Sheet metal component, produced by hot working flat steel product, and method for production thereof

A metal plate, thermoforming technology, applied in the direction of metal material coating process, furnace type, heat treatment furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be described in more detail below based on examples.

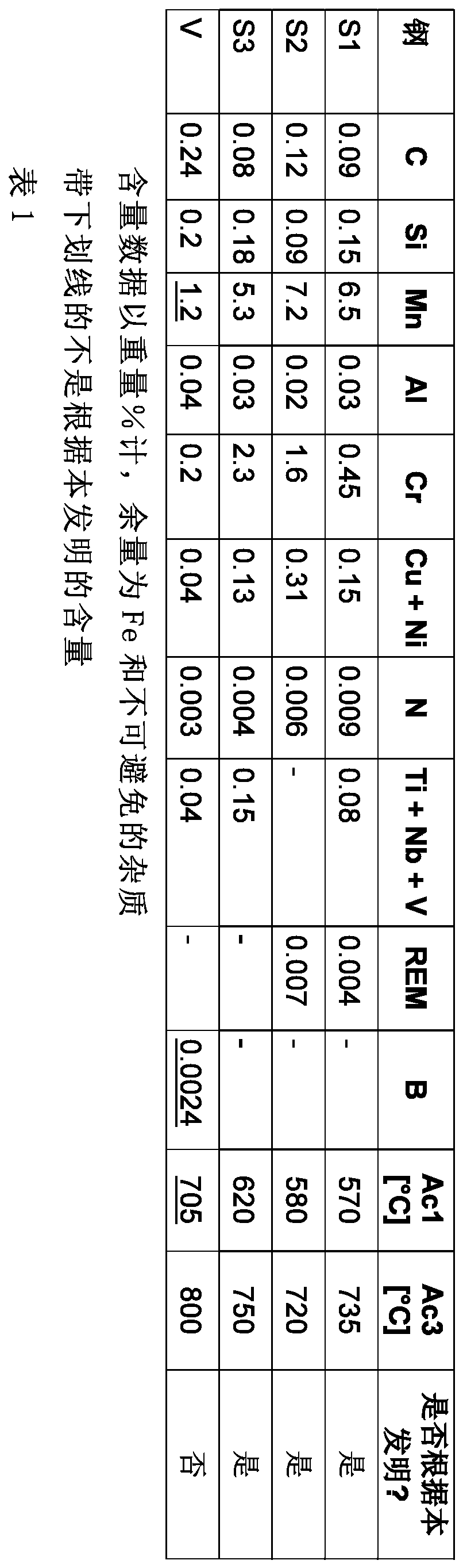

[0072] Three melts S1-S3 corresponding to the requirements of the present invention and one comparative melt V were melted, the composition of which is given in Table 1 in % by weight. Table 1 also lists the Ac1 and Ac3 temperatures in °C for steels S1-S3 and V according to SEP 1680:1990-12.

[0073] Comparative melt V was excluded from the specification of the invention due to its too low Mn content and the presence of B.

[0074] Sheet metal cut-outs are made of S1-S3 and V steel.

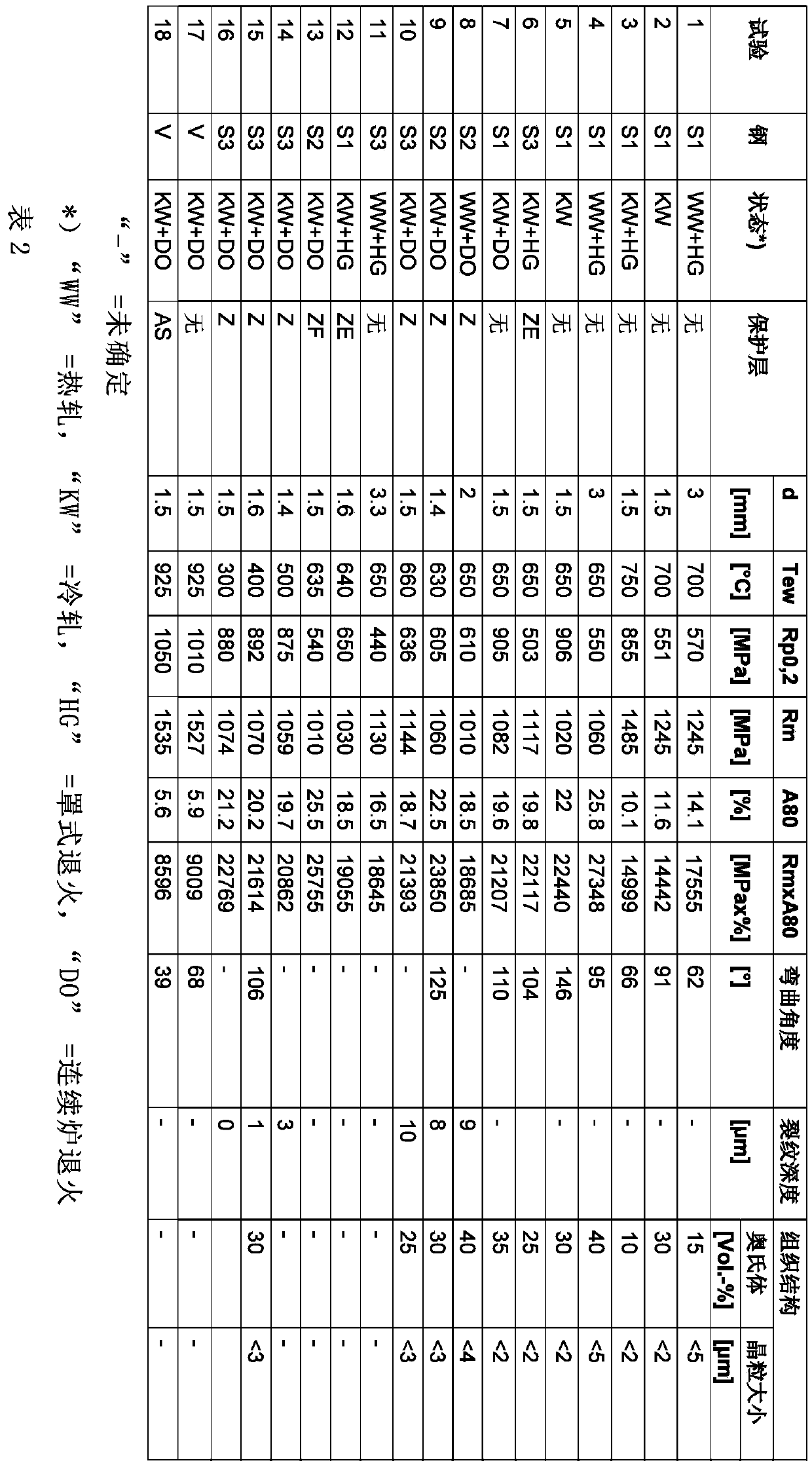

[0075] In Examples 1, 4, 11 and 8, samples of sheet metal cut from hot-rolled strip hot-rolled to thickness "d" (condition "WW" ), followed by annealing under the hood (state "HG") or in a continuous furnace (state "DO"). In Examples 2 and 5, sheet metal samples were cut from strips made from hot rolled strip, which were further cold rolled to thickness "d" (condition "KW"). Some cold-rolled strips were p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com