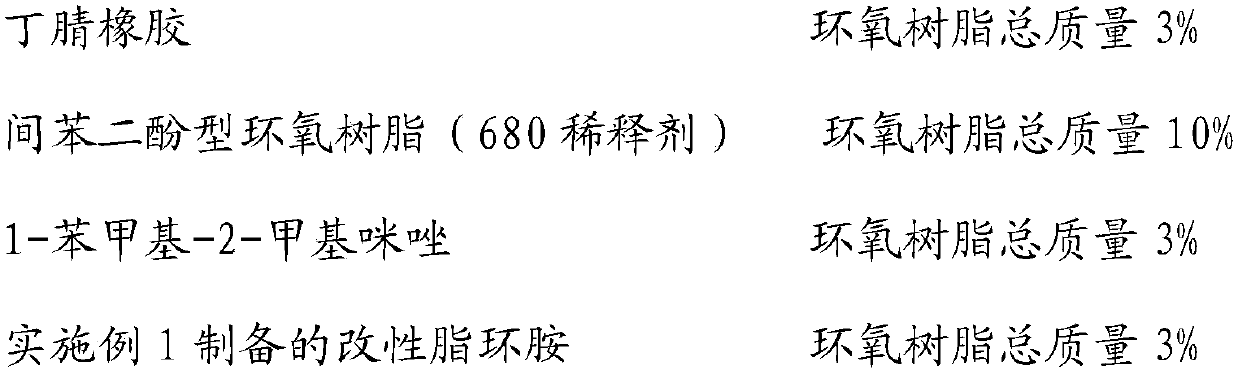

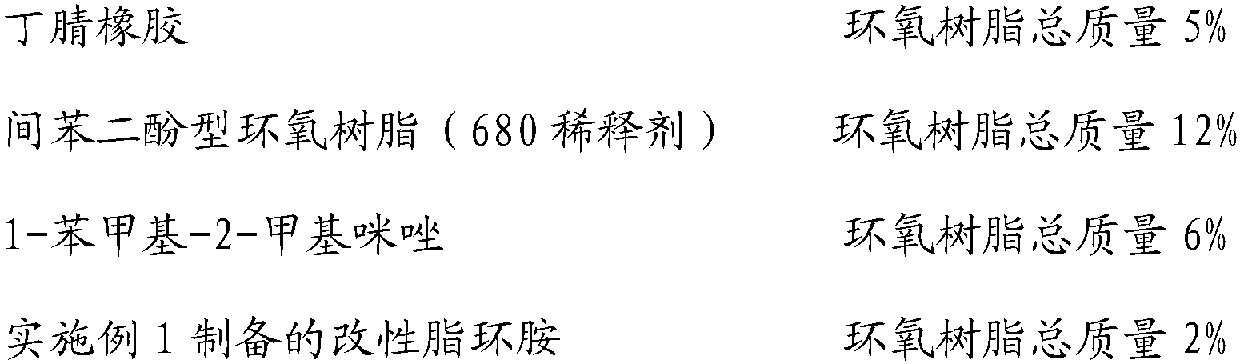

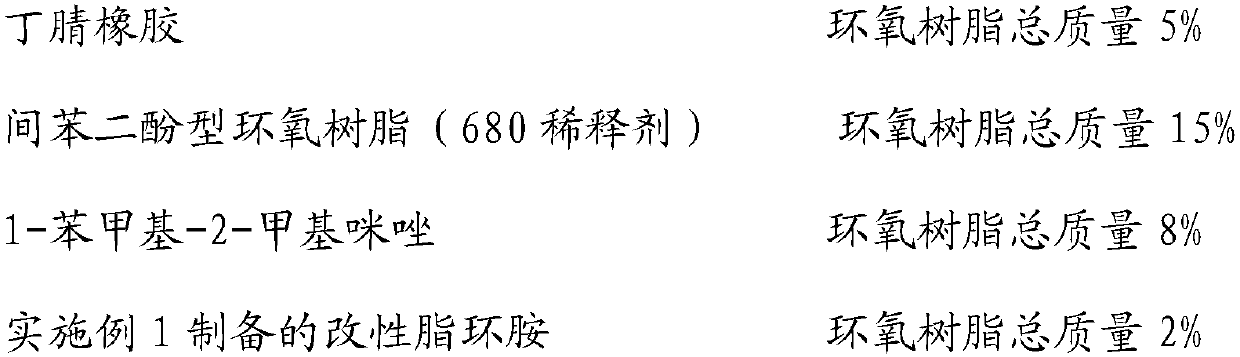

Fast-curing epoxy resin suitable for HP-RTM (high pressure-resin transfer molding) and preparation method

The invention provides fast-curing epoxy resin suitable for HP-RTM (high pressure-resin transfer molding) and a preparation method. The fast-curing epoxy resin is prepared from low-viscosity epoxy resin, a diluent and a modified curing agent, wherein room-temperature viscosity of the low-viscosity epoxy resin is not higher than 2500 mPa.s, epoxy value of the low-viscosity epoxy resin is not lowerthan 0.6, room-temperature viscosity of the diluent is not higher than 100 mPa.s, and the use quantity of the modified curing agent is 5%-15% of the total mass of the epoxy resin. By means of reasonable selection and matching of modified imidazole and a special modified alicyclic amine curing system, the curing time is shorter and is only 5-10 min, besides, the curing reaction is stable, fast curing molding of a resin based composite material can be realized, production efficiency is improved, and production cost is reduced.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

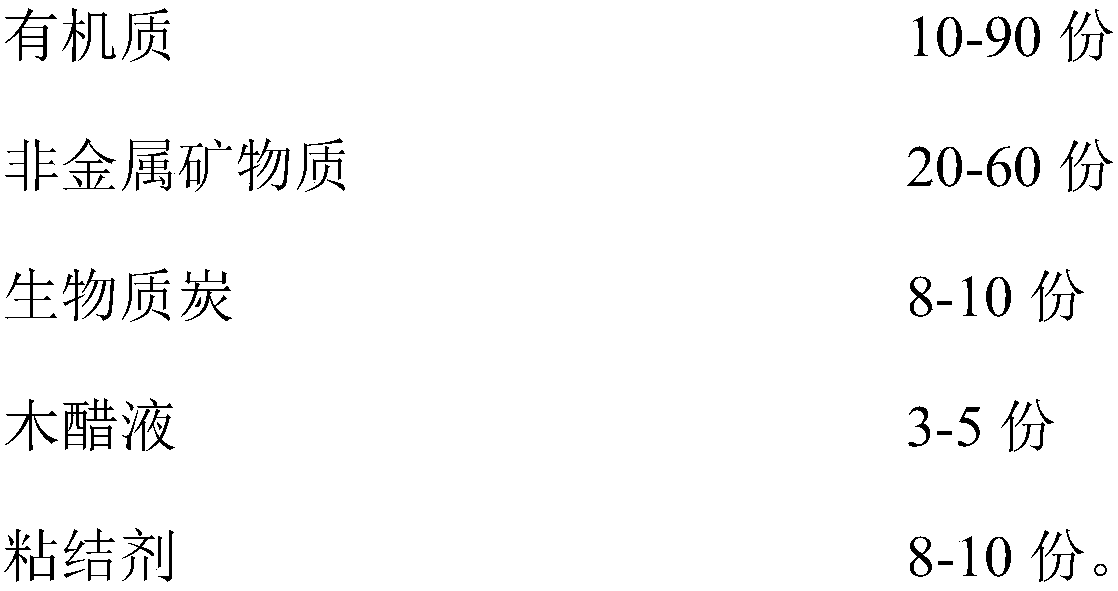

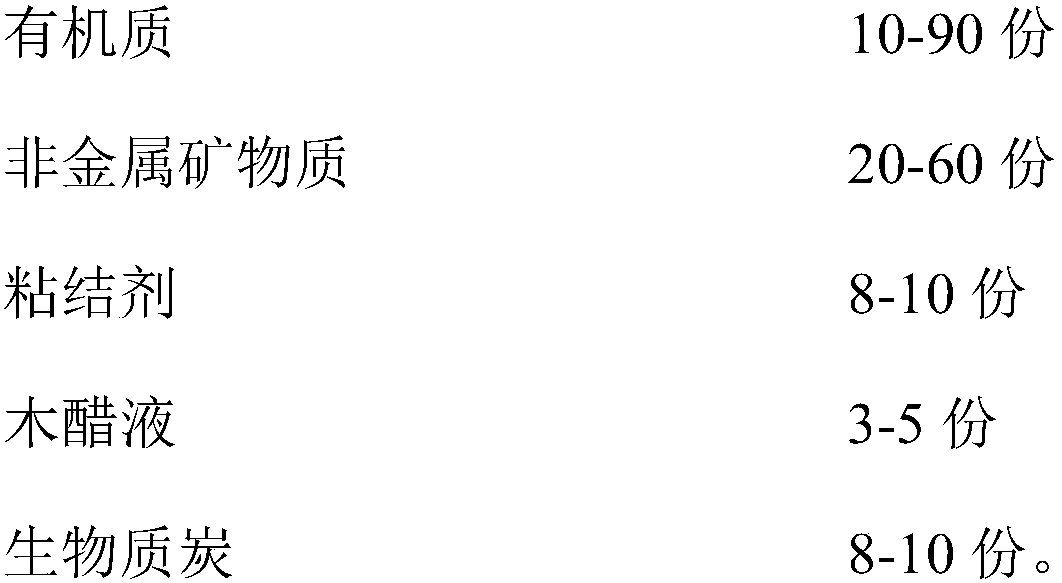

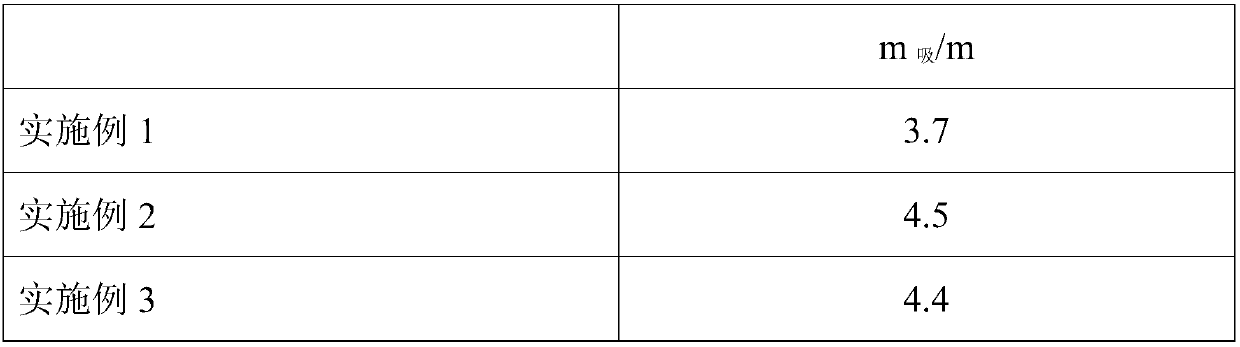

Culture substrate and preparation method thereof

InactiveCN107581023AImprove water retention and breathabilityReduce cloggingGrowth substratesCulture mediaParticulatesOxygen

The invention discloses a culture substrate and a preparation method thereof. According to the culture substrate, an organic matter, non-metallic minerals, an adhesive, pyroligneous liquor and biomasscharcoal with special proportion are adopted and are matched with one another; in the blending process, the ingredients and aggregations between the ingredients grow up through the binding effect ofa binder, and the blockage for holes of small particulate matters is reduced; holes of the culture substrate are balanced by utilizing biomass charcoal; the pyroligneous liquor is sprayed to the culture substrate, and penetrates into the culture substrate, the culture substrate is loosened, the ventilation and water retaining capability of the culture substrate can be enhanced, the condition thatroots have sufficient oxygen and water can be guaranteed, and the growth of crops is promoted. In addition, the culture substrate contains rich organic matters and microelements, so that nutrients needed by the crops can be provided, and the germination rate is increased due to sufficient oxygen and water.

