Processing apparatus and processing method for microwave cured fiber reinforced resin matrix composite

A composite material and microwave curing technology, which is applied in the field of composite material curing molding technology and equipment, can solve the problems of long time, temperature control hysteresis, differential compaction, etc., achieve small internal stress and deformation, improve quality and performance, The effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

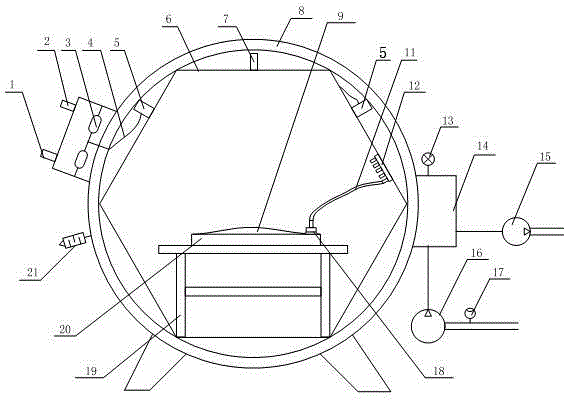

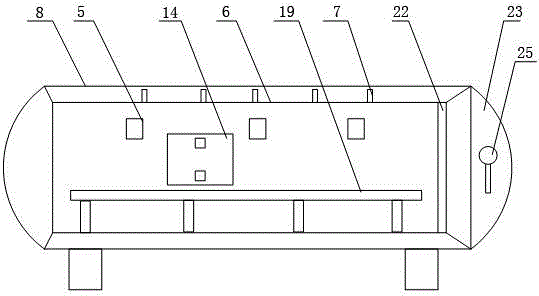

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

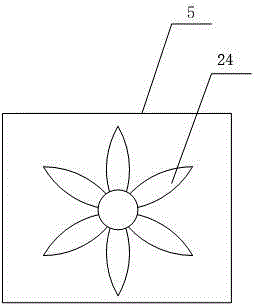

[0026] As shown in Figure 1 and Figure 2: the method and device for microwave curing composite materials, including a microwave source water cooling interface 1, a microwave source electrical interface 2, a magnetron 3, a magnetron antenna 4, a rectangular waveguide 5, and a polygonal multimode resonance Cavity 6, infrared temperature probe 7, tank body 8, composite material 9, vacuum tube 11, vacuum tube connector 12, pressure gauge 13, control cabinet 14, vacuum pump 15, air compressor 16, flow meter 17, vacuum valve 18, workbench 19, mold 20, pressure relief valve 21, resonant cavity sealing door 22, tank body sealing door 23, mode agitator 24, door handle 25, sealing tape 101, release agent 201, release cloth 301, vacuum bag 401, belt Hole isolation membrane 501, air felt 701, quick connector 901.

[0027] The tank body 8 is arranged with a polygonal multi-mode r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com