A forming device and forming method for a tubular three-dimensional braided composite material product

A composite material, three-dimensional weaving technology, applied in the field of matching molding devices, can solve the problems of low production efficiency, complicated molding process, single function, etc., and achieve the effects of convenient operation, simple structure and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

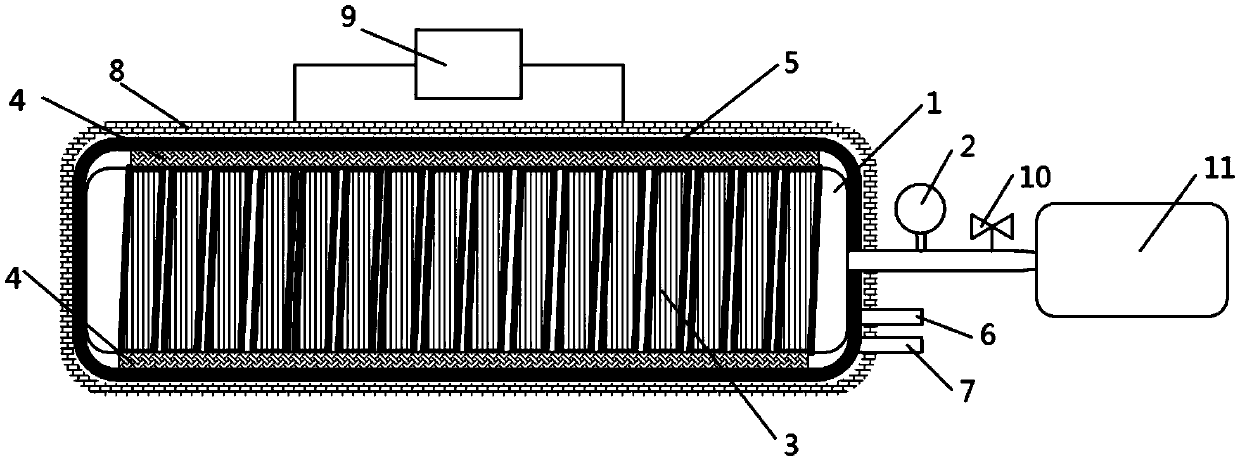

Embodiment 1

[0037] The circular tubular three-dimensional braided composite product molding device of the present invention is used in conjunction with a three-dimensional braiding machine to prepare a uniform circular tubular three-dimensional braided fabric composite product. First, a certain volume of compressed air is poured into the flexible mandrel 1 to ensure that the mandrel 1 The pressure is about 3MPa. After the air pressure reaches the requirement, the inflation port of the mandrel 1 is sealed firmly, and then a retractable demoulding device 3 is installed on the outer surface of the flexible inflatable mandrel 1, and the demoulding device 3 is coated on the surface of the inflated mandrel 1, and The retractable spring belt is adjusted by the locking knob so that it is closely adhered to the surface of the flexible mandrel 1, and the flexible mandrel 1 and the retractable spring belt are integrated. After the above device is assembled, put it on the three-dimensional braiding m...

Embodiment 2

[0039] Using the square tubular three-dimensional braided composite product forming device of the present invention in conjunction with a three-dimensional braiding machine to prepare a uniform square tubular three-dimensional braided fabric composite product, first pour a certain volume of water into the flexible mandrel 1 to ensure the mandrel 1. The pressure is about 2MPa. After the water pressure meets the requirements, the water filling port of the mandrel 1 is sealed firmly, and then a retractable demoulding device 3 is installed on the outer surface of the flexible water-filled mandrel 1, and the demoulding device 3 is coated on the water-filled mandrel 1 surface, and adjust the retractable spring belt by locking the knob to make it closely adhere to the surface of the flexible mandrel 1, and form a whole with the flexible mandrel 1 and the retractable spring belt. After the above device is assembled, put it on the three-dimensional braiding machine to weave the square ...

Embodiment 3

[0041] The elliptical tubular three-dimensional braided composite product molding device of the present invention is used in conjunction with a three-dimensional braiding machine to prepare a uniform oval tubular three-dimensional braided fabric composite product. First, a certain volume of heat-conducting oil is poured into the flexible mandrel 1 to ensure that the mandrel 1 The pressure is about 2.5MPa. After the heat-conducting oil pressure reaches the requirement, seal the oil-filled port of mandrel 1 firmly, and then install a retractable demoulding device 3 on the outer surface of the flexible oil-filled mandrel 1, and the demoulding device 3 covers the oil-filled core The surface of the mold 1, and adjust the retractable spring belt through the locking knob so that it is closely attached to the surface of the flexible core mold 1, and the flexible core mold 1 and the retractable spring belt are formed as a whole. After the above device is assembled, put it on the three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com