Owner:BEIJING SANJU GREEN ENERGY TECH CO LTD

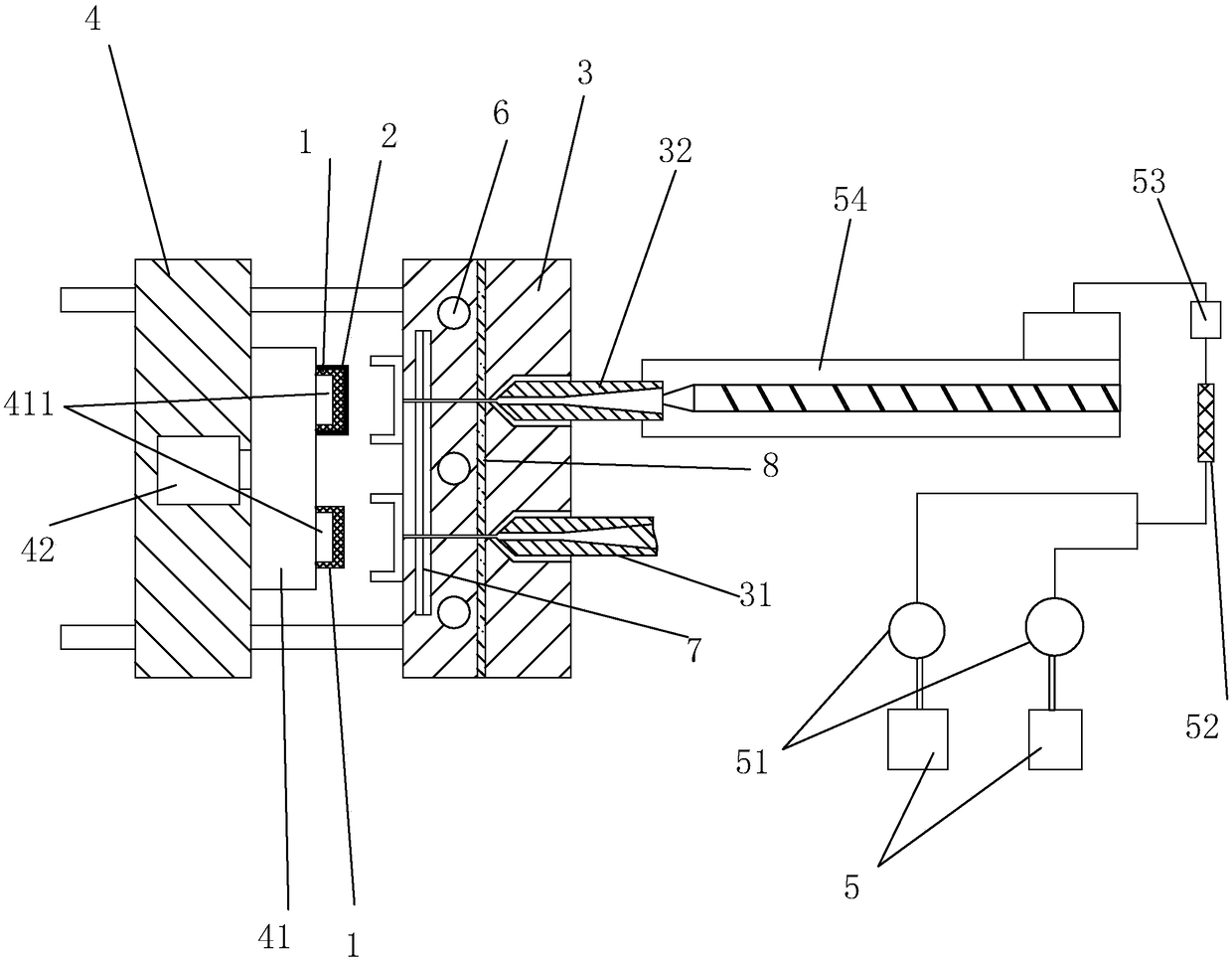

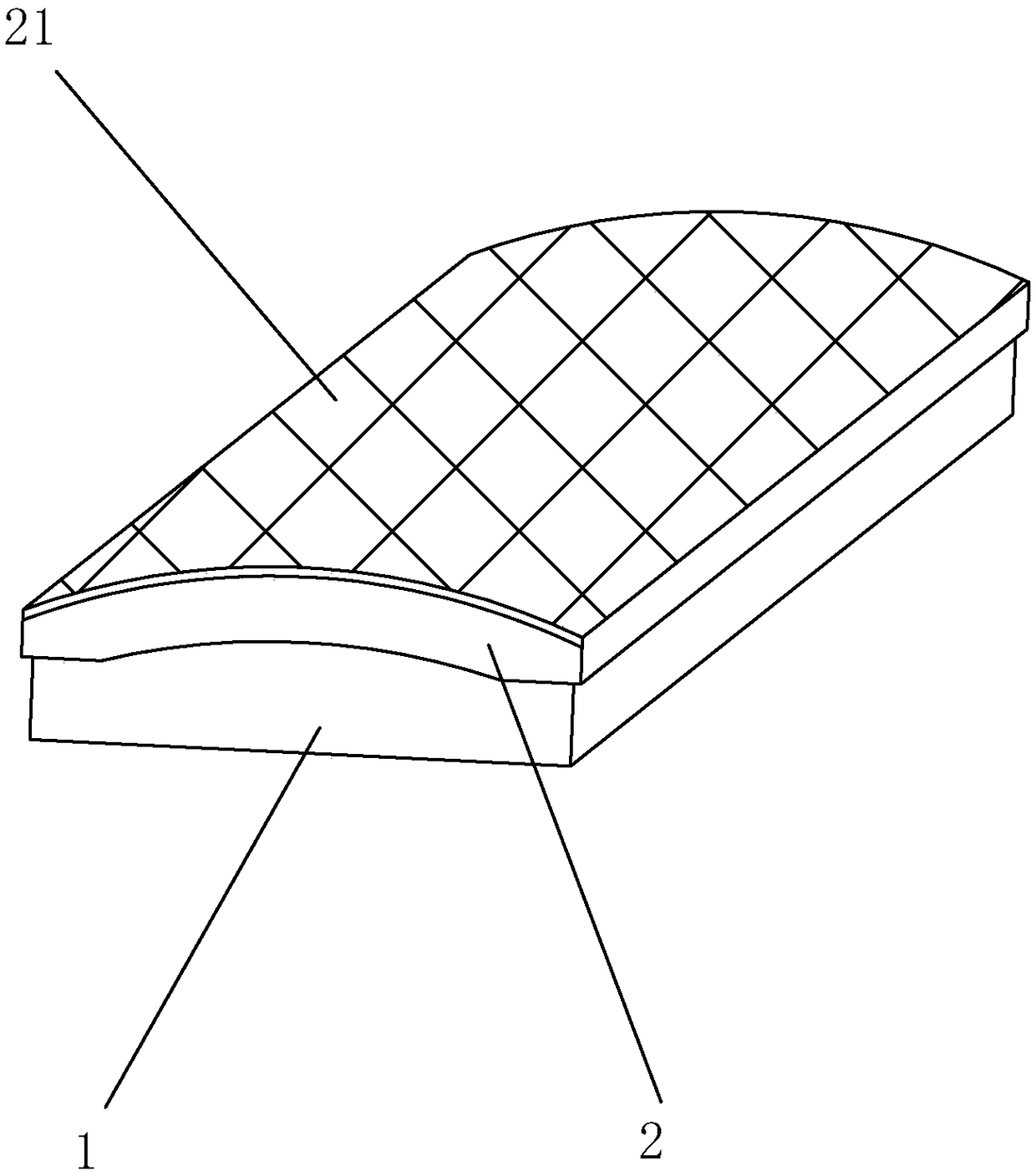

Laptop cooling pad, injection molding system for producing same and injection molding process for producing same

PendingCN108638438AImprove the cushioning effectImprove adhesionDigital data processing detailsThermoplasticInjection molding machine

The invention discloses a laptop cooling pad. The laptop cooling pad comprises a cooling pad cores formed through injection molding of thermoplastic plastic, and the bottom surfaces of the cooling padcores are bonded with LSR layers. The invention discloses an injection molding system for producing the laptop cooling pad, and the injection molding system comprises a fixed mold and a movable mold,the fixed mold is connected with a first plastic injection pipe and a second plastic injection pipe, the first plastic injection pipe is used for injecting PC, the second plastic injection pipe is used for injecting LSR, a rotating disc is rotationally arranged on the movable mold, mold cores are arranged on the rotating disc, and a driving part is arranged in the movable mold. Every time the rotating disc rotates, the movable mold moves from the first plastic injection pipe to the second plastic injection pipe, then the rotating disc rotates by 180 degrees, and the rotating disc rotates in areciprocating mode. The technical scheme of the injection molding system is characterized in that the PC and the LSR are sequentially injected by the first plastic injection pipe and the second plastic injection pipe through rotation of the rotating disc, so that the laptop cooling pad which is good in flexibility, excellent in buffering performance and excellent in anti-skid performance is formed.

Owner:苏州复盈新材股份有限公司

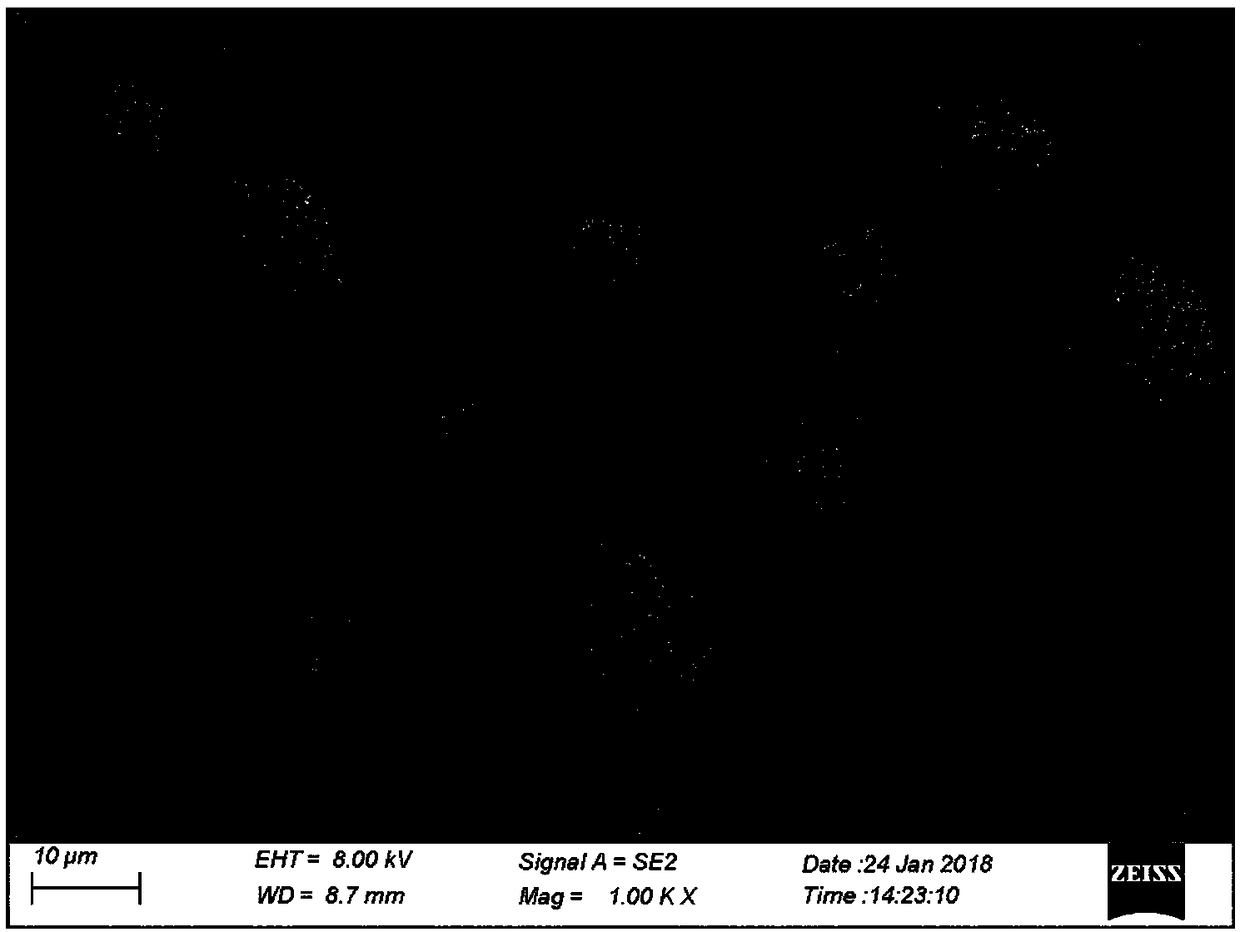

Preparation method of photosensitive particle stabilizing emulsion as well as preparation method of thin-wall hollow sphere

ActiveCN108610060AHas photosensitive propertiesRapid curing moldingAdditive manufacturing apparatusOligomerSlurry

The invention discloses a preparation method of photosensitive particle stabilizing emulsion as well as a preparation method of a thin-wall hollow sphere, and belongs to the technical field of a porous ceramic material. The photosensitive particle stabilizing emulsion is obtained by mixing and emulsifying oil phase and ceramic powder-containing aqueous phase slurry, wherein at least one of the aqueous phase and the oil phase contains a photosensitive material, and a corresponding photoinitiator is added; the thin-wall hollow sphere is prepared by the steps of diluting photosensitive emulsion and applying an external light field to initiate photosensitive oligomer molecular polymerization reaction to obtain a solidified ceramic granule assembling hollow sphere, separating and sintering; thephotosensitive emulsion prepared by the method can be applied to photocuring 3D printing; the hollow sphere prepared by the method is controllable in structure and is widely applied; and the preparation method provided by the invention has the advantages of simplicity, high efficiency and low cost and is easy in industrial promotion.

