Fast-curing epoxy resin suitable for HP-RTM (high pressure-resin transfer molding) and preparation method

A HP-RTM, epoxy resin technology, applied in the field of composite materials, can solve the problems of poor weather resistance, increased resin viscosity, short resin pot life, etc., to increase the control difficulty, speed up the reaction speed, and overcome the effects of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

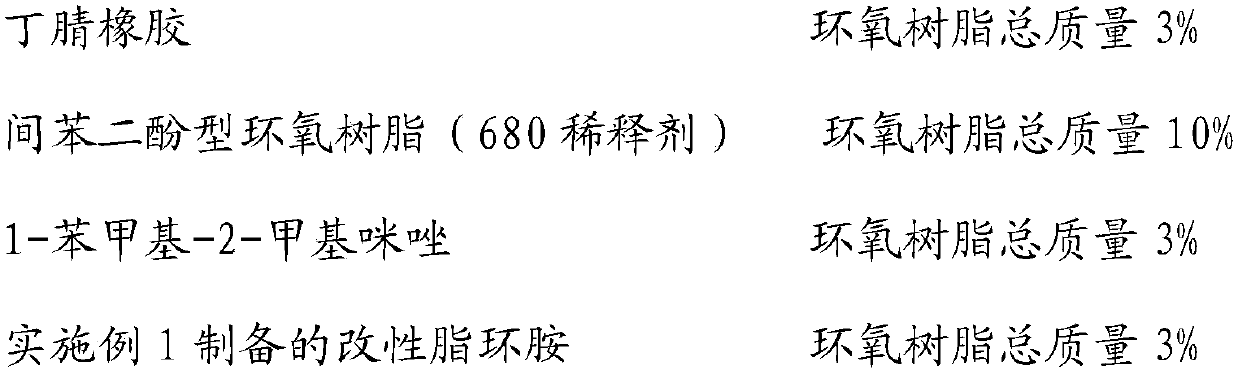

Embodiment 7

[0033] Resin ratio

[0034] Bisphenol A type epoxy resin E-51

[0035]

[0036] The preparation process is as follows:

[0037] 1. Take a certain amount of bisphenol A epoxy resin E-51, nitrile rubber and diluent, stir under room temperature to obtain mixture (1);

[0038]2. Add a certain amount of modified imidazole and the modified cycloaliphatic amine prepared in Example 1 to the mixture (1), and stir at room temperature to obtain the mixture (2);

[0039] 3. Mix mixture (1) and mixture (2), and mix evenly at room temperature to obtain a low-viscosity fast-curing epoxy resin suitable for HP-RTM process.

[0040] The viscosity of the resin system at 40°C, the process pot life at 40°C, the curing cycle and the properties of the cast body are shown in Table 2.

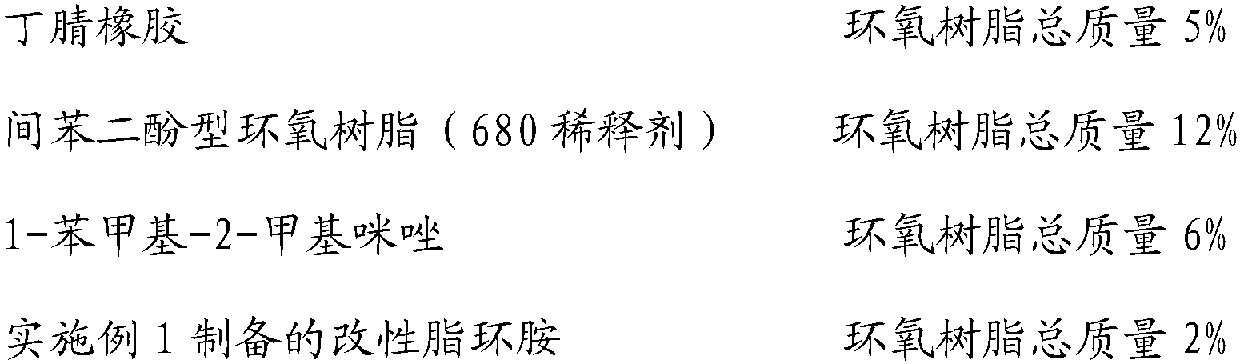

Embodiment 8

[0042] Bisphenol A type epoxy resin E-51

[0043]

[0044] The preparation process is the same as in Example 7.

[0045] The properties of the resin system are shown in Table 2.

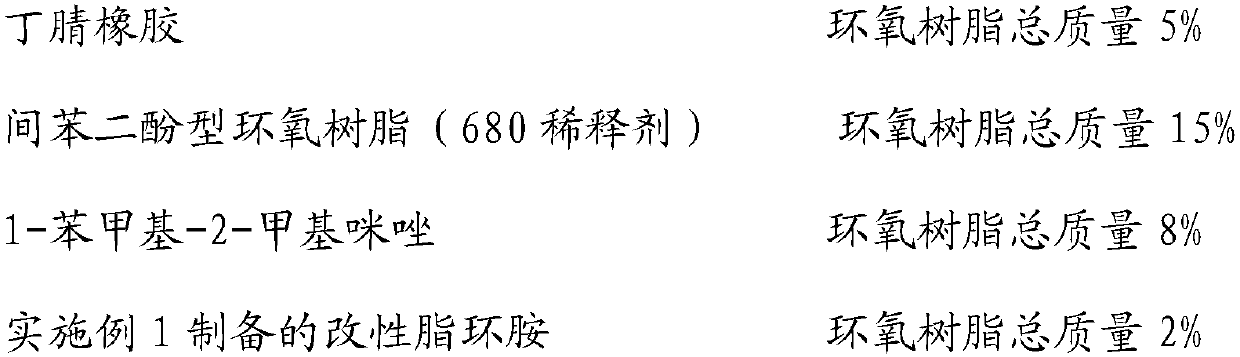

Embodiment 9

[0047] Bisphenol A type epoxy resin E-51

[0048]

[0049] The preparation process is the same as in Example 7.

[0050] The properties of the resin system are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com