3D printing ceramic preparation method and product thereof

A ceramic preparation and 3D printing technology, which is applied in the field of ceramic 3D printing, can solve problems such as easy cracks, increased difficulty of sintering, and different shrinkage rates in different directions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

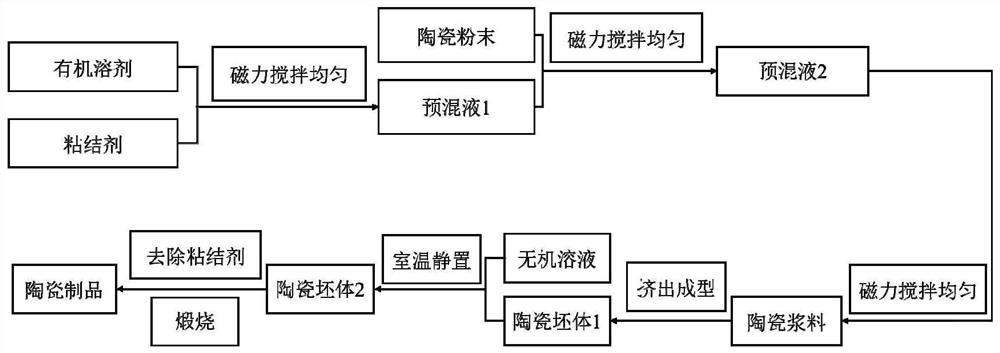

[0024] like figure 1 As shown, 3.34g of polyethersulfone was slowly added to 10.02g of N-methyl-2-pyrrolidone solvent, and stirred at 70°C for 1.5h with a magnetic stirrer at 800r / min until the polyethersulfone was uniformly dissolved in Premix 1 was obtained in the solvent. Then 10.00 g of ceramic powder was added to premix 1 to obtain premix 2, and the magnetic stirrer was stirred at 65° C. for 12 hours at a constant temperature of 800 r / min to obtain a uniform ceramic slurry. Then use micro-flow extrusion forming equipment to carry out extrusion molding, print out the ceramic green body 1, immediately and slowly immerse the printed ceramic green body 1 in deionized water, and let it stand for 12 hours until the organic solvent and water exchange are completed, the green body Solidify and harden to get the ceramic green body 2 . All ceramic bodies 2 were then dried at 75° C. for 12 h. The dried ceramic body 2 was kept at 600°C for 3 hours to remove the binder polyethersul...

Embodiment 2

[0026] Slowly add 3.33g of polyethylene glycol into 10.10g of N-methyl-2-pyrrolidone solvent, and stir with a magnetic stirrer at 800r / min at 70°C for 1.5h until polyethersulfone is uniformly dissolved in the solvent to obtain premix 1. Then 10.00 g of ceramic powder was added to premix 1 to obtain premix 2, and the magnetic stirrer was stirred at 65° C. for 12 hours at a constant temperature of 800 r / min to obtain a uniform ceramic slurry. Then use micro-flow extrusion forming equipment to carry out extrusion molding, print out the ceramic green body 1, immediately and slowly immerse the printed ceramic green body 1 in deionized water, and let it stand for 12 hours until the organic solvent and water exchange are completed, the green body Solidify and harden to get the ceramic green body 2 . All ceramic bodies 2 were then dried at 75° C. for 12 h. The dried ceramic body 2 was kept at 550°C for 3 hours to remove the binder polyethylene glycol, and then calcined at 1250°C for...

Embodiment 3

[0028] Slowly add 4.10g of polyethersulfone into 12.30g of dimethylformamide solvent, and stir with a magnetic stirrer at 800r / min at 70°C for 1.5h until the polyethersulfone is uniformly dissolved in the solvent to obtain a premixed solution 1. Then 12.00 g of ceramic powder was added to premix 1 to obtain premix 2, and the magnetic stirrer was stirred at 65° C. for 12 hours at a constant temperature of 800 r / min to obtain a uniform ceramic slurry. Then use micro-flow extrusion molding equipment to carry out extrusion molding, print out the ceramic green body 1, immediately and slowly immerse the printed ceramic green body 1 in deionized water, and let it stand for 12 hours until the organic solvent and water exchange are completed, the green body Solidify and harden to get the ceramic green body 2 . All ceramic bodies 2 were then dried at 75° C. for 12 h. The dried ceramic body 2 was kept at 550°C for 3 hours to remove the binder polyethersulfone, and then calcined at 1300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com