Owner:TSINGHUA UNIV +1

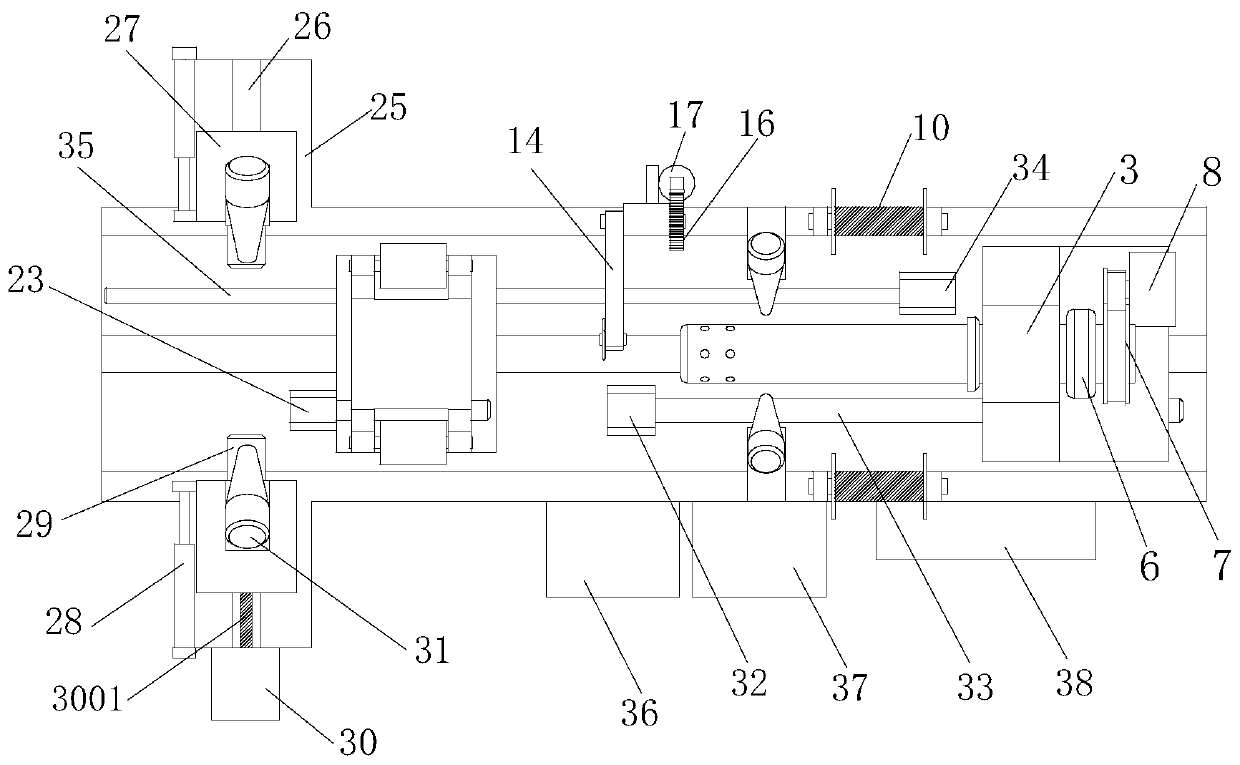

Bio-degradable film hot-press forming bag making machine

InactiveCN110861354AEasy to operateRapid curing moldingBag making operationsPaper-makingCold airHydraulic cylinder

The invention discloses a bio-degradable film hot-press forming bag making machine, and relates to the technical field of bio-degradable films. The bio-degradable film hot-press forming bag making machine aims at solving the problems that the structure is complex, and the bag making effect is poor. The bio-degradable film hot-press forming bag making machine specifically comprises a supporting bottom plate. One end of the outer wall of one side of the top of the supporting bottom plate is fixedly connected with a first supporting column, the top of one side of the first supporting column is rotationally connected with a pay-off roller, the middle position of the top of the supporting bottom plate is fixedly connected with a supporting table, the four corners of the top, close to the supporting table, of the supporting bottom plate are fixedly connected with fixing columns, the tops of the fixing columns are fixedly connected with a top plate, and the middle position of the top of the top plate is fixedly connected with a hydraulic cylinder. A cutter is heated, the bio-degradable films are subjected to thermal cutting type bag making treatment through the cutter, the operation is convenient, cold air enters a fixing groove through a vent port, thermally-cut degradable film bags are cooled through a heat guide plate, and the cutting surfaces of the degradable film bags are rapidly cured and formed.

Owner:HUNAN KELAIBAO BIO ENERGY TECH CO LTD

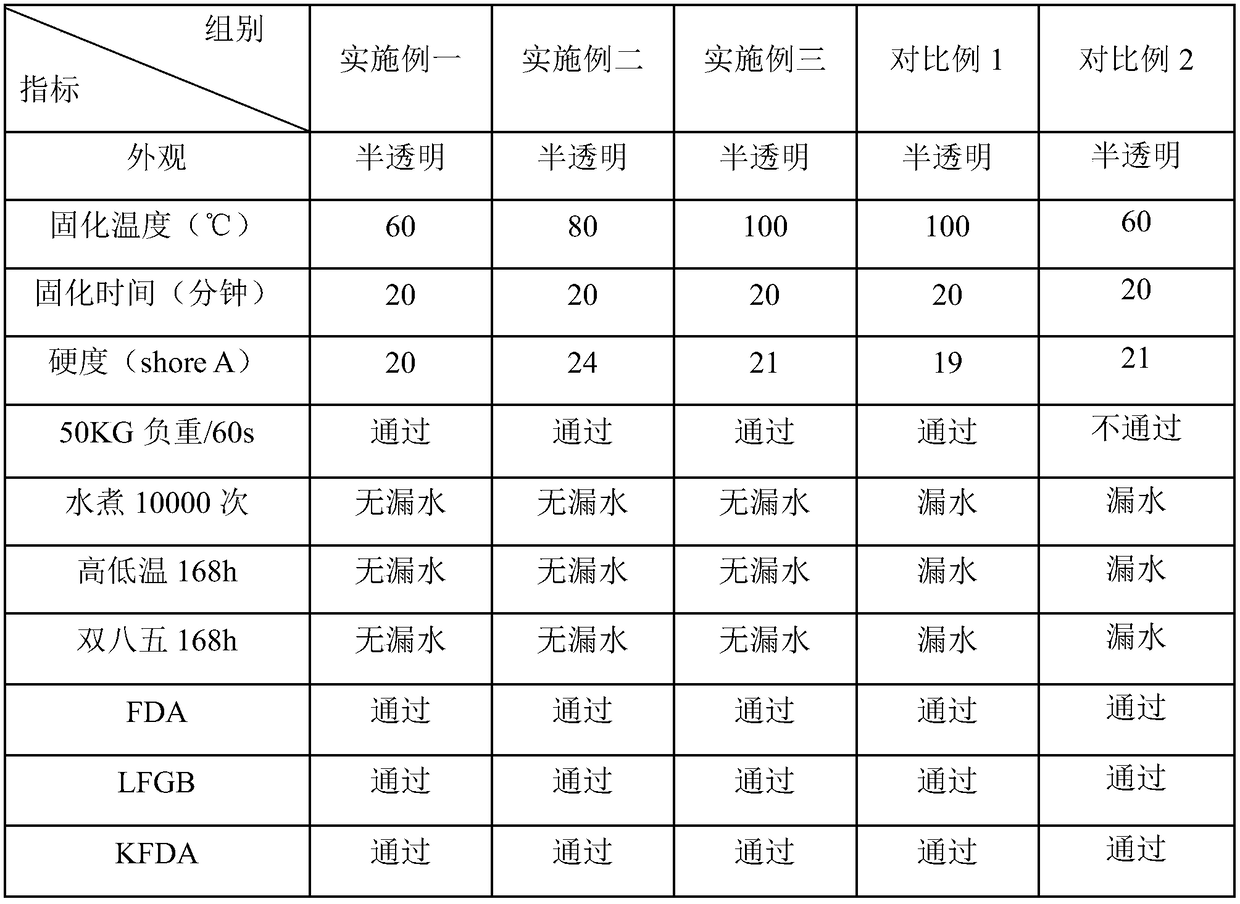

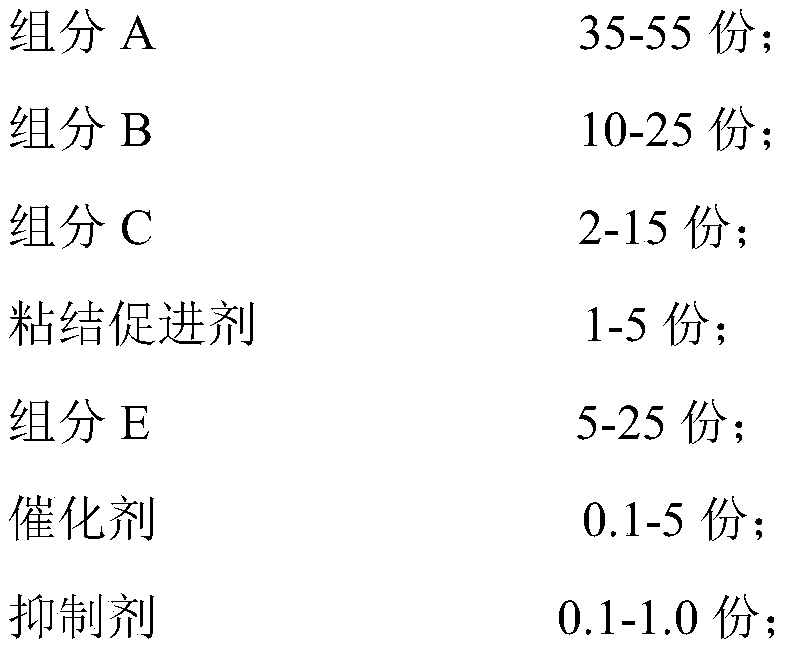

Double component additive sealing organic silicon material for electric kettle and preparation method thereof

The invention provides a double component additive sealing organic silicon material for an electric kettle. The material is prepared from components A and B equal in mass. The component A is preparedfrom the following raw materials in parts by mass: 70-100 parts of vinyl polysiloxane, 5-30 parts of white carbon black, 0.5-5 parts of an adhesive and 0.1-0.5 part of a catalyst. The component B is prepared from the following raw materials in parts by mass: 70-100 parts of vinyl polysiloxane, 5-30 parts of white carbon black, 2-20 parts of hydrogen-containing silicone oil and 0.001-0.2 part of aninhibitor. The invention belongs to the technical field of organic silicon materials. The double component additive sealing organic silicon material can be used for quickly adhering and curing the electric kettle, is low in curing temperature and short in time, simple in preparation raw materials, low in cost, safe and reliable and high in food grade, and can meet the demands on high-end standards such as FDA.

Owner:广东皓明有机硅材料有限公司

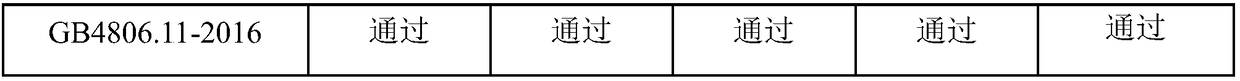

3D printing ceramic preparation method and product thereof

InactiveCN111792928AHigh intensity valueImprove liquidityAdditive manufacturing apparatusOrganic solventSlurry

The invention discloses a 3D printing ceramic preparation method and a product thereof. The preparation method comprises the following steps: S1, adding ceramic powder into a mixed solution of a binder and an organic solvent, and uniformly stirring to obtain slurry; S2, subjecting the slurry to extrusion moulding through micro-flow extrusion moulding equipment to obtain a ceramic blank, immediately immersing the printed ceramic blank into an inorganic solution, and rapidly moulding, wherein the organic solvent and the inorganic solution are mutually soluble; S3, after the ceramic blank is cured and hardened, taking out and drying the ceramic blank; S4, removing the binder; and S5, calcining at a high temperature to obtain ceramic. The provided ceramic slurry has good fluidity and stability, and has a proper solid phase content, the printed slurry has excellent shape retention ability, and the ceramic blank prepared by calcination is porous and not easy to crack. The porosity is regulated and controlled according to the ratio of the organic solvent to the ceramic powder, a hierarchical pore structure is realized, and ceramic parts with complex geometrical shapes can be prepared.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

