A rotary tobacco rod weaving machine

A rotary and rod weaving machine technology, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of low efficiency, mechanical rod weaving machine needle damage to tobacco tendons, leaf falling and baking paste, etc., to achieve high efficiency and avoid falling Or fracture, the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

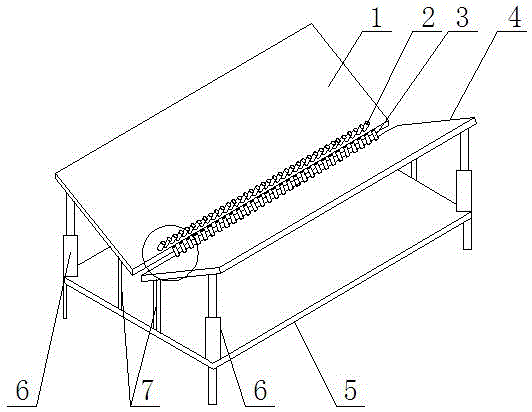

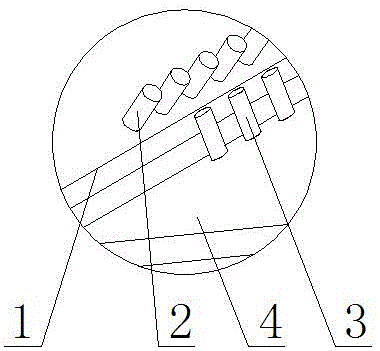

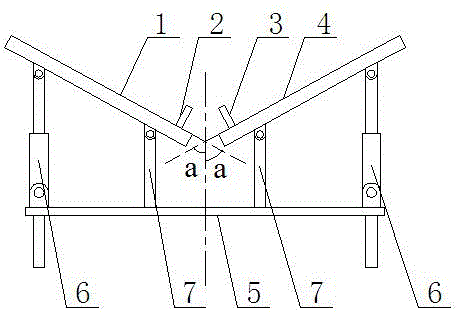

[0017] Such as figure 1 As shown, a rotary tobacco rod weaving machine includes a tobacco weaving platform and a base 5 for supporting the weaving platform, and the tobacco weaving platform includes a left splitter plate 1 and a right splitter plate symmetrically fixed on the base 5 4. The gap between the left splitter plate 1 and the right splitter plate 4 forms a working channel for tobacco leaf weaving rods, such as figure 2 As shown, the upper end surface of the left splitter plate 1 close to the working channel is evenly spaced with several left smoke exhaust pins 2 on the same straight line, and the right splitter plate 4 is set on the upper end surface near the working channel. There are a number of right smoke exhaust pins 3 interlaced with the left smoke exhaust pins and on the same straight line; On the end face; the bottoms of the left splitter plate 1 and the right splitter plate 4 close to the working channel are all fixed on the base 5 through fixed rods hinged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com