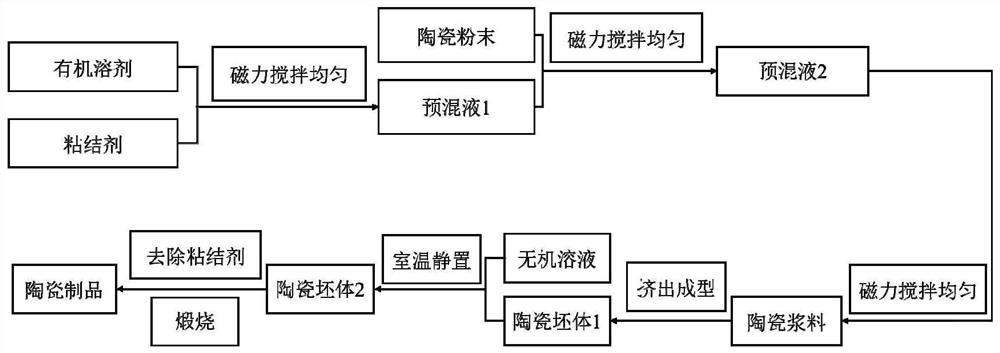

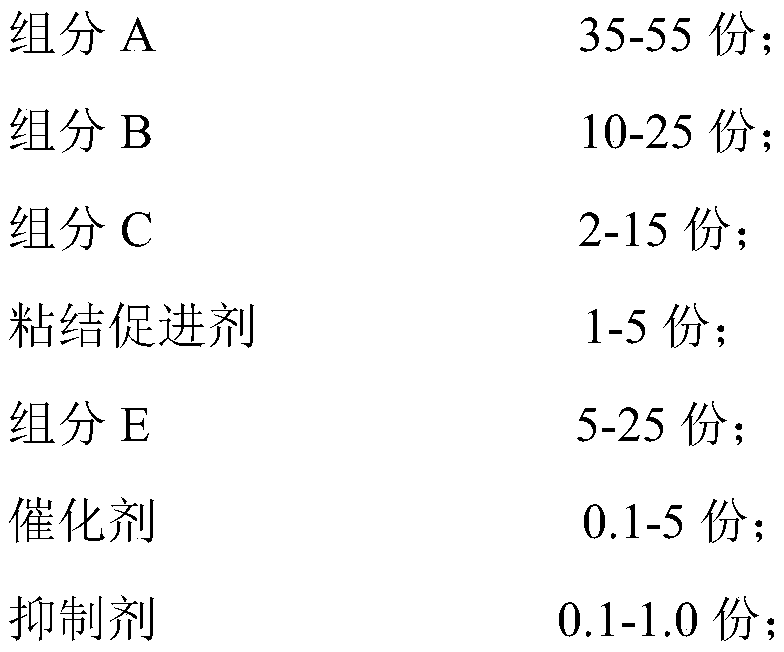

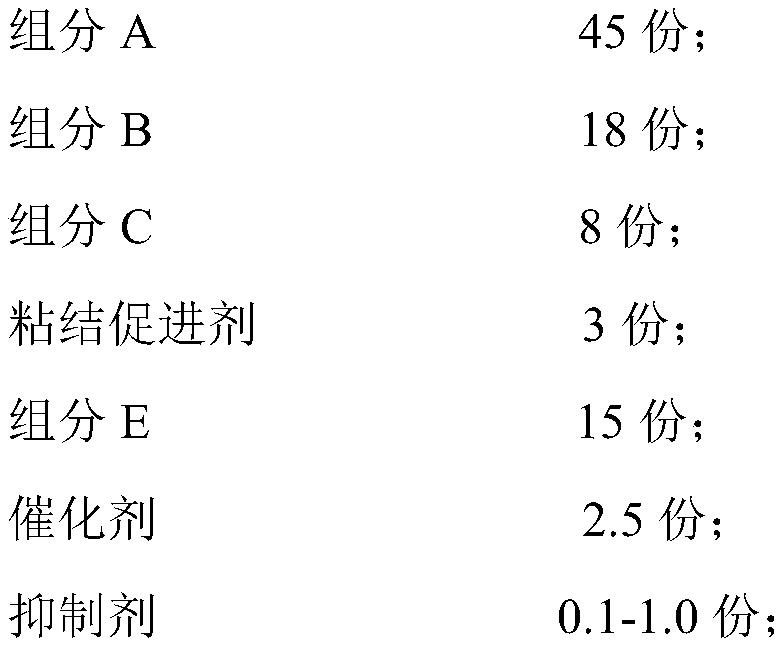

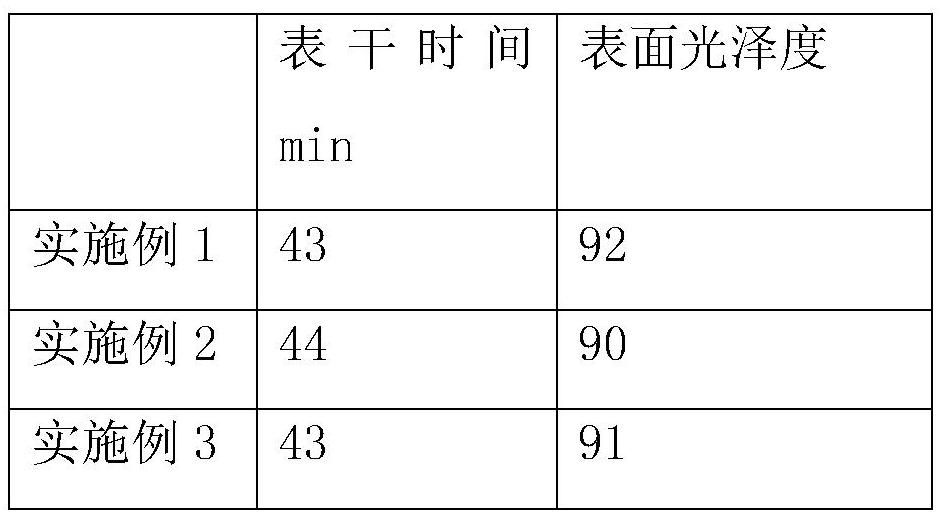

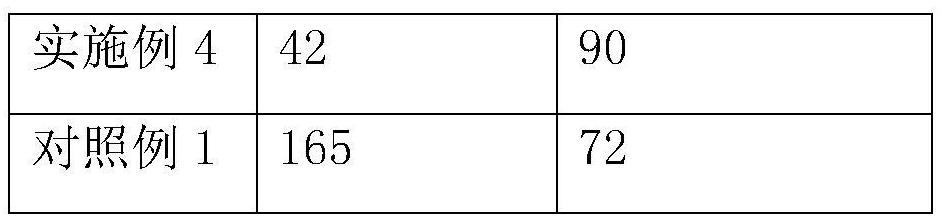

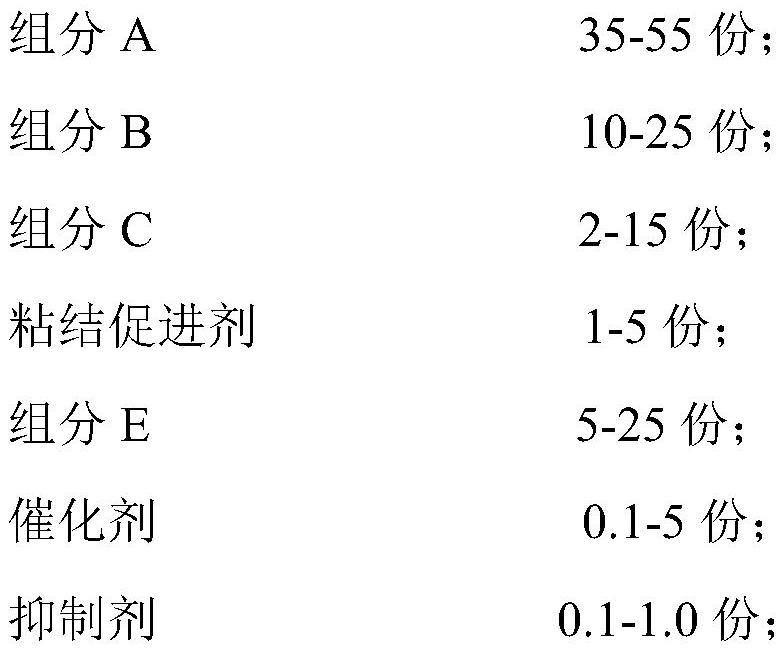

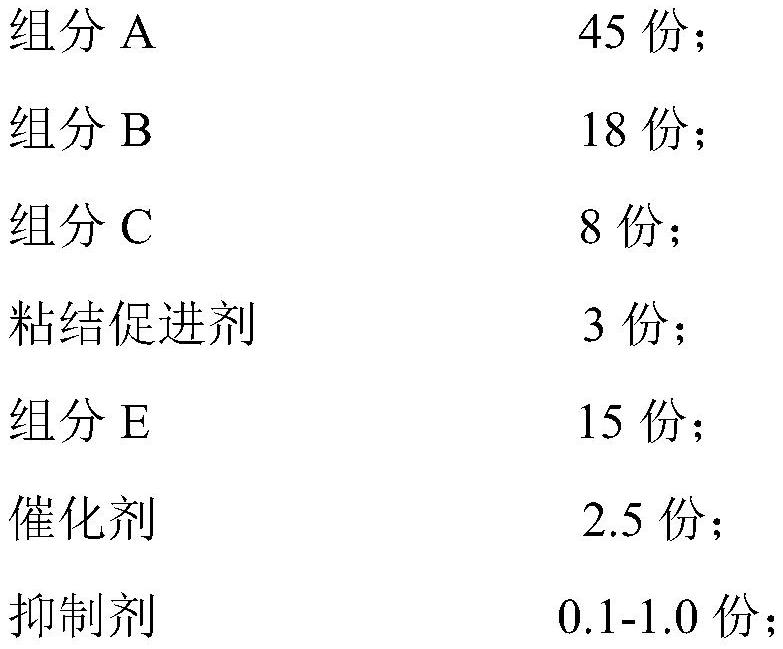

Transparent silica gel for liquid crystal display fitting

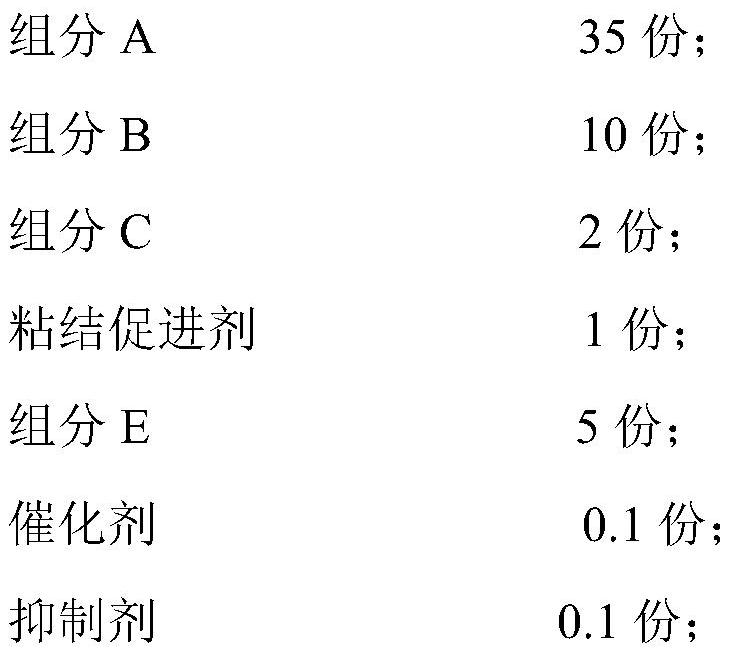

The invention relates to a transparent silica gel for liquid crystal display fitting. A raw material formula comprises 35-55 parts of component A, 10-25 parts of component B, 2-15 parts of component C, 5 parts of bonding accelerant, 5-25 parts of component E, 0.1-5 parts of catalyst and 0.1-1.0 part of inhibitor; the component A is vinyl-terminated polysiloxane conforming to general formula (1); the component B is allyloxy-terminated polypropylene oxide conforming to general formula (2); the component C is vinyl MQ silicon resin; ratio of M to Q is at 0.8-1.5; the component E is hydrogen-endedpolysiloxane conforming to general formula (3). The transparent silica gel for liquid crystal display fitting prepared according to the invention has the advantages of low viscosity, short defoamingtime, quick curing molding and moderate hardness.

Owner:铜陵桐力光电有限公司

3D low-temperature printing material and preparing method thereof

ActiveCN108467580AImproved rheological propertiesImprove heat resistanceAdditive manufacturing apparatusWire rodPlasticizer

The invention relates to a 3D low-temperature printing material and a preparing method thereof. The 3D low-temperature printing material comprises a base body material which is composed of polyoxyethylene (PEO) and a rigid low-temperature melt, the mass of PEO in the base body material accounts for 70-100%, the mass of the rigid low-temperature melt accounts for 0-30%, the 3D low-temperature printing material further comprises a stabilizer and a plasticizer, the dosage of the stabilizer accounts for 0.5-1 wt% of the mass of PEO, and the dosage of the plasticizer accounts for 0.1-10 wt% of themass of PEO. Polyoxyethylene serves as the main material, by adding the rigid low-temperature molten polymer, then through blending and extrusion pelletizing, a modified polyoxyethylene material is obtained, and then a wire of which the diameter is 1.75 mm is prepared through an extruder. Compared with the prior art, in the printing process, the material does not flow, and can be quickly cured andformed; meanwhile, the heat resistance of the material can be improved, and the 3D low-temperature printing material is novel and has a good application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

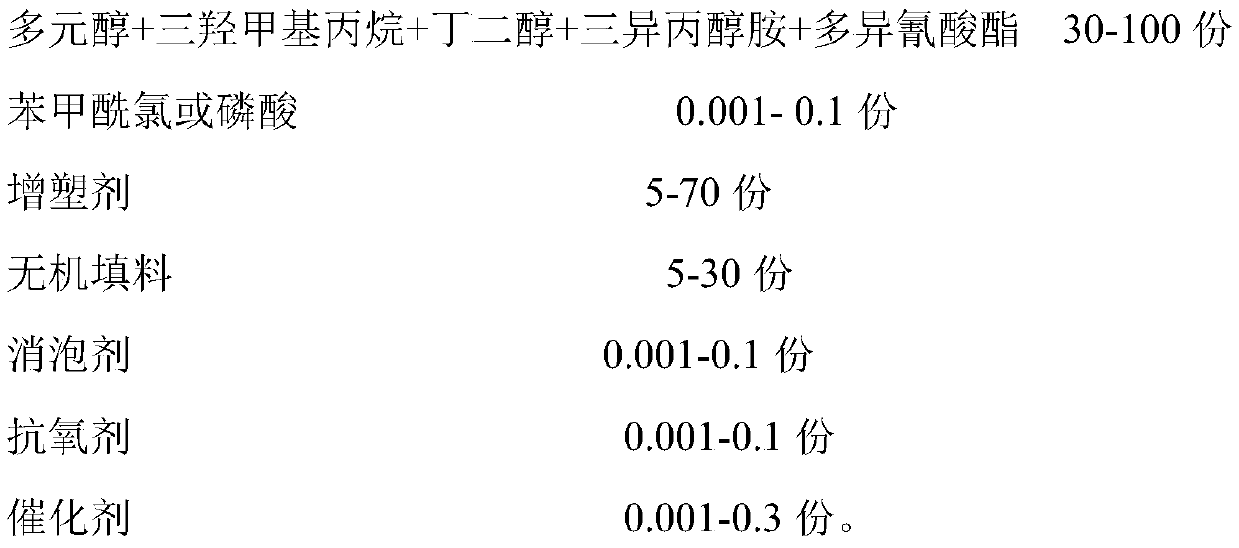

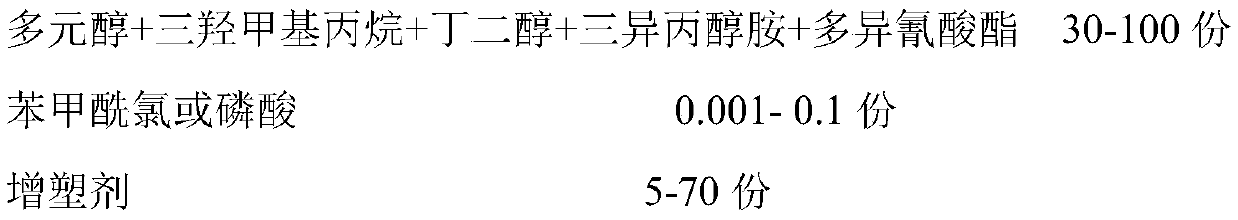

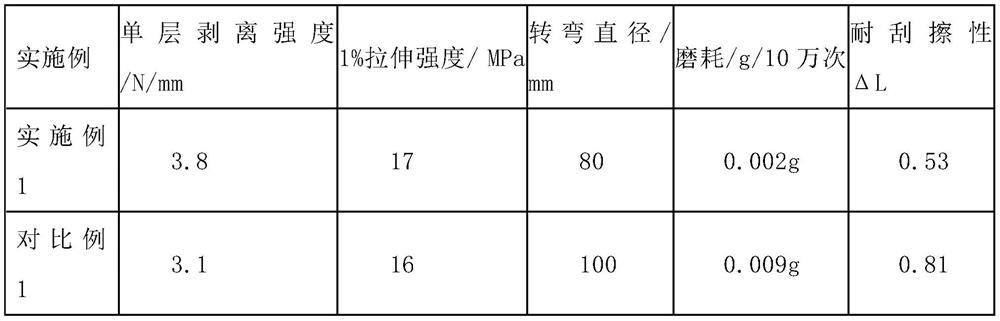

Solvent-resistant polyurethane composite and preparation method thereof

The invention discloses a solvent-resistant polyurethane composite. The composite is prepared from two components, namely the primary component and the secondary component. The primary component comprises an ingredient A, an ingredient B, an ingredient C, an ingredient E and an ingredient F, and the secondary component comprises an ingredient D, the ingredient B, the ingredient E and the ingredient F, wherein the ingredient A refers to a mixture of polyols and retarders, the ingredient B refers to a plasticizer, the ingredient C refers to inorganic filler, the ingredient D refers to a chain extender, the ingredient E refers to a mixture of a defoamer, an antioxidant and a catalyst auxiliary agent, and the ingredient F refers to polyisocyanate. The invention further discloses a preparationmethod of the solvent-resistant polyurethane composite, the service life of a rubber roll made from the solvent-resistant polyurethane composite is double of that of a rubber roll made from toluene diisocyanate, the processing performance of the rubber roll made from the solvent-resistant polyurethane composite is improved obviously, and the composite has a wider operating environment and better mechanical processing performance.

Owner:山西科灜科技有限公司

Building pipe pile with built-in reinforcing ribs

PendingCN112211184AHigh mechanical strengthIncrease contact areaBulkheads/pilesArchitectural engineeringMesh reinforcement

The invention discloses a building pipe pile with built-in reinforcing ribs, and belongs to the field of building construction. According to the technical scheme, the building pipe pile is characterized by comprising a pipe pile outer layer, a supporting inner pipe and a reinforcing rib set, wherein the supporting inner pipe is fixedly connected to the inner wall of the pipe pile outer layer, thereinforcing rib set is detachably connected to the inner wall of the supporting inner pipe, four fixing ribs which are annularly distributed with the circle center of the supporting inner pipe as thecenter are fixedly connected to the outer wall of the supporting inner pipe, and four positioning grooves which are annularly distributed with the circle center of the supporting inner pipe as the center are formed in the inner wall of the supporting inner pipe; and the four positioning grooves are formed in the inner wall of the pipe pile, the reinforcing rib set is additionally arranged inside in a detachable connection mode, a plurality of rectangular holes are further formed in the surface of the reinforcing rib set, the reinforcing rib set can be filled with pouring materials, the strength of the pipe pile is improved, a reinforcing mesh is poured through a mold to form the supporting inner pipe, reinforcing bars are placed in positioning circular grooves in the outer wall of the supporting inner pipe for secondary pouring to form the pipe pile outer layer, and the strength of the pipe pile is better guaranteed through the reinforcing rib set.

Owner:泉州市哦加斯科技有限公司

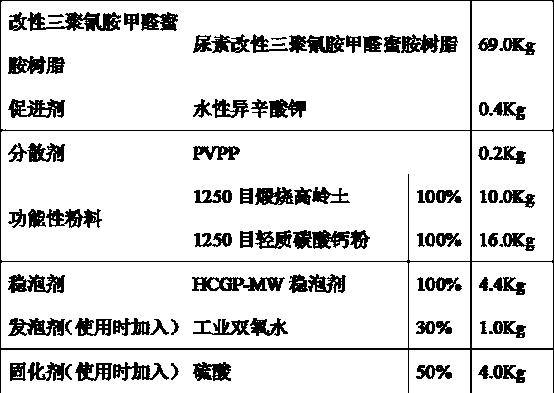

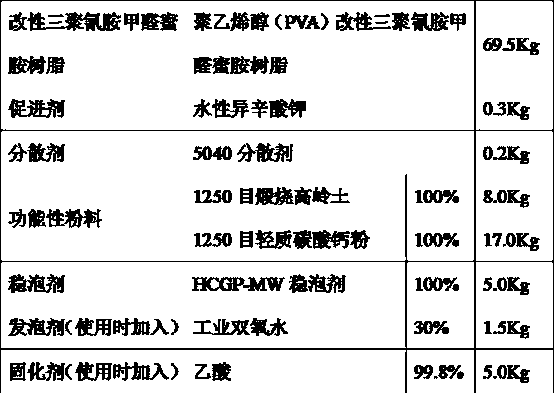

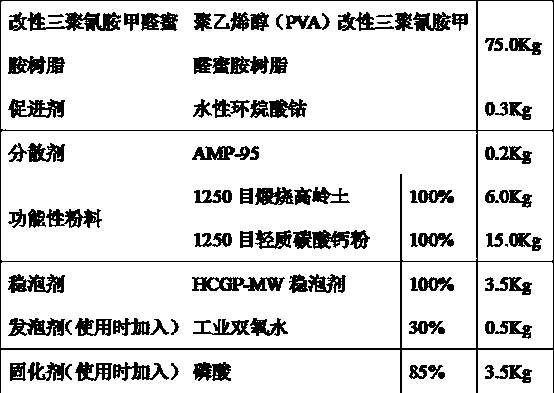

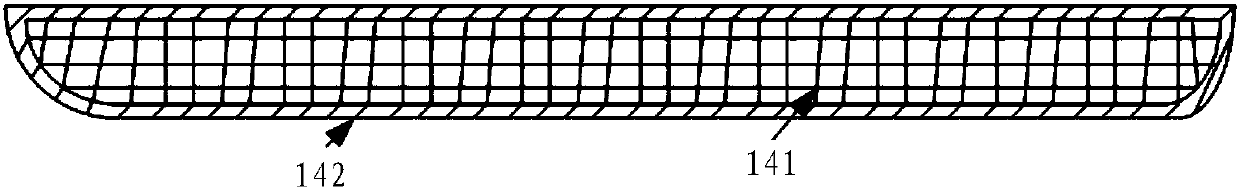

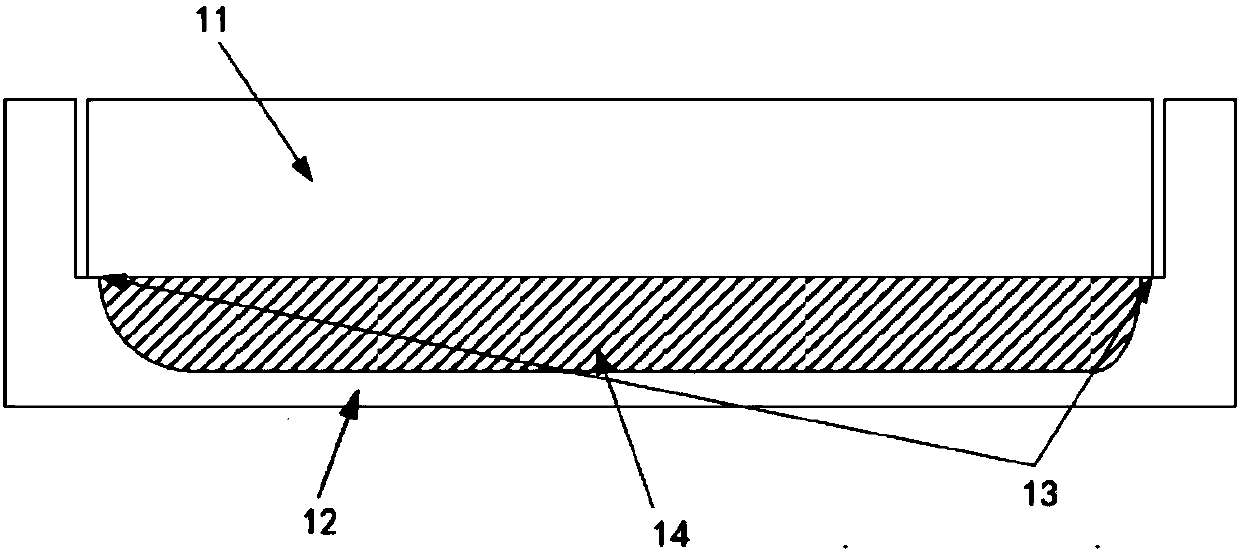

Environmental protection modified melamino-formaldehyde melamine resin foam material and preparation method

The invention discloses an environmental protection modified melamino-formaldehyde melamine resin foam material and a preparation method. The environmental protection modified melamino-formaldehyde melamine resin foam material is prepared from the following raw materials in parts by weight: 65-80 parts of modified melamino-formaldehyde melamine resin, 3-6 parts of a foam stabilizer, 0.2-2 parts ofa foaming agent, 20-35 parts of a functional powder material, 0.2-0.5 part of a dispersant, 0.3-0.6 part of an accelerant and 2-5 parts of a curing agent. According to the environmental protection modified melamino-formaldehyde melamine resin foam material, the modified melamino-formaldehyde melamine resin serves as a main material, through addition of the functional powder material, the cost islowered, the strength is improved, and shrinkage is reduced, the percentage of close area of the foam material is increased, and the flame retardant property is improved; a method combining chemical and physical foaming is adopted, meanwhile a self-developed efficient HCGP-MW foam stabilizer is used, the foam stabilizing time is long, the percentage of close area is high (larger than or equal to 96%), and thus the foam material is light in weight, high in strength, and efficient in heat insulation; and the prepared environmental protection modified melamino-formaldehyde melamine resin foam material can be normally used in -60 DEG C-180 DEG C of the high-low temperature corrosive environments for a long time.

Owner:新疆同业盛远工程技术有限公司

Molded product and production method thereof

InactiveCN107629474AReduce usageGood apparent performanceBathroom coversAir tightnessCompression molding

The invention provides a molded product and a production method thereof. The molded product comprises a core part and a shell part at least partially wrapping the core part, and the core part is obtained through compression molding of a first mixture comprising 8-30 parts by weight of thermosetting resin and 70-92 parts by weight of straw powder having a first granularity; and the shell part is obtained through compression molding of a second mixture comprising 8-30 parts by weight of the thermosetting resin and 70-92 parts by weight of straw powder having a second granularity, wherein the first granularity is more than the second granularity. The method comprises the following steps: 1, respectively preparing the first mixture and the second mixture for the core part and the shell part; 2, sequentially adding the first mixture and the second mixture into the cavity of a die, and allowing the first mixture to be at least partially wrapped with the second mixture; and 3, carrying out compression molding in the die cavity in an airtight and sealed state. The molded product and the production method thereof have the advantage of low manufacturing cost.

Owner:GUIZHOU TOPSEAT TECH CO LTD

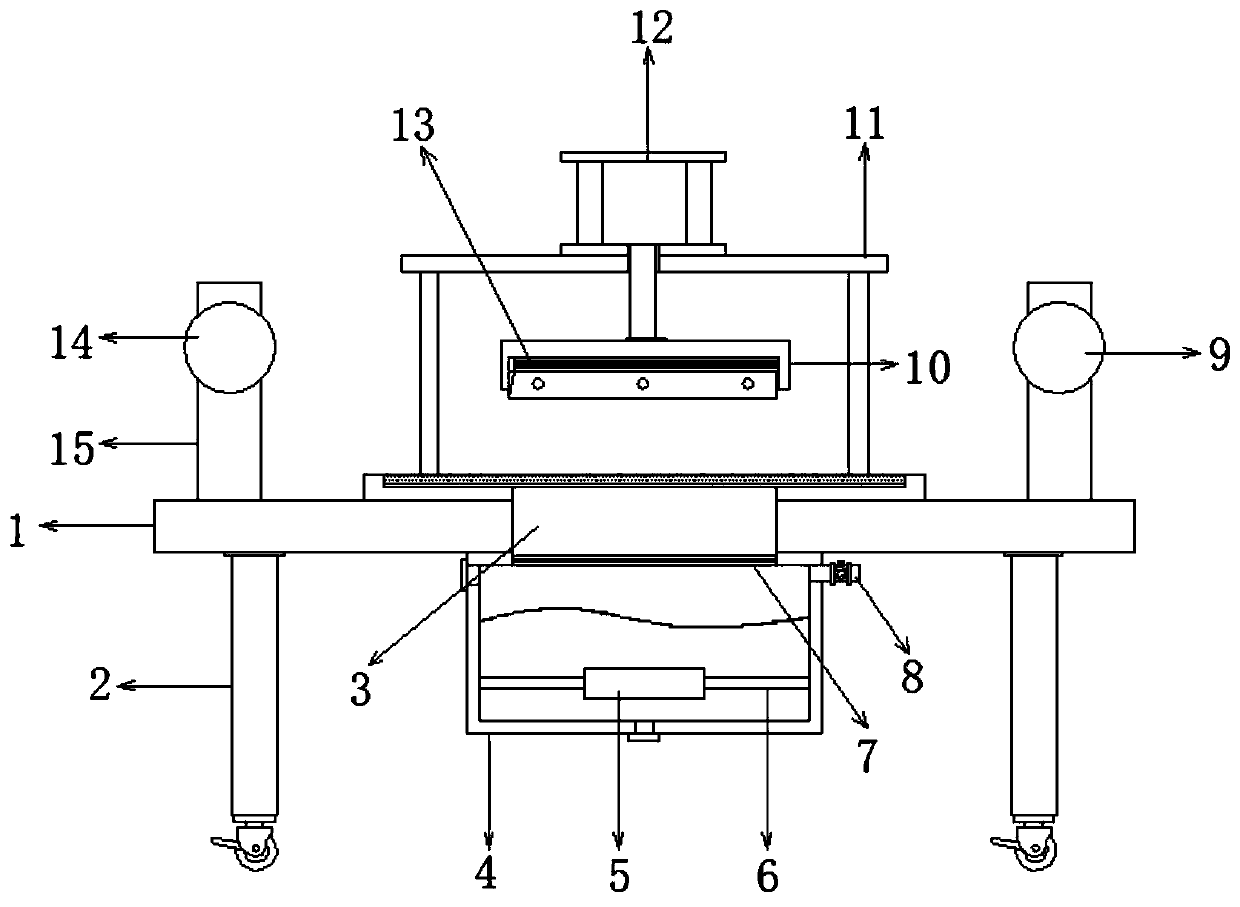

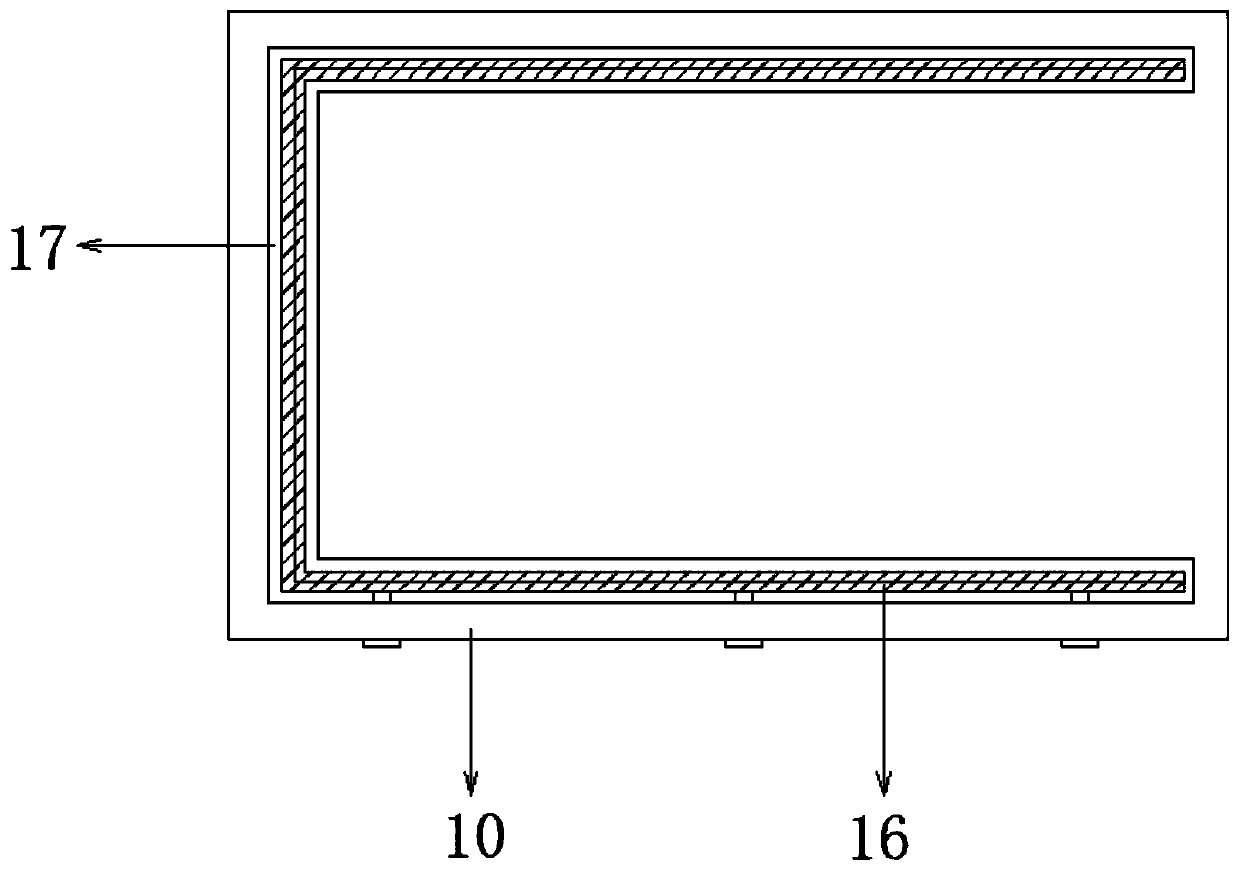

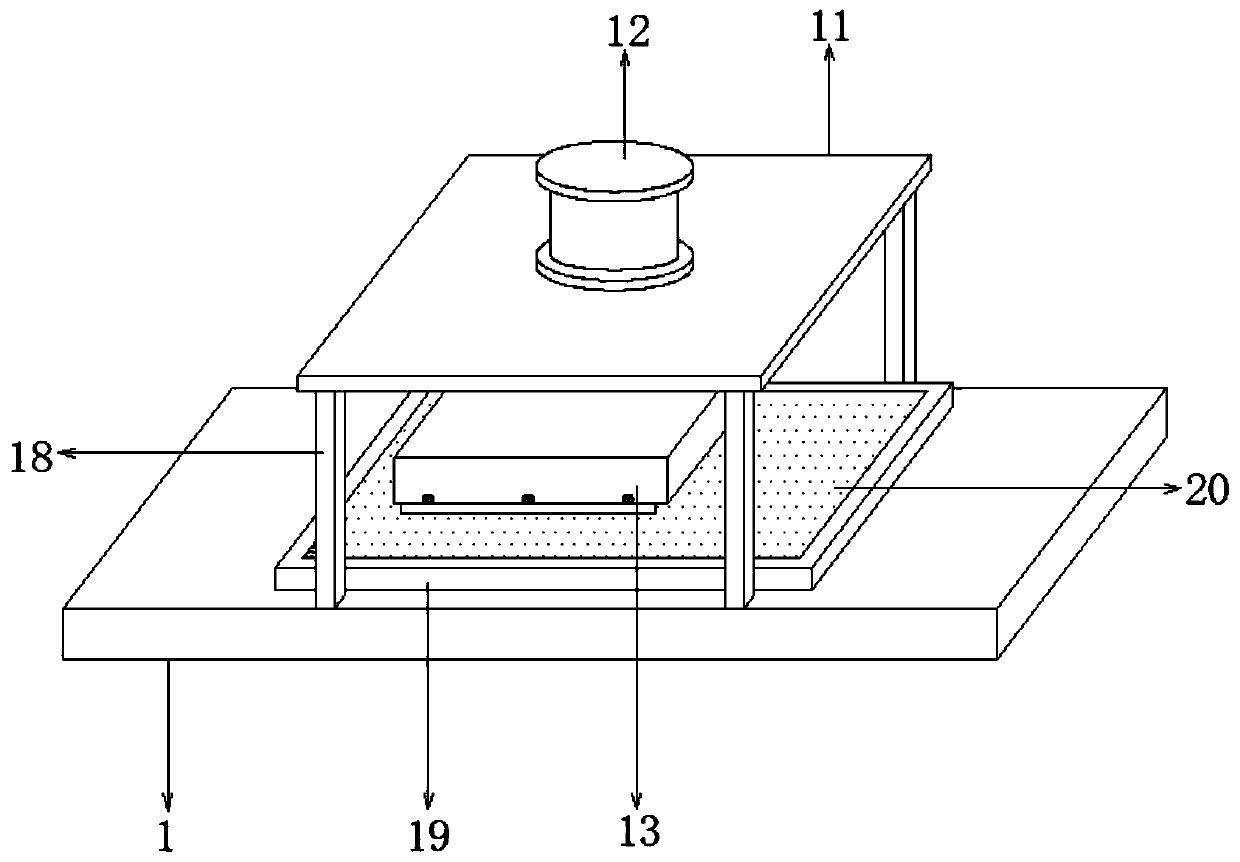

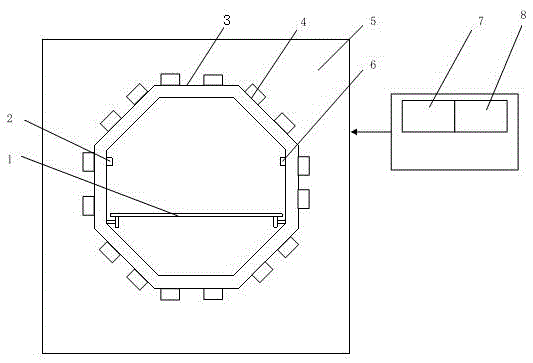

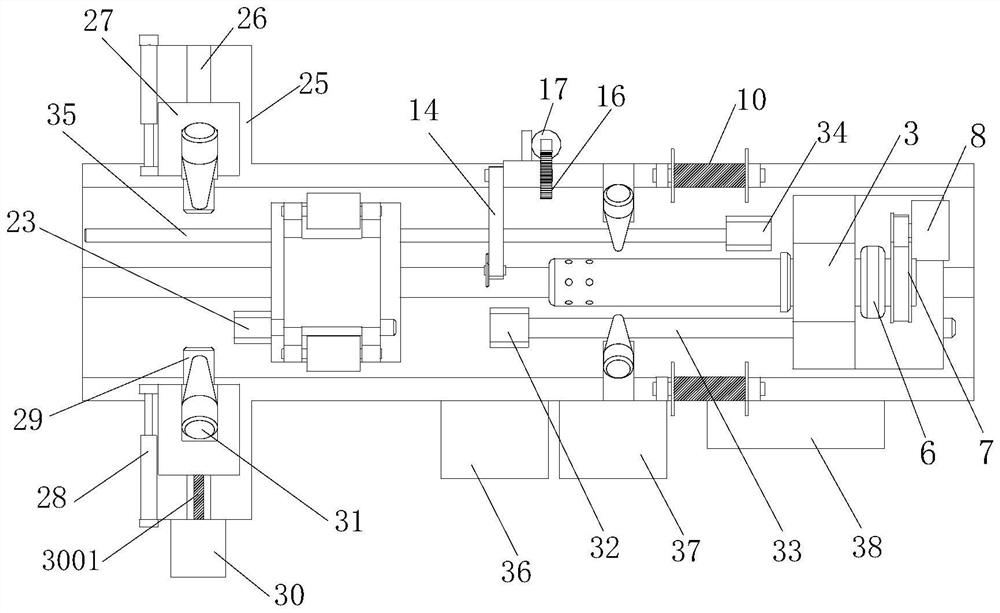

Method and device for microwave curing of fiber-reinforced resin-based composite components

The invention relates to a method and a device for curing a fiber-reinforced resin-based composite material component by utilizing microwaves. The microwaves which are generated by a microwave source with linearly-adjustable power are guided into a resonant cavity, and the microwaves penetrate through and heat the composite material, so that the composite material can be quickly cured and formed. By adopting the advanced octagonal microwave-mode resonant cavity, the uniformity of an electromagnetic field inside the device can be realized; the interference of the reflection wave on the microwave source can be reduced by adopting an automatic impedance matching system, so that the optimal transmission of the microwave power can be realized. A vacuum pipe connector and a temperature sensor are arranged on the inner side wall of the octagonal multi-mode resonant cavity, a glass worktable is arranged inside the resonant cavity, and the rotation of a ball screw is controlled through a stepper motor to control the back-forth movement of the worktable. A choking groove is adopted to prevent the leakage of the microwave. By adopting the method and the device, the problems of the traditional autoclave forming method that the time for manufacturing the fiber-reinforced composite material is long, the energy consumption is high and the heat is non-uniform can be solved, the curing time can be saved, and the quality and performance of the composite material component can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Organic silicon modified epoxy resin paint film and preparation method thereof

The invention discloses an organic silicon modified epoxy resin paint film and a preparation method thereof. The method comprises the following steps: uniformly mixing H-type epoxy resin, organic silicon resin and polysiloxane, heating to 70-80 DEG C, carrying out addition reaction for 1-5 hours until the reaction is complete, and cooling to the room temperature; and then adding nano carbonate and graphene, heating to 50-60 DEG C, keeping the temperature constant, dropwise adding ethylene glycol diglycidyl ether while stirring within 1 hour, then adding methyl ethyl ketone, and stirring at normal temperature for 1-2 hours. The H-type epoxy resin in the prior art is poor in glossiness, a small amount of organic silicon resin can improve the glossiness, and due to the addition of polysiloxane, the glossiness of the resin can be improved, and rapid curing forming can be achieved.

Owner:江西瀚泰新材料科技有限公司

A kind of transparent silicone gel for laminating liquid crystal screen

A transparent silicone gel for bonding liquid crystal screens. The raw material formula includes 35-55 parts of component A; 10-25 parts of component B; 15 parts of component C2; 5 parts of adhesion promoter; 5-25 parts of component E; 0.1-5 parts of the catalyst; 0.1-1.0 parts of the inhibitor; the component A is a vinyl-terminated polysiloxane conforming to the general formula (1): the component B is a vinyl-terminated polysiloxane conforming to the general formula (2) Propoxy polypropylene oxide: the component C is a vinyl MQ silicone resin, and the M:Q ratio is 0.8-1.5; the component E is a terminal hydrogen polysiloxane conforming to the general formula (3). The transparent silicone gel for bonding liquid crystal screens prepared by the invention has the advantages of low viscosity, short defoaming time, fast curing and molding, and moderate hardness.

Owner:铜陵桐力光电有限公司

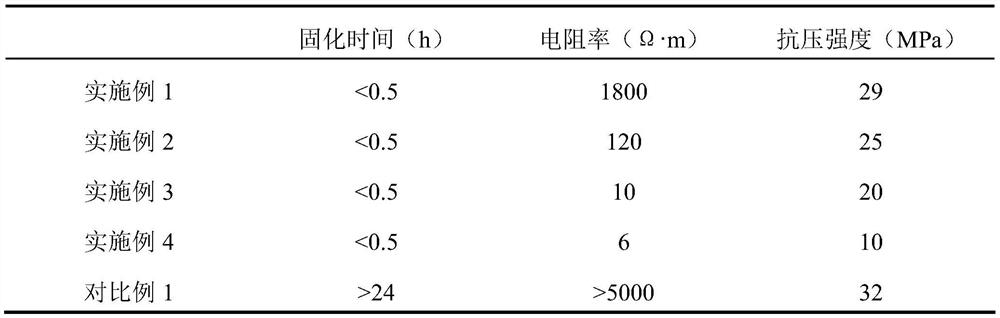

Conductive concrete composition capable of being rapidly cured and molded, preparation method and application thereof

The invention discloses a conductive concrete composition capable of being rapidly cured and molded, a preparation method and application thereof. The conductive concrete composition capable of being rapidly cured and molded comprises rapidly cured cement serving as a base material and conductive concrete combined slurry taking the base material as a benchmark, and the conductive concrete combined slurry comprises the following components by mass percentage: 0.05-2% of graphene, 0.5-3% of a graphene dispersing agent, 0-40% of a conductive filler and 15-30% of water. The rapidly cured cement is phosphorus-magnesium cement. The conductive concrete composition provided by the invention has the advantages of rapid mass production of concrete products with good conductivity, high mechanical strength, stable resistivity and good durability, not only improves the conductivity (the resistivity can reach 10ohm.cm) of a base material, but also accelerates the molding process (room temperature curing within 30min), and can be widely applied to the fields of electric heating, electric heating pavements and the like.

Owner:仙居科信智陶新材料有限公司

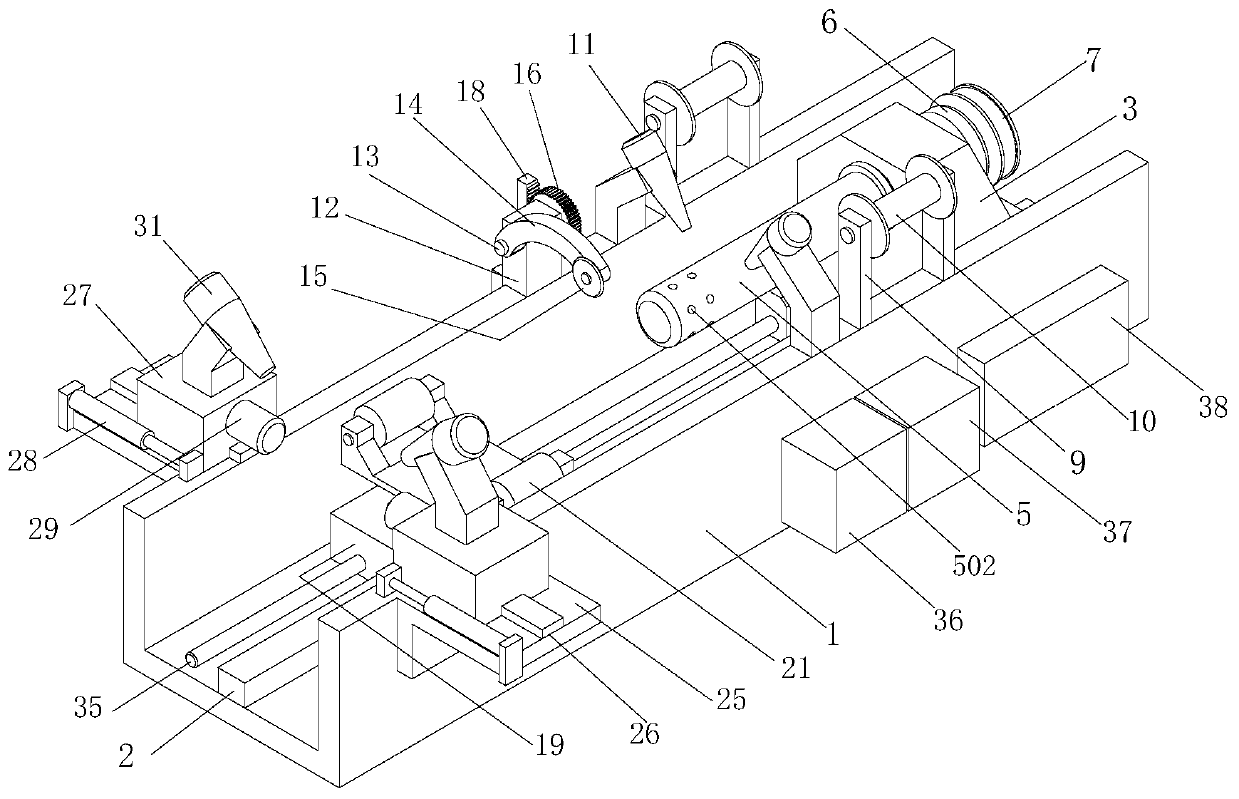

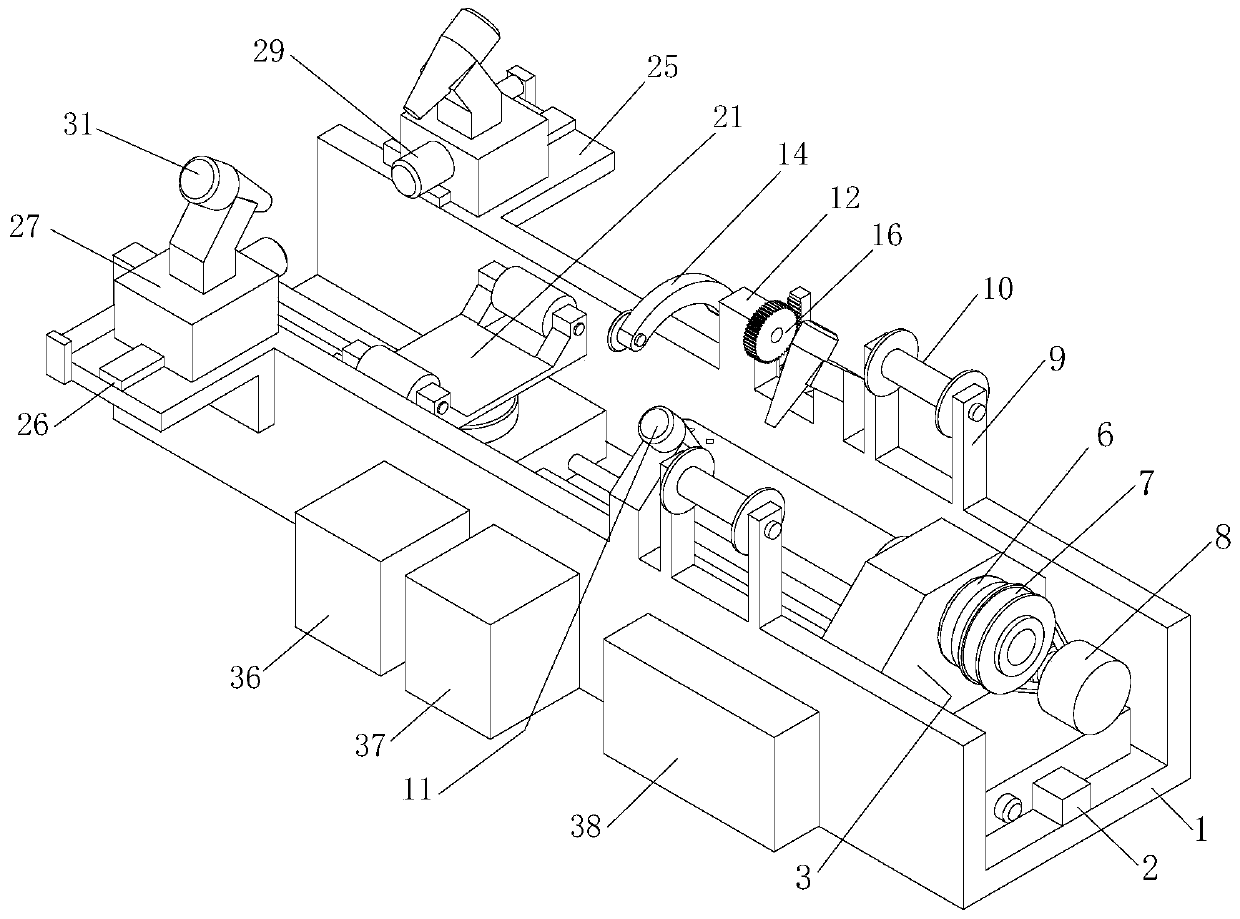

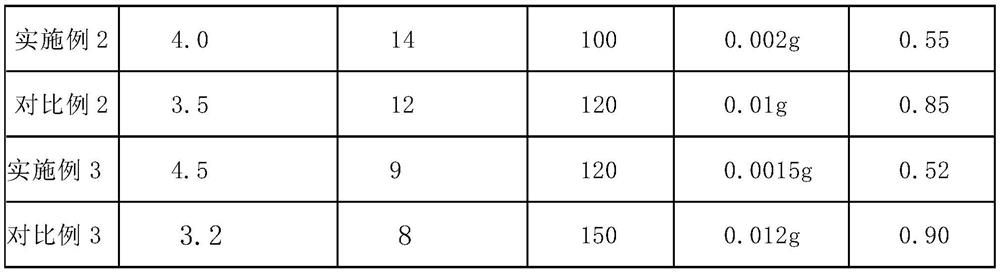

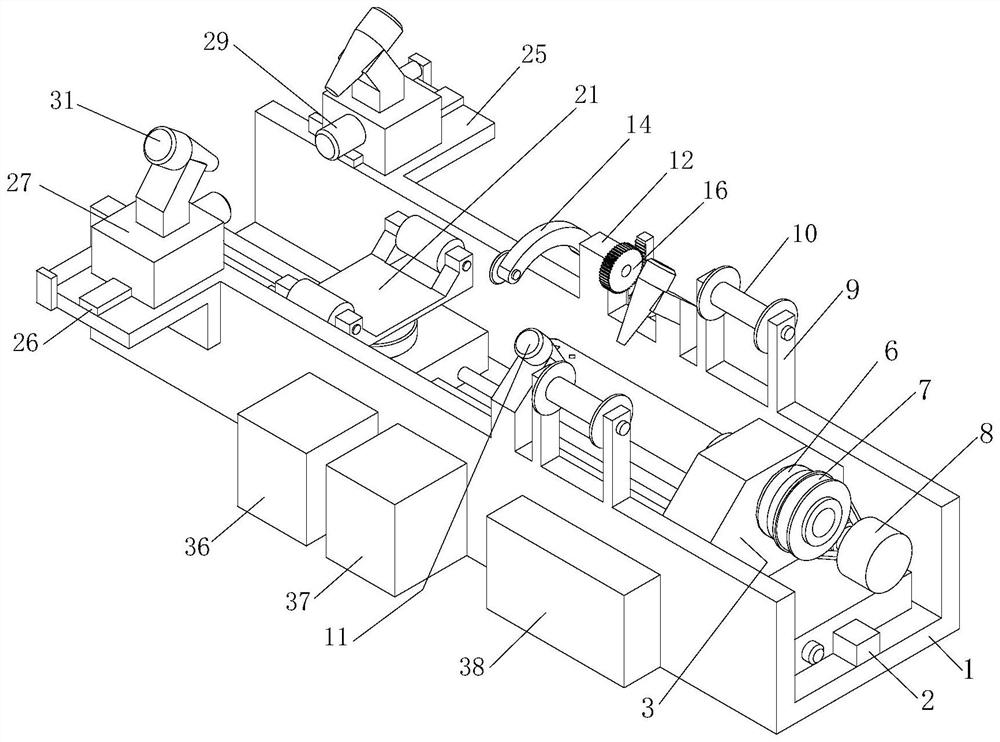

Device for preparing fiber product

ActiveCN111590918AFlexible Lean ProductionIncreased production flexibilityFiberStructural engineering

The invention discloses a device for preparing a fiber product and belongs to the field of preparation of fiber products. The device for preparing the fiber product comprises a groove type rack and ahollow mandrel. A longitudinal guide rail is fixed in the middle of an inner groove of the groove type rack, a spindle seat is movably embedded onto the right end of the groove type rack through the longitudinal guide rail, the spindle seat is rotatably connected to a cone hole spindle through a bearing, an air inlet groove is formed in an inner hole of the cone hole spindle, an air guiding perforated hole penetrates the excircle of the cone hole spindle, the air inlet groove communicates to the air guiding perforated hole, and the right end of the hollow mandrel is of a cone axis structure and is provided with an exhaust hole. The device can prepare the needed fiber product by winding, adhering, cutting and setting a fiber ribbon integrally, and has the advantages of being high in production flexibility and high in dimensional precision. The hollow mandrel and a setting die can be replaced according to dimension of the fiber product to achieve flexible lean production. The device hasthe advantage of being high in production flexibility, production quality and efficiency.

Owner:东莞匡谷新材料有限公司

Rapid cured flame retardation epoxy resin and preparation method thereof

The invention discloses rapid cured flame retardation epoxy resin. The rapid cured flame retardation epoxy resin is prepared from epoxy resin, an aluminum hydroxide fire retardant subjected to surface treatment, color paste, a curing agent and a promoter. The invention also discloses a preparation method of the rapid cured flame retardation epoxy resin. Through the novel curing agent, the epoxy resin is fast cured and molded. Through modification of the epoxy resin, excellent integrated performances are obtained. The rapid cured flame retardation epoxy resin provides technical support for a resin base as a carbon fiber composite material so that the carbon fiber composite material can be conveniently used in new energy automobile lightweighting.

Owner:苏州赛灵自动化科技有限公司

Steel plate conveying belt for conveying metal plates, and preparation method thereof

ActiveCN112606508AImprove cushioning elasticityAvoid pokingConveyorsLamination ancillary operationsPolyurethane adhesiveVulcanization

The invention discloses a steel plate conveying belt for conveying metal plates. The steel plate conveying belt is of a two-cloth two-glue structure and comprises a conveying belt upper layer part and a conveying belt lower layer part which are formed by laminating a solvent-free two-component polyurethane glue, wherein the conveying belt upper layer part is formed by compounding a high-strength fabric framework coated with a PU glue, a TPU coating layer and a silicon sulfide modified TPU thermoplastic resin coating layer, and the conveying belt lower layer part is formed by compounding a high-strength fabric framework coated with a PU glue and a foaming coating layer. The invention further discloses a preparation method of the steel plate conveying belt for conveying metal plates. According to the invention, the thickness of the two-cloth two-glue conveying belt can reach 3.5-6 mm, and compared with an existing steel plate conveying belt needing three to five times of coating attaching, the conveying belt is high in production efficiency and small in loss.

Owner:INO IND BELTING CO LTD

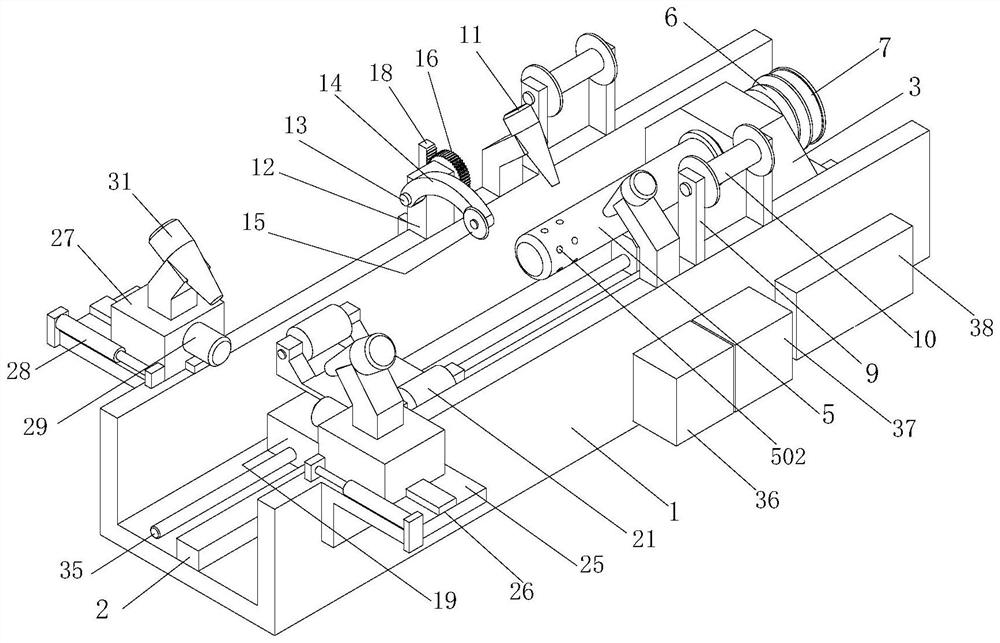

Preparation device for fiber product

InactiveCN114013062AIncreased production flexibilityHigh dimensional accuracyFiberStructural engineering

The invention discloses a preparation device for a fiber product, and belongs to the field of fiber product preparation. The preparation device for the fiber product comprises a groove-shaped rack and a hollow mandrel, a longitudinal guide rail is fixed to the middle of an inner groove of the groove-shaped rack, a spindle seat is movably embedded in the right end of the groove-shaped rack through the longitudinal guide rail, the spindle seat is rotationally connected with a taper hole spindle through a bearing, an air inlet groove is formed in an inner hole of the taper hole spindle, an air guide through hole penetrates through the outer circle of the taper hole spindle, the air inlet groove is communicated with the air guide through hole, and the right end of the hollow mandrel is of a taper shaft structure and is provided with an air exhaust hole. According to the device, a fiber ribbon can be integrally wound, bonded, cut off and shaped into a required fiber product, the device has the advantages of high production flexibility and high size precision, the hollow mandrel and a shaping mold can be replaced according to the size of the fiber product, flexible lean production is achieved, and the device has the advantages of high production flexibility, high production quality and high efficiency.

Owner:沈斌

A forming device and forming method for a tubular three-dimensional braided composite material product

Owner:SHANDONG UNIV

A kind of water-retaining matrix and its preparation method and application

ActiveCN107556110BImprove water absorptionReduce evaporation rateBio-organic fraction processingGrowth substratesFiberPolyester

The invention provides a water-retaining matrix, a preparation method and an application thereof. The water-retaining matrix contains the following components: soil, water-absorbing resin, plant fermentation products, perlite, vermiculite and fiber carriers with the weight ratio of 60-75:0.3-0.4:50-70:5-7:10-12; and the fiber carriers are coco coir and / or polyester fiber. The water-retaining matrix provided by the invention has the characteristics of high water-absorption rate, long water-retaining time, rapidness in curing, rich nutrition, improvement of cold resistance of plants and the like.

Owner:河南坤程生态科技有限公司

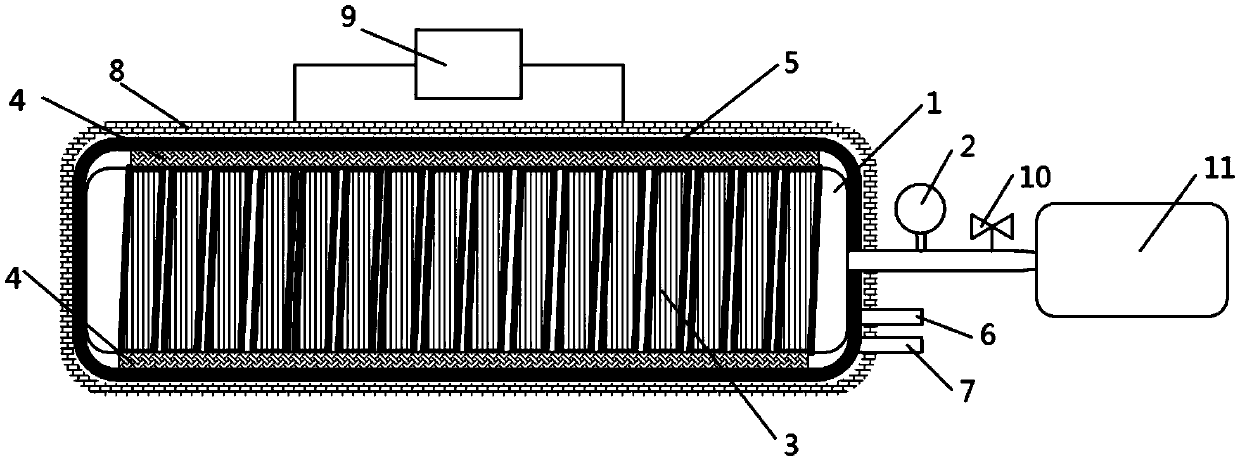

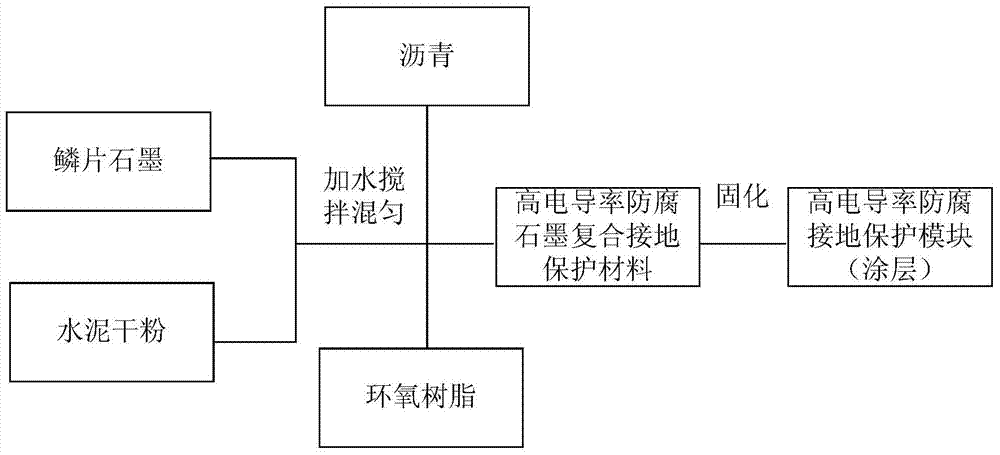

Graphite composite grounding protection material and preparation method thereof

ActiveCN104701644BDoes not affect the drag reduction effectImprove stabilityLine/current collector detailsConnection contact member materialEpoxyOperating life

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID +1

A kind of fast-curing flame-retardant epoxy resin and preparation method thereof

The invention discloses rapid cured flame retardation epoxy resin. The rapid cured flame retardation epoxy resin is prepared from epoxy resin, an aluminum hydroxide fire retardant subjected to surface treatment, color paste, a curing agent and a promoter. The invention also discloses a preparation method of the rapid cured flame retardation epoxy resin. Through the novel curing agent, the epoxy resin is fast cured and molded. Through modification of the epoxy resin, excellent integrated performances are obtained. The rapid cured flame retardation epoxy resin provides technical support for a resin base as a carbon fiber composite material so that the carbon fiber composite material can be conveniently used in new energy automobile lightweighting.

Owner:苏州赛灵自动化科技有限公司

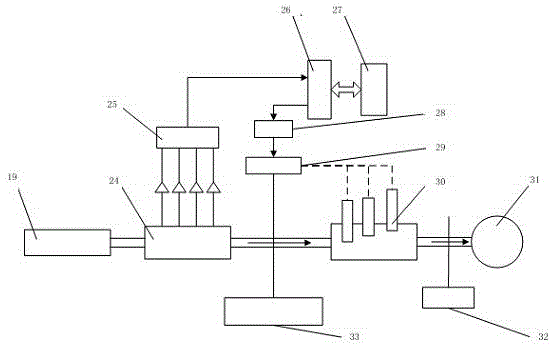

Processing apparatus and processing method for microwave cured fiber reinforced resin matrix composite

The invention relates to a processing apparatus and a processing method for a composite and especially to a processing apparatus and a processing method for a microwave cured fiber reinforced resin matrix composite. According to the invention, a polygonal multi-mode cavity is arranged in a tank; a microwave source water cooling interface and a microwave source electrical interface are connected with a magnetron; the magnetron is arranged at an outer side of the tank and connected with a rectangular waveguide tube through a magnetron antenna; the rectangular waveguide tube is arranged at an outer side of the polygonal multi-mode cavity; a vacuum pipe joint is arranged at an inside wall of the polygonal multi-mode cavity; a worktable is disposed in the polygonal multi-mode cavity; a die is disposed on the worktable; the composite is disposed in the die and a vacuum valve is arranged at the upper end of the die; and the vacuum valve is connected with the vacuum pipe joint through a vacuum pipe.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com